Abstract

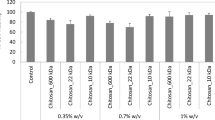

The purpose of these studies was to enhance mucosal and systemic antibody production in response to increased local residence time of a whole inactivated influenza virus administered as a dry powder nasal vaccine formulation. Spray-freeze-drying (SFD) particles suitable for nasal delivery were characterized for physico-chemical properties and stability. Mucoadhesive compounds (MA) were characterized for their effects on nasal residence time of vaccine powders in rats compared with published in vitro data and elicited immune responses. SFD particles (D50=26.9µm) were spherical with a specific surface area of 1.25 m2/g. Thermal analysis indicated SFD powders were amorphous and demonstrated improved stability with respect to liquid formulations under various storage conditions. In vitro physico-chemical studies and in vivo scintigraphic imaging experiments indicated sodium alginate (SA) and carboxymethylcellulose-high molecular weight (CMC-HMW) powder formulations most significantly increased residence time in Brown Norway rats. Intramuscular delivery provided equivalent serum antibody titers to intranasal (IN) powder without MA, in the presence of CMC-HMW, SA, and hydroxypropyl methylcellulose (HPMC-HMW) after initial dosing and all formulations except IN powder with chitosan after boosting. IN liquid provided equivalent serum antibody titers to all IN powders after the initial vaccination and significantly greater serum antibody titers than IN powder with chitosan after boosting. Trends were consistent between residence time studies and immune response; however, no statistically significant differences between powder and liquid formulations were observed. It was concluded that enhanced serum and mucosal antibody responses were elicited by a dry powder nasal vaccine, specifically, administered in the presence of sodium alginate.

Similar content being viewed by others

References

Smith, DJ, Bot S, Dellamary L, Bot A. Evaluation of novel aerosol formulations designed for mucosal vaccination against influenza virus.Vaccine. 2003;21:2805–2812.

Anderson J, Fishbourne E, Corteyn A, Donaldson AI. Protection of cattle against rinderpest by intranasal immunisation with a dry powder tissue culture vaccine.Vaccine. 2000;19:840–843.

LiCalsi C. Christensen T, Bennett JV, Phillips E, Witham C. Dry powder inhalation as a potential delivery method for vaccines.Vaccine. 1999;17:1796–1803.

LiCalsi C. Maniaci MJ, Christensen T, Phillips E, Ward GH, Witham C. A powder formulation of measles vaccine for aerosol delivery.Vaccine. 2001;19:2629–2636.

Illum L, Jabbal-Gill I, Hinchcliffe M, Fisher AN, Davis SS. Chitsoan as a novel nasal delivery system for vaccines.Adv Drug Deliv Rev. 2001;51:81–96.

Garmise RJ, Mar K, Crowder TM, et al. Formulation of a dry powder influenza vaccine for nasal delivery.AAPS PharmSciTech. 2006;7: article 19.

Huang J, Garmise RJ, Crowder TM, et al. A novel dry powder influenza vaccine and intranasal delivery technology: induction of systemic and mucosal immune responses in rats.Vaccine. 2004;23:794–801.

Costantino HR, Firouzabadian L, Wu C, et al. Protein spray freeze drying. 2. Effect of formulation variables on particle size and stability.J Pharm Sci. 2002;91:388–395.

Costantino HR, Firouzabadian L, Hogeland K, et al. Protein spray-freeze drying. Effect of atomization conditions on particle size and stability.Pharm Res. 2000;17:1374–1383.

Gombotz WR, Healy MS, Brown LR, Auer HE, inventors. Alkermes Controlled Therapeutics, Inc., assignee. Process for producing small particles of biologically active molecules. US patent 6569458. May 27, 2003.

Maa YF, Nguyen PA, Sweeney T, Shire SJ, Hsu CC. Protein inhalation powders: spray drying vs spray freeze drying.Pharm Res. 1999;16:249–254.

Carrasquillo KG, Stanley AM, Aponte-Carro JC, et al. Non-aqueous encapsulation of excipient-stabilized spray-freeze dried BSA into poly (lactide-co-glycolide) microspheres results in release of native protein.J Control Release. 2001;76:199–208.

Carrasquillo KG, Carro JC, Alejandro A, Toro DD, Griebenow K. Reduction of structural perturbations in bovine serum albumin by nonaqueous microencapsulation.J Pharm Pharmacol. 2001;53:115–120.

Bacon A, Makin J, Sizer PJ, et al. Carbohydrate biopolymers enhance antibody responses to mucosally delivered vaccine antigens.Infect Immun. 2000;68:5764–5770.

Aspden TJ, Mason JD, Jones NS, Lowe J, Skaugrud O, Illum L. Chitosan as a nasal delivery system: the effect of chitosan solutions on in vitro and in vivo mucociliary transport rates in human turbinates and volunteers.J Pharm Sci. 1997;86:509–513.

Cheng Y-H, Dyer AM, Jabbal-Gill I, et al. Intranasal delivery of recombinant human growth hormone (somatropin) in sheep using chitosan-based powder formulations.Eur J Pharm Sci. 2005;26:9–15.

Illum L, Fisher AN, Jabbal-Gill I, Davis SS. Bioadhesive starch microspheres and absorption enhancing agents act synergistically to enhance the nasal absorption of polypeptides.Int J Pharm. 2001;222:109–119.

Soane RJ, Frier M, Perkins AC, Jones NS, Davis SS, Illum L. Evaluation of the clearance characteristics of bioadhesive systems in humans.Int J Pharm. 1999;178:55–65.

Soane RJ, Hinchcliffe M, Davis SS, Illum L. Clearance characteristics of chitosan based formulations in the sheep nasal cavity.Int J Pharm. 2001;217:183–191.

Ugwoke MI, Agu RU, Jorissen M, et al. Nasal toxicological investigations of Carbopol 971P formulation of apomorphine: effects on ciliary beat frequency of human nasal primary cell culture and in vivo on rabbit nasal mucosa.Eur J Pharm Sci. 2000;9:387–396.

Ugwoke MI, Agu RU, Vanbilloen H, et al. Scintigraphic evaluation in rabbits of nasal drug delivery systems based on carbopol 971p((R)) and carboxymethylcellulose.J Control Release. 2000;68:207–214.

Martin AN, Bustamante P.Physical Pharmacy: Physical Chemmical Principles in the Pharmaceutical Sciences. Philadelphia, PA: Lea & Febiger; 1993.

Carstensen JT.Pharmaceutical Principles of Solid Dosage Forms. Lancaster, PA: Technomic Publishing Co.; 1993.

Carr RL, jr. Evaluating flow properties of solids.Chem Eng. 1965;72:163–168.

Carr RL, Jr. Classifying flow properties of solids.Chem Eng. 1965;72:69–72.

Staniforth JN. Powder flow. In: Aulton ME, ed.Pharmaceutics: The Science of Dosage Form Design. 1st ed. New York: Churchill Livingstone; 2002:197–210.

Yu Z, III, Johnston KP, III, Williams RO, III. Spray freezing into liquid versus spray-freeze drying: influence of atomization on protein aggregation and biological activity.Eur J Pharm Sci. 2006;27:9–18.

Surana R, Pyne A, Suryanarayanan R. Effect of preparation method on physical properties of amorphous trehalose.Pharm Res. 2004;21:1167–1176.

FDA.US FDA Draft Guidance for Industry. Q1A(R2) Stability Testing of New Drug Substances and Products. Bethesda, MD: USFDA; 2003.

Pikal MJ. Freeze-drying of proteins. In: Cleland JL, Langer R, eds.Formulation and Delivery of Proteins and Peptides. vol. 5567. Washington, DC: ACS Symposium Series; 1994:120–133.

Carpenter JF, Pikal MJ, Chang BS, Randolph TW. Rational design of stable lyophilized protein formulations: some practical advice.Pharm Res. 1997;14:969–975.

Carpenter JF, Chang BS. Lyophilization of protein pharmaceuticals. In: Avis KE, Wu VL, eds.Biotechnology and Biopharmaceutical Manufacturing, Processing, and Preservation. Buffalo Grove, IL: Interpharm Press; 1996:199–264.

Abdul-Fattah A, Truong-Le V, Yee L, et al. Drying-induced variations in physico-chemical properties of amorphous pharmaceuticals and their impact on stability II: stability of a vaccine.Pharm Res. 2007;24:715–727.

Garmise RJ, Hickey AJ. In vitro evaluation of mucoadhesive compounds for use in a dry powder nasal vaccine. Paper presented at: Respiratory Drug Delivery X; April 23–27, 2006; boca Raton, FL.

Nelson M, Prior JL, Lever MS, Jones HE, Atkins TP, Titball RW. Evaluation of lipopolysaccharide and capsular polysaccharide as subunit vaccines against experimental melioidosis.J Med Microbiol. 2004;53:1177–1182.

Author information

Authors and Affiliations

Corresponding author

Additional information

Published: October 12, 2007

Rights and permissions

About this article

Cite this article

Garmise, R.J., Staats, H.F. & Hickey, A.J. Novel dry powder preparations of whole inactivated influenza virus for nasal vaccination. AAPS PharmSciTech 8, 81 (2007). https://doi.org/10.1208/pt0804081

Received:

Revised:

Accepted:

DOI: https://doi.org/10.1208/pt0804081