Abstract

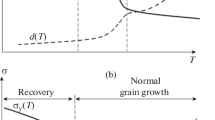

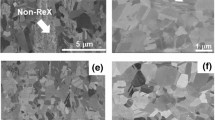

Yield strength σy, macroelastic limit σ0, and effective grain-boundary hardening coefficient Keff in the Hall–Petch relation (\({\sigma _y} = {\sigma _0} + {K_{eff}}/\sqrt d \)) in the submicrocrystalline (SMC) materials produced by equalchannel angular pressing are experimentally studied. It is shown that, as compared to parameter σ0 and K in the Hall–Petch relation for coarse-grained metals, the SMC metals are characterized by higher values of σ0 and lower values of Keff. The critical grain size (d1) at which Keff in the σy–d–1/2 relations of SMC materials changes falls in the range 0.2–0.5 μm. The dependences of macroelastic limit σ0 and coefficient Keff on the annealing temperature are found to be determined by recrystallization. If abnormal grain growth develops in annealing of SMC metals, anomalous hardening is detected and a nonmonotonic temperature dependence of coefficient Keff takes place. In the case of conventional recrystallization at a high annealing temperature, SMC metals exhibit a smooth decrease in σ0 and an increase in Keff to the values of K characteristic of coarsegrained materials.

Similar content being viewed by others

References

M. I. Goldshtein, V. S. Litvinov, and B. M. Bronfin, Physical Metallurgy of High-Strength Alloys (Metallurgiya, Moscow, 1986).

J. P. Hirth and J. Lothe, Theory of Dislocations (McGraw-Hill, New York, 1967).

Ultrafine Grain in Metals, Ed. by L. K. Gordienko (Metallurgiya, Moscow, 1973).

E. F. Dudarev, Microplastic Deformation and Yield Strength of Polycrystals (Tomskii Gos. Univ., Tomsk, 1988).

V. E. Panin, Yu. V. Grinyaev, V. I. Danilov, L. B. Zuev, V. E. Egorushkin, T. F. Elsukova, N. A. Koneva, E. V. Kozlov, T. M. Poletika, S. N. Kul’kov, S. G. Psakh’e, S. Yu. Korostelev, and N. V. Chertova, Structural Levels of Plastic Deformation and Fracture (Nauka, Novosibirsk, 1990).

M. A. Meyers, U. R. Andrade, and A. H. Chokshi, “The effect of grain size on the high-strain, highstrain-rate behavior of copper,” Met. Mater. Trans. A 26, 2881–2893 (1995).

R. Z. Valiev and T. G. Langdon, “Principles of equalchannel angular pressing as a processing tool for grain refinement,” Prog. Mater. Sci. 51 (7), 881–981 (2006).

V. M. Segal, I. J. Beyerlein, C. N. Tome, V. N. Chuvil’deev, and V. I. Kopylov, Fundamentals and Engineering of Severe Plastic Deformation (Nova Sci. Publ., New York, 2010).

M. Furukawa, Z. Horita, M. Nemoto, R. Z. Valiev, and T. G. Langdon, “Microhardness measurements and the Hall–Petch relationship in an Al–Mg alloys with submicrometer grain size,” Acta Materialia 44 (11), 4619–4629 (1996).

M. Furukawa, Y. Iwahashi, Z. Horita, M. Nemoto, N. K. Tsenev, R. Z. Valiev, and T. G. Langdon, “Structural evolution and the Hall–Petch relationship in an Al–Mg–Li–Zr alloys with ultra-fine grain size,” Acta Materialia 45 (11), 4751–4757 (1997).

H. K. Kim and W. J. Kim, “Microstructural instability and strength of an AZ31 Mg alloy after severe plastic deformation,” Mater. Sci. Eng. A 385 (1–2), 300–308 (2004).

M. V. Degtyarev, T. I. Chashchukhina, L. M. Voronova, A. M. Patselov, and V. P. Pilyugin, “Influence of the relaxation processes on the structure formation in pure metals and alloys under high-pressure torsion,” Acta Materialia 55 (18), 6039–6050 (2007).

H. Conrad, “Grain size dependence of the plastic deformation kinetics in Cu,” Mater. Sci. Eng. A 341 (1–2), 216–228 (2003).

E. Schafler and M. B. Kerber, “Microstructural investigation of the annealing behavior of high-pressure torsion (HPT) deformed copper,” Mater. Sci. Eng. A 462 (1–2), 139–143 (2007).

V. A. Pozdnyakov, “Mechanisms of plastic deformation and the anomalies of the Hall–Petch dependence in metallic nanocrystalline materials,” Phys. Met. Metallogr. 96 (1), 105–119 (2001).

C. W. Su, B. W. Chua, L. Lu, and M. O. Lai, “Properties of severe plastically deformed Mg alloys,” Mater. Sci. Eng. A 402 (1–2), 163–169 (2005).

W. J. Kim, C. W. An, Y. S. Kim, and S. I. Hong, “Mechanical properties and microstructures of an AZ61 Mg alloy produced by equal channel angular pressing,” Scripta Materialia 47 (1), 39–44 (2002).

G. A. Malygin, “Plasticity and strength of micro-and nanocrystalline materials: review,” Fiz. Tverd. Tela 49 (6), 961–982 (2007).

S. G. Zaichenko and A. M. Glezer, “Disclination mechanism of plastic deformation in nanocrystalline materials,” Fiz. Tverd. Tela 39 (11), 2023–2028 (1997).

M. A. Munoz-Morris, O. C. Garcia, and D. G. Morris, “Mechanical behavior of dilute Al–Mg alloy processed by equal channel angular pressing,” Scripta Materialia 48 (3), 213–218 (2003).

R. Z. Valiev and I. V. Aleksandrov, Nanostructured Materials Produced by Severe Plastic Deformation (Logos, Moscow, 2000).

M. R. Barnett, Z. Keshavarz, A. G. Beer, and D. Atwell, “Influence of grain size on the compressive deformation of wrought Mg–3Al–1Z,” Acta Materialia 52 (17), 5093–5103 (2004).

A. Yamashita, Z. Horita, and T. G. Langdon, “Improving the mechanical properties of magnesium and a magnesium alloy through severe plastic deformation,” Mater. Sci. Eng. A 300 (1–2), 142–147 (2001).

A. V. Nokhrin, V. N. Chuvil’deev, E. S. Smirnova, I. M. Makarov, Yu. G. Lopatin, and V. I. Kopylov, “Thermal stability of the structure of microcrystalline metals produced by equal-channel angular pressing,” Russ. Metall. (Metally), No. 2, 126–140 (2004).

X. Molodova, G. Gottstein, M. Winning, and R. J. Hellmig, “Thermal stability of ECAP processed pure copper,” Mater. Sci. Eng. A 460–461 (15), 204–213 (2007).

V. N. Chuvil’deev, V. I. Kopylov, A. V. Nokhrin, I. M. Makarov, L. M. Malashenko, and V. A. Kukareko, “Anomalous grain growth in nano-and microcrystalline metals produced by ECA pressing: I. Structural investigations,” Materialoved., No. 4, 9–18 (2003).

V. N. Chuvil’deev, A. V. Nokhrin, and V. I. Kopylov, “Anomalous strengthening upon annealing of microcrystalline metals produced by high-cycle equal-channel angular pressing,” Russ. Metall. (Metally), No. 3, 240–251 (2003).

A. V. Korznikov, S. Idrisova, and N. I. Noskova, “Structure and thermal stability of submicron-grained molybdenum,” Phys. Met. Metallogr. 85 (3), 327–331 (1998).

Yu. V. Ivanisenko, A. A. Sirenko, and A. V. Korznikov, “Effect of heating on the structure and mechanical properties of submicron-grained armco iron,” Fiz. Met. Metalloved. 87 (4), 78–83 (1999).

R. Z. Valiev, A. V. Sergueeva, and A. K. Mukherjee, “The effect of annealing on tensile deformation behavior of nanostructured SPD titanium,” Scripta Materialia 49 (7), 669–674 (2003).

V. N. Chuvil’deev, Nonequilibrium Boundaries in Grains in Metals. Theory and Applications (Fizmatlit, Moscow, 2004).

V. N. Chuvil’deev, V. I. Kopylov, and W. Zeiger, “Nonequilibrium grain boundaries. Theory and its applications for describing nano-and microcrystalline materials processed by ECAP,” Ann. Chim.: Sci. Mater. 27 (3), 56–64 (2002).

V. N. Chuvil’deev, A. V. Nokhrin, V. I. Kopylov, Yu. G. Lopatin, N. V. Melekhin, O. E. Pirozhnikova, M. M. Myshlyaev, and N. V. Sakharov, “Conditions for the applicability of the Hall–Petch relation for nanoand microcrystalline materials produced by severe plastic deformation,” Deform. Razr. Mater., No. 12, 17–25 (2009).

A. P. Kraev, “Microplastic deformation and its application for analysis of the structure and mechanical properties of steels,” Extended Abstract of Cand Sci. (Eng.) Dissertation, Nizhny Novgorod State University, Nizhny Novgorod, 1999.

A. V. Nokhrin and I. M. Makarov, “Studying the grain structure of nano-and microcrystalline metals by atomic force microscopy,” Zavod. Lab. 68 (1), 70–79 (2002).

A. V. Nokhrin, I. M. Makarov, and Yu. G. Lopatin, “Technique for an investigation of the granular structure of microcrystalline superplastic aluminum alloys by atomic force microscopy,” Zavod. Lab., No. 12, 18–26 (2004).

E. V. Kozlov, A. N. Zhdanov, N. A. Popova, E. E. Pekarskaya, and N. A. Koneva, “Subgrain structure and internal stress fields in UFG materials: problem of Hall–Petch relation,” Mater. Sci. Eng. A 387–389, 789–794 (2004).

A. Mishra, B. K. Kad, F. Gregori, and M. A. Meyers, “Microstructural evolution in copper subjected to severe plastic deformation: experiments and analysis,” Acta Materialia 55, 13–28 (2007).

R. Mishnev, I. Shakhova, A. Belyakov, and R. Kaibyshev, “Deformation microstructure, strengthening mechanisms, and electrical conductivity in a Cu–Cr–Zr alloy,” Mater. Sci. Eng. A 629, 29–40 (2015).

D. J. Dunstan and A. J. Bushby, “Grain size dependence of the strength of metals: the Hall–Petch effect does not scale as the inverse square root of grain size,” Intern. J. Plasticity 53, 56–65 (2014).

A. Loucif, R. B. Figueiredo, T. Baudin, F. Brisset, R. Cheman, and T. G. Langdon, “Ultrafine grains and the Hall–Petch relationship in an Al–Mg alloy processed by high-pressure torsion,” Mater. Sci. Eng. A 532, 139–145 (2012).

Y. Wang and H. Choo, “Influence of texture on Hall–Petch relationships in a Mg alloy,” Acta Materialia 81, 83–97 (2014).

W. Yuan, S. K. Panigrahi, J.-Q. Su, and R. S. Mishra, “Influence of grain size and texture on Hall–Petch relationship for a magnesium alloy,” Scripta Materialia 65, 994–997 (2011).

Y. K. Li, F. Liu, G. P. Zheng, D. Pan, Y. H. Zhao, and Y. M. Wang, “Strength scaling low, deformation kinetics and mechanisms of nanostructured Ti,” Mater. Sci. Eng. A 573, 141–147 (2013).

V. K. Babich, Yu. P. Gul’, and I. E. Dolzhenkov, Strain Aging of Steel (Metallurgiya, Moscow, 1972).

W. Wei, G. Chen, and J. Wang, “Microstructure and tensile properties of ultrafine grained copper processed by equal-channel angular pressing,” Rare Metals 25 (6), 697–703 (2006).

E. V. Kozlov, A. M. Glezer, N. A. Koneva, N. A. Popova, and I. A. Kurzina, Fundamentals of the Plastic Deformation of Nanostructured Materials, Ed. by A. M. Glezer (Fizmatlit, Moscow, 2016).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © V.N. Chuvil’deev, A.V. Nokhrin, M.M. Myshlyaev, V.I. Kopylov, Yu.G. Lopatin, N.V. Melekhin, A.V. Piskunov, A.A. Bobrov, O.E. Pirozhnikova, 2018, published in Metally, 2018, No. 1, pp. 81–102.

Rights and permissions

About this article

Cite this article

Chuvil’deev, V.N., Nokhrin, A.V., Myshlyaev, M.M. et al. Effect of Recovery and Recrystallization on the Hall–Petch Relation Parameters in Submicrocrystalline Metals: I. Experimental Studies. Russ. Metall. 2018, 71–89 (2018). https://doi.org/10.1134/S0036029518010044

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029518010044