Abstract

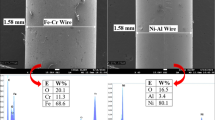

Surface finishing treatments such as shot blasting and wire brushing can be beneficial in improving the integrity of machined surfaces of austenitic stainless steels. These operations optimize in-service properties such as resistance to pitting corrosion and stress corrosion cracking (SCC). In this study, ground steel surfaces were subjected to a series of sand blasting and wire brushing treatments. The surfaces were then characterized by their hardness, surface residual stress state, and resistance to stress corrosion and pitting corrosion. Some samples were selected for depth profiling of residual stress. It is found that surface hardening and the generation of near-surface compressive residual stress are the benefits that can be introduced by sand blasting and brushing operations.

Similar content being viewed by others

References

J. Perrais, C. Martin, and J. Lédion: Influence du Brossage sur la Réactivité des Surfaces Métalliques, Sept.–Oct., 1990, Matériaux et Techniques, Paris, France, 1990, pp. 19–26 (in French).

C. Braham, J. Lédion, J. Perrais, and H. Sidhom: 4th Eur. Conf. on Advanced Materials and Processes, Associazione Italiana di Metallurgia, Milan, 1995, vol. H, pp. 85–90.

J. Perrais, J. Lédion, and J.M. Sprauel: Mise en Compression par Brossage de Surfaces d’Acier, Matériaux et Techniques, Paris, France, 1993, vol. 4–5, pp. 13–18 (in French).

Shot Peening, H. Wohlfahrt, R. Kopp, and O. Vöhringer, eds., Deutsche Gesellschaft für Metallkunde, München, Germany, 1987, p. 693 (in German).

G.T. Burstein and P.C. Pistorius: Corrosion, 1995, vol. 51 (5), pp. 380–85.

I. Altenberger, B. Scholtes, U. Martin, and H. Oettel: Mater. Sci. Eng., 1999, vol. A265, pp. 1–16.

P. Peyre, X. Scherpereel, L. Berthe, C. Carboni, R. Fabbro, G. Beranger, and C. Lemaitre: Mater. Sci. Eng., 2000, vol. A280, pp. 294–30.

A. Bouzina, C. Braham, and J. Lédion: La Rev. Métallurgie, 1998, pp. 1539–47 (in French).

P. Peyre, C. Braham, J. Lédion, L. Berthe, and R. Fabbro: J. Mater. Eng. Performance, 2000, vol. 9 (6), pp. 656–62.

C. Braham and J. Lédion: Oberfläche-Surface, 1992, Apr., No. 4, pp. 15–17 (in French).

A. Niku Lari: Traitements Mécaniques de Surface: Technologie, Applications Industrielles, Contrôles, Effets, Librairie de Traitement de Surface, Paris, 1984 (in French).

H.K. Tönshoff, J. Peters, I. Inasaki, and T. Paul: Ann. CIRP, 1992, vol. 41 (2), pp. 677–88.

X. Chen, W.B. Rowe, and D.F. McCormack: 15th Conf. on Computer-Aided Production Engineering, University of Durham, Durham, United Kingdom, Apr. 19–21, 1999.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Rhouma, A.B., Sidhom, H., Braham, C. et al. Effects of surface preparation on pitting resistance, residual stress, and stress corrosion cracking in austenitic stainless steels. J. of Materi Eng and Perform 10, 507–514 (2001). https://doi.org/10.1361/105994901770344638

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1361/105994901770344638