Abstract

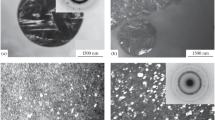

The results of the comparative analysis of the Ti50Ni25Cu25-alloy structures produced in the initial amorphous state by rapid quenching from the melt (RQM), after severe plastic deformation by torsion under high pressure (HPT), and postdeformation heat treatment (PHT) are presented. The study was carried out using neutron and X-ray diffraction, transmission and scanning electron microscopy, and measurements of electrical properties. The initially amorphous alloy has been established to nanocrystallize after torsion under a pressure of 7 GPa to 0.5 revolutions of the anvil. Then, after 1, 5, 10, and 15 rev, the alloy again undergoes the strain-induced amorphization even with the retention, even after 5–15 rev, of a large number of highly dispersed nanocrystals less than 3–4 nm in size with a distorted B2 lattice in the amorphous matrix. Their crucial role as nuclei of crystallization provides the total low-temperature nanocrystallization during subsequent annealing starting from 250–300°C. It is shown that PHT of the alloy amorphized by HPT makes it possible to produce extremely uniform nanocrystalline (NC), submicrocrystalline (SMC), or bimodal (NC + SMC) austenitic B2-type structures in it. A complete diagram of thermoelastic martensitic transformations in the region of B2-austenite states, from nanostructured state to conventional polycrystalline one, has been constructed. The size effect on the stabilization of martensitic transformation in nanocrystalline B2 alloy has been established.

Similar content being viewed by others

References

Otsuka, K., Shimizu, K., Suzuki, Y., Sekiguchi, Y., Tadaki, C., Honma, T., and Miyazaki, S., Shape Memory Alloys, Ed. by H. Funakubo (Kyoto, 1984; Metallurgiya, Moscow, 1990) [in Russian].

V. N. Khachin, V. G. Pushin, and V. V. Kondrat’ev, Titanium Nickelide: Structure and Properties (Nauka, Moscow, 1992) [in Russian].

V. G. Pushin, V. V. Kondrat’ev, and V. N. Khachin, Pretransition Effects and Martensite Transformations (Ural. Otd. Ross. Akad. Nauk, Ekaterinburg, 1998) [in Russian].

V. N. Zhuravlev and V. G. Pushin, Alloys with Thermomechanical Memory and Their Application in Medicine (Ural. Otd. Ross. Akad. Nauk, Ekaterinburg, 2000) [in Russian].

V. G. Pushin, S. D. Prokoshkin, R. Z. Valiev, et al., Titanium Nickelide Shape Memory Alloys. Part 1. Structure, Phase Transformations and Properties (Ural. Otd. Ross. Akad. Nauk, Ekaterinburg, 2006) [in Russian].

V. G. Pushin, “Alloys with a Thermomechanical Memory: Structure, Properties and Application,” Phys. Met. Metallogr. 90(Suppl. 1), S68–S95 (2000).

V. G. Pushin, “Structures, Properties, and Application of Nanostructured Shape Memory TiNi-Based Alloys,” in Nanomaterials by Severe Plastic Deformation, Ed. by M. Zehetbauer and R. Valiev (Wiley, Weinheim. 2004), pp. 822–828.

V. B. Fedorov, V. G. Kurdyumov, D. K. Khakimova, E. N. Yakovlev, I. D. Gorokhov, E. V. Tat’yanin, and O. K. Belousov, “Dispersion Effect at Plastic Deformation of Titanium Nickelide,” Dokl. Akad. Nauk SSSR 269(4), 885–888 (1983).

S. D. Prokoshkin, V. Brailovskii, A. V. Korotitskii, K. E. Inaekyan, and A. M. Glezer, “Specific Features of the Formation of the Microstructure of Titanium Nickelide upon Thermomechanical Treatment Including Cold Plastic Deformation to Degrees from Moderate to Severe,” Phys. Met. Metallogr. 110, 289–304 (2010).

E. V. Tat’yanin, V. G. Kurdyumov, and V. B. Fedorov, “Formation of TiNi Amorphous Alloy upon Shear Deformation under Pressure,” Fiz. Met. Metalloved. 62(1), 133–137 (1986).

V. G. Pushin, L. I. Yurchenko, and T. G. Koroleva, “Formation of Nanocrystalline Structure in TiNi-Based Bulk Alloys with Shape-Memory Effect,” in Structure and Properties of Nanocrystalline Materials (Ekaterinburg, 1999), pp. 77–82 [in Russian].

V. G. Pushin, V. V. Stolyarov, R. Z. Valiev, N. I. Kourov, N. N. Kuranova, E. A. Prokofiev, and L. I. Yurchenko, “Development of Methods of Severe Plastic Deformation for the Production of High-Strength Alloys Based on Titanium Nickelide with a Shape Memory Effect,” Phys. Met. Metallogr. 94(Suppl. 1), S54–S68 (2002).

V. G. Pushin, V. V. Stolyarov, R. Z. Valiev, N. I. Kourov, N. N. Kuranova, E. A. Prokofiev, and L. I. Yurchenko, “Features of Structure and Phase Transformations in Shape Memory TiNi-Based Alloys after Severe Plastic Deformation,” An. Chim. Sci. Mater. 27(3), 77–88 (2002).

A. V. Sergueeva, C. Song, R. Z. Valiev, and A. K. Mukherjee, “Structure and Properties of Amorphous and Nanocrystalline NiTi Prepared by Severe Plastic Deformation and Annealing,” Mater. Sci. Eng., A 339, 159–165 (2003).

V. G. Pushin, D. V. Gunderov, N. I. Kourov, L. I. Yurchenko, E. A. Prokofiev, V. V. Stolyarov, Y. T. Zhu, and R. Z. Valiev, “Nanostructures and Phase Transformations in Shape Memory TiNi-Based Alloys Subjected to Severe Plastic Deformation,” Proc. Int. Conf. on Ultrafine Grained Materials III, 2004, Ed. by Yu. T. Zhu, T. G. Langdon, R. Z. Valiev et al., pp. 481–486.

J. Y. Huang, Y. T. Zhu, X. Z. Liao, and R. Z. Valiev, “Amorphization of TiNi Induced by High-Pressure Torsion,” Philos. Mag. Lett. 84(3), 183–190 (2004).

T. Waitz, V. Kazykhanov, and H. P. Karnthaler, “Martensitic Phase Transformations in Nanocrystalline NiTi Studied by TEM,” Acta Mater. 52, 137–147 (2004).

S. D. Prokoshkin, I. Yu. Khmelevskaya, S. V. Dobatkin, I. B. Trubitsina, E. V. Tat’yanin, V. V. Stolyarov, and E. A. Prokof’ev, “Structure Evolution upon Severe Plastic Deformation of TiNi-Based Shape-Memory Alloys,” Phys. Met. Metallogr. 97, 619–625 (2004).

S. D. Prokoshkin, I. Yu. Khmelevskaya, S. V. Dobatkin, I. B. Trubitsyna, E. V. Tatyanin, V. V. Stolyarov, and E. A. Prokofiev, “Alloy Composition, Deformation Temperature, Pressure and Post-Deformation Annealing Effects in Severely Deformed Ti-Ni-Based Shape Memory Alloys,” Acta Mater. 53, 2703–2714 (2005).

S. D. Prokoshkin, I. Yu. Khmelevskaya, S. V. Dobatkin, E. V. Tatyanin, and I. B. Trubitsyna, “Studies of Severe Plastic Deformation Conditions for Amorphous and Nanocrystalline Structures Formation in Ti-Ni-Based Alloys,” Mater. Sci. Forum 503–504, 481–486 (2006).

V. G. Pushin, R. Z. Valiev, Y. T. Zhu, D. V. Gunderov, A. V. Korolev, N. I. Kourov, T. E. Kuntsevich, E. Z. Valiev, and L. I. Yurchenko, “Effect of Severe Plastic Deformation on the Behavior of Ti-Ni Shape Memory Alloys,” Mater. Trans. 47, 694–697 (2006).

D. V. Gunderov, N. N. Kuranova, A. V. Luk’yanov, A. N. Uksusnikov, E. A. Prokof’ev, L. I. Yurchenko, R. Z. Valiev, and V. G. Pushin, “Application of Severe Plastic Deformation by Torsion to Form Amorphous and Nanocrystalline States in Large-Size TiNi Alloy Sample,” Phys. Met. Metallogr. 108, 131–138 (2009).

N. N. Kuranova, D. V. Gunderov, A. N. Uksusnikov, A. V. Luk’yanov, L. I. Yurchenko, E. A. Prokof’ev, V. G. Pushin, and R. Z. Valiev, “Effect of Heat Treatment on the Structural and Phase Transformations and Mechanical Properties of TiNi Alloy Subjected to Severe Plastic Deformation by Torsion,” Phys. Met. Metallogr. 108, 556–568 (2009).

N. N. Kuranova, V. V. Makarov, V. G. Pushin, A. N. Uksusnikov, R. Z. Valiev, D. V. Gunderov, A. V. Luk’yanov, and E. A. Prokof’ev, “Amorphisation of Bulk TiNi-Based Alloys by Severe Plastic Deformation under High Pressure Torsion,” Bull. Russ. Acad. Sci.: Phys. 73, 1117–1119 (2009).

V. G. Pushin, S. B. Volkova, and N. M. Matveeva, “Structural and Phase Transformations in Quasi-Binary TiNi-TiCu Alloys Rapidly Quenched from the Melt: I. High-Copper Amorphous Alloys,” Phys. Met. Metallogr. 83, 275–282 (1997).

V. G. Pushin, S. B. Volkova, and N. M. Matveeva, “Structural and Phase Transformations in Quasi-Binary TiNi-TiCu Alloys Rapidly Quenched from the Melt: II. Alloys with Mixed Amorphous-Crystalline Structure,” Phys. Met. Metallogr. 83(3), 283–288 (1997).

V. G. Pushin, S. B. Volkova, and N. M. Matveeva, “Structural and Phase Transformations in Quasi-Binary TiNi-TiCu Alloys Rapidly Quenched from the Melt: III. Mechanisms of Crystallization,” Phys. Met. Metallogr. 83, 435–443 (1997).

V. G. Pushin, S. B. Volkova, N. M. Matveeva, L. I. Yurchenko, and A. S. Chistyakov, “Structural and Phase Transformations in Quasi-Binary TiNi-TiCu Alloys Rapidly Quenched from the Melt: IV. The Microstructure of Crystalline Alloys,” Phys. Met. Metallogr. 83, 673–678 (1997).

V. G. Pushin, S. B. Volkova, N. M. Matveeva, L. I. Yurchenko, and A. S. Chistyakov, “Structural and Phase Transformations in Quasi-Binary TiNi-TiCu Alloys Rapidly Quenched from the Melt: V. Effect of Heat Treatment,” Phys. Met. Metallogr. 83, 679–683 (1997).

V. G. Pushin, S. B. Volkova, N. M. Matveeva, L. I. Yurchenko, and A. S. Chistyakov, “Structural and Phase Transformations in Quasi-Binary TiNi-TiCu Alloys Rapidly Quenched from Melt: VI. Martensitic Transformations,” Phys. Met. Metallogr. 84, 441–448 (1997).

N. M. Matveeva, V. G. Pushin, A. V. Shelyakov, Yu. A. Bykovskii, S. B. Volkova, and V. S. Kraposhin, “Effect of the Conditions of Crystallization of Amorphous TiNi-TiCu Alloys on their Structure and Shape Memory,” Phys. Met. Metallogr. 83, 626–632 (1997).

R. Z. Valiev, V. G. Pushin, D. V. Gunderov, and A. G. Popov, “The Use of Severe Deformations for Preparing Bulk Nanocrystalline Materials from Amorphous Alloys,” Dokl. Phys. 49, 519–521 (2004).

D. V. Gunderov, V. G. Pushin, R. Z. Valiev, and E. Z. Valiev, “Structural and Phase Transformations in Amorphous Rapidly Quenched Ti-Ni-Cu Alloy Subjected to Intensive Plastic Deformation and Heat Treatment,” Deform. Razrush. Mater., No. 4, 22–25 (2006).

G. I. Nosova, A. V. Shalimova, R. V. Sundeev, A. M. Glezer, M. N. Pankova, and A. V. Shelyakov, “An Observation of Amorphous-Crystalline Phase Transitions at Severe Plastic Deformation of the Ti50Ni25Cu25 Alloy,” Crystallogr. Rep. 54, 1058–1065 (2009).

A. M. Glezer, G. I. Nosova, R. V. Sundeev, and A. V. Shalimova, “Phase Transformations in Crystalline Ti-Ni-Cu Alloy upon Severe Plastic Deformation,” Bull. Russ. Acad. Sci.: Phys. 74, 1515–1521 (2010).

Author information

Authors and Affiliations

Additional information

Original Russian Text © V.G. Pushin, N.N. Kuranova, A.V. Pushin, E.Z. Valiev, N.I. Kourov, A.E. Teplykh, A.N. Uksusnikov, 2012, published in Fizika Metallov i Metallovedenie, 2012, Vol. 113, No. 3, pp. 286–298.

Rights and permissions

About this article

Cite this article

Pushin, V.G., Kuranova, N.N., Pushin, A.V. et al. Formation of nanocrystalline structure in the amorphous Ti50Ni25Cu25 alloy upon severe thermomechanical treatment and the size effect of the thermoelastic martensitic B2 ↔ B19 transformation. Phys. Metals Metallogr. 113, 271–282 (2012). https://doi.org/10.1134/S0031918X1203012X

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X1203012X