Abstract

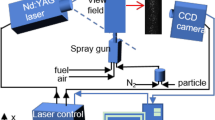

A laboratory spray gun and a production spray gun were investigated in a scale-up study. Two Schlick spray guns, which are equipped with a new antibearding cap, were used in this study. The influence of the atomization air pressure, spray gun-to tablet bed distance, polymer solution viscosity, and spray rate were analyzed in a statistical design of experiments. The 2 spray guns were compared with respect to the spray width and height, droplet size, droplet velocity, and spray density. The droplet size, velocity, and spray density were measured with a Phase Doppler Particle Analyzer.

A successful scale-up of the atomization is accomplished if similar droplet sizes, droplet velocities, and spray densities are achieved in the production scale as in the laboratory scale. This study gives basic information for the scale-up of the settings from the laboratory spray gun to the production spray gun. Both spray guns are highly comparable with respect to the droplet size and velocity. The scale-up of the droplet size should be performed by an adjustment of the atomization air pressure. The scale-up of the droplet velocity should be performed by an adjustment of the spray gun to tablet bed distance. The presented statistical model and surface plots are convenient and powerful tools for scaling up the spray settings if the spray gun is changed from laboratory spray gun to the production spray gun.

Similar content being viewed by others

References

Lefebvre AH.Atomization and Sprays. New York, NY: Hemisphere Publishing Corp; 1989.

Aulton ME, Twitchell AM. Solution properties and atomization in film coating. In: Cole G, ed.Pharmaceutical Coating Technology. London, UK: Taylor & Francis: 1995:65–117.

Aulton ME, Twitchell AM. Film coat quality. In: Cole GC, ed.Pharmaceutical Coating Technology. London, UK: Taylor & Francis; 1995:363–408.

Missaghi S, Fassihi R. A novel approach in the assessment of polymeric film formation and film adhesion on different pharmaceutical solid substrates.AAPS PharmSciTech. 2004;5:E29.

Ebey DG. A thermodynamic model for aqueous film-coating.Pharm Technol. 1987;5:40–50.

am Ende MT, Berchielli A. A thermodynamic model for organic and aqueous tablet film coating.Pharm Dev Technol. 2005;10: 47–58.

Porter SC. Scale-up of film coating. In: Levin M, ed.Pharmaceutical Process Scale-up. New York, NY: Marcel Dekker Inc; 2001: 259–310.

Gerstner S. Keine Schwächen—Mehr Betriebssicherheit beim Tablettencoating.Pharma Food. 2001;5:62–63.

Ruck B. Laser Doppler Anemometry—a nonintrusive optical measuring technique for fluid velocity.Part Charact. 1987;4:26–37.

Mitschke M.PDA-relevante Streulichteigenschaften: Phänomene, Parameterwahl und mathematische Korrektur. Düsseldorf, Germany: VDI Verlag GmbH; 2000.

Zhang Z, Ziada S. PDA measurements of droplet size and mass flux in the three-dimensional atomization region of water jet in air cross-flow.Exp Fluids. 2000;28:29–35.

Müller R, Kleinebudde P. Comparison study of laboratory and production spray guns in film coating: effect of pattern air and nozzle diameter.Pharm Dev Technol. 2006;11:425–433.

Nukiyama S, Tanasawa Y. Experiments on the atomization of liquids in an airstream.Trans Soc Mech Eng Japan. 1939;5:68–75.

Twitchell AM.Studies on the role of atomization in aqueous tablet film coating [PhD thesis]. Leicester, UK: De Montfort University; 1990.

Turton R, Cheng XX. The scale-up of spray coating processes for granular solids and tablets.Powder Technol. 2005;150:78–85.

Pandey P, Turton R. Movement of different-shaped particles in a pan-coating device using novel video-imaging techniques.AAPS PharmSciTech. 2005;6:E237-E244.

Author information

Authors and Affiliations

Corresponding author

Additional information

Published: January 19, 2007

Rights and permissions

About this article

Cite this article

Mueller, R., Kleinebudde, P. Comparison of a laboratory and a production coating spray gun with respect to scale-up. AAPS PharmSciTech 8, 3 (2007). https://doi.org/10.1208/pt0801003

Received:

Accepted:

DOI: https://doi.org/10.1208/pt0801003