Abstract

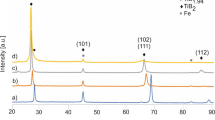

M–B–(N) (M = Mo, Cr, Ti) coatings were obtained by the magnetron sputtering of MoB, CrB2, TiB, and TiB2 targets in argon and in gaseous mixtures of argon with nitrogen. The structure and composition of the coatings have been investigated using scanning electron microscopy, glow-discharge optical emission spectroscopy, and X-ray diffraction. The mechanical and tribological properties of the coatings have been determined by nanoindentation, scratch-testing, and ball-on-disk tribological tests. The experiments on estimating the oxidation resistance of coatings were carried out in a temperature range of 600–1000°С. A distinctive feature of TiB2 coatings was their high hardness (61 GPa). The Cr–B–(N) coatings had high maximum oxidation resistance (900°С (CrB2) and 1000°С (Cr–B–N)) and possessed high resistance to the diffusion of elements from the metallic substrate up to a temperature of 1000°С. The Mo–B–N coatings were significantly inferior to the Ti–B–(N) and Cr–B–(N) coatings in their mechanical properties and oxidation resistance, as well as had а tendency to oxidize in air atmosphere after long exposure at room temperature. All of the coatings with nitrogen possessed a low coefficient of friction (in a range of 0.3–0.5) and low relative wear ((0.8–1.2) × 10–6 mm3 N–1 m–1.

Similar content being viewed by others

References

W. Wallgram and U. Schleinkofer, “Synthesis, structure, and behavior of a new CVD TiB2 coatings with extraordinary properties for high performance applications,” Proc. 17th Plansee Seminar, 2009, vol. 2, pp. 32/1–32/14.

S. Taktak, “Tribological behavior of borided bearing steels at elevated temperatures,” Surf. Coat. Technol. 201, 2230–2239 (2006).

H. B. Hassan and Z. A. Hamid, “Electroless Ni–B supported on carbon for direct alcohol fuel cell applications,” Int. J. Hydrogen Energy 36, 849–856 (2011).

L. Hejun, Y. Dongjia, F. Qiangang, L. Lei, Zh. Yulei, Y. Xiyuan, W. Yongjie, and L. Hailiang, “Anti-oxidation and ablation properties of carbon/carbon composites infiltrated by hafnium boride,” Carbon 52, 418–426 (2013).

R. Ribeiro, S. Ingole, M. Usta, C. Bindal, A. H. Ucisik, and H. Liang, “Tribological investigation of tantalum boride coating under dry and simulated body fluid conditions,” Wear 262, 1380–1386 (2007).

A. A. Goncharov, P. I. Ignatenko, V. V. Petukhov, V. A. Konovalov, G. K. Volkova, V. A. Stupak, and V. A. Glazunova, “Composition, structure and properties of tantalum boride nanostructured films,” Tech. Phys. 51, 1340–1343 (2006).

A. A. Goncharov, V. V. Petukhov, D. N. Terpii, P. I. Ignatenko, and V. A. Stupak, “Nanostructured films of vanadium borides,” Inorg. Mater. 41, 696–699 (2005).

F. Kunc, J. Musil, P. H. Mayrhofer, and C. Mitterer, “Low-stress superhard Ti–B films prepared by magnetron sputtering,” Surf. Coat. Technol. 174–175, 744–753 (2003).

V. Ferrando, C. Tarantini, P. Manfrinetti, I. Pallecchi, M. Salvato, and C. Ferdeghini, “Growth of diborides thin films on different substrates by pulsed laser ablation,” Thin Solid Films 515, 1439–1444 (2006).

B. T. Mayumi, N. Atsushi, N. Yasuo, K. Shozo, H. Masanobu, H. Yuichiro, A. Eiji, M. Hideakia, and M. Kazuya, “Low temperature deposited Zr–B film applicable to extremely thin barrier for copper interconnect,” Appl. Surf. Sci. 256, 1222–1226 (2009).

A. Chatterjee, S. Jayaraman, J. E. Gerbi, N. Kumar, J. R. Abelson, P. Bellon, A. A. Polycarpou, and J. P. Chevalier, “Tribological behavior of hafnium diboride thin films,” Surf. Coat. Technol. 201, 4317–4322 (2006).

K. A. Khor, L. G. Yu, and G. Sundararajan, “Formation of hard tungsten boride layer by spark plasma sintering boriding,” Thin Solid Films 478, 232–237 (2005).

J. V. Rau, A. Latini, A. R. Generosi, V. Albertini, D. Ferro, R. Teghil, and S. M. Barinov, “Deposition and characterization of superhard biphasic ruthenium boride films,” Acta Mater. 57, 673–681 (2009).

Z.-W. Ji, C.-H. Hu, D.-H. Wang, Y. Zhong, J. Yang, W.-Q. Zhang, and H.-Y. Zhou, “Mechanical properties and chemical bonding of the Os–B system: A firstprinciples study,” Acta Mater. 60, 4208–4217 (2012).

F. V. Kiryukhantsev-Korneev, A. N. Sheveyko, E. A. Levashov, and D. V. Shtansky, “Perspective nanostructural coatings for machinery construction,” Vopr. Materialoved., No. 2 (154), 187–201 (2008).

E. A. Levashov, D. V. Shtansky, Ph. V. Kiryukhantsev-Korneev, M. I. Petrzhik, M. Ya. Tyurina, and A. N. Sheveyko, “Multifunctional nanostructured coatings: Formation, structure, and the uniformity of measuring their mechanical and tribological properties,” Russ. Metall. (Engl. Transl.) 2010, 917–935 (2010).

H. Holzschuh, “Deposition of Ti–B–N (single and multilayer) and Zr–B–N coatings by chemical vapor deposition techniques on cutting tools,” Thin Solid Films 469–470, 92–98 (2004).

S. Jayaraman, J. E. Gerbi, Y. Yang, D. Y. Kim, A. Chatterjee, P. Bellon, G. S. Girolami, J. P. Chevalier, and J. R. Abelson, “HfB2 and Hf–B–N hard coatings by chemical vapor deposition,” Surf. Coat. Technol. 200, 6629–6633 (2006).

A. I. Bazhin, A. A. Goncharov, V. V. Petukhov, T. D. Radjabov, V. A. Stupak, and V. A. Konovalov, “Magnetron sputtering of a vanadium-diboride target in Ar + N2 gaseous mixtures,” Vacuum 80, 918–922 (2006).

P. Holubar, M. Jilek, and M. Sima, “Present and possible future applications of superhard nanocomposite coatings,” Surf. Coat. Technol. 133–134, 145–151 (2000).

M. Usta, I. Ozbek, C. Bindal, A. H. Ucisik, S. Ingole, and H. Liang, “A comparative study of borided pure niobium, tungsten and chromium,” Vacuum 80, 1321–1325 (2006).

E. N. Eremina, V. V, Kurbatkina, E. A. Levashov, A. S. Rogachev, and N. A. Kochetov, “Obtaining the composite MoB material by means of force SHS compacting with preliminary mechanical activation of Mo–10% B mixture.” Chem. Sustainable Dev. 13, 197–204 (2005).

V. V. Kurbatkina, E. A. Levashov, E. I. Patsera, N. A. Kochetov, and A. S. Rogachev, “Combustion and formation in the mechanoactivated Cr–B system,” Int. J. Self-Propag. High-Temp. Synth. 17, 189–194 (2008).

T. S. Azatyan, V. M. Mal’tsev, A. G. Merzhanov, and V. A. Seleznev, “Combustion wave propagation mechanism in titanium–boron mixtures,” Combust., Explos. Shock Waves 16, 163–167 (1980).

F. V. Kiryukhantsev-Korneev, “Elemental analysis of coatings by high-frequency glow discharge optical emission spectroscopy,” Prot. Met. Phys. Chem. Surf. 48, 585–590 (2012).

D. V. Shtansky, S. A. Kulinich, E. A. Levashov, A. N. Sheveiko, Ph. V. Kiryukhantsev-Korneev, and J. J. Moore, “Localized deformation of multicomponent thin films,” Thin Solid Films 420–421, 330–337 (2002).

D. V. Shtansky, K. A. Kuptsov, Ph. V. Kiryukhantsev-Korneev, and A. N. Sheveyko, “High thermal stability of TiAlSiCN coatings with “comb” like nanocomposite structure,” Surf. Coat. Technol. 206, 4840–4849 (2012).

S. A. Glatz, C. M. Koller, H. Bolvardi, S. Kolozsvári, H. Riedl, and P. H. Mayrhofer, “Influence of Mo on the structure and the tribomechanical properties of arc evaporated Ti–Al–N,” Surf. Coat. Technol. 311, 330–336 (2017).

J. M. Wheeler, R. Raghavan, V. Chawla, M. Morsteinb, and J. Michlera, “Deformation of hard coatings at elevated temperatures,” Surf. Coat. Technol. 254, 382–387 (2014).

D. Peak, G. W. Luther III, and D. L. Sparks, “ATRFTIR spectroscopic studies of boric acid adsorption on hydrous ferric oxide,” Geochim. Cosmochim. Acta 67, 2551–2560 (2003).

A. Najafi, F. Golestani-Farda, H. R. Rezaiea, and N. Ehsania, “Effect of APC addition on precursors properties during synthesis of B4C nano powder by a sol–gel process,” J. Alloys Compd. 509, 9164–9170 (2011).

D. Tsiourvas, A. Tsetsekou, M. Arkas, S. Diplas, and E. Mastrogianni, “Covalent attachment of a bioactive hyperbranched polymeric layer to titanium surface for the biomimetic growth of calcium phosphates,” J.Mater. Sci.: Mater. Med. 22, 85–96 (2011).

Y. Toshiya, “In-situ observation of Mo–O stretching vibrations during the reduction of Mo–O, with hydrogen by diffuse reflectance ftir spectroscopy,” Appl. Surf. Sci. 40, 179–181 (1989).

Z.-H. Zhou, H. Wang, P. Yu, M. M. Olmstead, and S. P. Cramer, “Structure and spectroscopy of a bidentate bis-homocitrate dioxo-molybdenum(VI) complex: Insights relevant to the structure and properties of the FeMo-cofactor in nitrogenase,” J. Inorg. Biochem. 118, 100–106 (2013).

T. Rainer, “Determination of the H3BO3 concentration in fluid and melt inclusions in granite pegmatites by laser Raman microprobe spectroscopy,” Am. Mineral. 87, 56–68 (2002).

Sassolite R060496. http://rruff.info/chem=H,%20B, %20O/display=default/ R060496.

L. Karlsson, L. Hultman, M. P. Johansson, J.-E. Sundgren, and H. Ljungcrantz, “Growth, microstructure, and mechanical properties of arc evaporated TiCxN1–x (0 = x =1) films,” Surf. Coat. Technol. 126, 1–14 (2000).

A. Leyland and A. Matthews, “On the significance of the H/E ratio in wear control: A nanocomposite coating approach to optimized tribological behavior,” Wear 246, 1–11 (2000).

E. A. Levashov, M. I. Petrzhik, D. V. Shtansky, Ph. V. Kiryukhantsev-Korneev, A. N. Sheveiko, R. Z. Valiev, D. V. Gunderov, S. D. Prokoshkin, A. V. Korotitskiy, and A. Yu. Smolin, “Nanostructured titanium alloys and multicomponent bioactive films: Mechanical behavior at indentation,” Mater. Sci. Eng., A 570, 51–62 (2013).

F. V. Kiryukhatsev-Korneev, N. A. Shirmanov, A. N. Sheveyko, E. A. Levashov, M. I. Petrzhik, and D. V. Shtansky, “Nanostructural wear-resistant coatings produced on metal-cutting tools by electric-arc evaporation and magnetron sputtering,” Russ. Eng. Res. 30, 910–920 (2010).

C.-H. Cheng, J. W. Lee, L. W. Ho, H.-W. Chen, Y.-C. Chan, and J.-G. Duh, “Microstructure and mechanical property evaluation of pulsed DC magnetron sputtered Cr–B and Cr–B–N films,” Surf. Coat. Technol. 206, 1711–1719 (2011).

Ph. V. Kiryukhantsev-Korneev, J. F. Pierson, M. Y. Bychkova, O. S. Manakova, E. A. Levashov, and D. V. Shtansky, “Comparative study of sliding, scratching, and impact-loading behavior of hard CrB2 and Cr–B–N films,” Tribol. Lett. 63, 44 (2016).

F. V. Kiryukhatsev-Korneev, P. A. Trukhanov, A. V. Bondarev, N. V. Shvyndina, and E. A. Levashov, “Structure and properties of tribological coatings in Cu–B system,” Phys. Met. Metallogr. 115, 716–722 (2014).

F. V. Kiryukhatsev-Korneev, M. I. Petrzhik, A. N. Sheveyko, E. A. Levashov, and D. V. Shtansky, “Effect of Al, Si and Cr on thermal stability and high temperature oxidation resistance of coatings based on titanium boronitride,” Phys. Met. Metallogr. 104, 167–174 (2007).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © F.V. Kiryukhantsev-Korneev, A.V. Novikov, T.B. Sagalova, M.I. Petrzhik, E.A. Levashov, D.V. Shtansky, 2017, published in Fizika Metallov i Metallovedenie, 2017, Vol. 118, No. 11, pp. 1202–1213.

Rights and permissions

About this article

Cite this article

Kiryukhantsev-Korneev, F.V., Novikov, A.V., Sagalova, T.B. et al. A comparative study of microstructure, oxidation resistance, mechanical, and tribological properties of coatings in Mo–B–(N), Cr–B–(N) and Ti–B–(N) systems. Phys. Metals Metallogr. 118, 1136–1146 (2017). https://doi.org/10.1134/S0031918X17110059

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X17110059