Abstract

β-Ga2O3 is a promising wide-bandgap semiconductor material for power electronic applications and as a conducting substrate for GaN growth. In this work, we report the growth of high quality single crystal β-Ga2O3 by the optical floating zone technique. A detailed study of the effect of gas ambient on the quality of Ga2O3 single crystals was carried out, with the structural quality investigated using Laue, single crystal and powder X-ray diffraction measurements, and the optical properties studied using transmission, photoluminescence, and Raman scattering measurements. Under optimized conditions high-quality, ∼ 1 cm diameter and ∼ 8-10 cm length Ga2O3 single crystals with X-ray FWHM values of ∼ 22'' for the (400) reflection, comparable to commercially available Ga2O3 wafers, could be demonstrated.

Export citation and abstract BibTeX RIS

This is an open access article distributed under the terms of the Creative Commons Attribution 4.0 License (CC BY, http://creativecommons.org/licenses/by/4.0/), which permits unrestricted reuse of the work in any medium, provided the original work is properly cited.

Ga2O3 is a promising wide bandgap transparent conducting oxide1,2 with potential applications in power electronic devices3 as well as for conducting transparent substrates for optoelectronics devices4 due to transparency in the visible to UV region.5 Among the different polymorphs of Ga2O3 β − Ga2O3 is the most stable1 and hence widely studied as a substrate for GaN growth6–8 and also for use in power electronics applications. Due to its monoclinic crystal structure, various physical and optoelectronic properties of β-Ga2O3 are different along the different crystallographic directions. One of the remarkable features of Ga2O3 is that single crystals can be grown from a melt, which is quite uncommon for most wide-bandgap materials like SiC, AlN or GaN. Single crystal β-Ga2O3 can be grown by different methods such as edge-defined film-fed growth (EFG),9,10 vertical Bridgman,11 and Czochralski12,13 techniques. These methods require a crucible which is generally made of iridium (Ir) or an iridium alloy. The degradation of the crucible during high temperature growth can potentially lead to contamination of the crystal from Ir impurities, and also adds the complexity of the process. On the other hand, the optical floating zone technique is a well-known crucible-free single crystal growth method that has been used to grow high purity oxide crystals, albeit with a limitation in the diameter to a few centimeters. Though there are some reports14,15 on the growth of single crystal β-Ga2O3 via the optical floating zone technique, getting single crystals of high quality is difficult.14 The propensity of the crystal to cleave naturally, appearance of cracks, formation of bubbles during growth and evaporation due to decomposition of the Ga2O3 feedstock makes the growth of Ga2O3 challenging. In this work we report high quality single crystal β − Ga2O3 grown by the optical floating zone technique. In particular, we discuss the effect of the ambient gas composition and flow rate on the quality of Ga2O3 crystals and describe the variation of their structural and optical properties due to the changes in the gas ambient, and show how optimization of the gas ambient allows the growth of high-quality ∼ 8–10 cm-long and ∼ 1 cm diameter Ga2O3 crystals.

Ga2O3 Growth

5N purity Ga2O3 powder (ABSCO Ltd, U.K) was used as the starting material for the preparation of feed and seed rods. The Ga2O3 powder was packed tightly in a latex balloon with uniform pressure. The air inside the balloon was removed using a vacuum pump and a hydrostatic pressure of ∼ 70 MPa was applied to densify the rod uniformly. The compacted rods were sintered in a box type furnace at 1450°C for 24 hours. The crystal growth was carried out in an optical floating zone furnace (Fig. 1). This furnace has 4 halogen lamps of 1 kW power each that are focused using four elliptical mirrors at the center of the furnace. Both the feed and seed rods can be independently rotated (usually in opposite directions) for better uniformity. The rotation speed was varied from 5-20 rpm. The crystal was pulled at linear speeds ranging from 5-20 mm/hr, in the downward direction.

Figure 1. Schematic diagram of the optical floating zone furnace.

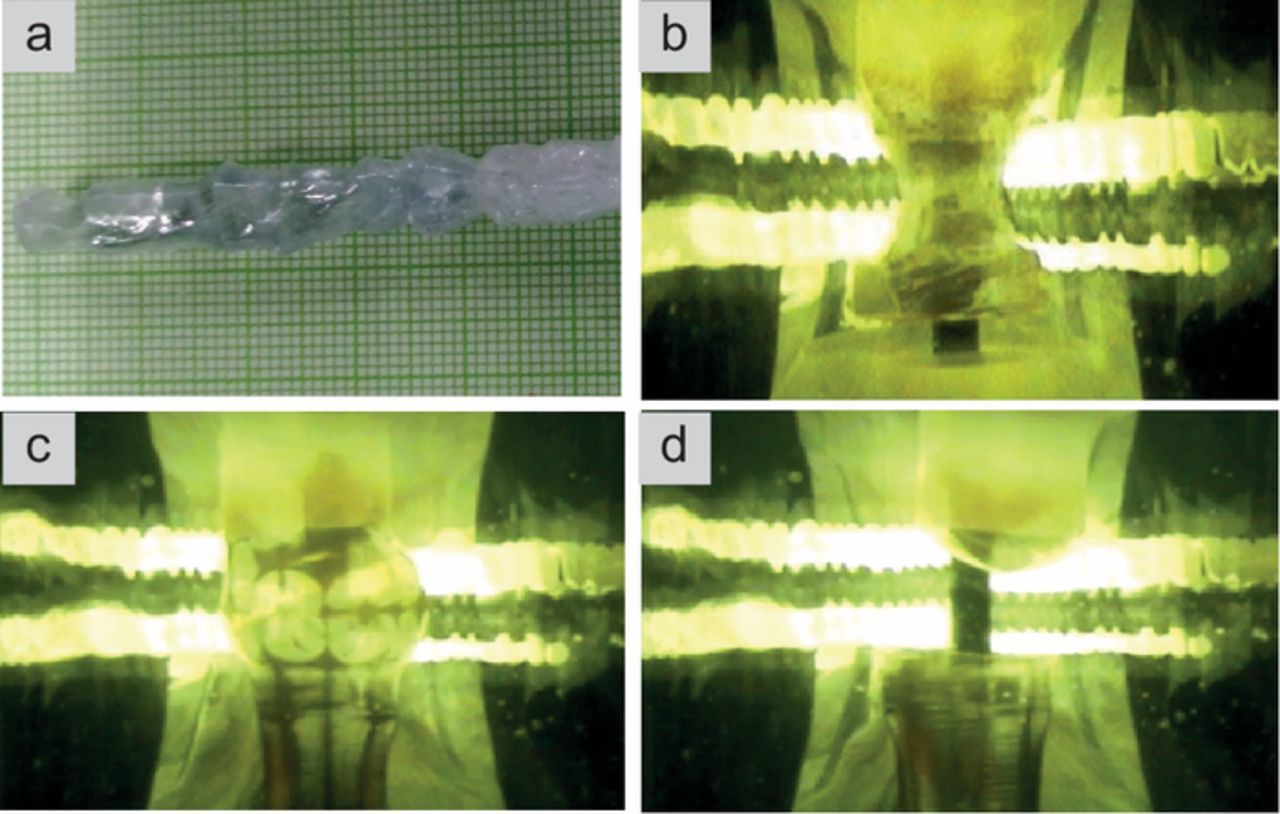

Initially, the as-sintered rods were used as feed and seed to grow the Ga2O3 crystal. It was observed that the grown crystal had several cracks, due to the polycrystalline seed which resulted in multiple nucleation sites, as shown in 2a. However, the use of an oriented seed crystal helped in getting much better results. Since no high-temperature glues can be used to attach the seed crystal to the rod, a (100) oriented seed crystal was first cleaved from a polycrystalline sample grown earlier, and then attached to the rod from top side by melting the seed rod (Fig. 2b). Then the seed rod with the oriented seed Ga2O3 crystal along [100]-direction was used for the growth of Ga2O3 single crystal. After attaching the single crystalline seed with the (100)-plane, the seed rod was fixed at the bottom and the feed rod was hung from the top. For the growth, the top portion of the feed rod was melted and gently attached to the (100)-oriented seed. Although, we started with the oriented seed crystal, we performed a necking process by translating the seed relatively faster compared to the feed, so that only one grain grows into a larger crystal. The growth details and the growth parameters are given in Table I.

Figure 2. Optical image of (a) the Ga2O3 crystal grown using polycrystalline seed consisting of multiple cracks, (b) single crystal (100) oriented seed attached to polycrysalline seed rod, (c) formation of a bubble causing insatiability in the molten zone (d) the detached feed and seed rod after the bubble explosion.

Table I. Details of the parameters used for the optical floating zone growth of β-Ga2O3 crystals and the corresponding structural and electrical characterization data.

| Sample | Rotation | Rotation | Feed pulling | Seed pulling | Gas | Flow | Carrier | Mobility | RC FWHM |

|---|---|---|---|---|---|---|---|---|---|

| Id | of feed (rpm) | of seed (rpm) | rate (mm/hr) | rate (mm/hr) | ambient | rate (l/m) | conc. (cm-1) | (cm2/V s) | (400) |

| FZ17005 | 5 | 5 | 10 | 10 | O2 | 0.05 | - | - | 46 |

| FZ17008 | 20 | 14 | 10 | 15-20 | O2 | 0.1 | - | - | 60 |

| FZ17010 | 10-20 | 20 | 10 | 20 | Air | 2 | 1.4 × 1015 | 40 | 27 |

| FZ17011 | 20 | 20 | 10 | 5 | O2 | static | - | - | 76 |

| FZ17013 | 20 | 20 | 20-40 | 20-40 | Ar | 0.2 | - | - | 123 |

| FZ17014 | 20 | 20 | 10 | 10 | 90%Ar, 10%O2 | 0.18 (Ar), 0.02 (O2) | 1.4 × 1018 | 36 | 22 |

Another factor limiting the growth of long Ga2O3 crystals is the formation of bubbles inside the molten zone due to decomposition of Ga2O3 especially when growing in a 100% oxygen ambient. It has been previously observed that Ga2O3 starts decomposing above 1200°C, with the rate of decomposition increasing with temperature.16 The decomposition reaction16 is given by

![Equation ([1])](https://content.cld.iop.org/journals/2162-8777/8/7/Q3144/revision1/d0001.gif)

![Equation ([2])](https://content.cld.iop.org/journals/2162-8777/8/7/Q3144/revision1/d0002.gif)

![Equation ([3])](https://content.cld.iop.org/journals/2162-8777/8/7/Q3144/revision1/d0003.gif)

This disturbs the growth process since the gaseous products due to decomposition of the Ga2O3 form a bubble inside the molten zone (Fig. 2c). In general, since the oxygen partial pressure is typically kept very high while growing oxides, such bubbles cannot easily diffuse out of the melt into the ambient. The gases accumulate inside bubbles over time and increase its size. This causes instability in the molten portion while rotating and beyond some critical size, the bubbles burst and as a result, the feed and seed rods get detached with each other. Fig. 2d shows the optical image of the crystal just taken after such a bubble explosion. This interrupts the growth of long Ga2O3 crystals, to a large extent. We find that the ambient atmosphere plays an important role in controlling the formation of bubbles. If air, or a mixture of argon and oxygen is used as the ambient the partial pressure of the oxygen is reduced. As a result, it is easier for any bubble that is formed to diffuse out of the molten zone. However, there is another critical trade-off. The reduction of the ambient oxygen partial pressure increases the decomposition of Ga2O3 resulting in gallium oxide powder being deposited on the quartz tube (Fig. 3). This whitish deposit reduces the transparency of the quartz tube, diminishing the lamp power reaching the focus and hence necessitates more power to the lamp. If oxygen partial pressure is very less or zero the deposition of powder on the quartz tube can be so severe that the opacity renders the crystal growth impossible. As a result, a proper optimization of the air or argon/oxygen mixture, and the flow rate is needed to grow long, good quality crystals. Fig. 4 shows the optical image of Ga2O3 crystals grown in different gas ambient. It was observed that the quality of the crystal is better for a flowing gas environment compared to that of a closed ambient. The crystals grown in an oxygen rich ambient are transparent and colorless in nature. The presence of argon in the ambient creates oxygen vacancies in the crystal, which give it a bluish color which gets deeper with increasing argon concentration in the ambient.

Figure 3. Deposition of white gallium oxide powder released from molten zone during the growth under a pure Argon ambient. The opacity of the coating on the quartz tube reduces the power incident from the lamps on the molten zone.

Figure 4. Optical image of single crystal β- Ga2O3 samples grown under different conditions.(a) O2 ambient with flow rate 0.05 l/m, (b) O2 ambient with flow rate 0.15 l/m, (c) air ambient with flow rate 2 l/m, (d) static O2 ambient, (e) argon ambient with flow rate 0.2 l/m, (f) optimized ambient condition (90% Ar,10% O2) with Ar flow rate 0.18 l/m and O2 flow rate 0.02 l/m.

Structural Characterization

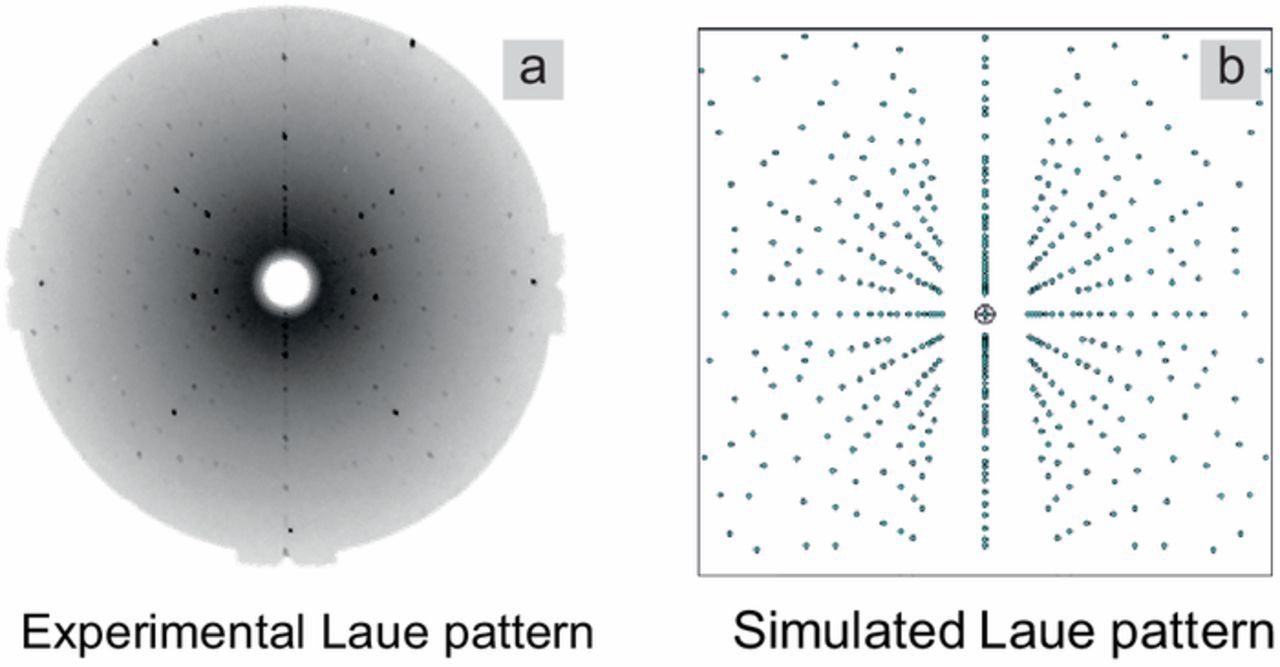

Single crystal Ga2O3 is prone to cleave along the (100) plane. Some small pieces of Ga2O3 of diameter ∼ 1 cm and thickness 300 μm were mechanically cleaved from the Ga2O3 crystals grown under different conditions. The Ga2O3 samples were placed on top of a goniometer in front of a white X-ray source to obtain a Laue diffraction pattern. Fig. 5a shows the Laue diffraction pattern in the reflection geometry for the crystal grown under optimized growth conditions. The sharp spots in the Laue pattern confirm good crystallinity of the grown Ga2O3 crystal. The stereographic projections of the Ga2O3 crystal about various symmetry axes were simulated to match with the obtained Laue pattern to determine the orientation of the single crystal. Fig. 5b shows the simulated Laue pattern corresponding to (100) direction which matches with the experimentally obtained Laue pattern reasonably well. It confirms the sample was cleaved along (100) surface. The powder XRD pattern of the Ga2O3 crystal (Fig. 6b) also has sharp peaks corresponding to(400), (600), and (800) reflections showing evidence of the good crystallinity. To examine the structural quality further, single crystal XRD measurements (Rigaku SmartLab) were done on cleaved Ga2O3 slices. The rocking curve shown in Fig. 6b having an FWHM of ∼ 22 arcsec for the (400) reflection points to a high degree of crystallinity of the Ga2O3 single crystal, comparable to that measured for commercially-available (100)Ga2O3 substrates9 under similar instrumental conditions (see supporting information for details).

Figure 5. (a) Experimental and (b) simulated Laue diffraction pattern for (100) oriented β- Ga2O3.

Figure 6. (a) Rocking curve for the (400) reflection (b) Powder XRD pattern showing the multiple reflections for the best grown β- Ga2O3 crystal.

Optical Characterization

Polarization-dependent optical transmission, photoluminescence, and Raman scattering measurements were done to investigate the optical properties of the Ga2O3 crystals grown under different gas ambient. Fig. 7a compares the optical transmission of four Ga2O3 samples grown under different conditions, measured on a Cary 5000 UV-VIS-NIR spectrophotometer with unpolarized light in the wavelength range from 200 to 2500 nm. The transmission curve is flat beyond the band edge for the sample grown in the pure oxygen ambient. A slight decrease of the sub-band-gap transmission curve is observed for the Ga2O3 crystal grown in Air atmosphere. However, for the sample grown in the 90% Ar and 10% oxygen atmosphere, there is significant absorption in the visible and infrared range, as also evident from the bluish color of the crystal. This is attributed to the free carrier absorption caused by the oxygen vacancies in the Ga2O3 crystal. As expected, the sample grown in a pure argon atmosphere shows enhanced absorption. Due to the monoclinic crystal structure of β- Ga2O3 the optical transmission is anisotropic. Fig. 7b shows the polarization dependent transmission spectrum with 0° and 90° coresponding to E//b and E//c respectively . The fundamental absorption edge has different values for the incident light field (E) direction being parallel to the c-axis or b-axis of the crystal. At intermediate angles of the polarizer, the optical absorption curve shows two steps, arising from the two band edges along the two orthogonal crystal axes.17

Figure 7. (a) The unpolarized transmission spectrum for β- Ga2O3 grown in different ambient. The black, red, blue and green curve coreponding to the β- Ga2O3 grown in pure oxygen, air, 90% argon 10% oxygen and pure argon ambient. (b) Polarization dependent transmission, (c) Photoluminescence and (d) Raman spectra of for β- Ga2O3 grown in 90% argon 10% oxygen ambient (FZ17014).

Room temperature photoluminescence measurements were carried out using 266 nm UV laser excitation. No band edge luminescence was seen, however, a broad defect luminescence band was observed (Fig. 7c) which can be deconvolved into several peaks (dashed) corresponding to emission from defect complexes emitting at ∼ 353 (UV), 389 (blue/violet), 430 (blue), 457 (blue) nm respectively. Among these peaks, the UV peak does not depend on the impurity concentration and sample history, therefore, it is reported to be arising due to the intrinsic transition corresponding to the recombination of acceptor-bound exciton .18 The blue emissions are reported to be due to the donor-acceptor recombination. The splitting of the blue peaks is assumed to be due to the complex structure of β-Ga2O3 having two crystallographic sites for gallium and 3 crystallographic sites for oxygen.19

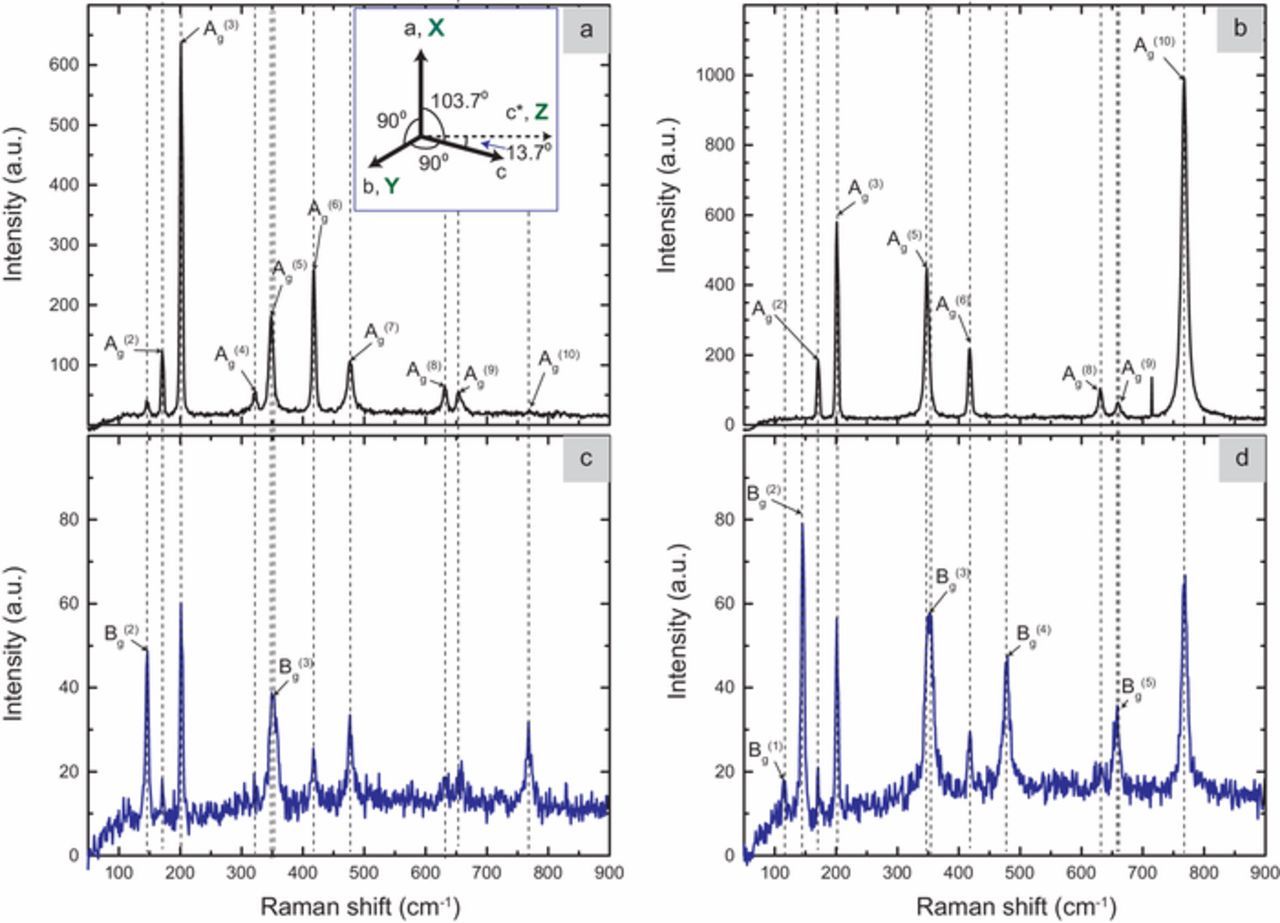

Raman measurements were done at room temperature on the best-grown Ga2O3 sample (FZ17014) using a WITec α-300 monochromator with a 1800 rulings/mm grating and a 532 nm laser source. β-Ga2O3 has a space group symmetry C2/m. The unit cell consists of two types of gallium (GaI, GaII) atoms and three types of oxygen (OI, OII, OIII,) atoms. Hence the primitive unit cell of β-Ga2O3 consists of 10 atoms which results in 3 × 10=30 vibrational modes. Among the 30 vibrational modes, 3 are acoustic and 27 are optical. The irreducible representations for the acoustic and the optical vibrational modes are as follows.20

![Equation ([4])](https://content.cld.iop.org/journals/2162-8777/8/7/Q3144/revision1/d0004.gif)

![Equation ([5])](https://content.cld.iop.org/journals/2162-8777/8/7/Q3144/revision1/d0005.gif)

Among the optical modes the Ag and Bg modes are Raman active and due to odd parity, the modes Au and Bu are infrared active.21 Fig. 7d shows the Raman spectrum of the grown Ga2O3 single crystal with all 10 peaks corresponding to the Ag modes. The peaks corresponding to the Bg modes except for B(2)g are very near to the peaks corresponding to Ag modes. So the Bg modes except the B(2)g are not distinguishable. To identify Ag and Bg modes separately, polarization-dependent Raman measurements were carried out in the back-scattering geometry (Fig. 8). The relative orientation between the crystallographic axes (a, b, c) and the observed X, Y, Z axes is shown in the inset of Fig. 8a. The X-axis is taken along (100) direction and is perpendicular to the cleaved surface. The Y-direction is taken along (010)-direction. The angle between the crystallographic a and c axis is 103.7o resulting in an offset of 13.7o between crystallographic c and Z axis. The excitation of the vibrational modes depends on the polarization selection rules. The Ag modes are allowed in XX, YY, ZZ and ZX configurations, and the Bg modes are allowed in XY, YZ configurations.20 The first letter of the configuration denotes the polarization of the incident light and the second one denotes the polarization of the scattered light. In our Raman measurements, the direction of propagation of the incident and scattered light is along X and -X directions, respectively. Fig. 8 shows the polarization dependent Raman spectra taken in different polarization configurations. Figs. 8a and 8b are the Raman spectra taken in YY and ZZ configurations, respectively. As a result, only Ag modes are activated in this configuration. On the other hand, Figs. 8c and 8d are the spectra taken in YZ and ZY configurations. In this configuration, the intensity of the Bg modes is enhanced while the intensity of the Ag modes is suppressed, thus allowing the Bg modes to be seen clearly.

Figure 8. Polarization dependent Raman spectra taken in different polarization configurations. The spectrum is taken in backscattering geometry with the propagation of incident and scattered light along X and -X direction respectively. The figure shows Raman spectra taken in the (a) YY, (b) ZZ, (c) YZ, (d) ZY configurations, respectively where the first alphabet denotes the polarization direction of the incident light and the second alphabets denotes the direction of scattered light. The inset in (a) shows the orientation of the crystal axes and the axes along which the light is incident or scattered.

Conclusions

The effect of the gas ambient on the growth of β- Ga2O3 was studied. A pure oxygen ambient atmosphere leads to the formation of bubbles inside the melt while a pure argon ambient leads to deposition of gallium oxide powder on the walls of the quartz tube that reduces the power delivered to the melt. Both extreme conditions are not desirable for the growth of high-quality β- Ga2O3. The optimized ambient of flowing 90% argon and 10% oxygen mixture allows high-quality light bluish color long β- Ga2O3 crystal to be grown. The structural and the optical properties of β- Ga2O3 and their dependence on the gas ambient and growth conditions were also studied.

Acknowledgments

The authors thank Prof. Sandip Ghosh for the help and discussion in the optical measurements. The authors are also thankful to Nilesh Kulkarni, Mahesh Gokhale and Vilas Mhatre for discussion and help in XRD measurements, Kushal Darje and TIFR central workshop for making accessories for the growth system, and Amit Shah for the help in electrical measurements.

ORCID

Emroj Hossain 0000-0002-6556-0856

Rajib Mondal 0000-0001-7395-6634

A. Azizur Rahman 0000-0002-9006-474X

Arumugam Thamizhavel 0000-0003-1679-4370

Arnab Bhattacharya 0000-0003-4187-5025