Abstract

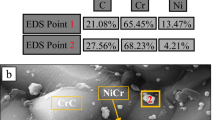

The influence of superficial CeO2 coatings on isothermal and cyclic high temperature corrosion behavior of 2.25 Cr-1 Mo steel in oxidation and sulfidation (SO2 + O2) atmosphere have been reported in this paper. The CeO2 coating of three different depositions rate (0.15 mg/cm2, 0.30 mg/cm2 and 0.50 mg/cm2) were prepared for experimental investigations. The isothermal corrosion study of uncoated and CeO2 coated specimens was carried out in SO2 + O2 environment at 973K for 150 hours. The results clearly indicate that CeO2 coated specimen improves the high temperature corrosion resistance than uncoated specimens. The post corroded CeO2 coated specimen shows reduction of scale growth and improved scale adhesion to the substrate. The cyclic corrosion study was also carried out in both coated and uncoated specimen in same environment at 973K for 100 h. The CeO2 coated specimens on thermal cycling also shows significant improvement of the corrosion resistance without scale cracking and spallations. In contrary, the uncoated specimen in both isothermal as well as cyclic environment shows higher corrosion rate along with scale cracking and spallations. The results of the reaction kinetics have been substantiated by post corrosion analysis of alloy/scales combinations by SEM and XRD. The details mechanism of the corrosion in presence of CeO2 coating was further discussed in the paper.

Similar content being viewed by others

References

Natesan, K., High Temperature Corrosion, Houston: TX, NACE, 1982, p. 336.

Stringer, J., High Temperatures Oxidation and Sulfidation Processes, Embury, J.D., Ed., N.Y.: Permagon, 1990, p. 257.

Gesmundo, F., Young, D.J., and Roy, S.K., High Temperature Mater Proc., 1989, vol. 8, p. 149.

Whiltle, D.P. and Stringer, J., Phil Trans. Roy. Soc. London, 1980, vol. A295, p. 309.

Moon, D.P. and Bennett, M.J., Mater. Sci. Forum., 1989, vol. 143, p. 269.

Papaiacovou, P., Hussy, R.J., Mitchell, D.F., and Graham, M.J., Oxid Met., 1990, p. 3319.

Strooosnijder, M.F., Guttmann, V., Fransen, T., and Dewit, J.H.W., Oxid Met., 1990, vol. 33, p. 371.

Ramanathan, L.V., Proc. of the 11th ICMC, Florence, Italy, April 2–6, 1990, vol. 4, p. 177.

Mitra, S.K., Roy, S.K., and Bose, S.K., Oxid Met., 1990, vol. 34, p. 101.

Bannett, M.J. and Moon, D.P., The Role of Active Elements in the Oxidation Behavior of High Temperature Metals. Commission of Europe Communities, Lang, E., Ed., 1989, p. 111.

Stringer, J., Wilcox, B.A., and Jaffee, R.J., Oxid Met., 1972, vol. 5, p. 11.

Ecer, G.M., Singh, R.B., and Meier, G.H., Oxid Met., 1982, vol. 18, p. 55.

Author information

Authors and Affiliations

Corresponding author

Additional information

The article is published in the original.

Rights and permissions

About this article

Cite this article

Ghosh, D., Shukla, A.K. & Mitra, S.K. Influence of CeO2 superficial coating on the high temperature corrosion behavior of 2.25 Cr-1 Mo Steel in SO2 + O2 atmospheres. Prot Met Phys Chem Surf 49, 749–752 (2013). https://doi.org/10.1134/S2070205113060208

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2070205113060208