Abstract

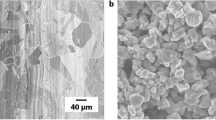

The effect of B additions on the structure and mechanical and tribological properties of Cu coatings produced by magnetron sputtering from mosaic targets has been investigated. It has been shown that the introduction of B results in structure refinement of the coatings. The hardness, elasticity modulus, elastic recovery, and plasticity index of Cu-B coatings have been determined. It has been established that the introduction of 7–15 at % of boron favors a decrease in the coefficient of friction and reduced wear. It has been shown that high tribological characteristics of coatings in the Cu-B system are connected with the formation of solid H3BO3 lubrication on the coating surface.

Similar content being viewed by others

References

P. H. Mayrhofer, C. Mitterer, L. Hultman, and H. Ciemens, “Microstructural design of hard coatings,” Prog. Mater. Sci. 51, 1032–1114 (2006).

M. Ghorbani, A. Mazaheri, and A. Afshar, “Wear and friction characteristics of electrodeposited graphitebronze composite coatings,” Surf. Coat. Technol. 190, 32–38 (2005).

M. Ghorbani, K. Mazaheri, Y. Khangholi, and Y. Kharazi, “Electrodeposition of graphite-brass composite coatings and characterization of the tribological properties,” Surf. Coat. Technol. 148, 71–76 (2001).

M. Musil, Z. Louda, M. Soukup, and M. Kubásek, “Relationship between mechanical properties and coefficient of friction of sputtered a-C/Cu composite thin films,” Diamond Relat. Mater. 17, 1905–1911 (2008).

T. Kubart, L. Polcar, R. Kopecky, D. Novak, and D. Novakova, “Temperature dependence of tribological properties of MoS2 and MoSe2 coatings,” Surf. Coat. Technol. 193, 230–233 (2005).

W. D. Münz, “Large-scale manufacturing of nanoscale multilayered hard coatings deposited by cathodic arc/unbalanced magnetron sputtering,” MRS Bull. 28, 173–179 (2003).

N. M. Renevier, N. Lobiondo, V. C. Fox, D. G. Teer, and J. Hampshire, “Performance of MoS2/metal composite coatings used for dry machining and other industrial applications,” Surf. Coat. Technol. 123, 84–91 (2000).

J. M. Carrapichano, J. R. Gomes, and R. F. Silva, “Tribological behavior of Si3N4-BN ceramic materials for dry sliding applications,” Wear 223, 1070–1076 (2002).

B. Navinsek, P. Panjan, M. Cekada, and D. T. Quinto, “Interface characterization of combination hard/solid lubricant coatings by specific methods,” Surf. Coat. Technol. 154, 194–203 (2002).

A. Erdemir, R. A. Erck, and J. Robles, “Relationship of Hertzian contact pressure to friction behavior of self-lubricating boric acid films,” Surf. Coat. Technol. 49, 435–438 (1991).

Modern Tribology Handbook, Vol. 2, Ed. by B. Erdemir and B. Bhushan (CRC, Boca Raton, 2001), pp. 787–825.

I. L. Singer, S. D. Dvorak, K. J. Wahl, and T. W. Scharf, “Role of third bodies in friction and wear of protective coatings,” J. Vacuum Sci. Technol., A 21, 232–240 (2003).

B. Prakash and J. P. Celis, “Plasma immersion ion implanted Ti-B-based coatings: Tribological behavior at room and high temperatures,” Surf. Coat. Technol. 200, 182–185 (2005).

C. Higdon, B. Cook, J. Haringa, A. Russell, J. Goldsmith, J. Qu, and P. Blau, “Friction and wear mechanisms in AlMgB14-TiB2 nanocoatings,” Wear 271, 2111–2115 (2011).

M. Mori, T. Shibayanagi, M. Maeda, and M. Naka, “Characteristics of nanostructured Cr-B films produced by RF magnetron sputtering,” Scr. Mater. 44, 2035–2038 (2001).

M. Mikula, B. Grančič, V. Buršikova, A. Csuba, M. Držik, Š. Kavecký, A. Plecenik, and P. Kúš, “Mechanical properties of superhard TiB2 coatings prepared by DC magnetron sputtering,” Vacuum 82, 278–281 (2008).

Y. Wu, Ch. Li, X. Liu, and K. Lu, “In situ formation of superhard Cu-B based composite by reducing reaction,” J. Alloys Compd. 527, 184–187 (2012).

N. Schalk, T. Weirather, C. Polzer, P. Polcik, and C. Mitterer, “A comparative study on Ti1 − x AlxN coatings reactively sputtered from compound and from mosaic targets,” Surf. Coat. Technol. 205, 4705–4710 (2011).

K. Singh, A. C. Bidaye, and A. K. Suri, “Experimental verification of model for prediction of coating composition deposited by sputtering using mosaic target in nitrogen,” Vacuum 86, 56–61 (2011).

S. A. Shiryaev, M. V. Atamanov, M. I. Guseva, Yu. V. Martynenko, A.V. Mitin, V.S. Mitin, and P. G. Moskovkin, “Production and properties of metal-carbon composite coatings with a nanocrystalline structure,” Tech. Phys. 47, 238–243 (2002).

M. Audronis, P. J. Kelly, R. D. Arnell, A. Leyland, and A. Matthews, “Deposition of multicomponent chromium boride based coatings by pulsed magnetron sputtering of powder targets,” Surf. Coat. Technol. 200, 1616–1623 (2005).

Ph. V. Kiryukhantsev-Korneev, “Elemental analysis of coatings by high-frequency glow discharge optical emission spectroscopy,” Prot. Metals Phys. Chem. Surf. 48, 585–590 (2012).

B. A. Movchan and A. V. Demchishin, “Study of structure and properties of nickel, titanium, tungsten, aluminum oxide and zirconium dioxide thick vacuum condensates,” Fiz. Met. Metalloved. 28, 653–660 (1969).

D. J. Chakrabarti and D. E. Laughlin, Phase Diagrams of Binary Copper Alloys (ASM Int., Materials Park, Ohio, 1994).

H. Werheit, V. Filipov, U. Kuhlmann, U. Schwarz, M. Armbrüter, A. Leithe-Jasper, T. Tanaka, I. Higashi, T. Lundström, V. N. Gurin, and M. M. Korsukova, “Raman effect in icosahedral boron-rich solids,” Sci. Technol. Adv. Mater. 11, 1–27 (2010).

I. Dreiling, C. Raisch, J. Glaser, D. Stiens, and T. Chassé, “Characterization and oxidation behavior of MTCVD Ti-B-N coatings,” Surf. Coat. Technol. 206, 479–486 (2011).

S. Chowdhury, M. T. Laugier, and I. Z. Rahman, “Characterization of DLC coatings deposited by RF magnetron sputtering,” J. Mater. Proc. Technol. 153–154, 804–810 (2004).

E. A. Levashov, M. I. Petrzhik, Ph. V. Kiryukhantsev- Korneev, D. V. Shtansky, S. D. Prokoshkin, A. N. Sheveiko, A.V. Korotitsky, D. V. Gunderov, and R. Z. Valiev, “Structure and mechanical behavior during indentation of biocompatible nanostructured titanium alloys and coatings,” Metallurgist 56, 395–407 (2012).

E. A. Levashov, M. I. Petrzhik, D. V. Shtansky, Ph. V. Kiryukhantsev-Korneev, A. N. Sheveyko, R. Z. Valiev, D. V. Gunderov, S. D. Prokoshkin, A. V. Korotitskiy, and A. Yu. Smolin, “Nanostructured titanium alloys and multicomponent bioactive films: Mechanical behavior at indentation,” Mater. Sci. Eng., A 570, 51–62 (2013).

Yu. V. Milman, A. A. Golubenko, and S. N. Dub, “Indentation size effect in nanohardness,” Acta Mater. 59, 7480–7487 (2011).

M. Yu. Gutkin and I. A. Ovid’ko, “Yield strength and plastic deformation of nanocrystalline materials,” Usp. Mech. 2, 68–125 (2003).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © Ph.V. Kiryukhantsev-Korneev, P.A. Trukhanov, A.V. Bondarev, N.V. Shvyndina, E.A. Levashov, 2014, published in Fizika Metallov i Metallovedenie, 2014, Vol. 115, No. 7, pp. 763–770.

Rights and permissions

About this article

Cite this article

Kiryukhantsev-Korneev, P.V., Trukhanov, P.A., Bondarev, A.V. et al. Structure and properties of tribological coatings in Cu-B system. Phys. Metals Metallogr. 115, 716–722 (2014). https://doi.org/10.1134/S0031918X14040085

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X14040085