Abstract

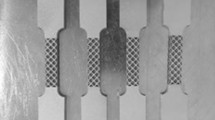

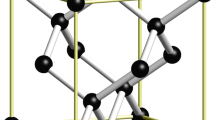

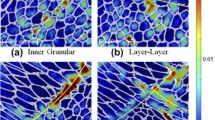

The deformation behavior of 3D 03X17H14M2 steel samples with various lattice structures created by selective laser melting has been studied under compression conditions using the digital image correlation method. Spatially temporal patterns of localization of transverse (εxx) and longitudinal (εyy) deformations of topological structure actual types have been studied. It has been found that it is possible to achieve a relative density of 20% for 3D printed products with lattice G-structures and cell sizes of 1.5 and 3 mm. However, all lattice 3D samples lose their plasticity, the Young’s modulus decreases by more than an order of magnitude, and the Poisson’s ratio increases by 1.3–2 times compared to the corresponding parameters for solid 3D samples.

Similar content being viewed by others

REFERENCES

I. V. Shishkovsky, Principles of High Resolution Additive Technology (Piter, St. Petersburg, 2016) [in Russian].

X. Wang, S. Xu, S. Zhou, W. Xu, M. Leary, P. Choong, P. Choong, M. Qian, M. Brandt, and Y. Xie, Biomaterials 83, 127 (2016). https://doi.org/10.1016/j.biomaterials.2016.01.012

J. Liu, A. T. Gaynor, S. Chen, Z. Kang, K. Suresh, A. Takezawa, L. Li, J. Kato, J. Tang, C. Wang, L. Cheng, X. Liang, and A. To, Struct. Multidiscip. Optim. 57, 2457 (2018). https://doi.org/10.1007/s00158-018-1994-3

M. A. Sutton, J. J. Orteu, and H. Schreier, Image Correlation for Shape, Motion and Deformation Measurements. Basic Concepts, Theory and Applications (Springer, Berlin, Heidelberg, 2009).

C. B. Gamboa, S. Martın-Béjar, F. Vilches, G. López, and L. Hurtado, Materials 12, 4156 (2019). https://doi.org/10.3390/ma12244156

A. Sola, S. Defanti, S. Mantovani, A. Merulla, and L. Denti, 3D Print. Addit. Manuf. 7 (1) (2020). https://doi.org/10.1089/3dp.2019.0119

ACKNOWLEDGMENTS

The authors thank nTopology Element Inc. for the opportunity to use the software.

Funding

This work was partially funded within the framework of the unified industry thematic plan EOTP-MT-097 of Rosatom State Corporation.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflict of interest.

Additional information

Translated by N. Petrov

Rights and permissions

About this article

Cite this article

Firsov, D.G., Konev, S.D., Dubinin, O.N. et al. Localization of Deformation in Lattice Structures of 3D-Printed Samples of 03X17H14M2 Steel. Tech. Phys. Lett. 46, 683–686 (2020). https://doi.org/10.1134/S1063785020070160

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063785020070160