Abstract

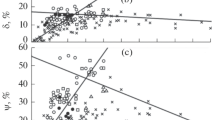

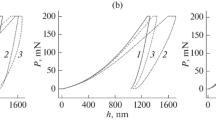

The manufacturability of a gadolinium-alloyed intermetallic VIT5 titanium ortho alloy during deformation at temperatures of 800–1100°C is studied. The mechanical properties and the structure of plates rolled according to two deformation regimes are analyzed. The effect of the morphology of the Ti2AlNb ortho phase on the strength, plastic, and high-temperature properties of the alloy is investigated. The formation of a specified structure is shown to provide a high level of plasticity and high-temperature strength. The relative elongation at 20°C is 7.0%, the tensile strength at 700°C is 950 MPa, and the long-term tensile strength at 700°C for 100 h is 300 MPa.

Similar content being viewed by others

Notes

The test temperature range was chosen taking into account the conditions of deformation of VTI-4 ortho alloys. The samples were not compressed at higher temperatures, because the alloy has a high technological plasticity and its behavior is similar to that of REE-free ortho alloys at temperatures above 1115 ± 5°C (in a single-phase β/B2 region) [23].

REFERENCES

H. Clemens and S. Mayer, “Intermetallic γ-titanium aluminide-based alloys from a metallographic point of view—A continuation,” Pract. Metallogr. 48 (2) 64–99 (2011).

N. A. Nochovnaya, O. A. Bazyleva, D. E. Kablov, and P. V. Panin, Titanium-Based and Nickel-Based Intermetallic Alloys, Ed. by E. N. Kablov, (VIAM, Moscow, 2018).

E. V. Rodin, Yu. G. Bykov, and K. A. Kyaramyan, “Application of new materials in the design of HPC of an advanced engine,” in Proceedings of International Conference on Promising Trends in the Development of Aviation Engine Industry (Skifiya, St. Petersburg, 2016), pp. 301–308.

E. N. Kablov, “New generation materials are the foundation for innovations, technological leadership, and national security in Russia,” Intellekt Technol. 14 (2), 16–21 (2016).

V. V. Antipov, “Outlook of aluminum, magnesium, and titanium alloys in the aerospace equipment,” Aviats. Mater. Technol., No. S, 264–271 (2017). https://doi.org/10.18577/2071-9140-2017-0-S-186-194

V. G. Antashev, N. A. Nochovnaya, T. V. Pavlova, and V. I. Ivanov, “High-temperature titanium alloys,” in All Materials. Encyclopedic Reference Book (2007), No. 3, pp. 7–8.

Titanium and Titanium Alloys. Fundamentals and Applications, Ed. by C. Leyens and M. Peters (Wiley-VCH, Weinheim, 2003).

W. Chen, J. W. Li, L. Xu, and B. Lu “Development of Ti2AlNb alloys: Opportunities and challenges,” Adv. Mater. Processes. 172 (5), 23–27 (2014).

E. N. Kablov, O. G. Ospennikova, and A. V. Vershkov, “Rare metals and rare earth elements—materials of modern and high technologies of the future,” Trudy VIAM, No. 2, St. 01 (2013). http://www.viam-works.ru. Cited January 16, 2019.

A. I. Khorev, N. A. Nochovnaya, and A. L. Yakovlev, “Microalloying with rare-earth metals of titanium alloys,” Aviats. Mater. Technol., No. S, 206–212 (2012).

Y.-Y. Chen, B.-H. Li, and F.-T. Kong, “Effects of minor yttrium addition on hot deformability of lamellar Ti–45Al–5Nb alloy,” Trans. Nonferrous Met. Soc. China. 17 (1), 58–63 (2007).

Y.-Y. Chen, F.-T. Kong, J. Han, Z. Chen, and J. Tian, “Influence of yttrium on microstructure, mechanical properties and deformability of Ti–43Al–9V alloy,” Intermetallics 13 (3, 4), 263–266 (2005).

J. Hieda, M. Niinomi, M. Nakai, and K. Cho, “Mechanical properties of biomedical β-type titanium alloy with rare-earth metal oxide particles formed by rare-earth metal addition,” in Proceedings of 143rd Annual Meeting and Exhibition TMS 2014 (Wiley, 2014), pp. 129–135.

C. M. Liu, K. Xia, and W. Li, “Effect of cerium on the microstructure and grain sizes of cast TiAl alloys,” J. Mater. Sci. 35, 975–980 (2000).

J.-R. Dai, H.-M. Lu, Z.-J. Cai, and C. An, “Grain refining or Er added to Ti–22Al–25Nb alloy and morphology of erbium precipitates,” Rare Met. 32 (1), 5–11 (2013).

A. I. Khorev, G. P. Mukhina, and I. P. Zhegina, “Influence of Rare-Earth Elements on the Properties of Titanium Alloys,” in Alloying and Heat Treatment of Titanium Alloys (VIAM, Moscow, 1977), pp. 106–114.

E. B. Alekseev, N. A. Nochovnaya, A. V. Novak, and P. V. Panin, “Yttrium-alloyed deformed intermetallic titanium ortho alloy. Part 1. Investigation of ingot microstructure and building the rheological curves,” Trudy VIAM, 66 (6), 12–21 (2018). https://doi.org/10.18577/2307-6046-2018-0-6-12-21

E. B. Alekseev, N. A. Nochovnaya, A. V. Novak, and P. V. Panin, “Yttrium-alloyed deformed intermetallic titanium ortho alloy. Part 2. The effect of heat treatment on the microstructure and mechanical properties of a rolled plate,” Trudy VIAM, 72 (12), 37–45 (2018). https://doi.org/10.18577/2307-6046-2018-0-12-37-45

Y.-F. Si, Y.-Y. Chen, Z.-G. Liu, and F.-T. Kong, “Influence of yttrium on microstructure and properties of Ti–23Al–25Nb alloy after heat treatment,” Trans. Nonferrous Met. Soc. China. 16, 849–853 (2006).

Niu Hongzhi, Zhang Yusheng, Lu Jinwen, Zhang Wei, Zhang Pingxiang, “Ti2AlNb alloy with low density and high plasticity,” CN Patent 104372202, 2015.

N. A. Nochnovnaya, E. B. Alekseev, P. V. Panin, and A. V. Novak, “Investigation of the structure and mechanical properties of the deformed intermetallic VIT5 gadolinium-alloyed titanium alloy,” Titanium, No. 2, 21–29 (2017).

E. N. Kablov, N. A. Nochovnaya, P. V. Panin, E. B. Alekseev, and A. V. Novak, “Study of the structure and properties of heat-resistant alloys based on titanium aluminides with gadolinium microadditives,” Inorg. Mater. Appl. Res., No. 3, 3–10 (2017).

E. B. Alekseev, N. A. Nochovnaya, S. V. Skvortsova, P. V. Panin, and O. Z. Umarova, “Analysis of technological parameters of deformation of experimental heat-resistant alloy based on Ti2AlNb intermetallic compound,” Titan, No. 2, 34–39 (2014).

E. N. Kablov, “Innovative developments of the FSUE VIAM SSC of RF for the realization of Strategic Directions in Developing Materials and Their Processing Technologies up to 2030,” Aviats. Mater. Technol. 34 (1), 3–33 (2015). https://doi.org/10.18577/2071-9140-2015-0-1-3-33

ACKNOWLEDGMENTS

The research was carried out using the certified and accredited equipment at the Test Center of All-Russia Institute of Aviation Materials VIAM.

The results were processed at the Competence Center for Development and Production of Titanium Intermetallic Alloys for Aircraft Engines and Terrestrial Power Plants (VIAM).

Funding

This work was carried out within the framework of complex scientific direction 7.1 Titanium-Based Intermetallic Alloys and Strategic Trends in the Development of Materials and Technologies of Their Processing for the Period until 2030 [24].

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by T. Gapontseva

Rights and permissions

About this article

Cite this article

Novak, A.V., Nochovnaya, N.A. & Alekseev, E.B. Influence of the Deformation Parameters on the Morphology of the Strengthening O Phase and the Mechanical Properties of an Intermetallic VIT5 Titanium Alloy. Russ. Metall. 2020, 318–324 (2020). https://doi.org/10.1134/S0036029520040205

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029520040205