Abstract

Analytical method validation is a vital element of drug formulation and delivery studies. Here, high-performance liquid chromatography in conjunction with UV detection (HPLC-UV) has been used to produce a straightforward, quick, yet sensitive analytical approach to quantify carvedilol (CAR). A C18 column was used to isolate the analyte from the mixture by isocratic elution with a mobile phase comprising a mixture of 0.1% v/v trifluoroacetic acid in water and acetonitrile in a ratio of 65:35 v/v at a flow rate of 0.6 mL min−1. Linearity was observed for CAR concentrations within the range of 1.5–50 μg mL−1 (R2 = 0.999) in phosphate buffer saline and within the range of 0.2–6.2 μg mL−1 (R2 = 0.9999) in methanol. The International Council on Harmonization (ICH) requirements were followed throughout the validation of the isocratic approach, rendering it specific, accurate, and precise. Moreover, robustness tests indicated that the method remained selective and specific despite small deliberate changes to environmental and operational factors. An efficient extraction procedure was also developed to extract and quantify CAR from excised neonatal porcine skin, resulting in recovery rates ranging from 95 to 97%. The methods reported here have been successfully utilised to evaluate CAR permeation, both transdermally and intradermally following application of a dissolving microarray patch (MAP) to excised neonatal porcine skin.

Graphical Abstract

Similar content being viewed by others

Introduction

An estimated 17.9 million people worldwide die from cardiovascular disease each year, with 9.4 million of those deaths being attributable to complications from hypertension (1). Genetic predisposition is a critical factor involved in the development and progression of cardiovascular disease. However, modifiable risk factors, such as lifestyle and diet identified from epidemiologic studies and randomised clinical trials, have provided compelling evidence that cardiovascular disease is largely preventable (2). Undoubtedly, one of the most significant risk factors for developing cardiovascular and cerebrovascular disorders in individuals is hypertension. In terms of disease, besides lifestyle changes, there are several active pharmacological agents that have been used in the treatment and management of cardiovascular disease. These agents include diuretics, calcium channel blockers, angiotensin converting enzyme (ACE) inhibitors, vasodilators, β-blockers, and angiotensin receptor blockers.

Carvedilol (CAR) is one of the most frequently prescribed drugs for cardiovascular illnesses, particularly as an adjunct to diuretics or ACE inhibitors in the treatment of symptomatic chronic heart failure. As a third generation non-selective β-blocker, it has activity on both β1- and β2-receptors and α1-adrenergic receptors, resulting in an improvement in myocardial function in patients with heart failure and reduction (or reversal) of adverse myocardial remodeling. The bioavailability of CAR is hindered by significant first-pass metabolism, despite being easily absorbed by the gastrointestinal tract, leading to an absolute bioavailability of only 25% (3). Therefore, there is a need to explore alternative delivery routes which could improve the bioavailability of CAR in a minimally invasive fashion.

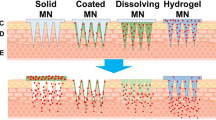

Microarray technology provides an elegant approach to deliver cardiovascular drugs across the skin and into systemic circulations without eliciting any pain or discomfort (4). Such drug delivery systems are inserted into the skin, resulting in the formation of microchannels in the stratum corneum, which protrude further into the underlying skin strata, enabling drug molecules to penetrate the skin to the microcirculation for systemic absorption (5, 6). This drug delivery platform offers numerous benefits relative to traditional hypodermic injections, including pain-free administration of drugs and avoidance of first-pass hepatic metabolism which is associated with oral drug delivery. The simplicity of applying microarray patches (MAPs) enables self-administration by patients, mitigating the need for assistance from healthcare professionals. This approach provides a simple, yet effective, strategy to deliver CAR for the management of symptomatic chronic heart failure. It has been reported that CAR is frequently prescribed to multimorbid individuals with heart failure and these patients are most prevalent within the geriatric patient group (7, 8). Since approximately 15–20% of geriatric patients typically suffer dysphagia, the use of MAPs to deliver CAR transdermally is a great advantage, circumventing the need for an oral-based delivery system and the drawbacks that accompany it (9).

It is well established that the design and engineering of novel drug delivery systems are underpinned by the development of a rapid, robust, and reliable analytical procedure. Such analytical methods would enable researchers to elucidate and evaluate the delivery profile of the formulations developed in order to detect any necessary steps that ought to be taken in order to improve and meet the clinical endpoint of the formulation. With respect to CAR, there are a few established analytical procedures that have been developed to quantify the concentration of the β-blocker in plasma (10,11,12,13,14), serum (14,15,16), urine (11, 17), and cardiac tissue (18) using mass spectrometry, UV detection, and fluorescence. The majority of these published methods have been reported to be highly sensitive and selective, with limits of detection (LOD) of 0.1 ng/mL (19) or 0.01 ng/mg (18). Nevertheless, these methods necessitate expensive internal standards or complex sample preparation procedures, including derivatisation, solid-phase extraction, and liquid-liquid extraction prior to sample analysis.

The creation of a straightforward yet accurate analytical technique to assess CAR after in vitro skin permeation studies is presented here for the first time. Following MAP application in vitro, the analytical technique was utilised to evaluate the permeation of CAR into and across skin tissues in accordance with the International Council on Harmonization (ICH) criteria. This is very important for assessing how well a MAP formulation delivers cardiovascular drugs into and across the skin for the management of cardiovascular disease. This HPLC method was developed with the aim of serving as a potential analytical tool to aid formulators in the design and development of transdermal delivery systems for CAR across the skin as well as detect any potential drug eluting depot formed within the skin upon MAP application. The development of a MAP-based drug delivery system may be more advantageous to patients over the conventional oral product as it could maintain steady drug plasma levels, thus overcoming issues with fluctuating blood pressure in elderly patients.

Materials and Methods

Materials

Carvedilol (purity > 98%) was purchased from Alfa Aesar (Product number C2260, Lancashire, UK). Sigma-Aldrich (Dorset, UK) was used to obtain poly(vinyl alcohol) 9–10 kDa (Product number 360627) and Ashland (Kidderminster, UK) provided the poly(vinylpyrrolidone) (PVP) 58 kDa (Product number 878366) and PVP 90 kDa (product number 830840). HPLC column XSelect CSH C18 (Waters, 3.0 × 150 mm, 3.5-μm particle size) was purchased from Waters (Dublin, Ireland). All other chemical reagents were of analytical grade and purchased from Fisher Scientific (Leicestershire, UK) and Sigma-Aldrich (Dorset, UK). Full-thickness skin from stillborn piglets was collected less than 24 h after delivery and was frozen at −20°C until it was needed.

Preparation of Stock, Calibration Standards, and Quality Control Solutions

To prepare stock solutions, 10 mg of CAR was dissolved in methanol or phosphate buffered saline (PBS) and made up to 10 mL to attain a final concentration of 1 mg mL−1. Calibration standards (CSs) were attained by performing serial dilutions of the stock solution, resulting in concentrations ranging from 0.19 to 6.25 μg mL−1 in methanol and from 1.56 to 50 μg mL−1 in PBS pH 7.4. Quality control (QC) solutions were also prepared in a similar manner through serial dilutions of the stock solution. QC concentrations used in the study were 0.25, 1 and 5 μg mL−1 for CAR in methanol and 4, 10, and 40 μg mL−1 for CAR in PBS pH 7.4, using six replicates of each concentration.

Instrumentation and Chromatographic Conditions

To enable separation, detection, and quantification of CAR, sample analysis was performed using RP-HPLC on an Agilent Technologies 1220 Infinity compacted LC series system (Agilent Technologies UK Ltd, Stockport, UK) coupled with a UV detector. A XSelect CSH C18 column with a 3.0 mm internal diameter, 150 mm length, 3.5 μm particle size, and a pore size of 130 Å was used to separate the analytes (Waters, Dublin, Ireland). The column was preceded by a VanGuard® cartridge (3.9 mm internal diameter, 5 mm length) (Waters, Dublin, Ireland) maintaining identical chemistry to the main column. The mobile phase consisted of a mixture of 0.1% v/v trifluoroacetic acid in water and acetonitrile in a ratio of 65:35 v/v and a flow rate of 0.6 mL min−1. Analysis was performed at 30°C with an injection volume of 10 μL and UV detection conducted at 210 nm, resulting in a run time of 8 min.

HPLC Method Validation

Linearity, LOD, and LOQ

By constructing calibration curves based on the CSs provided in “Preparation of stock, calibration standards, and quality control solutions” section, linearity was evaluated. Six CSs with various CAR concentrations were examined to acquire the calibration curves. Equations (1) and (2) below were used to calculate the limits of detection (LOD) and quantification (LOQ).

where σ is the standard deviation of the responses of the calibration curve and S is the slope of calibration curve.

Accuracy and Precision

To examine the accuracy and precision of the analytical method, six replicates at low, medium, and high concentrations across the calibration range were employed as QC samples. Intra-day and inter-day accuracies were evaluated by calculating the relative standard deviation (RSD) of the responses. Intra-day and inter-day precisions were determined using the relative errors (RE) (20). If the RE and RSD from all samples were less than 20% and 15%, respectively, the procedure was considered accurate and precise (21).

Robustness

The effects of slight, deliberate variations in chromatographic parameters were tested to determine the robustness of the HPLC approach, such as mobile phase ratio, flow rate, and column temperature. The retention time and peak area of CAR were recorded when each change was made. All samples were prepared in three replicates.

Skin Extraction Method

To assess the efficiency of the skin extraction method, CAR concentrations extracted from full thickness neonatal porcine skin were compared to standard solutions of known CAR concentrations, namely 20, 50, and 100 μg mL−1. In order to ensure the experiment was comparable to that of an ex vivo skin deposition study, sections of skin were immersed in known concentrations of CAR, with subsequent incubation at 37°C for 24 h. Control samples contained CAR without skin; however, all other steps in the procedure remained identical. After 24 h, skin was cut into smaller sections and 0.5 mL of deionised water and 2 stainless steel beads (5 mm diameter) were added to the samples. The samples were homogenised at 50 Hz for 15 min using a Tissue Lyser (Qiagen Ltd., Manchester, UK). Subsequently, 1 mL of methanol was added to the samples and homogenised for a second time at 50 Hz using a Tissue Lyser for 15 min. Following a 15-min centrifugation of the samples at 14,500 rpm, the supernatant was collected and diluted appropriately prior to HPLC analysis, using the method previously outlined in “Instrumentation and chromatographic conditions” section.

Stability Studies

To investigate the degradation of CAR in the release media, PBS pH 7.4, stability studies were conducted. A standard solution containing 10 μg mL−1 was prepared in a glass vial by diluting a stock solution of CAR 1 mg mL−1 in PBS pH 7.4. CAR solutions were then placed in various conditions to represent environments of in vitro permeation studies and storage environments. Specifically, solutions were stored at ambient temperature, in the fridge (2–8°C), in a −20°C freezer, and in an incubator that was held at 37°C. Aliquots of 1 mL were removed from each vial at pre-defined intervals over 7 days. To determine percentage recovery, samples were made in triplicate and HPLC analysis was performed.

Fabrication of Dissolving MAP Loaded with CAR

A double casting technique, similar to those previously described, was used to create dissolving MAPs that contained CAR (6, 22). Silicone moulds were used to facilitate fabrication of MAPs which consisted of 16 × 16 pyramidal needles having a height of 850 μm, 300 μm width at base, and 300 μm interspacing resulting in a 0.36 cm2 patch area. The first layer cast was a CAR-containing layer, forming the needle tips of the MAP. The matrix of the needle tips was composed of a polymeric blend containing 20% w/w PVA (9–10 kDa) and 20% w/w PVP (58 kDa). A silicone mould was filled with approximately 50 mg of each of the CAR-containing mixtures listed in Table I. To ensure the formulation filled the entirety of the microneedle cavity, the moulds were placed in a positive pressure chamber at 4 bar for 5 min. Subsequently, excess formulation was removed using a spatula and the moulds were centrifuged at 5000 rpm for 10 min to remove air bubbles in the formulation. After drying at ambient temperature for 6 h, 850 μL of the drug-free second layer, which contained an aqueous blend of 30% w/w PVP (90 kDa) and 1.5% w/w glycerol, was cast on to the moulds. The moulds were then centrifuged at 3500 rpm for 10 min. The moulds were dried for 24 h at ambient temperature, demoulded, and the sidewalls were cut off with scissors. The moulds were then dried for another 12 h at 37°C.

Characterisation of Dissolving MAPs Loaded with CAR

Using a digital light microscope (Leica EZ4 D, Leica Microsystems, Milton Keynes, UK), the morphology of dissolving MAPs was visually assessed. The ability of the MAP to withstand a compressive force of 32 N, which is typically encountered during skin insertion, was evaluated using TA-TX2 Texture Analyser (TA) (Stable Microsystems, Haslmere, UK). The samples were evaluated under compression mode based on a previously reported methodology (23, 24). The change in needle height prior and post compression was measured and recorded, with subsequent calculation of needle height reduction using Equation (3).

where Ha is the height before compression and Hb is the height after compression.

Several dissolving MAPs were inserted into full-thickness neonatal porcine skin and others were inserted into eight layers Parafilm® M to replicate the thickness of skin. To assess the insertion and penetration depth of the needles, an EX-101 optical coherence tomography (OCT) microscope (Michelson Diagnostics Ltd., Kent, UK) was utilised, following a method that has been previously reported (25). In order to accurately measure the height of the inserted needle, ImageJ® (National Institutes of Health, Bethesda MD, USA) was used (26). To determine the drug content in the needles, MAPs were submerged in 4 mL deionised water and sonicated for 30 min to dissolve the hydrophilic polymer. Methanol (4 mL) was added to the mixture and sonicated for 30 min. This step not only enabled precipitation of the polymer prior to HPLC analysis but also ensured the drug was completely dissolved. Subsequently, the sample was centrifuged at 14,500 rpm for 15 min, diluted appropriately, and analysed using HPLC.

In vitro Permeation Study Utilising the Validated Method

To measure CAR penetration into and across full-thickness neonatal porcine skin, Franz diffusion cells (Permergear, Hellertown PA, USA) were employed. The release media, PBS (pH 7.4), was added to the receiver chamber after being pre-heated to 37 ± 1°C. The temperature of PBS was maintained at 37 ± 1°C throughout the duration of the experiment. Cyanoacrylate glue was used to attach the 28-mm-diameter excised skin to the donor compartments of Franz cells. CAR-containing dissolving MAPs were inserted into the skin by applying manual thumb pressure for 20 s. A 5.0 g cylindrical stainless-steel weight was set on top of the MAPs after the donor and receiver chambers were secured with clamps. At 24 h the release media and skin from all donor compartments were gathered and investigated using HPLC.

Statistical Analysis

Version 8.0 of the GraphPad Prism® application was used for statistical analysis (GraphPad Software, San Diego, CA, USA). All results and data are shown as means ± standard deviation (SD), unless otherwise stated. One-way analysis of variance (ANOVA) was used to compare multiple cohorts. In all cases, p < 0.05 was used to signify statistical significance, where p-value outputs were 0.033 (*), 0.002 (**), <0.001 (***), and <0.0001 (****).

Results and Discussion

Chromatographic Method Development

A RP-HPLC UV analytical method for quantifying CAR was developed to quantify the permeation of CAR following skin permeation studies. The final optimised isocratic method utilised a mobile phase that consisted of a mixture of 0.1% v/v trifluoroacetic acid in water and acetonitrile in a ratio of 65:35 v/v. When analysis was conducted at 30°C with UV detection adjusted to 210 nm, a well-resolved, symmetrical CAR peak eluted at 7.4 mins, as shown in Fig. 1, resulting in an overall run time of 8 min. No endogenous interfering peaks were discovered in the blank samples (Figure S1) at the retention times of CAR, verifying the specificity of the developed method (Fig. 1).

HPLC Method Validation

Linearity, LOD, and LOQ

Linearity was established over 3 consecutive days by constructing calibration curves of peak area versus CAR concentration. Six replicates of a range of CAR concentrations were analysed. The calibration curve was constructed based on analysing samples in PBS and methanol as these are representative of samples from receptor fluid and skin extract, respectively, following Franz cell permeation studies. It was deemed appropriate to quantify CAR concentrations in skin samples, as the application of the MAP to the skin results in microneedle dissolution, generating a drug-loaded depot within the skin. It was hoped that the intradermal depot would enable continuous delivery of CAR even after patch removal. As shown in Table II, the properties of the calibration curve such as slope, y-intercept, coefficient of correlation, LOD, and LOQ were determined. It was evident that the calibration curves for CAR displayed a linear response with a regression coefficient (R2) ≥ 0.999 over the desired concentration range. The LOQ was found to be 1 μg/mL for CAR in PBS, while the LOQ for CAR in methanol was as low as 0.12 μg/mL. These values suggest that both analytical methods offer acceptable sensitivity to quantify CAR concentrations in receptor fluid and skin extract following permeation studies.

Accuracy and precision

The accuracy and precision of the devised analytical method were assessed by measuring intra-day and inter-day variabilities at low, medium, and high concentrations. The accuracy and precision results obtained for the QC samples are reported in Table III. For an analytical method to be considered accurate, the %RE value should lie below 20%. Based on the results shown, the %RE for all QC samples was within the range 0.01–8.56%, rendering the methods accurate and suitable for their intended purpose. In terms of precision, the ICH guidelines state that the %RSD value should be within 15% of the true value (21). Taking both methods into consideration, the %RSD values were found to conform to the ICH guidelines as they were within the range of 1.39–10.87%. Overall, the findings from the validation procedures supported the validity and suitability of the analytical method for CAR quantification after in vitro skin permeation investigations.

Robustness

In order to determine if the analytical method would be affected by slight alterations in method parameters, the robustness of the HPLC method was assessed. Robustness tests also help gauge if small changes to parameters (factors) may affect the sensitivity and selectivity of the analytical method. Such small deviations in analytical parameters may occur should the method be transferred and adapted from one institute to another (27). The parameters to be examined in a robustness test can be connected to the analytical procedure, termed operational factors, and to the ambient conditions in which the method was evaluated, termed environmental factors. In the current work the column temperature was purposely varied between 29.5 and 30.5°C to represent changes to the environmental factors as this parameter has been widely reported to affect the retention time of analytes following HPLC-UV analysis (28). However, after altering the temperature, no significant changes (p > 0.05) on the retention time and peak area of the analyte were observed. In addition, changes to operational factors (mobile phase composition and flow rate) of the analytical method did not cause any notable changes to the retention time and peak area of the analyte as shown in Table IV. Overall, the findings demonstrate that the analytical procedure developed was robust and small deliberate adjustments to analysis parameters had little impact on the selectivity of the method.

Skin Extraction Recovery

Portions of full-thickness skin were incubated for 24 h with various concentrations of CAR (20, 50, and 100 μg mL−1), after which CAR extraction from skin was conducted. Skin extraction recoveries were determined by comparing the concentration of CAR from skin samples to known standard solutions. The results in Table V highlight the highly efficient nature of the extraction approach as mean recoveries of CAR were between 95 and 97%. The extraction procedure was regarded as precise as %RSD values lie well below 15% and were found to be within the range of 1.9–8.0% (21, 29).

With respect to methods for extracting CAR from the skin, several sample processing methods have been reported in the literature. For instance, Chen et al. (30) evaluated CAR penetration into the skin layers from a nano-transferosome formulation using a tape-stripping method. In this work, the stratum corneum layer was sequentially removed and the remaining skin layers were collected in 1 mL of 50% methanol and homogenised to extract the drug (30). Furthering this, Shamim et al. (31) analysed the penetration of CAR into the skin layers by also using the tape stripping method, followed by the addition of 0.4 mL of PBS and 0.6 mL of methanol to extract CAR from the remaining skin (31). Similarly, Amarachinta et al. (32) evaluated the skin retention of CAR from ethosomal formulation by soaking the skin into 10 mL of methanol for 5 min (32). However, there is no method to date that have evaluated CAR extraction from the skin by comparing the drug concentration extracted from full-thickness neonatal porcine skin to standard working solutions. In addition, these papers, although they have attempted to extracted CAR from the skin, did not report the extraction efficiency of the sample processing procedures. This is a critical parameter that ought to be reported as this will enable us to gauge how effective is the sample processing step in extracting the drug from skin matrix. In the current work we have demonstrated that our sample processing step was capable of achieving an extraction efficiency of 95–98%.

Stability Studies

The stability of CAR within the receptor media (PBS pH 7.4) was investigated. Several storage conditions were evaluated to ascertain which ones would enable CAR to remain stable in solution. Degradation was measured in this study as a decrease in percentage drug recovery every 24 h. Figure 2 illustrates that after 7 days of storage, there were negligible changes in %CAR recovery under all settings evaluated, except samples frozen at −20°C. In most instances, storing a pharmacological ingredient at subzero temperatures reduces the concerns associated with liquid storage, such as deterioration and shipping stress, implying that freezing samples is the best long-term storage option in most cases. However, it has been reported in some cases that significant levels of degradation may be observed when a drug is stored below 0°C (33). This could be due to the uncontrolled rate of freezing, which causes ice crystals to form. These ice crystals can cause cryoconcentration of the drug solution since the moving ice front excludes solute molecules, establishing concentrated drug zones. The presence of zones with enhanced drug concentration provides an opportunity for drug aggregation, that may in some instances, result in degradation (34).

However, when the freeze thaw experiment for 10 ug/mL CAR was repeated, no observable no drug precipitation was noted which suggests that cryoconcentration may not be a probable cause for the loss in drug recovery following the storage of CAR in PBS solution at −20°C. In contrast, Kim et al. (35) and Eiamart et al. (36) observed no significant loss in CAR recovery when the drug solution is stored at −70°C in human plasma for 60 days and 148 days, respectively. This may suggest that the storage of the drug in plasma, which contain plasma protein, may endow some level of stability to the drug during cryopreservation even when stored at pH 7.4 (pH of human plasma) followed by several freeze thaw cycles. This would probably be the case for CAR due to the high protein binding nature of the drug (37). The binding of drug molecules to albumin present in human plasma has been shown to endow stability to drug small molecules (38). Extensive work by Lanzanova et al. (39) on the stability of CAR has shown that the drug molecule is indeed stable under acidic and neutral solutions which rules out the possibility on the impact of pH on the loss in CAR recovery observed in our current work as the drug was stored in PBS pH 7.4. However, it has been reported that when the drug molecules are subjected to cryopreservation (storage at very low temperature), the molecules become susceptible to oxidative stress which arises when the sample undergoes a freeze and thaw cycle (40). Lanzanova et al. (39) have shown that CAR is indeed susceptible to oxidative stress which promotes drug degradation. Reflecting upon our current work by which the drug is frozen in PBS which is void of any plasma protein, the thawing and analysis of the drug may have promoted some level of oxidative stress on CAR that may result in drug loss when the sample was stored at −20°C and subsequently thawed.

In summary, it is possible to prepare and store CAR working solutions for up to 7 days, without the need of refrigeration as they are stable at room temperature and pressure. The stability observed from Figure 2 implies that the samples do not require elaborate sample storage as well as immediate processing and analysis after the permeation study. The prolonged stability observed, for up to 7 days at ambient condition, would enable sample transfer between institutes without the need of any cold storage, such as dry ice, thus reducing the overall shipping and storage cost. On top of that, the rapid HPLC analysis (8 min) may be advantageous should large sample analysis be required during the early stages of formulation screenings and optimisation.

Characterisation of Dissolving MAPs Loaded with CAR

CAR-containing dissolving polymeric MAPs were manufactured using the micromoulding technique which entailed casting an aqueous drug and polymer blend into polydimethylsiloxane moulds and allowing it to dry. Digital microscope images of the manufactured MAPs are shown in Fig. 3(a) and (b), revealing noticeable obelisk micro-projections with a needle length of ∼ 800 μm, which protrude from a smooth baseplate. Upon removal from the moulds, the fabricated MAPs were evaluated for their mechanical properties and their ability to insert into a skin model and ex vivo neonatal porcine skin.

Digital images of dissolving MAPs for formulations a F1 and b F2. c Approximate insertion depths after dissolving MAP formulations containing CAR were inserted (means ± S.D., n = 3). d Microneedle height reduction for the formulation loaded with CAR after applying a force of 32 N which is equivalent to thumb pressure (means + S.D., n = 3). e Microneedle drug content for formulations F1 and F2 (means + S.D., n = 3). f Real-time images of microneedle penetration into the skin simulant Parafilm® in real-time M along with average insertion depth into the skin model (means + S.D., n = 3). g Optical coherence tomography imaging of full-thickness neonatal porcine skin (means + S.D., n = 3)

Figure 3(c) and (f) highlights the insertion properties of the CAR loaded MAP into the skin simulant, Parafilm®M. The MAPs were inserted into the Parafilm®M stack by providing a 32 N force, which is comparable to thumb pressure. Figure 3(c) displays that 100% of needles from both formulations, F1 and F2, were successfully inserted into the first layer of Parafilm® following application, resulting in the lack of any error bars. The insertion depth of the MAP into the Parafilm® M layers was determined using OCT analysis. It was observed that both formulations resulted in an insertion depth of 300 μm into the skin simulant. Mechanical characterisation of the MAPs revealed that when the microneedles were subjected to a compression force of 32 N, both formulations underwent height reduction. Nevertheless, the percentage height reduction for both formulations was below 10% and is in line with previous findings reported in literature for dissolving MAPs (6). However, it was apparent that the microneedle formulation that exhibited higher drug loading (F2) displayed a higher percentage height reduction upon compression, as shown in Fig. 3(d). This suggests that a high CAR loading may result in the formation of brittle microneedles which could fracture upon compression (41).

An ex vivo skin insertion investigation was used to further assess both dissolving MAP formulations, with the hope of evaluating if the observations from the in vitro characterisation tests would translate into skin tissue. The OCT images in Fig. 3(g) indicate that the MAPs were successful in penetrating the stratum corneum allowing the microneedles to be inserted intradermally. When inserted into ex vivo skin, both MAP formulations resulted in an insertion depth of 600 μm, representing approximately 75% of the initial needle height. This insertion depth was significantly (p < 0.05) deeper than the insertion of MAPs into Parafilm®M. It is postulated that this difference in insertion profile could be ascribed to the absence of interstitial fluid within the Parafilm®M layers in comparison to the aqueous rich dermis that is inherently present within ex vivo porcine skin. Such difference would impede any polymers, used in the manufacture of the MAP, from swelling upon insertion into the Parafilm® M layer (42). In comparison to ex vivo skin, this would result in a shallower MAP insertion into the Parafilm®M layers (6).

Application of Validated Method to In Vitro Permeation Studies

Following MAP application to the skin using a Franz cell permeation setup as shown in Fig. 4, the validated HPLC method was used to determine the amount of CAR delivered into and across skin. The amount of medication recovered from the skin after 24 h was found to be 0.4 mg and 0.9 mg for formulations F1 and F2, respectively. The twofold increase in drug deposition into the skin was analogous to the twofold difference in drug loading between formulations F1 and F2. This suggests that increasing the drug loading of CAR in dissolving MAPs also resulted in enhanced drug deposition into the skin. However, when the MAP drug loading increased by twofold, there was a notable decrease in the amount of drug permeated into the receptor compartment as shown in Fig. 4. This decrease in transdermal drug delivery with increased drug loading may be attributed to longer microneedle dissolution time with increased drug loading, as CAR is considered to be a poorly water-soluble drug with a log P of 3.42 (43). Nevertheless, when the overall amount of drug transported into and across the skin was taken in consideration, it was discovered that increasing the drug loading in the MAP improved the overall delivery efficiency, from 31.35 to 45.34%, as shown in Fig. 4.

CAR delivery efficiency (%) quantified from the extraction of the analyte from skin and receptor fluid following MAP application to full-thickness neonatal skin after 24 h using Franz diffusion cell set up (values represent means + S.D., n = 4). T-tests were used to calculate differences, which were declared significant when the p-value outputs were 0.05(*), 0.002(**), 0.001(***), and 0.0001 (****)

From a formulation development perspective, the application of CAR-loaded MAPs to porcine skin resulted in both intradermal (into the skin) and transdermal (across the skin) delivery of the drug. Although the overall goal of the formulation is to achieve systemic delivery, the enhanced delivery of the drug into the skin may be viewed as an advantage, resulting in the formation of a CAR-loaded intradermal depot from which sustained release of CAR could be achieved even after the patch has been removed. The presence of this depot would provide an approach to maintain steady drug plasma levels for the patient, thus overcoming the issue of fluctuating blood pressure in patients. On the other hand, the localised delivery of CAR to the skin could also be exploited for the management of skin ailments. For instance, Zhang et al. discovered that localised administration of CAR to the skin may also be viewed as an emerging therapy for the treatment of rosacea. This is due to CAR exhibiting anti-inflammatory properties through the inhibition of macrophage TLR2 expression (44). The utilisation of MAPs as a drug delivery platform would be an ideal strategy to deliver CAR in a minimally invasive manner for the treatment of localised skin inflammation.

The delivery profile of dissolving MAPs could be extremely useful in providing systemic and intradermal doses of cardiovascular drugs for managing the treatment of chronic heart failure. The ability of this approach to deliver CAR intradermally may provide a great therapeutic benefit as the drug delivered into the skin may function as a depot for continuous drug release even after patch removal. Nevertheless, such extrapolation warrants future in vivo work involving pharmacokinetics and skin deposition studies in order to validate such hypothesis. Based on the poor solubility of the drug, the systemic absorption of the drug from the site of administration may be limited which could culminate in drug levels which are below the therapeutic limits. On the other hand, the high plasma protein binding nature of the drug may generate a sink condition that could promote the partition of the drug from the intradermal depot into systemic circulation, enabling therapeutic level of drug to be delivered upon application (37). Again, such prediction warrants additional in vivo studies in order to validate this prediction. We acknowledge that the lack of in vivo work is one of the challenges and limitations of the current work.

Collectively, the results presented highlight that the HPLC method developed and validated in this work was successful in quantifying and evaluating CAR permeation from various dissolving MAP formulations. Such quantification enables determination of the delivery efficiency of MAP formulations with different drug loadings. Indeed, the current study shows that the analytical methods were effective in aiding evaluation of the permeation profile of CAR following MAP application. However, it is envisaged that this analytical method might be used to assess the delivery profiles of various transdermal drug delivery systems.

Based on the current work, it may be an extrapolation to predict the utility of MAP as an alternative formulation approach to deliver CAR without any additional pharmacokinetic studies. However, it has been highlighted that the purpose of the current work focuses upon the development of a simple and straightforward RP HPLC-UV method to enable us to screen a different MAP formulation in vitro. The development of this analytical method would be pertinent for future screening of alternative CAR-loaded MAP which are capable of loading higher doses of CAR, which would be capable of delivering therapeutic doses of the cardiovascular drug for the treatment of symptomatic chronic heart failure. However, based on previous work which have attempted and demonstrated the feasibility of using MAP as a formulation approach to deliver antihypertensive drugs (4, 45), it is not too improbable that this pharmaceutical strategy may provide a simple and minimally invasive platform to deliver CAR. Considering the drug loading of MAP formulation in this present work, which is 2 mg, along with the daily dose of CAR, which is 50 mg daily, it is estimated that a patch size of 9 cm2 (3 cm × 3 cm) would be needed to deliver the recommended daily dose of the drug. Nevertheless, further work supported by sound pharmacokinetic studies would be necessary in order to validate such prediction.

Conclusion

To conclude, the current research reported here demonstrates that a simple and straightforward RP HPLC-UV method has been developed and validated in accordance with ICH guidelines. The validated method has demonstrated specificity, linearity, accuracy, and precision across the desired concentration range. Additionally, LOD and LOQ values have confirmed the distinct sensitivity of the method. The method has proven to enable reliable detection and quantification of CAR following in vitro permeation studies on CAR-containing dissolving MAPs. It is anticipated that the method described here may be of great heuristic value in preclinical formulation screening, evaluation, and development.

References

Amini M, Zayeri F, Salehi M. Trend analysis of cardiovascular disease mortality, incidence, and mortality-to-incidence ratio: results from global burden of disease study 2017. BMC Public Health. 2021;21:1–12. https://doi.org/10.1186/s12889-021-10429-0.

Nabel EG. Cardiovascular disease. N Engl J Med. 2003;60–72. https://doi.org/10.1056/NEJMra035098.

Möllendorff EV, Reiff K, Neugebauer G. Pharmacokinetics and bioavailability of carvedilol, a vasodilating beta-blocker. Eur J Clin Pharmacol. 1987;33:511–3. https://doi.org/10.1007/BF00544245.

Quinn HL, Bonham L, Hughes CM, Donnelly RF. Design of a dissolving microneedle platform for transdermal delivery of a fixed-dose combination of cardiovascular drugs. J Pharm Sci. 2015;104:3490–500. https://doi.org/10.1002/jps.24563.

Bin SAH, Anjani QK, Utomo E, Ripolin A, Donnelly RF. Development and characterization of a dry reservoir-hydrogel-forming microneedles composite for minimally invasive delivery of cefazolin. Int J Pharm. 2022;617:121593. https://doi.org/10.1016/j.ijpharm.2022.121593.

Anjani QK, Sabri AHB, Utomo E, Domínguez-Robles J, Donnelly RF. Elucidating the impact of surfactants on the performance of dissolving microneedle array patches. Mol Pharm. 2022;19(4):1191–208. https://doi.org/10.1021/acs.molpharmaceut.1c00988.

Sessa M, Rasmussen DB, Jensen MT, Kragholm K, Torp-Pedersen C, Andersen M. Metoprolol versus carvedilol in patients with heart failure, chronic obstructive pulmonary disease, diabetes mellitus, and renal failure. Am J Cardiol. 2020;125:1069–76. https://doi.org/10.1016/J.AMJCARD.2019.12.048.

Dave CV, Strom BL, Kobylarz FA, Horton DB, Gerhard T, Tseng CL, Dejanovic I, Nyandege A, Setoguchi S. Risk of clinically relevant hyperglycemia with metoprolol compared to carvedilol in older adults with heart failure and diabetes. Pharmacoepidemiol Drug Saf. 2021;30:1420–7. https://doi.org/10.1002/PDS.5303.

Aslam M, Vaezi MF. Dysphagia in the elderly. Gastroenterol Hepatol (N Y). 2013;9(12):784–95.

Hokama N, Hobara N, Kameya H, Ohshiro S, Sakanashi M. Rapid and simple micro-determination of carvedilol in rat plasma by high-performance liquid chromatography. J Chromatogr B Biomed Sci Appl. 1999;732:233–8. https://doi.org/10.1016/S0378-4347(99)00248-0.

Spahn H, Henke W, Langguth P, Schloos J, Mutschler E. Measurement of carvedilol enantiomers in human plasma and urine using S-naproxen chloride for chiral derivatization. Arch Pharm (Weinheim). 1990;323:465–9. https://doi.org/10.1002/ARDP.19903230805.

Eisenberg EJ, Patterson WR, Kahn GC. High-performance liquid chromatographic method for the simultaneous determination of the enantiomers of carvedilol and its O-desmethyl metabolite in human plasma after chiral derivatization. J Chromatogr. 1989;493:105–15. https://doi.org/10.1016/S0378-4347(00)82713-9.

Ptáček P, Macek J, Klíma J. Liquid chromatographic determination of carvedilol in human plasma. J Chromatogr B Anal Technol Biomed Life Sci. 2003;789:405–10. https://doi.org/10.1016/S1570-0232(03)00078-3.

Varin F, Cubeddu LX, Powell JR. Liquid chromatographic assay and disposition of carvedilol in healthy volunteers. J Pharm Sci. 1986;75:1195–7. https://doi.org/10.1002/JPS.2600751218.

Yamsani VV, Gannu R, Yamsani MR, Veerabrahma K. High-performance liquid chromatography determination of carvedilol in pig serum. J Chromatogr Sci. 2010;48:348–52. https://doi.org/10.1093/CHROMSCI/48.5.348.

Clohs L, McErlane KM. Development of a capillary electrophoresis assay for the determination of carvedilol enantiomers in serum using cyclodextrins. J Pharm Biomed Anal. 2001;24:545–54. https://doi.org/10.1016/S0731-7085(00)00468-4.

Gergov M, Robson JN, Duchoslav E, Duchoslav I. Automated liquid chromatographic/tandem mass spectrometric method for screening β-blocking drugs in urine. J Mass Spectrom. 2000;35:912–8.

Behn F, Läer S, Scholz H. Determination of carvedilol in human cardiac tissue by high-performance liquid chromatography. J Chromatogr Sci. 2001;39:121–4. https://doi.org/10.1093/CHROMSCI/39.3.121.

Jeong DW, Kim YH, Ji HY, Youn YS, Lee KC, Lee HS. Analysis of carvedilol in human plasma using hydrophilic interaction liquid chromatography with tandem mass spectrometry. J Pharm Biomed Anal. 2007;44:547–52. https://doi.org/10.1016/J.JPBA.2006.12.017.

Anjani QK, Utomo E, Domínguez-Robles J, Detamornrat U, Donnelly RF, Larrañeta E. A new and sensitive HPLC-UV method for rapid and simultaneous quantification of curcumin and D-panthenol: application to In vitro release studies of wound dressings. Molecules. 2022;27:1759. https://doi.org/10.3390/MOLECULES27061759.

González O, Blanco ME, Iriarte G, Bartolomé L, Maguregui MI, Alonso RM. Bioanalytical chromatographic method validation according to current regulations, with a special focus on the non-well defined parameters limit of quantification, robustness and matrix effect. J Chromatogr A. 2014;1353:10–27. https://doi.org/10.1016/J.CHROMA.2014.03.077.

Cárcamo-Martínez Á, Mallon B, Anjani QK, Domínguez-Robles J, Utomo E, Vora LK, Tekko IA, Larrañeta E, Donnelly RF. Enhancing intradermal delivery of tofacitinib citrate: comparison between powder-loaded hollow microneedle arrays and dissolving microneedle arrays. Int J Pharm. 2021;593. https://doi.org/10.1016/j.ijpharm.2020.120152.

Donnelly RF, McCrudden MTC, Alkilani AZ, Larrañeta E, McAlister E, Courtenay AJ, Kearney MC, Thakur RRS, McCarthy HO, Kett VL, Caffarel-Salvador E, Al-Zahrani S, Woolfson AD. Hydrogel-forming microneedles prepared from “super swelling” polymers combined with lyophilised wafers for transdermal drug delivery. PLoS One. 2014;9:1–12. https://doi.org/10.1371/journal.pone.0111547.

Donnelly RF, Thakur RRS, Garland MJ, Migalska K, Majithiya R, McCrudden CM, Kole PL, Mahmood TMT, McCarthy HO, Woolfson AD. Hydrogel-forming microneedle arrays for enhanced transdermal drug delivery. Adv Funct Mater. 2012;22:4879–90. https://doi.org/10.1002/adfm.201200864.

Anjani QK, Permana AD, Cárcamo-Martínez Á, Domínguez-Robles J, Tekko IA, Larrañeta E, Vora LK, Ramadon D, Donnelly RF. Versatility of hydrogel-forming microneedles in in vitro transdermal delivery of tuberculosis drugs. Eur J Pharm Biopharm. 2021;294–312:294–312. https://doi.org/10.1016/j.ejpb.2020.12.003.

Donnelly RF, Garland MJ, Morrow DIJ, Migalska K, Thakur RRS, Majithiya R, Woolfson AD. Optical coherence tomography is a valuable tool in the study of the effects of microneedle geometry on skin penetration characteristics and in-skin dissolution. J Control Release. 2010;147:333–41. https://doi.org/10.1016/j.jconrel.2010.08.008.

Vander Heyden Y, Nijhuis A, Smeyers-Verbeke J, Vandeginste BGM, Massart DL. Guidance for robustness/ruggedness tests in method validation. J Pharm Biomed Anal. 2001;24:723–53. https://doi.org/10.1016/S0731-7085(00)00529-X.

Adlof R, List G. Analysis of triglyceride isomers by silver-ion high-performance liquid chromatography: effect of column temperature on retention times. J Chromatogr A. 2004;1046:109–13. https://doi.org/10.1016/j.chroma.2004.06.012.

Permana AD, Wahyudin E, Ismail AMN, Raihan M, Anjani QK, Utomo E, Layadi P, Donnelly RF. New and sensitive HPLC-UV method for concomitant quantification of a combination of antifilariasis drugs in rat plasma and organs after simultaneous oral administration. Anal Methods. 2021;13:933–45. https://doi.org/10.1039/d0ay02258f.

Chen M, Shamim MA, Shahid A, Yeung S, Andresen BT, Wang J, Nekkanti V, Meyskens FL, Kelly KM, Huang Y. Topical delivery of carvedilol loaded nano-transfersomes for skin cancer chemoprevention. Pharmaceutics. 2020;12:1–17. https://doi.org/10.3390/PHARMACEUTICS12121151.

Abdullah Shamim A, Yeung M, Shahid S, Abdullah Shamim M, Yeung S, Shahid A, Chen M, Wang J, Desai P, Parsa C, Orlando R, Meyskens Jr FL, Kelly KM, Andresen BT, Huang Y (2021) Topical carvedilol delivery prevents UV-induced skin cancer with negligible systemic absorption. https://doi.org/10.1016/j.ijpharm.2021.121302.

Amarachinta PR, Sharma G, Samed N, Chettupalli AK, Alle M, Kim JC. Central composite design for the development of carvedilol-loaded transdermal ethosomal hydrogel for extended and enhanced anti-hypertensive effect. J Nanobiotechnology. 2021;19:1–15. https://doi.org/10.1186/S12951-021-00833-4/FIGURES/9.

Rayfield WJ, Kandula S, Khan H, Tugcu N. Impact of freeze/thaw process on drug substance storage of therapeutics. J Pharm Sci. 2017;106:1944–51. https://doi.org/10.1016/j.xphs.2017.03.019.

Kozikowski BA, Burt TM, Tirey DA, Williams LE, Kuzmak BR, Stanton DT, Morand KL, Nelson SL. The effect of freeze/thaw cycles on the stability of compounds in DMSO. J Biomol Screen. 2003;8:210–5. https://doi.org/10.1177/1087057103252618.

Kim S-H, Lee SH, Lee HJ. Rapid and sensitive carvedilol assay in human plasma using a high-performance liquid chromatography with mass/mass spectrometer detection employed for a bioequivalence study. Am J Anal Chem. 2010;01:135–43. https://doi.org/10.4236/AJAC.2010.13017.

Eiamart W, Prompila N, Jumroen Y, Sayankuldilok N, Chariyavilaskul P, Wittayalertpanya S. A simple LC-MS/MS method for pharmacokinetic study of carvedilol and 4/-hydroxyphenyl carvedilol at a low dose. Res Pharm Sci. 2022;17:231. https://doi.org/10.4103/1735-5362.343077.

Morgan T. Clinical pharmacokinetics and pharmacodynamics of carvedilol. Clin Pharmacokinet. 1994;26:335–46. https://doi.org/10.2165/00003088-199426050-00002.

Stewart SA, Waite D, Domínguez-Robles J, McAlister E, Permana AD, Donnelly RF, Larrañeta E (2021) HPLC method for levothyroxine quantification in long-acting drug delivery systems. Validation and evaluation of bovine serum albumin as levothyroxine stabilizer. J Pharm Biomed Anal 203: 10.1016/J.JPBA.2021.114182.

Lanzanova FA, Argenta D, Arend MZ, Brum L, Cardoso SG (2009) LC and LC-MS evaluation of stress degradation behavior of carvedilol. 32:526–543. https://doi.org/10.1080/10826070802671481.

Liu X, Xu Y, Liu F, Pan Y, Miao L, Zhu Q, Tan S. The feasibility of antioxidants avoiding oxidative damages from reactive oxygen species in cryopreservation. Frontiers in Chemistry. 2021;9:64. https://doi.org/10.3389/FCHEM.2021.648684/BIBTEX.

González-Vázquez P, Larrañeta E, McCrudden MTC, Jarrahian C, Rein-Weston A, Quintanar-Solares M, Zehrung D, McCarthy H, Courtenay AJ, Donnelly RF. Transdermal delivery of gentamicin using dissolving microneedle arrays for potential treatment of neonatal sepsis. J Control Release. 2017;265:30–40. https://doi.org/10.1016/j.jconrel.2017.07.032.

Chen YY, Hughes LP, Gladden LF, Mantle MD. Quantitative ultra-fast MRI of HPMC swelling and dissolution. J Pharm Sci. 2010;99:3462–72. https://doi.org/10.1002/JPS.22110.

Sharma M, Sharma R, Kumar D, Saraf A. International Journal of Biological Macromolecules Enhancement of oral bioavailability of poorly water soluble carvedilol by chitosan nanoparticles : optimization and pharmacokinetic study. Int J Biol Macromol. 2019;135:246–60. https://doi.org/10.1016/j.ijbiomac.2019.05.162.

Zhang J, Jiang P, Sheng L, Liu Y, Liu Y, Li M, Tao M, Hu L, Wang X, Yang Y, Xu Y, Liu W. A novel mechanism of carvedilol efficacy for Rosacea treatment: toll-like receptor 2 inhibition in macrophages. Front Immunol. 2021;12:2777. https://doi.org/10.3389/FIMMU.2021.609615/BIBTEX.

Luu E, Ita KB, Morra MJ, Popova IE. The influence of microneedles on the percutaneous penetration of selected antihypertensive agents: diltiazem hydrochloride and perindopril erbumine. Current Drug Delivery. 2018;15:1449. https://doi.org/10.2174/1567201815666180730125941.

Funding

The authors acknowledge Wellcome Trust for funding this project with Fund number WT094085MA.

Author information

Authors and Affiliations

Contributions

Conceptualisation, QKA; supervision and project administration, RFD; conduct the experimental work, QKA and HL; methodology, QKA and HL; write the first draft, QKA, AHS, and HL; writing/editing, MBM, KAH, and RFD; data analysis, QKA; computational investigations and software analysis, QKA.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Guest Editors: Jayachandra Babu Ramapuram and Ashana Puri.

Supplementary Information

ESM 1

(DOCX 49 kb)

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Anjani, Q.K., Sabri, A.H.B., McGuckin, M.B. et al. In Vitro Permeation Studies on Carvedilol Containing Dissolving Microarray Patches Quantified Using a Rapid and Simple HPLC-UV Analytical Method. AAPS PharmSciTech 23, 273 (2022). https://doi.org/10.1208/s12249-022-02422-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1208/s12249-022-02422-6