Abstract

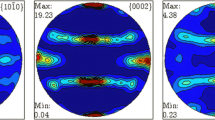

The crystallographic aspects of the phase transformations in zirconium alloys under compressive stresses are studied, and the changes in the sizes of cladding tubes, rods, and rings made of E110opt and E125 alloys at compressive stresses and without them are determined. The temperature of the onset of the phase transformation on heating is found to shift toward low temperatures under a load applied to a cladding tube ring in the diametral direction, and a noticeable strain leading to the appearance of ellipticity of the rings are detected. Some of the versions of the Burgers orientation relationship are operative during the reverse β‒α phase transformation under compressive stresses, which manifests itself in the suppression of growth of texture maxima in the applied load direction during cooling. Deformation is shown to be accelerated on heating in the two-phase α + β region under compressive stresses, and the parameters of high-temperature creep are calculated using the temperature dependences of the strain.

Similar content being viewed by others

REFERENCES

Z. Duan et al., “Current status of materials development of nuclear fuel cladding tubes for light water reactors,” Nucl. Eng. Design. 316, 131–150 (2017).

A. V. Nikulina, “Structural materials for elements of nuclear-reactor active zones: zirconium alloys in nuclear power engineering,” Met. Sci. Heat Treat. 46 (11, 12), 458–462 (2004).

R. Thieurmel et al., “Contribution to the understanding of brittle fracture conditions of zirconium alloy fuel cladding tubes during LOCA transient,” J. Nucl. Mater. 527, 151815 (2019).

T. Alam et al., “A review on the clad failure studies,” Nucl. Eng. Des. 241 (9), 3658–3677 (2011).

M. G. Isaenkova et al., “Thermal expansion of cladding tubes and rods of a Zr–1% Nb alloy in the temperature range 293–873 K (20–600°C) according to X-ray diffraction and dilatometric results,” Fiz. Khim. Obrab. Mater., No. 3, 53–65 (2020).

M. G. Isaenkova et al., “Regularities of thermal expansion of cladding tubes and rods made of E110opt alloy within the temperature range of 273–1473 K (20–1200°C),” Inorg. Mater. Appl. Res. 12 (3), 820–830 (2021).

S. Stolbov et al., “Dependence of thermal expansion of Zr-based products on their crystallographic texture,” IOP Conf. Ser. Mater. Sci. Eng. 1121 (1), 012036 (2021).

E. N. Pirogov, Yu. A. Perlohich, M. G. Isaenkova, L. L. Artyukhina, et al., “Superplasticity mechanism of N-1 zirconium alloy,” Atom. Energ. 63 (2), 142–144 (1987).

Yu. Perlovich and M. Isaenkova, “Effects of dynamical deformation ageing on structure and texture of hot-rolled sheets from alloyed BCC metals,” Int. J. Mater. Form. 3 (1), 1143–1146 (2010).

Yu. A. Perlovich, M. G. Isaenkova, P. L. Dobrokhotov, A. E. Rubanov, S. D. Stolbov, I. O. Bannykh, O. A. Bannykh, and M. V. Antsyferova, “Effect of layer-by-layer texture inhomogeneity on the mechanical properties of hot-rolled steel sheets,” Russ. Metall. (Metally), No. 11, 1027–1034 (2018).

Yu. Perlovich et al., “Texture evidences of interaction between plastic deformation and phase transformations in Zr-based alloys,” Mater. Sci. Forum 702–703, 283–286 (2012).

M. Isaenkova, “Effect of the crystallographic texture in the α phase on the anisotropy of the properties of pseudo-α and (α + β) titanium alloy sheets,” Russ. Metall. (Metally), No. 4, 430–436 (2021).

I. N. Izmalkov, L. P. Loshmanov, and A. V. Kostyukhina, “Mechanical properties of an E110 alloy at temperatures up to 1273 K,” Izv. Vyssh. Uchebn. Zaved., Yadern. Energetika 2, 64–70 (2013).

G. Moulin et al., “High temperature creep properties of zirconium and Zircaloy-4 in vacuum and oxygen environments,” J. Nucl. Mater. 362 (2, 3), 309–315 (2007).

J. Echols et al., “Temperature and time effects of post-weld heat treatments on tensile properties and microstructure of Zircaloy-4,” J. Nucl. Mater. 551, 152952 (2021).

J. K. Chakravartty et al., “Hot-working characteristics of Zircaloy-2 in the temperature range of 650–950°C,” J. Nucl. Mater. 187 (3), 260–271 (1992).

C. Aranas et al., “Deformation-induced phase transformation in Zircaloy-4 below the beta transus,” Mater. Lett. 220, 229–233 (2018).

C. S. Daniel, “Co-deformation and dynamic annealing effects on the texture development during alpha–beta processing of a model Zr–Nb alloy,” Acta Mater. 205, 116538 (2021).

R. A. Lebensohn and G. R. Canova, “A self-consistent approach for modeling texture development of two-phase polycrystals: application to titanium alloys,” Acta Mater. 45, 3687–3694 (1997).

M. G. Glavicic et al., “Modeling of texture evolution during hot forging of alpha/beta titanium alloys,” Met. Mater. Trans. A 39 (4), 887–896 (2008).

R. E. Logé et al., “Sensitivity of α-ZY4 high-temperature deformation textures to the β-quenched precipitate structure and to recrystallization: application to hot extrusion,” Acta Mater. 48 (15), 3917–3930 (2000).

L. D. G. Prakash et al., “Microstructure and texture evolution during thermomechanical processing of β‑quenched Zr,” Acta Mater. 88, 389–401 (2015).

S. L. Semiatin, “An overview of the thermomechanical processing of α/β titanium alloys: current status and future research opportunities,” Met. Mater. Trans. A Phys. Met. Mater. Sci. 51 (6), 2593–2625 (2020).

Z. Gao et al., “Comparison of the oxidation behavior of a zirconium nitride coating in water vapor and air at high temperature,” Corros. Sci. 138, 242–251 (2017).

C. Chauvy, P. Barberis, and F. Montheillet, “Microstructure transformation during warm working of β‑treated lamellar Zircaloy-4 within the upper α‑range,” Mater. Sci. Eng. A 431 (1, 2), 59–67 (2006).

K. K. Saxena et al., “Hot deformation behavior of Zr–1Nb alloy in two-phase region—microstructure and mechanical properties,” J. Alloys Compd. 741, 281–292 (2018).

Q. Zeng et al., “Effect of initial orientation on dynamic recrystallization of a zirconium alloy during hot deformation,” Mater. Charact. 145, July, 444–453 (2018).

Ya. D. Vishnyakov and A. A. Babareko, Theory of Texture Formation in Metals and Alloys (Nauka, Moscow, 1979).

C. Cochrane, M. A. Gharghouri, and M. R. Daymond, “Evidence for deformation-induced phase transformation in a high Sn content zirconium alloy,” Acta Mater. 161, 311–319 (2018).

C. Cochrane and M. R. Daymond, “Effect of temperature and loading sense on deformation-induced phase transformation in a high Sn content zirconium alloy,” Mater. Sci. Eng. A 748, January, 313–326 (2019).

P. Chen, F. Wang, and B. Li, “Misfit strain induced phase transformation at a basal/prismatic twin boundary in deformation of magnesium,” Comput. Mater. Sci. 164, June, 186–194 (2019).

P. Chen, F. Wang, and B. Li, “Transitory phase transformations during {101\(\bar {2}\)} twinning in titanium,” Acta Mater. 171, April, 65–78 (2019).

H. Zhao et al., “Atomic-scale understanding of stress-induced phase transformation in cold-rolled Hf,” Acta Mater. 131, 271–279 (2017).

H. C. Wu et al., “Rolling-induced face centered cubic titanium in hexagonal close packed titanium at room temperature,” Sci. Rep. 6, March, 1–8 (2016).

M. Ruda, D. Farkas, and G. Bertolino, “Twinning and phase transformations in Zr crack tips,” Comput. Mater. Sci. 49 (4), 743–750 (2010).

N. Gey et al., “Study of the β → α variant selection for a zircaloy-4 rod heated to the β transus in presence or not of an axial tensile stress,” J. Nucl. Mater. 328 (2, 3), 137–145 (2004).

N. Gey et al., “Study of the α/β phase transformation of Zy-4 in presence of applied stresses at heating: analysis of the inherited microstructures and textures,” J. Nucl. Mater. 302 (2, 3), 175–184 (2002).

N. Gey and M. Humbert, “Characterization of the variant selection occurring during the α → β → α phase transformations of a cold rolled titanium sheet,” Acta Mater. 250 (2), 277–287 (2002).

M. Isaenkova and Yu. Perlovich, “Features of the phase transformations in sheets, tubes and welding seams of the alloy Zr–2.5% Nb,” Textures & Microstruct. 30 (1, 2), 55–70 (1997).

M. G. Isaenkova et al., “Regularities of recrystallization of rolled single crystals and polycrystals of zirconium and alloy Zr–1% Nb,” Phys. Met. Metallogr. 115 (8), 756–764 (2014).

M. Isaenkova, Yu. Perlovich, and V. Fesenko, “Modern methods of experimental construction of texture complete direct pole figures by using X-ray data,” IOP Conf. Ser. Mater. Sci. Eng. 130, 12055 (2016).

D. Duglas, Physical Metallurgy of Zirconium (Atomizdat, Moscow, 1975).

V. Petukhov, “Thermal expansion of zirconium in the solid phase,” High Temp.–High Press. 35–36 (1), 15–23 (2003).

M. Isaenkova, Yu. Perlovich, and V. Fesenko, “Texture aspects of delayed hydride cracking in products from Zr-based alloys,” Appl. Texture Anal. Ceram. Trans. 201, 189–196 (2008).

B. Garrison, Y. Yan, and S. TerMaath, “Determining failure properties of as-received and hydrided unirradiated Zircaloy-4 from ring compression tests,” Eng. Fail. Anal. 125, March, 105362 (2021).

L. R. Bunnell, J. L. Bates, and G. B. Mellinger, “Some high-temperature properties of Zircaloy-oxygen alloys,” J. Nucl. Mater. 116 (2, 3), 219–232 (1983).

T. Jailin et al., “Thermo-mechanical behavior of Zircaloy-4 claddings under simulated post-DNB conditions,” J. Nucl. Mater. 531, 151984 (2020).

M. Sattari, R. A. Holt, and M. R. Daymond, “Variant selection and transformation texture in zirconium alloy Excel,” J. Nucl. Mater. 453 (1–3), 120–123 (2014).

L. Chai et al., “Experimental observation of 12 α variants inherited from one β grain in a Zr alloy,” J. Nucl. Mater. 440 (1–3), 377–381 (2013).

Funding

This work was supported by the Ministry of Education and Science of the Russian Federation, project no. 075-15-2021-1352.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by K. Shakhlevich

Rights and permissions

About this article

Cite this article

Stolbov, S.D., Isaenkova, M.G., Korotitskii, A.V. et al. Effect of the Stressed State on the Phase Transformations in Zirconium-Based Alloys. Russ. Metall. 2022, 250–260 (2022). https://doi.org/10.1134/S0036029522030119

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029522030119