Abstract

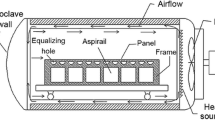

It is recognized that the uniformity of mould temperature fields during the composite curing process has a vital important effect on the component and, thereby, the product quality. Previous studies mainly considered the temperature along the thickness direction of the mould or composite component, or under a rather simple external environment, leading to some deviations from the actual composite autoclave curing process. In this paper, taking into consideration some factors such as auxiliaries, framed mould and forced convection phenomenon inside an autoclave, a simulation model has been established on the mould curing temperature field in an autoclave. On this basis, simulation and thermal analysis of the framed mould temperature fields with regard to composite structure and material system in the aviation industry have been performed. Besides, the influences of the time of heat preservation, heating rate have been also investigated, and two nondimensional factors are introduced for evaluating temperature uniformity and heating quality. It is found that increasing the time of heat preservation and the number of periods could improve the uniformity significantly, and, thus, the improvements of heating efficiency and uniformity of temperature field are achieved, and that a smaller heating rate would give much better heating quality.

Similar content being viewed by others

References

Loos, A.C. and Springer G.S., Curing of Epoxy Matrix Composites, J. Compos. Mat., 1983, vol. 17, pp. 135–69.

Heisler, M.P., Temperature Charts for Induction and Constant-Temperature Heating, Trans. ASME, 1947, vol. 69, pp. 227–236.

Twardowski, T.E., Lin, S.E., and Cell, P.H., Curing in Thick Composite Laminates: Experiment and Simulation, J. Compos. Mat., 1993, vol. 27, pp. 215–250.

Oh, J.H. and Lee D.G., Cure Cycle for Thick Glass/Epoxy Composite Laminates, J. Compos. Mat., 2002, vol. 36, pp. 19–45.

Bogetti, T.A. and Gillespie, J.W., Jr., Two-Dimensional Cure Simulation of Thick Thermosetting Composite, J. Compos. Mat., 1991, vol. 25, pp. 239–273.

Park, H.C. and Lee, S.W., Cure Simulation of Thick Composite StructuresUsing the Finite Element Method, J. Compos. Mat., 2001, vol. 35, pp. 188–201.

Ciriscioli, P.R., Wang, Q., and Springer, G.S., Autoclave Curing—Comparison of Model and Test Results, J. Compos. Mat., 1992, vol. 26, pp. 90–102.

Hojjati, M. and Hoa, S.V., Curing Simulation of Thick Thermosetting Composites, Compos. Manuf., 1994, vol. 5, pp. 159–169.

Gniatczyk, J.L., Acuuilina, G.R., and Deaver, D.C., Composite Molding Tools and Parts and Processes of Forming Molding Tools, US Patent, B29C 33/38, PCT/US00/21745, 2000.

Michael, C.N. and Michael, N., Composite Airframe Structures, 5th ed., Hong Kong Conmilit Press, 2005.

Magali, D., Investigation and Modeling of the Heat Transfer Process in Carbon FIBRE/EPOXY Composite Tools, PhD thesis, Carleton University, Canada, 2005.

Blest, D.C., Duffy, B.R., McKee, S., and Zulkifle, A.K., Curing Simulation of Thermoset Composites, Compos., A, 1999, vol. 30, pp. 1289–1309.

Martinez, G.M., Fast Cure for Thick LaminatedOrganic Matrix Composites, Chem. Eng. Sci., 1991, vol. 46, pp. 439–50.

Kim, J.S. and Lee, D.G., Development of an Autoclave Cure Cycle with Cooling and Reheating Steps for Thick Thermoset Composite Laminates, J. Compos. Mat., 1997, vol. 31, pp. 2264–2282.

Michael, H., Examination of Heat Transfer during Autoclave Processing of Polymer Composites, University of Manitoba, Canada, 2001.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xie, G.N., Liu, J., Zang, W.H. et al. Simulation and improvement of temperature distributions of a framed mould during the autoclave composite curing process. J. Engin. Thermophys. 22, 43–61 (2013). https://doi.org/10.1134/S1810232813010062

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1810232813010062