Abstract

Wireless sensor networks have become integral to enabling numerous applications for the Internet of Things, such as environmental sensing or healthcare monitoring. Powering these networks has been the focus of significant research efforts due to the need for reliable and continuous operation of the sensing nodes. In this review, we outline the progress made in the sensing nodes with a particular focus on their power demands. These requirements are used as a framework for surveying the theoretical limits and developments for various power sources, including energy storage, power distribution, and power scavenging techniques. Finally, we conclude by identifying that harvesting techniques are largely insufficient for powering IoT nodes due to limited power densities or inconsistencies as to when power is harvested; accordingly, direct wiring and storage sources such as batteries are the most promising approaches for IoT applications.

Export citation and abstract BibTeX RIS

This is an open access article distributed under the terms of the Creative Commons Attribution 4.0 License (CC BY, http://creativecommons.org/licenses/by/4.0/), which permits unrestricted reuse of the work in any medium, provided the original work is properly cited.

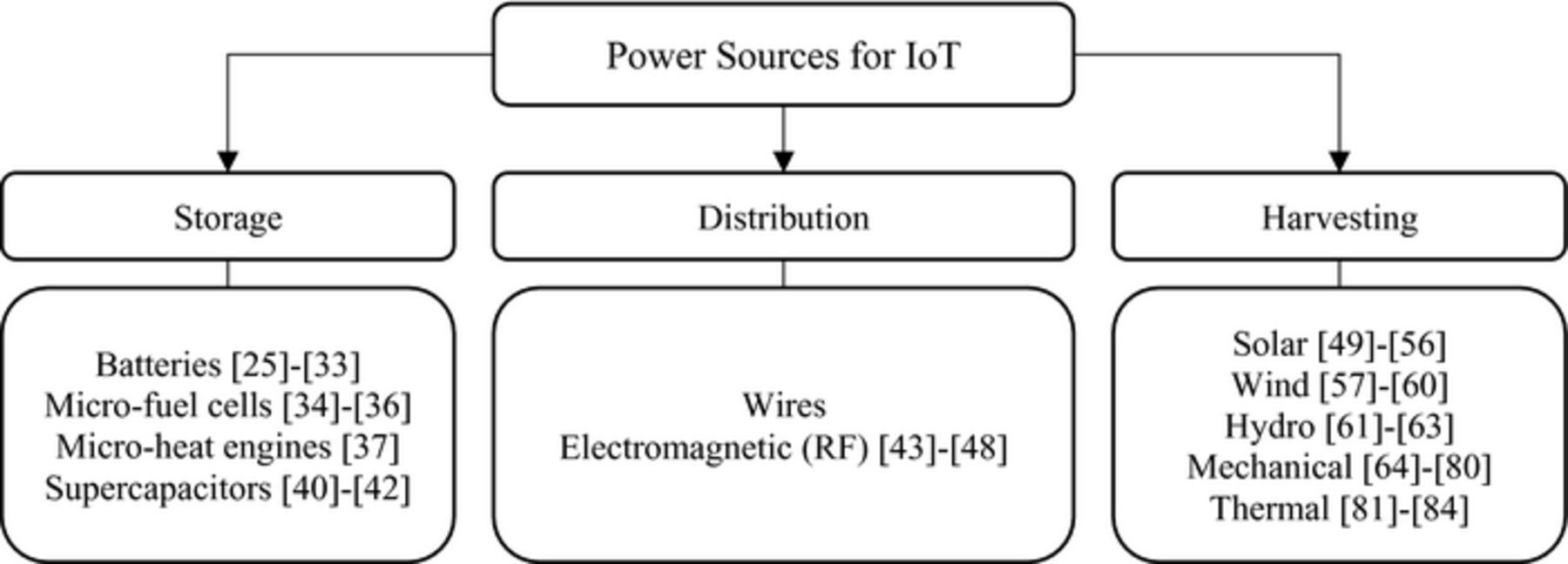

The Internet of Things (IoT) is defined as a network of devices that are used to gather information from and interact with our environment. Nodes in these networks can function as sensors, communication relays, and information processors, and taken together, provide useful information for many applications including environmental sensing, structural health monitoring (SHM), and healthcare.1–3 Stable and reliable power sources are key for enabling these applications, due to the need for continuous operation over the period of several months to years.4 These power sources have been classified into three main categories, as illustrated in Figure 1: 1) energy reservoirs, 2) power distribution, and 3) power scavenging.5 In practice, primary batteries are the most commonly used source of power for wireless sensor networks (WSNs), but significant research efforts have been undertaken with regards to improving the flexibility and coupling of energy storage, distribution and scavenging techniques in the past 14 years, since Roundy's paper on Power Sources for Wireless Sensor Networks.5 This is exemplified by the fact that the number of energy harvesting research papers published per year has increased from less than 40 before 2004 to over 1500 in 2017.6 Nevertheless, these efforts, while heroic, only work to emphasize this challenging point: regardless of improvements in mechanisms, the rate of improvement for device efficiency outpaces progress in energy generation, and primary power is by far the most reliable.

Figure 1. Overview of the various power sources available for IoT networks.

In this review, we discuss developments in WSNs with a focus on power consumption in Power consumption in IoT systems section. Energy storage–Energy harvesting sections will then highlight progress made in the aforementioned categories of energy sources for commercial IoT applications. Based on this progress, as well as theoretical asymptotes for the various power sources, we conclude by proposing specific energy solutions for a given node's power requirements.

Power Consumption in IoT Systems

With the increased availability of inexpensive and low power integrated circuits enabled by system on chip (SoC) designs, we have seen significant increases in the demand for smart sensors.7 In the past seven years alone, there has been a 4x increase in unit sales for commercial smart sensors, while the average sales price for those units has halved.8 Moreover, the advent of open-source single board computers powered by a 5V USB line such as the Raspberry Pi or Arduino has enabled a low barrier for initial system development.9 For commercially available sensors, widely used node platforms such as Crossbow Technology's MICAz and the IMote2 from Intel Research consume an average power of 2.8 and 12 mW, respectively, with the majority of that power used by the radio module, despite improvements in power consumption at the sensor level.10,11 In 2002, state-of-the-art low power radio transceivers had active power consumptions of 100 mW; now, the low power radio standard is typically a ZigBee module that still consumes on the order of tens of milliwatts during operation.10,12 The following paragraphs in this section will outline characteristics of common commercial IoT systems and the typical power consumption for nodes in these networks.

In the smart home space, wireless climate control, gas-/water- leak detectors, security systems and light controls are all common forms of IoT applications. Of these, wireless thermostats that interact with distributed temperature sensors and mobile devices are the most ubiquitous form of IoT with regards to continuously communicating nodes. With regards to just the temperature sensor, 7 μW was considered the epitome for low power temperature sensing in 1996;13 by 2014, a reduction by two orders of magnitude was achieved with a temperature sensor consuming 71 nW.1 Despite this reduction in power consumption for the sensor, commercial systems operate at much higher levels. Common system implementations such as the Nest or ecobee thermostats consume on the order of 1 W at any given time, and are directly powered through a 24 V AC line.14,15 In the case of the ecobee thermostats, remote temperature sensors are powered by a 210 mAh lithium primary CR2032 coin cell and rated to last up to four years.16 This corresponds to an average power consumption of approximately 18 μW to not only monitor temperature, but also relay that information to the thermostat. Higher capacity lithium primary batteries are also commonly used in smoke detectors, which operate continuously for up to ten years.

Wearable health monitoring systems have also gained traction as one of the largest applications for IoT. Motivated by increasing healthcare costs, implementations of these devices range from simple pulse monitors to activity monitors, and even implantable sensors, and these sensing capabilities have improved drastically over time.17 IBM's WatchPad in 2001, for example, had just a single tilt sensor for detecting the user's hand movements and was powered by a lithium polymer battery with 60 mAh capacity at a voltage of 3.7 V.18 At the time of commercialization, larger capacity batteries up to 200 mAh were available with the same areal footprint; cost considerations led to the adoption of the 60 mAh cell. With the processor requiring an average of 27.5 mA during operation, this device only lasted several hours before needing to be recharged. In the time since then, power consumption for data processing has reduced significantly, and sensors have been expanded to now monitor heart rate, sleep quality, and activity levels. Additionally, decreasing battery costs have enabled widespread adoption of ∼200 mAh Li-ion cells in these devices; for common smartwatches capable of monitoring heart rate, sleep and exercise such as the Apple Watch or Samsung Gear Fit2, these batteries correspond to a rated lifetime of 18 hours and 3–4 days and average current draw of 11.4 and 2 mA, respectively.19,20 By eliminating certain device functionality such as continuous monitoring or syncing, devices such as the Xiaomi Mi Band 2 with just a 70 mAh battery can last up to 20 days, while the Fossil Q Hybrid Smartwatch demonstrate lifetimes up to 6 months on a 320 mAh Li primary CR2430 coin cell battery by removing the interactive display.21,22

Taken together, these findings indicate that the minimum instantaneous power levels from a power source can be as low as tens of microwatts, but are typically over a milliwatt to be widely relevant for "high touch" applications. Another key takeaway from both of these application spaces is that IoT networks are typically limited in scope, with less than 10 nodes in a network that can vary widely in power consumption depending on the application. Even one of the largest implementations of a wireless sensor network, SHM of the 2nd Jindo Bridge in South Korea, only utilizes 70 sensor nodes and two base stations.23 This falls short of the vision for IoT systems interfacing hundreds to thousands of devices in a single network;12,24 however, these limited scales provide an advantage in that device or energy source replacement becomes a more feasible endeavor. As a final point, power sources should be of a similar size and cost when compared with the sensing node. These considerations will be used as a framework for surveying each of the power sources in the following sections.

Energy Storage

Storage in the form of batteries has traditionally been the dominant source for power in wireless IoT systems. In this section, we outline the progress made since 2004 in batteries, as well as in other energy storage devices such as micro-fuel cells, micro-heat engines, and capacitors.

Batteries

The primary barrier for the miniaturization of batteries is the dependence of performance on the quantity of material in a given system. In the case of microelectronics, smaller devices directly lead to improvements in performance and cost due to a reduction in defects and power requirements, as well as an increase in yield of devices for the same wafer size. This is not the case for batteries in that a reduction in size translates into less material available for electrochemical reactions. Despite this limitation, the energy density for rechargeable Li-ion cells, the highest energy density cells available commercially, has increased from ∼55 Wh/L in 2008 to ∼295 Wh/L in 2015 due to improvements in separators, electrolyte additives, and cathode chemistries.25,26 At the same time, the price for these lithium-ion batteries has significantly dropped. In just seven years, Li-ion batteries with regards to cell pricing has decreased from over $1000/kWh in 2010 to $145/kWh in 2016.27,28 These batteries are commonly packaged as 18650 cylindrical cells which are rated for up to 3.4 Ah at a 2C rate, or approximately 7 A, corresponding to energy and peak power densities of approximately 180 mWh/cm3 and 350 mW/cm3, respectively.26,29 In practice for IoT applications, as batteries are energy reservoirs, it is also important to consider the lifetime for a node's operation without battery replacement or recharging. Such a battery is capable of powering an IoT node consuming an average of 10 mA for roughly two weeks before needing to be recharged. At the research level, many efforts are being undertaken to develop flexible secondary batteries for wearable applications.30–32 These devices suffer from severely limited capacities when compared to their commercially available counterparts, before even considering packaging and long term stability issues. Consequently, rigid form factors such as Li-ion cells with established manufacturing processes (as are already used in smartphones) drastically reduce storage overhead and costs for a wearable application.

Primary batteries offer an attractive, lower cost solution when compared with rechargeable Li-ion systems. Costing less than 50 cents per battery on the order of ∼2 Wh, lithium primary coin cells are used in a number of wireless sensor nodes, as described in Power consumption in IoT systems section; ranging in capacity from 90 to 650 mAh at a nominal 3V, these cells are capable of running the aforementioned node for up to two days.33 For this level of current, prolonged operation can be achieved with alkaline zinc-manganese dioxide batteries which offer even higher capacities for a primary cell. AAA, AA and D sized alkaline cells are all commercially available for less than a dollar per battery, and are rated for 1600 mAh, 2900 and 29000 mAh, respectively, at a nominal 1.5V; with these capacities, the stated sensing node can be operated for up to four months before replacement is necessary.33 Moreover, for niche IoT applications, alkaline batteries are capable of providing instantaneous power above 1 W (approximately 100 mW/cm3 in the case of AA cells). It is important to note that the aforementioned timescales assume continuous current draw; in the case power consumption is reduced or intermittent, these batteries enable node operation for proportionally longer periods of time. Moreover, these batteries can be deployed anywhere, with no demand for specific external conditions.

Micro-fuel cells, micro-heat engines, and capacitors

Alternative forms of energy storage have seen limited deployment in IoT networks. Fuel cells also utilize electrochemical energy conversion to generate electricity, but differ from batteries due to the fact that electrodes do not undergo electrochemical changes and the overall system consumes reactants which must be replenished. In 2004, Roundy found that fuel cells must reach efficiencies over 20% to be competitive with primary batteries and that demonstrated efficiencies at that point in time were generally below 1%. At this time, reported micro-fuel cells based on hydrogen or methanol generated on the order of tens of mW/cm2, not inclusive of overhead for fuel storage.34 Since then, high costs, low efficiencies and difficulties in fuel storage and delivery have continued to limit the deployment of micro-fuel cells for IoT applications. Typical devices exhibit the same order of magnitude in output power as devices from 2004, and expectations for commercialization have not been realized.35 One example higher than this range achieves up to 145 mW/cm2, again, not inclusive of overhead for fuel storage, and relies on the additional pumped flow of both acid and alkali solutions to achieve its higher cell potential; moreover, this device was only operated for six cycles, and long term performance has yet to be demonstrated.36

Numerous attempts have also been made toward the realization of a micro-heat engine utilizing energy dense hydrocarbon fuels, as envisioned by Epstein in the 1990s.37 In 2004, Roundy noted that most these efforts were at initial stages of development with no demonstrable performance; 14 years later, little has changed and size sealing to IoT node dimensions, friction, efficiency and thermal management continue to be substantial barriers toward the utilization of micro-heat engines for IoT applications.5,38

Conventional electrolytic capacitors offer high currents and specific powers, but are limited by poor specific energy and self-discharge over the course of days. Supercapacitors seek to remedy this limitation through the use of an electrolyte solution between electrodes instead of a solid dielectric, but still suffer from self-discharge and fall well below the energy densities provided by Li-ion batteries.39–41 While the majority of work in this area has focused on electrode engineering, one example of a realized micro-supercapacitor demonstrates energy and power densities of 7.4 mWh/cm3 and 128 W/cm3, respectively.42 While high power density seems initially attractive, these levels of power consumption are uncommon for IoT nodes and energy density becomes the more critical parameter, thereby limiting the implementation of capacitors for many IoT applications; commercially available supercapacitors are indeed used for high power application spaces such as regenerative braking systems or start/stop systems.

Energy Distribution

Wireless communication between devices is an integral component of IoT systems. That said, wireless power sources are not necessarily required for a large number of IoT applications. This section outlines the key distribution techniques employed in IoT systems.

Wires

For many system designs, the need for an energy source is removed by directly connecting the device to grid electricity, as in the case of smart thermostats described in Power consumption in IoT systems section. For SHM applications in buildings in which access to power lines is trivial, 5 or 3.3 V adapters enable USB-powered sensor networks to operate in perpetuity. When fully wireless applications are necessary, as with the case of wearable health monitors, wires alone are obviously not a feasible solution; however, they still play a crucial role in supplying storage sources with grid electricity.

Electromagnetic (RF)

Roundy et al. introduced radio frequency (RF) radiation as the most common method of distributing power to wireless nodes.5 In practice, implementations of RF energy harvesting suffer from attenuation at increasing distances, and energy conversion losses. In the 14 years since Roundy's review, considerable research efforts have been exerted to minimize these losses and achieve node operation from both dedicated and ambient RF sources.43 With dedicated sources, transmitters offer the advantage of predictability and optimization with regards to proximity to the sensing node; however, their deployment is costly (a single transmitter can cost ∼$200), requires grid-based input power (120V AC, potentially from a local source), and the output power is limited by regulations due to health and safety concerns.44,45 With ambient RF harvesting, deployment costs are reduced as systems seek to take advantage of RF energy present in the environment such as TV broadcasts, cellular systems and mobile devices. Despite cost advantages, ambient RF energy harvesting is not practical due to the fact that ambient sources provide less than 1 μW/cm2.46 In practice, for dedicated sources, up to 189 μW of power have been harvested with higher levels in that range corresponding to higher transmitted power as well as reduced distance between the transmitter and harvester.43,47 Higher values for harvested power outside of this range have also been achieved, but rely on oversized system designs or close proximity to a dedicated high power source.43,48 For the former solution, spatial overhead may be better used for an alternative power source and for the latter, cost savings can be immediately realized by replacing the dedicated transmitters with the sensing nodes, such that the need for harvesting is removed altogether. While there is significant interest in long range wireless transfer, the range-power dynamic, even for coupled resonance systems, continues to limit practical adoption (e.g., for a node in place, why use a complex wireless transfer scheme for 1 ft of distance?).

Energy Harvesting

Many techniques for energy harvesting have been developed as a means for long term operation of IoT nodes. This section highlights the progress made since 2004 in solar cells, flow systems, and mechanically- and thermally-based scavenging techniques.

Solar

Energy harvesting based on photovoltaic conversion has been well researched due to the abundance of energy for solar radiation. Solar irradiance provides a power source of 100 mW/cm2 and for optimal outdoor conditions, single crystal silicon cells have improved from the 15–20% conversion efficiencies reported in 2004, to a record of 26.7% in 2017.5,49 This corresponds to a power density of 26.7 mW/cm2; the Shockley-Queisser limit for a single junction silicon solar cell of approximately 32 mW/cm2 is not significantly higher, in consideration of IoT nodes.50 That said, actual global irradiances average between 10 and 30 mW/cm2 due to seasonal and daily variations in the sun's position, and can drop even further due to suboptimal conditions such as cloud cover.51 Moreover, indoor lighting conditions provide a far lower power density than outdoor conditions, and also provide a suboptimal spectrum for photovoltaic conversion using conventional silicon photovoltaics. Specifically, indoor irradiance ranges between 0.1–1 mW/cm2 and conversion efficiency for crystalline silicon drops due to a narrowing in the incident light spectrum, thereby yielding cell output on the order of 10 μW/cm2 to power wireless nodes.52 Alternative photovoltaics such as amorphous silicon or dye-sensitized solar cells take advantage of higher absorption in the visible wavelength range, providing power densities ranging from 37.9 to 92.6 μW/cm2 for bright indoor conditions; the higher densities in this range correspond to III-V semiconductor materials that are expensive to produce using conventional epitaxial growth processes, thereby precluding them from many low-cost IoT applications.53 Similar to the case for batteries, many researchers have worked toward developing low-cost flexible solar cells for wearable applications; as with batteries, these devices pale in comparison to their rigid counterparts; for example, while standard perovskite-based solar cells have reached conversion efficiencies as high as 15%, their fabrication on flexible substrates yields devices with only 7% power conversion efficiencies.54

Examples of solar-based energy harvesting have been implemented in several forms, primarily for use in outdoor conditions, to provide outputs ranging between 8 and 12 mW/cm2 during operation, which begins approaching useful power levels for IoT applications.55,56 An important consideration for both the outdoor and indoor cases is that the peak instantaneous power harvested is not guaranteed at all times, and conditions such as cloud cover, nighttime or indoor lights turning off can create conditions under which the power demanded by a wireless node is not met. For these circumstances, some form of energy storage is required to continue node operation.

Flow systems (wind and hydro)

Many systems have been designed to harness power from rotational movements caused by the flow of air or water. Typically, these modes of energy harvesting are utilized at large scales through structures such as wind turbines or hydroelectric dams. Similar to the case of solar cells, a major drawback with utilizing these systems for wireless sensor nodes is that power generation is inconsistent, in this case being directly coupled with flow velocity; when wind or water flow is zero, energy harvesting is not possible and some alternative power source is necessary for continued operation.

In the case of wind-sourced power, Roundy et al. plotted the theoretical asymptote for specific power as a function of this flow rate.5 From this figure, we note that air flow must be approximately 1 m/s or greater at average conversion efficiencies for large scale windmills before the power generated reaches 10 μW/cm2. Already, this level of air flow is much greater than the typical flow rates of 0.1 m/s found in indoor environments. Even for applications in which air flow is reliable, energy harvesters for wind energy suffer from lower conversion efficiencies at small scales and are often much larger than the sensing nodes they are powering. One example of this is the AmbiMax system that measured 200 mm in length with a blade radius of 155 mm to power a node including a secondary battery that measured only 13 × 10 × 8 mm.57 Other implementations of wind harvesting systems have also been demonstrated, but all generate less than 10 mW for system designs ranging between 20 and 300 cm3.58–60

Hydro-based energy harvesting techniques rely on moving or falling water in order to capture energy. While this technique is conventionally applied to large scale systems like hydroelectric dams, it may also be relevant for a limited number of IoT applications. Limited research has been done in this area; in 2002, small-scale hydro was considered to be comprised of river diversions to turbines generating 10–500 kW of power.61 Since then, smaller system designs have been implemented but are typically still focused on urban applications for grid level storage.62 One example specifically aimed at powering a wireless sensor network is an energy harvester that makes use of water flow in a domestic pipeline to generate between 2 and 720 mW for flow rates between 3 and 20 l/min to power a smart metering system.63 Again, the main limitation with these systems is that the energy harvested during intermittent water flow may not match that demanded by the IoT node, especially when continuous operation of the node is desired.

Mechanical

Roundy identifies environmental vibrations, examples including HVAC ducts, automobiles and small household appliances, as promising sources for mechanically-based scavenging techniques.5 In this work, theoretical asymptotes for power densities are plotted as a function of vibration amplitude and frequency. Under optimal conditions of 75 Hz and 10 m/s2 (higher power densities are associated with lower frequencies and higher acceleration), up to 10 mW/cm3 can be obtained from vibrations, without considering conversion losses from mechanical kinetic energy to electrical energy.64 For this actual conversion, it is found that piezoelectric generators offer higher potential power densities, are more architecturally simplistic, and also more scalable than alternative conversion techniques such as electromagnetic or electrostatic methods.65 In 2003, 375 μW/cm3 was generated from an input of 2.25 m/s2 at 60 Hz by such a piezoelectric power converter; as of 2014, devices achieve the same order of magnitude or less in power output for similar vibrational frequencies and amplitudes as the comparison case.66–69

Triboelectric nanogenerators present an alternative architecture for mechanical to electrical energy conversion; since their introduction in 2012, they have been applied to a wide array of applications including natural vibrations, motion caused by air or water flow, and bodily motions.70 That said, reported power densities of up to 50 mW/cm2 are misleading in that power from these systems is not continuously available, and highly dependent on coupling to the input mechanical motion as well as duty cycle for operation. The aforementioned 50 mW/cm2 corresponds to peak power converted from actuation of a controlled linear motor.71 Moreover, long term operation of IoT nodes requires reliable power sources and while 10 million cycles appear to be an attractive validation of stability, this corresponds to only ∼5 hours of operation.72

Commercial implementations of vibrational energy harvesters made available in the past 17 years generate power densities of approximately 20 μW/cm3 and cost hundreds of dollars for a single device, with cost savings achieved when purchased in bulk.73,74 One of the key challenges with these devices is ensuring optimal vibration levels during deployment to achieve resonance matching between the source and harvester; additionally, the need for a continuously vibrating source must also be taken into consideration for uninterrupted IoT node operation.

For mobile applications, many research efforts have focused on utilizing human energy as a source for mechanical energy harvesting. Generally, the most energy rich source of power in the human body derives from active movements. Walking is a particularly attractive source for harvesting due to the multiple forms of excitations produced by the foot. Early shoe inserts based on a piezoelectric strip demonstrated an average power generation of 336 μW/cm2.75 Since then, a variety of devices have been created to harness power from different parts of the body such as the knee, torso and arms. These device developments are well reviewed in literature, with the best performing devices having achieved peak power densities up to 8.5 mW/cm3.76–78 That said, limitations with this form of harvesting derive from the obtrusiveness and durability of the harvester and requisite power electronics, issues regarding the relay of power to the target IoT application, and the fact that no power is generated when the wearer is idle. To overcome the last limitation, scientists have proposed harvesting human energy from passive physiological sources, such as movement of the heart or lungs to power biomedical devices. Here, researchers have demonstrated harvesting from a bovine heart with a power density up to 1.2 μW/cm2, and from a sheep heart with a power output of 16.7 μW (estimated power density of 0.85 μW/cm2 based on the size of the modified wristwatch); while these levels are sufficient for powering local biomedical devices like pacemakers, they still face issues of durability while falling short of power levels required for IoT applications.79,80

Thermal

The use of temperature gradients to generate power has been well studied in literature, particularly in the case of harnessing body heat to generate electricity. The maximum efficiency of power conversion from such a gradient can be found by the Carnot efficiency; for a source 5 and 10°C above room temperature conditions of 20°C, this yields 1.7 and 3.4%, respectively. This upper limit has yet to be realized, despite numerous research efforts in thermal energy harvesting systems. Thermoelectric devices that make use of the Seebeck effect suffer from limited heat exchange, thereby resulting in a decrease of the actual temperature gradient.81 One of the earliest demonstrations of a thermoelectric generator, in 1998, was capable of generating 20 μW/cm2 from a 20°C gradient and up to 140 μW/cm2 from a 60°C gradient.82 In the time since then, the power generated from practical implementations has remained on the same order of magnitude, ranging between 14 and 60 μW/cm2 for a temperature gradient of 5°C.10 One thermoelectric generator attached to a radiator has indeed demonstrated power harvesting up to 1.8 mW/cm2 for a gradient of 34°C; however, it is important to note that the output voltage of this generator was insufficient for powering practical sensing nodes, and the consequential need for a DC-DC converter results in efficiency losses ranging between 51 and 71%.83 Moreover, radiators are often not continuously operational over the course of a year or even a single day, and an alternative power source would be required while the radiator is inactive. Pyroelectric cells have been reported to promise a higher efficiency alternative to thermoelectric generators, but these devices are limited due to the need for cyclical temperature variations to effect continuous changes in the crystal structure of a material, and materials with high heat exchange coefficients.81 In practice, these devices have achieved average output powers less than 10 μW/cm3, suffer from long term degradation, and require significant temperature variations, on the order of 8.5°C/s.81,84

Overview of Progress in IoT Nodes and Power Sources

Sensors and commercial IoT nodes have experienced rapid progress during the last two decades with regards to device efficiency, as was outlined in Power consumption in IoT systems section. Accordingly, Table I displays power consumption for several currently available IoT nodes and systems. To power these systems, harvesting sources with the exception of solar cells were not commercially available at the time of Roundy's review in 2004.5 In the 14 years since then, little has changed in this market and primary batteries still serve as the workhorse for powering wireless nodes. Here, in Table II, we update the summary data from Roundy's work to include the peak powers reported as of 2017 for each of the various techniques.

Table I. Overview of power demands in commercial IoT networks.

| IMote210 | MICAz10 | Ecobee (remote sensor) | Apple Watch19 | Samsung Gear Fit220 | |

|---|---|---|---|---|---|

| Average | 12 mW | 2.8 mW | 18 μW | 42 mW | 7.7 mW |

| Peak | 170 mW | 53 mW | * | * | * |

| Communication | 141 mW | 47–53 mW | * | * | * |

| Processing | 99–170 mW | 22 mW | * | * | * |

Table II. Comparison of power sources for IoT applications. Values shown are demonstrated quantities.

| Power Source | P/cm3 (mW/cm3) | E/cm3 (mWh/cm3) | P/cm3/yr (mW/cm3) | Secondary Storage Needed | Commercially available | Comments |

|---|---|---|---|---|---|---|

| Primary battery (Li coin cell) | 110* | 670 | 0.076 | No | Yes | Inexpensive, no need for voltage regulation33 |

| Primary battery (alkaline AA cell) | 200* | 565 | 0.064 | No | Yes | Inexpensive, no need for voltage regulation33 |

| Secondary battery (Li-ion 18650) | 2170* | 760 | 0.087 | - | Yes | Highest energy density storage option, considering device lifetime[29] |

| Micro-fuel cell | 145** | - | - | Maybe | No | Low efficiencies and fuel storage/delivery challenges36 |

| Micro-heat engine | - | - | - | Yes | No | Scaling, efficiency and thermal management challenges38 |

| Supercapacitor | 128 | 7.4 | - | Maybe | Yes | Limited energy density, self-discharge42 |

| Dedicated RF | 0.440 | - | - | Maybe | Yes | Expensive, limited by range, requires AC input for RF source43 |

| Solar (outdoors) | 26.7** | - | - | Yes | Yes | Solar intermittency49 |

| Solar (indoors) | 0.0926** | - | - | Yes | Yes | Expensive53 |

| Air flow | 0.03 | - | - | Yes | No | Unpredictable, unavailable for many IoT applications59 |

| Water flow | 1*** | - | - | Yes | No | Unpredictable, unavailable for many IoT applications63 |

| Temperature | 1.8** | - | - | Yes | No | Conversion inefficiencies, voltage regulation required83 |

| Mechanical (piezoelectric) | 0.375 | - | - | Yes | Yes | Unpredictable, long term stability issues66 |

| Mechanical (triboelectric) | 50** | - | - | Yes | No | Unpredictable, long term stability issues70 |

| Mechanical (active human motion) | 8.5 | - | - | Yes | Yes | Unpredictable, obtrusive, long term stability issues76 |

| Mechanical (physiological motion) | 0.0012** | - | - | Yes | No | Predictable, insufficient power for IoT80 |

*Denotes the maximum amount of power obtainable from the given storage device. **Denotes power characterized by unit area (cm2) rather than unit volume (cm3). ***Based on an estimated volume from dimensions reported.

Conclusions

Given that modern IoT nodes have a wide range of power requirements, power sources should be identified based on a specific application. For devices that instantaneously require hundreds of milliwatts, harvesting is insufficient and direct wiring or batteries are the only viable solutions. For consumption of tens of milliwatts or less, power from solar cells or some mechanically-based techniques can be sufficient, but inconsistencies regarding when power is harvested must be balanced by energy storage. Accordingly, we posit that overhead used for harvesting is better utilized for expanding battery size, and future research should focus on the development of higher energy density batteries enabled by lithium metal anodes and solid state electrolytes. As devices continue to lower their power demands, these batteries enable operation for proportionally longer periods of time and energy scavenging can be utilized most efficaciously as a means of limiting depth of discharge, thereby extending battery lifetime.

The second key insight highlighted in this work is that reductions in the power consumption and cost of WSNs have outpaced improvements in energy harvesting. As devices become cheaper to fabricate with smaller fabrication nodes and increased production scales, there should be a corresponding paradigm shift such that devices replacement becomes desirable over energy source replacement. An instructive example of this is seen through the smartphone market: Li-ion batteries in cell phones are optimized for 500 cycles due to the fact that devices are often replaced on a biennial basis in many countries.85 Even after 500 cycles, the battery can still be utilized, but with some fraction, ∼80%, of its initial capacity. In the case of laptops, Apple rates their batteries for 1000 cycles until the 80% residual capacity point is reached.86 At the same time, advances in processing capabilities offer improvements that may make entire system replacement desirable. A similar treatment could be applied to wireless sensors deployed today, with a different timescale for device replacement depending on the application and its power requirements. Generally, IoT networks are limited in scale with regards to the number of nodes operated wirelessly, and updating those nodes regularly can offer attractive benefits.

We leave the reader with this final thought: the parable of the "Yak Shave" applied to energy harvesting and scavenging for IoT devices.87 As a field, we set out to replace primary batteries by harvesting the apparently abundant energy available in close proximity to the device. But we had to miniaturize existing harvesting technology to do so. And to miniaturize existing technology, we had to apply new materials. And in applying new materials, we had to invent new processes. And in inventing new processes, we had to invent new methods to characterize the processes. And as the parable ends, we find ourselves at midnight in our bathroom shaving a yak rather than sleeping in a world of deployed IoT devices with environmentally agnostic primary batteries.

Acknowledgments

This material is based upon work supported by the National Science Foundation Graduate Research Fellowship under grant No. DGE-1656466. The authors thank Jeung Hun Park for useful discussions.

ORCID

Dan Steingart 0000-0002-8184-9641