Abstract

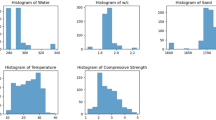

Estimation of compressive strength of rubberized concrete is important for engineering safety. In this study, measured data (the compressive strength of rubberized concrete and its impacting factors) were collected by literature review (457 samples). In order to accurately predict the compressive strength of rubberized concrete, four machine learning models [artificial neural network (ANN), k-nearest neighbor (KNN), regression trees (RT), and random forests (RF)] were developed and compared to estimate the compressive strength of rubberized concrete, and the modeling results were compared with two traditional expressions. The model performance was evaluated using three performance indicators: the Nash–Sutcliffe efficiency coefficient (NSC), the root-mean-squared error (RMSE), and the mean absolute error (MAE). The results showed that the RT model performs the best, followed by the ANN and RF in the model training phase. In the model testing phase, the ANN model performs the best, followed by the RT, RF, and KNN. The overall results indicated that the ANN model performs the best, followed by RT and RF, and the KNN model performs the worst. The ANN and RT models outperformed the two traditional expressions. The tree-based models (RT and RF) and KNN model may not be applicative to estimate the compressive strength of rubberized concrete due to the generally poor performances in the model testing phase compared with that in the model training phase. The results showed that the traditional ANN model is sufficient for the accurate estimation of the compressive strength of rubberized concrete when the model is properly trained. The results in the present research can provide reference for the prediction of the compressive strength of rubberized concrete, which will benefit engineering management and safety as well.

Similar content being viewed by others

References

S. Ismail, K.W. Hoe, M. Ramli, Procedia Soc. Behav. Sci. (2013). https://doi.org/10.1016/j.sbspro.2013.07.183

M. Sienkiewicz, H. Janik, K. Borzędowska-Labuda, J. Kucińska-Lipka, J. Clean. Prod. (2017). https://doi.org/10.1016/j.jclepro.2017.01.121

I. Šandrk Nukić, I. Miličević, Interdiscip. Descr. Complex Syst. (2019). https://doi.org/10.7906/indecs.17.2.9

S.T. Yildirim, N.P. Duygun, Mechanical and physical performance of concrete including waste electrical cable rubber, in IOP Conference Series: Materials Science and Engineering. https://iopscience.iop.org/article/10.1088/1757-899X/245/2/022054/meta. Accessed 10 June 2020

B.S. Thomas, R.C. Gupta, Renew. Sustain. Energy Rev. (2016). https://doi.org/10.1016/j.rser.2015.10.092

A.L. Puşcǎ, S. Bobancu, A. Dutǎ, Mechanical properties of rubber: an overview. Bull. Transilv. Univ. Brasov. Eng. Sci. Ser. I 3, 107 (2010)

P.T. Williams, Pyrolysis of waste tyres: a review (2013). https://doi.org/10.1016/j.wasman.2013.05.003

D.L. Presti, Recycled tyre rubber modified bitumens for road asphalt mixtures: a literature review. Constr. Build. Mater. 49, 863–881 (2013). https://doi.org/10.1016/j.conbuildmat.2013.09.007

X. Shu, B. Huang, Recycling of waste tire rubber in asphalt and Portland cement concrete: an overview. Constr. Build. Mater. (2014). https://doi.org/10.1016/j.conbuildmat.2013.11.027

R. Siddique, T.R. Naik, Properties of concrete containing scrap-tire rubber: an overview. Waste Manage. (2004). https://doi.org/10.1016/j.wasman.2004.01.006

K.B. Najim, M.R. Hall, A review of the fresh/hardened properties and applications for plain-(PRC) and self-compacting rubberized concrete (SCRC). Constr. Build. Mater. (2010). https://doi.org/10.1016/j.conbuildmat.2010.04.056

A.M. Rashad, A comprehensive overview about recycling rubber as fine aggregate replacement in traditional cementitious materials. Int. J. Sustain. Built Environ. (2016). https://doi.org/10.1016/j.ijsbe.2015.11.003

R. Roychand, R. Gravina, Y. Yan Zhuge, X. Ma, O. Youssf, J.E. Mills, A comprehensive review on the mechanical properties of waste tire rubber concrete. Constr. Build. Mater. (2020). https://doi.org/10.1016/j.conbuildmat.2019.117651

M.M. Al-Tayeb, B.A. Bakar, H.M. Akil, H. Ismail, Exp. Mech. (2013). https://doi.org/10.1007/s11340-012-9651-z

W. Wu, G.C. Dandy, H.R. Maier, Environ. Model Softw. (2014). https://doi.org/10.1016/j.envsoft.2013.12.016

R. Bušić, I. Miličević, T.K. Šipoš, K. Strukar, Recycled rubber as an aggregate replacement in self-compacting concrete—literature overview. Materials (2018). https://doi.org/10.3390/ma11091729

N.N. Hilal, Hardened properties of self-compacting concrete with different crumb rubber size and content. Int. J. Sustain. Built Environ. (2017). https://doi.org/10.1016/j.ijsbe.2017.03.001

Z.K. Khatib, F.M. Bayomy, J. Mater. Civ. Eng. (1999). https://doi.org/10.1061/(ASCE)0899-1561(1999)11:3(206)

A.M. Ghaly, J.D. Cahill IV, Can. J. Civ. Eng. (2005). https://doi.org/10.1139/l05-063

M.F.M. Zain, S.M. Abd, K. Sopian, M. Jamil, A.I. Che-Ani, Mathematical regression model for the prediction of concrete strength, in Proceedings of the Tenth WSEAS International Conference on Mathematical Methods, Computational Techniques and Intelligent Systems. https://dl.acm.org/doi/10.5555/1562334.1562406. Accessed 15 May 2020

O. Youssf, M.A. ElGawady, J.E. Mills, X. Ma, An experimental investigation of crumb rubber concrete confined by fibre reinforced polymer tubes. Constr. Build. Mater. (2014). https://doi.org/10.1016/j.conbuildmat.2013.12.007

M. Hadzima-Nyarko, I. Miličević, Equations for prediction of rubberized concrete compressive strength: a literature review, in New Materials in Civil Engineering, 1st Edn, eds. Pijush Samui, P., Dookie Kim, D., Iyer, N., Chaudhary, S. (Butterworth-Heinemann, 2020). https://www.elsevier.com/books/new-materials-in-civil-engineering/samui/978-0-12-818961-0. Accessed 24 July 2020

J.S. Chou, C.K. Chiu, M. Farfoura, I. Al-Taharwa, J. Comput. Civ. Eng. (2011). https://doi.org/10.1061/(ASCE)CP.1943-5487.0000088

J.S. Chou, C.F. Tsai, A.D. Pham, Y.H. Lu, Constr. Build. Mater. (2014). https://doi.org/10.1016/j.conbuildmat.2014.09.054

M. Nikoo, F. Torabian Moghadam, Ł. Sadowski, Adv. Mater. Sci. Eng. (2015). https://doi.org/10.1155/2015/849126

A.M.N. El-Khoja, A.F. Ashour, J. Abdalhmid, X. Dai, A. Khan, Int. J. Struct. Constr. Eng. (2018). https://doi.org/10.5281/zenodo.2021549

M. Hadzima-Nyarko, E.K. Nyarko, N. Ademović, I. Miličević, T. Kalman Šipoš, Materials (2019). https://doi.org/10.3390/ma12040561

Ł. Sadowski, M. Piechówka-Mielnik, T. Widziszowski, A. Gardynik, S. Mackiewicz, J. Clean. Prod. (2019). https://doi.org/10.1016/j.jclepro.2018.12.059

H. Naderpour, M. Mirrashid, J. Clean. Prod. (2020). https://doi.org/10.1016/j.jclepro.2020.121886

B. Ahmadi-Nedushan, Eng. Appl. Artif. Intell. (2012). https://doi.org/10.1016/j.engappai.2012.01.012

P. Chopra, R.K. Sharma, M. Kumar, T. Chopra, Adv. Civ. Eng. (2018). https://doi.org/10.1155/2018/5481705

N.N. Eldin, A.B. Senouci, Rubber-tire particles as concrete aggregate. J. Mater. Civ. Eng. (1993). https://doi.org/10.1061/(ASCE)0899-1561(1993)5:4(478)

L. Lavagna, R. Nisticò, M. Sarasso, M. Pavese, An analytical mini-review on the compression strength of rubberized concrete as a function of the amount of recycled tires crumb rubber. Materials (2020). https://doi.org/10.3390/ma13051234

E. Guneyisi, M. Gesoglu, T. Ozturan, Properties of rubberized concretes containing silica fume. Cem. Concr. Res. (2004). https://doi.org/10.1016/j.cemconres.2004.04.005

M. Gesoğlu, E. Güneyisi, Strength development and chloride penetration in rubberized concretes with and without silica fume. Mater. Struct. (2007). https://doi.org/10.1617/s11527-007-9279-0

N.J. Azmi, B.S. Mohammed, H.M.A. Al-Mattarneh, Engineering properties of concrete containing recycled tire rubber, International Conference on Construction and Building Technology, ICCBT 2008, 16–20 June 2008, Kuala Lumpur, Malasia (2008), pp. 373–382

A. Grinys, H. Sivilevičius, M. Daukšys, Tyre rubber additive effect on concrete mixture strength. J. Civ. Eng. Manag. (2012). https://doi.org/10.3846/13923730.2012.693536

O. Onuaguluchi, D.K. Panesar, Hardened properties of concrete mixtures containing pre-coated crumb rubber and silica fume. J. Clean. Prod. (2014). https://doi.org/10.1016/j.jclepro.2014.06.068

Z. Grdić, G. Topličić-Ćurčić, N. Ristić, D. Grdić, P. Mitković, Hydro-abrasive resistance and mechanical properties of rubberized concrete. Građevinar (2014). https://doi.org/10.14256/JCE.910.2013

H. Liu, X. Wang, Y. Jiao, T. Sha, Experimental investigation of the mechanical and durability properties of crumb rubber concrete. Materials (2016). https://doi.org/10.3390/ma9030172

R.B. Murugan, E.R. Sai, C. Natarajan, S. Chen, Flexural fatigue performance and mechanical properties of rubberized concrete. Građevinar (2017). https://doi.org/10.14256/JCE.1427.2015

H.H. Toutanji, The use of rubber tire particles in concrete to replace mineral aggregates. Cem. Concr. Compos. (1996). https://doi.org/10.1016/0958-9465(95)00010-0

M.M. Taha, A.S. El-Dieb, M.A. AbdEl-Wahab, M.E. Abdel-Hameed, Mechanical, fracture, and microstructural investigations of rubber concrete. J. Mater. Civ. Eng. 20(10), 640–649 (2008). https://doi.org/10.1061/(ASCE)0899-1561(2008)20:10(640)

El-Sherbini, Y.; Abdel-Gawad, A.K.; Shalaby, A.; El-Gammal, A, Compressive strength of concrete utilizing waste tire rubber. J. Emerg. Trends Eng. Appl. Sci. 1(1), 96–99 (2010)

M.K. Batayneh, I. Marie, I. Asi, Promoting the use of crumb rubber concrete in developing countries. Waste Manag (2008). https://doi.org/10.1016/j.wasman.2007.09.035

M.A. Aiello, F. Leuzzi, Waste tyre rubberized concrete: properties at fresh and hardened state. Waste Manag (2010). https://doi.org/10.1016/j.wasman.2010.02.005

A. Fiore, G.C. Marano, C. Marti, M. Molfetta, On the fresh/hardened properties of cement composites incorporating rubber particles from recycled tires. Adv. Civ. Eng. (2014). https://doi.org/10.1155/2014/876158

A.M. Almaleeh, S.M. Shitote, T. Nyomboi, Use of waste rubber tires as aggregate in concrete. J. Civ. Eng. Constr. Technol. (2017). https://doi.org/10.5897/JCECT2016.0421

C. Albano, N. Camacho, J. Reyes, J.L. Feliu, M. Hernández, Influence of scrap rubber addition to Portland I concrete composites: destructive and non-destructive testing. Compos. Struct. (2005). https://doi.org/10.1016/j.compstruct.2005.09.037

H.A. Toutanji, Cem. Concr. Compos. (1996). https://doi.org/10.1016/0958-9465(95)00010-0

E. Güneyisi, M. Gesoğlu, T. Özturan, Cem. Concr. Res. (2004). https://doi.org/10.1016/j.cemconres.2004.04.005

T. Rajaee, S.A. Mirbagheri, M. Zounemat-Kermani, V. Nourani, Sci. Total Environ. (2009). https://doi.org/10.1016/j.scitotenv.2009.05.016

S. Zhu, S. Heddam, E.K. Nyarko, M. Hadzima-Nyarko, S. Piccolroaz, S. Wu, Environ. Sci. Pollut. Res. (2019). https://doi.org/10.1007/s11356-018-3650-2

S. Zhu, B. Hrnjica, M. Ptak, A. Choiński, B. Sivakumar, J. Hydrol. (2020). https://doi.org/10.1016/j.jhydrol.2020.124819

R. Graf, S. Zhu, B. Sivakumar, J. Hydrol. (2019). https://doi.org/10.1016/j.jhydrol.2019.124115

M. Sharif, D.H. Burn, J. Hydrol. Eng. (2007). https://doi.org/10.1061/(ASCE)1084-0699(2007)12:1(42)

A. Nemes, R.T. Roberts, W.J. Rawls, Y.A. Pachepsky, M.T. Van Genuchten, Environ. Model Softw. (2008). https://doi.org/10.1016/j.envsoft.2007.05.018

M. Timur Cihan, Adv. Civ. Eng. (2019). https://doi.org/10.1155/2019/3069046

M. Akin, C. Hand, E. Eyduran, B.M. Reed, Plant Cell Tissue Organ Cult. (2018). https://doi.org/10.1007/s11240-017-1353-x

J. Mahjoobi, A. Etemad-Shahidi, Appl. Ocean Res. (2008). https://doi.org/10.1016/j.apor.2008.11.001

C.E. Lennert-Cody, M. Minami, P.K. Tomlinson, M.N. Maunder, Fish. Res. (2010). https://doi.org/10.1016/j.fishres.2009.11.014

L. Breiman, Mach. Learn. (2001). https://doi.org/10.1023/A:1010933404324

A.M. Prasad, L.R. Iverson, A. Liaw, Ecosystems (2006). https://doi.org/10.1007/s10021-005-0054-1

R. Genuer, J.M. Poggi, C. Tuleau-Malot, Pattern Recogn. Lett. (2010). https://doi.org/10.1016/j.patrec.2010.03.014

A. Lahouar, J.B.H. Slama, Renew. Energy (2017). https://doi.org/10.1016/j.renene.2017.03.064

Acknowledgements

The authors acknowledge the funding support by Croatian Science Foundation under the project UIP-2017-05-7113 Development of Reinforced Concrete Elements and Systems with Waste Tire Powder—ReCoTiP and China Postdoctoral Science Foundation (2018M640499).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Rights and permissions

About this article

Cite this article

Hadzima-Nyarko, M., Nyarko, E.K., Lu, H. et al. Machine learning approaches for estimation of compressive strength of concrete. Eur. Phys. J. Plus 135, 682 (2020). https://doi.org/10.1140/epjp/s13360-020-00703-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1140/epjp/s13360-020-00703-2