Abstract

To obtain high performance CH3NH3PbI3 perovskite solar cells, it is highly important to realise a high open-circuit voltage. Calculation results based on a modified diode model have indicated that a low bare ratio ϕ of the perovskite film is the most important factor determining the open-circuit voltage, where ϕ is defined as the ratio of the projection of the uncovered area of the perovskite film to the apparent area of the total substrate surface. To realise a low ϕ, we investigate the nucleation behaviour of crystals on rough substrates. The analysis results predict that, when CH3NH3PbI3 is deposited on conventional transparent conductive oxide substrates such as fluorine-doped tin oxide, preferential heterogeneous nucleation will occur on the concave regions of the substrate; then, depending on the subsequent growth step, full coverage of the perovskite film at both the macroscopic and microscopic scales is realised. As a result, an ultra-high open-circuit voltage, i.e., 1.20 V, can be achieved in devices using the full coverage CH3NH3PbI3 film. The thermodynamics theory of precipitation nucleation should shed light on solution engineering of thin films.

Similar content being viewed by others

Introduction

Perovskite solar cells (PSCs) are another promising candidate, after dye-sensitised solar cells, for converting sunlight to electricity1,2. Many efforts have been made to improve their conversion efficiency3,4,5. A high open-circuit voltage (Voc) is known to be important for obtaining high conversion efficiency. Previous results suggested that a Voc exceeding 1.1 V may have been obtained in CH3NH3PbI3 PSCs by reducing the non-radiative losses6,7. Recently, Snaith et al.8 even estimated that the maximum Voc is close to 1.3 V for CH3NH3PbI3 PSCs and can be realised by filling the deep traps in the material. The ideal Voc is higher than the normally reported value of ~1.0 V9,10,11,12; therefore, it is vital to identify the factors determining Voc to realise a high Voc.

The I−V properties of heterojunction solar cells can be analysed using the diode model13,14. According to the diode model, when the shunt resistance Rsh is large enough, Voc can be determined from the photo-irradiated constant current (JL) and reverse saturated current of a PN junction diode (J0) because  , where A is the ideality factor of a heterojunction, KB is the Boltzmann constant, T is the absolute temperature, and e is the elementary charge13,15. However, the shunt resistance Rsh is not always large enough16,17,18; for example, a Schottky-based CsSnI3 solar cell showed a Voc of 0.42 V at a low Rsh. Therefore, Voc is influenced not only by JL and J0, but also by Rsh. In PSCs with planar configuration, which are more suitable for industrial roll-to-roll processes19,20,21, the perovskite film is sandwiched between the electron transport layer and hole transport layer22,23,24. Because the perovskite film always exhibits incomplete coverage when it is deposited by a one-step solution deposition process25,26,27, both shunting pathways and deleterious effects on charge dissociation, transport and recombination will be introduced in the uncovered areas28,29,30,31, strongly degrading the shunt resistance Rsh. Therefore, to achieve a high Voc for planar PSCs, it is necessary to clarify the effect of non-full coverage areas on Voc.

, where A is the ideality factor of a heterojunction, KB is the Boltzmann constant, T is the absolute temperature, and e is the elementary charge13,15. However, the shunt resistance Rsh is not always large enough16,17,18; for example, a Schottky-based CsSnI3 solar cell showed a Voc of 0.42 V at a low Rsh. Therefore, Voc is influenced not only by JL and J0, but also by Rsh. In PSCs with planar configuration, which are more suitable for industrial roll-to-roll processes19,20,21, the perovskite film is sandwiched between the electron transport layer and hole transport layer22,23,24. Because the perovskite film always exhibits incomplete coverage when it is deposited by a one-step solution deposition process25,26,27, both shunting pathways and deleterious effects on charge dissociation, transport and recombination will be introduced in the uncovered areas28,29,30,31, strongly degrading the shunt resistance Rsh. Therefore, to achieve a high Voc for planar PSCs, it is necessary to clarify the effect of non-full coverage areas on Voc.

To reduce the shunt resistance Rsh resulting from the non-full coverage areas, it is necessary to control of the crystallisation process of perovskite films to obtain full coverage on both the macroscopic and microscopic scales. Nucleation is the second step to form the final crystals during the crystallization process, i.e. supersaturation, nucleation and growth up. The classical thermodynamics theory of nucleation states that the energy barrier for heterogeneous nucleation (nucleation on the substrate) is lower than that for homogeneous nucleation (nucleation in the solution). Consequently, heterogeneous nucleation on a substrate surface plays an important role in crystallisation of perovskite films32,33,34. In fact, previous results have proved that substrate surface modification (controlling the surface roughness and perovskite/substrate interface energy) is an effective way to enhance the coverage ratio35,36,37,38. Docampo et al.35 obtained coverage ratio of 80% for perovskite films on an indium tin oxide (ITO)/poly(3,4-ethylenedioxythiophene) polystyrene sulfonate (PEDOT:PSS) substrate and 90% on a fluorine-doped tin oxide (FTO)/PEDOT:PSS substrate under the same deposition conditions; the reason for the difference may be that FTO has a rougher surface than ITO. Surface treatment36,37, such as pre-deposition of 3-aminopropanoic acid on the ZnO substrate, can also greatly increase the perovskite film coverage ratio, mainly by increasing the substrate’s miscibility with perovskite crystals38. In addition, the surface properties of the substrate can also affect the microstructure of perovskite films32,39. However, classical heterogeneous nucleation shows a spherical crown morphology as well as a constant contact angle θ at the solution/substrate/nucleus interface, so it requires a uniform flat substrate surface. This is not the case for common substrates, such as FTO and ITO, which always have a rough surface40,41,42. Therefore, it is necessary to investigate the nucleation behaviour on rough substrates to control the crystallisation process of perovskite film.

In this study, the detrimental effect of areas of non-full coverage in perovskite films on the Voc value of planar PSCs was first investigated using a modified diode model. To reduce this effect, we further developed the thermodynamics theory of nucleation of perovskite on a rough substrate surface. On the basis of these analyses, full coverage of CH3NH3PbI3 films on rough substrates was experimentally realised. Finally, planar PSCs were assembled and exhibited a maximum Voc of 1.20 V owing to a limited shunt path in the solar cells.

Results and Discussion

Correlation between areas of non-full coverage of perovskite films and open-circuit voltage for planar configuration PSCs

Herein, we determine the correlation between the area of non-full coverage and the Voc value of planar PSCs using the diode model. In a standard diode model (Fig. 1a)13, there is only one recombination pathway (Rsh) in the cell. The I−V characteristic of a heterojunction solar cell are given by

Diode model for full coverage PSCs and non-full coverage PSCs: (a) standard diode model with zero bare ratio (ϕ = 0) and (b) modified diode model with bare ratio ϕ (0 < ϕ ≤ 100%). ϕ is defined as the ratio of the projection of the uncovered area in a perovskite film to the apparent area of the total solar cell. The configuration of both solar cells is FTO/compact layer (CL)/perovskite film (PVK)/hole transport material (HTM)/Au from bottom to top. JL is the light induced constant current. JD is the diffusion current of the PN junction. Rsh is the total shunt resistance of the solar cell. Rc is the shunt resistance when the perovskite film fully covers on the substrate surface.  is the shunt resistance in the covered areas.

is the shunt resistance in the covered areas.  is the shunt resistance in uncovered areas. Rs is the series resistance.

is the shunt resistance in uncovered areas. Rs is the series resistance.

In the open-circuit state (i.e., J ≈ 0 mA · cm2), Voc and Rsh have the following relationship:

where J is the current passed through the external circuit; V is the output voltage; Rsh is the shunt resistance, which results from the defects introduced by the preparation process and the material itself; and Rs is the series resistance, which consists of the sheet resistance of FTO and the contact resistance of the cell.

If the perovskite film does not fully cover on the substrate (Fig. 1b), it will create another recombination pathway to the cell because of direct contact between the compact layer (CL) and hole transport material (HTM) (see the model of the non-full coverage PSC in Fig. 1b). The bare ratio ϕ (0 ≤ ϕ ≤ 100%) is introduced to represent the degree of incomplete coverage; it is defined as the ratio of the projection of the area not covered by perovskite film to the apparent area of the total substrate surface. When ϕ = 0, the perovskite film fully covers the substrate surface. The standard diode model works in this ideal case, and Rsh is actually equivalent to Rc, where Rc is the shunt resistance for a perovskite film fully covering on the substrate surface. When ϕ = 100%, Rsh consists mainly of Rn−c, which is the shunt resistance when there is no perovskite film on the substrate. When 0 < ϕ < 100%, the Rsh value of the non-full coverage solar cell is the parallel of the shunt resistance in the covered areas ( ) and the shunt resistance in the uncovered areas (

) and the shunt resistance in the uncovered areas ( ). Considering the load connection between shunt resistance, the recombination resistance of the covered areas and uncovered areas can be expressed as

). Considering the load connection between shunt resistance, the recombination resistance of the covered areas and uncovered areas can be expressed as

Therefore, the total shunt resistance Rsh of the modified model is expressed as

If we substitute equations (3) and (4) into equation (5), then:

For the non-full coverage PSC, the photo-irradiated constant current  can be expressed as

can be expressed as

Using equations (6), (7) and (2), the following correlation can be established between the bare ratio ϕ and Voc:

Figure 2 shows the correlation between the bare ratio ϕ and Voc according to equation (8). The Voc decreases with increasing of the bare ratio ϕ, in good agreement with previous results of that showed Voc increases with the coverage ratio. The inset shows a magnified view of the curve for small ϕ. A critical point (ϕcritical) clearly appears in the relationship ϕ and Voc. When ϕ < ϕcritical, Voc remains almost constant. This case represents a full coverage PSC (FC SC). However, when ϕ > ϕcritical, a remarkable drop in Voc is observed with decreasing ϕ. This represents a non-full coverage PSC (N-FC SC). On the basis of previous results, ϕcritical is usually expected to be extremely small32,38,43,44,45,46,47,48. Therefore, the significant dependence of Voc on ϕ for ϕ < ϕcritical has generally been neglected, and the perovskite film is assumed have full coverage. When ϕ is larger than ϕcritical, it is hard to achieve a high Voc. To realise a high Voc, it is essential to realise perovskite films with a ϕ lower than ϕcritical.

Theory for nucleation on rough surface toward full coverage perovskite film

To realise a full coverage perovskite film by controlling the crystallisation process, it is essential to investigate the nucleation behaviour of crystals on a rough substrate surface. We consider the theory of nucleation on a rough substrate surface as follows. A rough substrate surface always consists of concave and convex regions. To simplify the quantitative description, the concavo-convex substrate surface is assumed to have axial symmetry, i.e., conical concaves existing on the substrate surface (Fig. 3a). As the cone angle β increases from 0° to 180° and then 360°, the substrate shape changes from convex to flat to concave (Supplementary Fig. S1). The contact angle θ is a function of the energy of the nucleu/substrate/precursor solution interface, which represents the wettability between the perovskite film and the substrate. Table 1 lists the relationship between the cone angle β and contact angle θ, and the detailed calculation processes are shown in equations (S2)–(S5) in the Supplementary Information. According to the calculation results, the energy barrier (ΔGHeter−rough) for nucleation on a rough substrate surface can be expressed by equations (9),(10),(11), and the detailed calculation processes are given in equations (S6)–(S21) in the Supplementary Information. Both the cone angle β and contact angle θ determine ΔGHeter−rough.

where σNuc−Sol is the free energy of the nucleus/solution interface.

Figure 3b shows the correlation between the energy barrier (ΔGHeter−rough) and cone angle β according to equation (11).ΔGHeter−rough decreases with increasing β, and it is always smaller than that for homogeneous nucleation (ΔGHomo, which corresponds to β = 0°) all the time. Therefore, for a constant contact angle θ, ΔGHeter−rough decreases following the sequence concave < flat < convex, indicating that heterogeneous nuclei form preferentially on sites in order from concave regions to flat regions and then convex regions as shown in Fig. 3c.

To prove this theory, we further performed an experimental validation by depositing CH3NH3PbI3 films with different thicknesses on FTO substrates to identify the nucleation sites. FTO with obvious concavo-convex fluctuation (feature diameter of ~186 nm and feature height of ~88 nm), which will be useful for observation, was selected as an example of a rough substrate. To determine where the nuclei prefer to form during precipitation, the entire substrate, including concave, flat, and convex regions, should be immersed in a supersaturated CH3NH3PbI3/N,N-dimethylformamide (DMF) solution during crystallisation process. This ensures the entire substrate has the same active energy for nucleation. In addition, considering the technical challenge of distinguishing the nucleation site in situ, the height of a CH3NH3PbI3 film should be smaller than the feature height (88 nm) of the FTO for convenient observation of the nucleation site. Finally, different initial precursors were chosen to obtain the as-prepared perovskite films with mean heights of 18 and 34 nm, and the detailed processes are shown in Fig. 4.

As shown in Fig. 4, first, we determined the thickness of the CH3NH3PbI3/DMF solution left on the substrate after spin coating by measuring the solution weight, which was done by measuring the weight difference between bare FTO and the CH3NH3PbI3/DMF/FTO after spin coating. To reduce the inaccuracy caused by evaporation of the DMF during the measurement, the ambient temperature was kept below 25 °C and the entire weight measurement process reguired less than 1 min. The saturation concentration of the CH3NH3PbI3/DMF solution is ~54.62 wt% at 25 °C. Therefore, when the thickness of the 2.43 wt% initial solution decreases to 138 nm and that of the 4.55 wt% initial solution decreases to 258 nm, they will be in the saturated state. In the saturated state, the thicknesses of the precursor solutions exceed the highest point of the substrate (~88 nm). When the solvent is completely evaporated, the as-prepared CH3NH3PbI3 films show the average heights of 18 and 34 nm, respectively. The height of all of the as-prepared films is below the highest point of the substrate (~88 nm).

The experimental validation results are shown in Supplementary Fig. S7 and S8, Supplementary Table S1, and Fig. 5a–c. The thickness of the perovskite film deposited on the FTO substrate is roughly evaluated by using atomic force microscopy (AFM) images. On basis of the AFM images (Supplementary Fig. S7), the bare FTO shows an average root mean square (RMS) roughness of 45.91 nm. After the precursors with initial concentrations of 2.43 to 4.55 wt% were deposited, the RMS roughness of the substrates decreased from 26.35 to 20.59 nm (Supplementary Fig. S8 and Supplementary Table S1), which illustrates that the perovskite crystals grow up from the concave region of the substrate. Fig. 5a shows the bare FTO substrate. When the perovskite film is about 18 nm thick, the surface of the CH3NH3PbI3/FTO electrode (Fig. 5b) resembles that of the FTO substrate. The CH3NH3PbI3 nanoparticles are concentrated in the valleys between the SnO2 grains. As the film thickness increases, the CH3NH3PbI3 nanoparticles appear more clearly between the SnO2 grains, as shown in Fig. 5c. In Fig. 5d, the quantitative grain size distribution decreases after CH3NH3PbI3 precipitation. This is because the CH3NH3PbI3 crystals cover the pristine morphology of the FTO substrate. Moreover, the grain size increases slightly as the mean film thickness increases from 18 to 34 nm. This behaviour can be attributed to growth of CH3NH3PbI3 crystals with increasing precursor quantity. These phenomena reveal that all the CH3NH3PbI3 grains form preferentially in concave regions rather than flat or convex region when nucleation begins. This fact directly proves the theory developed in this study; i.e., the ΔGHeter−rough value for nucleation is lower in concave regions than in flat or convex regions.

Surface morphologies of (a) bare FTO and the CH3NH3PbI3 films deposited on the rough FTO substrate with perovskite layers: having mean thicknesses of (b) 18 nm and (c) 34 nm. (d) Grain sizes of bare FTO and CH3NH3PbI3 crystals deposited on rough FTO substrate. Microstructures of a 240 nm-thick CH3NH3PbI3 film deposited on the FTO substrate surface using a precursor with a concentration of 30 wt%: (e) surface morphology and (f) cross-sectional view. (g) Schematic diagram of formation of full coverage CH3NH3PbI3 film assuming nucleation on concave regions.

According to the above results, a full coverage CH3NH3PbI3 film can be realised depending on the following three steps, as illustrated in Fig. 5g. First, nuclei appear on the concave regions of the substrate. Second, CH3NH3PbI3 crystals grow upward not only along the out-of-plane direction (perpendicular to the apparent substrate surface), but also along the in-plane direction (parallel to the apparent substrate surface) of the concavo-convex substrate. Third, the CH3NH3PbI3 crystals come to contact with each other in the crosswise direction during growth. Eventually, a full coverage CH3NH3PbI3 film on the substrate can be realised by further film growth and thickening. Fig. 5e shows an example of a ~240 nm-thick CH3NH3PbI3 film prepared by increasing the precursor concentration to 30 wt%. The CH3NH3PbI3 grains nucleated in the concave region and grew upward until they come into contact with each other to form grain boundaries (arrows in Fig. 5f). In addition, the CH3NH3PbI3 film tended to fit itself to the concavo-convex surface of the substrate. The X-ray diffraction (XRD) pattern of the perovskite film shows strong (110), (220), and (310) diffraction peaks and minor (112) and (211) peaks, which are consistent with the tetragonal perovskite phase (Supplementary Fig. S9)49.

Photovoltage of full coverage and non-full coverage PSCs

As shown in Fig. 2, a high Voc could be achieved by reducing of the bare ratio ϕ. Therefore, both the full coverage CH3NH3PbI3 films (ϕ < 3%) and the CH3NH3PbI3 films with the bare ratio of 3–6% were assembled into full coverage and non-full coverage PSCs, named as FC SC and N-FC SC separately. Supplementary Fig. S10 shows the cross-sectional views of both solar cells. The photovoltaic performance is shown in Fig. 6. For cell sizes of 0.245 and 0.717 cm2, the Voc values of the FC SCs range from 1.07 to 1.20 V, and the average value is 1.14 V, whereas those of the N-FC SCs range from 0.80 to 1.07 V, and the average value is 0.98 V. Comprehesive analysis the value of FC SC and N-FC SC, the decreasing of Voc is initially small when the bare ratio ϕ is low, and then, as ϕ increases, there is an obvious drop in Voc. Furthermore, several PSCs with higher bare ratio ϕ (~27%, ~35% and ~67%) were also assembled, and their photovoltaic parameters are listed in Supplementary Table S2. Supplementary Fig. S11 and Supplementary Table S3 show a simple correlation between ϕ and Voc based on the experiment data presented thus far. Though it is difficult to determine the concrete value of ϕcritical on basis of the experimental results in Supplementary Fig. S11, the correlation between ϕ and Voc is consistent with the prediction in Fig. 2. Note also that the devices show a maximum Voc of 1.2 V. This is the highest value reported to date for pure CH3NH3PbI3-based solar cells50. The typical current density−voltage (J−V) curves, taken with both forward and reverse scan, of the perovskite solar cells with Voc values of 1.2 and 0.87 V are shown in Supplementary Fig. S12 and Supplementary Table S4, and the detailed photovoltaic parameters of all the PSCs with a Voc of 1.2 V are listed in Supplementary Table S5. For the PSCs with a cell size of 0.245 cm2, the short circuit density (Jsc) increases slightly with increasing Voc, as shown in Supplementary Fig. S13, which may result from the decreased bare ratio ϕ of the perovskite film. Overall, the FC SCs show a higher conversion efficiency than the N-FC SCs, as shown in Supplementary Fig. S14.

From Supplementary Fig. S12, the Rsh values of both solar cells under forward and reverse scanning are estimated from the slope of J−V curve at low voltage. The FC SC shows an Rsh value of 972.88 Ω · cm2 (reverse scan), which is larger than the N-FC SC (Rsh = 384.49 Ω · cm2, reverse scan). To comprehensively represent the charge recombination ability of both solar cells, further characterisation are also presented. The photoluminescence (PL) intensities of the cells are comparable (Fig. 7a), which demonstrates that incompletely covered areas in a relatively high coverage state have a negligible effect on the PL intensity. Electrochemical impedance spectroscopy (EIS) results are shown in Fig. 7b. The arc at high frequencies is related to the charge transportation in 2,2′,7,7′-tetrakis(N,N-di-p-methoxyphenylamine) -9,9′-spirobifluorene (spiro-OMeTAD)51,52. In both spectras, because the conductivity of the hole transport material is large, the arc at high frequencies almost vanishes and cannot be observed. At low frequencies, a Gerischer (G) pattern is clearly identified. The G pattern consists of a straight line with a 45° slope followed by an arc lying below the extension of the straight line53. The G resistance (RG) is the square root of the product of the transport resistance (Rtr) and the recombination resistance (Rrec), so it cannot be separately determined53,54. The obtained EIS patterns were fitted using the equivalent circuit shown in the inset of Fig. 7b; the FC SC shows a larger RG (649 Ω) than the N-FC SC (RG = 481 Ω). Although Rrec cannot be directly estimated from RG, one can speculate that the FC SC has a larger RG value than N-FC SC because of the increased Rrec resulting from the decreased bare ratio of the perovskite film. The charge recombination mechanism can also be understood in terms of the dark current of both cells (Fig. 7c). The FC SC exhibits a much lower dark current density than the N-FC SC, indicating suppressed charge recombination in the former. This is related to the lower bare ratio of the perovskite film. To further characterise the output voltage capability of voltage of the cells under illumination, the net photocurrent (i.e., the difference between photocurrent and dark current densities versus the voltage, ΔJ) was tested (Fig. 7d). For a PN junction solar cell, if the dark current is negligible, Jsc is comparable to JL, which can be compensated by applying a bias equal to Voc. However, because the dark current is not negligible, Jsc will deviate from JL. There should be a compensating voltage V0 at which the net photocurrent is zero55,56. Therefore, V0 represents the upper limit of Voc56. The FC SC has a higher V0 (1.31 V) than the N-FC SC (V0 = 1.12 V), which implies that in principle the FC SC has a higher output voltage capability. In brief, with decreasing bare ratio, the PSCs showed an improved G resistance, a lower dark current and an improved compensation voltage because of the limited recombination circuit, which resulted in high Voc.

(a) Steady-state PL spectra of the FC and N-FC films. Charge transport and recombination processes in FC SCs and N-FC SCs: (b) Nyquist plot and (c) dark current. (d) Net photocurrent of the FC SCs and N-FC SCs. Inset in (b) shows the equivalent circuit proposed to fit the EIS data, and the dots and lines in (b) represent experimental data and fitting results, respectively.

Conclusion

In summary, a modified diode model is proposed to describe the work principle of planar configuration solar cells, in which a shunt path resulting from direct contact between the electron transport layer and hole transport layer is added to describe PSCs with incomplete film coverage. The calculated results show that when the bare ratio ϕ < ϕcritical, Voc remains almost constant, whereas when ϕ > ϕcritical, a slight increase in ϕ induces a remarkable drop in Voc. Furthermore, to decrease the bare area of the perovskite film, we investigated the thermodynamics theory of nucleation on a rough substrate surface by considering the assumed condition of a flat substrate in classical nucleation theory. The theoretical investigation showed that heterogeneous nuclei form preferentially on the concave regions of the substrate. Consequently, full coverage of the perovskite film on both the macroscopic and microscopic scales was realised according to the subsequent growth up. Finally, the full coverage PSCs exhibit an ultra-high Voc, i.e., 1.20 V for champion cells, which is the highest value reported to date. In brief, the heterogeneous nucleation theory afforded an in-depth understanding of the precipitation behaviour on a rough substrate surface and thus can contribute significantly to the development of high quality perovskite films and high performance PSCs.

Methods

Materials

Lead iodide (PbI2, purity >99.9%) and methylammonium (ICH3NH3, purity >99.9%) were purchased from Weihua Solar Co. Ltd.(China). DMF (purity >99.8%) was purchased from Sigma-Aldrich (Germany). Other materials were purchased from Xi’an Polymer Light Technology Corp (China). All the chemicals were used as received unless otherwise specified. Transparent FTO (TEC-15, LOF) conductive glass was employed as a substrate; the substrate were cleaned successively in ultrasonic acetone and alcohol baths and dried under high purity nitrogen gas.

Perovskite film preparation and characterisation

Precursor solutions of stoichiometric amounts of PbI2 and ICH3NH3 in DMF were prepared at different concentrations by stirring for more than 5 h at 70 °C. Before each perovskite film was prepared, the precursor solution was filtered using a polytetrafluoroethylene filter with a pore size of 0.22 μm. The solution was then dropped on the substrate and spin coating at 4000 rpm for 10 s; it was subsequently dried using a gas pump method57. All the processes were performed in atmosphere without inert gas protection. During film preparation, the ambient temperature was kept below 25 °C.

The microstructures of the CH3NH3PbI3 films were examined by field emission scanning electron microscopy (SEM, TESCAN, Czech Republic) and AFM (Innova, America). The crystalline structure of the films was characterised by XRD (SHIMADZU, Japan) using Cu Kα radiation. PL was measured using a steady state spectrophotometer (Fluoromax-4, Horiba Jobin Yvon, France) with an excitation wavelength of 560 nm. The bare ratio of the perovskite films was calculated from the SEM images using the Image J software (Image J2x, 2011), and the detailed statistical process is described in the Supplementary information as Fig. S15 and Fig. S16.

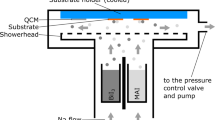

Planar configuration solar cell preparation and characterization

A thin compact ZnO film was sputtered on the etched FTO substrate (ZnO/FTO substrate) and then annealed at 120 °C for 15 min with a hot plate. Then the perovskite film was deposited on the ZnO/FTO substrate as illustrated in the perovskite film preparation and characterisation section. After the as-prepared perovskite film was annealed at 100 °C for 30 min, the spiro-OMeTAD solution was deposited by spin coating at 3000 rpm for 30 s. The spiro-OMeTAD solution was prepared by dissolving 80 mg of spiro-OMeTAD in 28.5 μl of 4-tert-butylpyridine and 17.5 μl of lithium-bis (trifluoromethanesulfonyl)imide (Li-TFSI) solution (520 mg of Li-TFSI in 1 ml of acetonitrile) in 1 ml chlorobenzene. Finally, an ~80 nm-thick Au layer was thermally deposited on the spiro-OMeTAD film layer.

The photocurrent (J−V) curves were measured using a Keithley 2400 digital source meter under simulated AM 1.5 sunlight at an irradiance of 100 mW cm−2 generated by a solar simulator (Oriel 94023 A, Newport, USA). To measure the dark current, the solar cells were measured without any illumination. The EIS spectra were measured using an electrochemical workstation (IM6, ZAHNER, Germany) under illumination and at an amplitude of 20 mV oover the frequency range from 10−1 to 106 Hz.

Additional Information

How to cite this article: Li, Y. et al. Ultra-high open-circuit voltage of perovskite solar cells induced by nucleation thermodynamics on rough substrates. Sci. Rep. 7, 46141; doi: 10.1038/srep46141 (2017).

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

Li, M. H., Yum, J. H., Moon, S. J. & Chen, P. Inorganic p-type semiconductors: their applications and progress in dye-sensitized solar cells and perovskite solar cells. Energies 9, 331 (2016).

Bella, F. Polymer electrolytes and perovskites: lights and shadows in photovoltaic devices. Electrochim. Acta 175, 151–161 (2015).

Kim, H. S. et al. Lead iodide perovskite aensitized all-solid-state submicron thin film mesoscopic solar cell with efficiency exceeding 9%. Sci. Rep. 2, 591 (2012).

Jung, M. C., Raga, S. R., Ono, L. K. & Qi, Y. B. Substantial improvement of perovskite solar cells stability by pinhole-free hole transport layer with doping engineering. Sci. Rep. 5, 9863 (2015).

Tavakoli, M. M. et al. Fabrication of efficient planar perovskite solar cells using a one-step chemical vapor deposition method. Sci. Rep. 5, 14083 (2015).

Yang, W. C., Yao, Y. & Wu, C. Q. Origin of the high open circuit voltage in planar heterojunction perovskite solar cells: Role of the reduced bimolecular recombination. J. Appl. Phys. 117, 095502 (2015).

Tress, W. et al. Predicting the open-circuit voltage of CH3NH3PbI3 perovskite solar cells using electroluminescence and photovoltaic quantum efficiency spectra: the role of radiative and non-radiative recombination. Adv. Energ. Mater 5, 1400812 (2015).

Com, T. L. et al. Carriers trapping and recombination: the role of defect physics in enhancing the open circuit voltage of metal halide perovskite solar cells. Energ. Environ. Sci. doi: 10.1039/C6EE01729K (2016).

Kim, J. et al. Efficient planar-heterojunction perovskite solar cells achieved via interfacial modification of a sol-gel ZnO electron collection layer. J. Mater. Chem. A 2, 17291–17296 (2014).

Guo, Y. et al. Enhancement in the efficiency of an organic-inorganic hybrid solar cell with a doped P3HT hole-transporting layer on a void-free perovskite active layer. J. Mater. Chem. A 2, 13827–13830 (2014).

Pascoe, A. R. et al. Enhancing the optoelectronic performance of perovskite solar cells via a textured CH3NH3PbI3 morphology. Adv. Funct. Mater. 26, 1278–1285 (2016).

Eperon, G. E. et al. Formamidinium lead trihalide: a broadly tunable perovskite for efficient planar heterojunction solar cells. Energ. Environ. Sci. 7, 982–988 (2014).

Shi, J. J. et al. Hole-conductor-free perovskite organic lead iodide heterojunction thin-film solar cells: High efficiency and junction property. Appl. Phys. Lett. 104, 063901 (2014).

Cojocaru, L. et al. Origin of the hysteresis in I-V curves for planar structure perovskite solar cells rationalized with a surface boundary-induced capacitance model. Chem. Lett. 44, 1750–1752 (2015).

Lian, J. R., Wang, Q., Yuan, Y. B., Shao, Y. C. & Huang, J. S. Organic solvent vapor sensitive methylammonium lead trihalide film formation for efficient hybrid perovskite solar cells. J. Mater. Chem. A 3, 9146–9151 (2015).

Subbiah, A. S. et al. Inorganic hole conducting layers for perovskite-based solar cells. J. Phys. Chem. Lett. 5, 1748–1753 (2014).

Chen, Z., Wang, J. J., Ren, Y. H., Yu, C. L. & Shum, K. Schottky solar cells based on CsSnI3 thin-films. Appl. Phys. Lett. 101, 093901 (2012).

Horantner, M. T. et al. Shunt-blocking layers for semitransparent perovskite solar cells. Adv. Mater. Inter. 3, 1500837 (2016).

Jung, J. W., Williams, S. T. & Jen, A. K. Y. Low-temperature processed high-performance flexible perovskite solar cells via rationally optimized solvent washing treatments. Rsc Adv. 4, 62971–62977 (2014).

Liu, D. Y. & Kelly, T. L. Perovskite solar cells with a planar heterojunction structure prepared using room-temperature solution processing techniques. Nat. Photonics 8, 133–138 (2014).

Schmidt, T. M., Larsen-Olsen, T. T., Carle, J. E., Angmo, D. & Krebs, F. C. Upscaling of perovskite solar cells: fully ambient roll processing of flexible perovskite solar cells with printed back electrodes. Adv. Energ. Mater. 5, 1500569 (2015).

Mali, S. S. & Hong, C. K. P-i-n/n-i-p type planar hybrid structure of highly efficient perovskite solar cells towards improved air stability: synthetic strategies and the role of p-type hole transport layer (HTL) and n-type electron transport layer (ETL) metal oxides. Nanoscale 8, 10528–10540 (2016).

Tseng, Z. L., Chiang, C. H. & Wu, C. G. Surface engineering of ZnO thin film for high efficiency planar perovskite solar cells. Sci. Rep. 5, 13211 (2015).

Jeon, Y. J. et al. Planar heterojunction perovskite solar cells with superior reproducibility. Sci. Rep. 4, 6953 (2014).

Salim, T. et al. Perovskite-based solar cells: impact of morphology and device architecture on device performance. J. Mater. Chem. A 3, 8943–8969 (2015).

Chueh, C. C. et al. The roles of alkyl halide additives in enhancing perovskite solar cell performance. J. Mater. Chem. A 3, 9058–9062 (2015).

Conings, B. et al. Perovskite-based hybrid solar cells exceeding 10% efficiency with high reproducibility using a thin film sandwich approach. Adv. Mater. 26, 2041–2046 (2014).

Qiu, W. et al. Pinhole-free perovskite films for efficient solar modules. Energ. Environ. Sci. 9, 484–489 (2016).

Min, J. et al. Interface engineering of perovskite hybrid solar cells with solution-processed perylene-diimide heterojunctions toward high performance. Chem. Mater. 27, 227–234 (2015).

Hsiao, Y. C., Wu, T., Li, M. X. & Hu, B. Magneto-optical studies on spin-dependent charge recombination and dissociation in perovskite solar cells. Adv. Mater. 27, 2899–2906 (2015).

Liu, Z. & Lee, E. C. Solvent engineering of the electron transport layer using 1,8-diiodooctane for improving the performance of perovskite solar cells. Org. Electron. 24, 101–105 (2015).

Bi, C. et al. Non-wetting surface-driven high-aspect-ratio crystalline grain growth for efficient hybrid perovskite solar cells. Nat. Commun. 6, 7747 (2015).

Tidhar, Y. et al. Crystallization of methyl ammonium lead halide perovskites: Implications for photovoltaic applications. J. Am. Chem. Soc. 136, 13249–13256 (2014).

Chen, C. C. et al. Perovskite/polymer monolithic hybrid tandem solar cells utilizing a low-temperature, full solution process. Mater. Horiz. 2, 203–211 (2015).

Docampo, P., Ball, J. M., Darwich, M., Eperon, G. E. & Snaith H. J. Efficient organometal trihalide perovskite planar-heterojunction solar cells on flexible polymer substrates. Nat. Commun. 4, 3761 (2013).

Zuo, L. J. et al. Enhanced photovoltaic performance of CH3NH3Pbl3 perovskite solar cells through interfacial engineering using self-assembling monolayer. J. Am. Chem. Soc. 137, 2674–2679 (2015).

Jeng, J. Y. et al. Nickel oxide electrode interlayer in CH3NH3PbI3 perovskite/PCBM planar-heterojunction hybrid solar cells. Adv. Mater. 26, 4107–4113 (2014).

Deng, H. et al. Growth, patterning and alignment of organolead iodide perovskite nanowires for optoelectronic devices. Nanoscale 7, 4163–4170 (2015).

Kim, J. H. et al. High-performance and environmentally stable planar heterojunction perovskite solar cells based on a solution-processed copper-doped nickel oxide hole-transporting layer. Adv. Mater. 27, 695–701 (2015).

Cojocaru, L. et al. Surface treatment of the compact TiO2 layer for efficient planar heterojunction peroyskite solar cells. Chem. Lett. 44, 674–676 (2015).

Pauporte, T. & Jirka, I. A method for electrochemical growth of homogeneous nanocrystalline ZnO thin films at room temperature. Electrochim. Acta 54, 7558–7564 (2009).

Wang, X. M., Fang, Y. L., He, L., Wang, Q. & Wu, T. Influence of compact TiO2 layer on the photovoltaic characteristics of the organometal halide perovskite-based solar cells. Mat. Sci. Semicon. Proc. 27, 569–576 (2014).

Dualeh, A. et al. Effect of annealing temperature on film morphology of organic-inorganic hybrid pervoskite solid-state solar cells. Adv Funct Mater 24, 3250–3258 (2014).

Chang, C. Y . et al. Tuning perovskite morphology by polymer additive for high efficiency solar cell. Acs Appl. Mater. Interfaces 7, 4955–4961 (2015).

Chueh, C. C. et al. The roles of alkyl halide additives in enhancing perovskite solar cell performance. J Mater. Chem. A 3, 9058–9062 (2015).

Huang, F. Z. et al. Gas-assisted preparation of lead iodide perovskite films consisting of a monolayer of single crystalline grains for high efficiency planar solar cells. Nano Energy 10, 10–18 (2014).

Xie, F. X. et al. Vacuum-assisted thermal annealing of CH3NH3PbI3 for highly stable and efficient perovskite solar cells. Acs Nano 9, 639–646 (2015).

Yan, K. Y. et al. Hybrid halide perovskite solar cell precursors: colloidal chemistry and coordination engineering behind device processing for high efficiency. J Am Chem Soc 137, 4460–4468 (2015).

Baikie, T. et al. Synthesis and crystal chemistry of the hybrid perovskite (CH3NH3)PbI3 for solid-state sensitised solar cell applications. J. Mater. Chem. A 1, 5628–5641 (2013).

Li, F. M. et al. Laser-assisted crystallization of CH3NH3PbI3 films for efficient perovskite solar cells with a high open-circuit voltage. Chem. Commun. 52, 5394–5397 (2016).

Hui-Seon, K. et al. Mechanism of carrier accumulation in perovskite thin-absorber solar cells. Nat Commun. 4, 375–381 (2013).

Dualeh, A., Moehl, T., Nazeeruddin, M. K. & Grätzel, M. Temperature dependence of transport properties of spiro-MeOTAD as a hole transport material in solid-state dye-sensitized solar cells. Acs Nano 7, 2292–2301 (2013).

Bisquert, J., Mora-Sero, I. & Fabregat-Santiago, F. Diffusion–recombination impedance model for solar cells with disorder and nonlinear recombination. Chemelectrochem 1, 289–296 (2013).

Gonzalez-Pedro, V. et al. General working principles of CH3NH3PbX3 perovskite solar cells. Nano Lett 14, 888–893 (2014).

Kim, H. S. et al. High efficiency solid-state sensitized solar cell-based on submicrometer rutile TiO2 Nanorod and CH3NH3PbI3 perovskite sensitizer. Nano. Lett. 13, 2412–2417 (2013).

Malliaras, G. G., Salem, J. R., Brock, P. J. & Scott, J. C. Photovoltaic measurement of the built-in potential in organic light emitting diodes and photodiodes. J. Appl. Phys. 84, 1583–1587 (1998).

Bin, D. et al. Facile and scalable fabrication of highly efficient lead iodide perovskite thin-film solar cells in air using gas pump method. Acs Appl. Mater. interfaces 8, 20067–20073 (2016).

Acknowledgements

This work was supported by the National Program for Support of Top-notch Young Professionals.

Author information

Authors and Affiliations

Contributions

G.-J. Y. designed and supervised the project; Y. L., B. D. and Q.-Q. C. conducted the experiments; Y. L., B. D., Q.-Q. C., G.-J. Y. and M.K. W. analysed the data; Y. L., B. D., G.-J. Y. and M.K. W. wrote the paper; all the authors contributed to discussions.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Li, Y., Ding, B., Chu, QQ. et al. Ultra-high open-circuit voltage of perovskite solar cells induced by nucleation thermodynamics on rough substrates. Sci Rep 7, 46141 (2017). https://doi.org/10.1038/srep46141

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep46141

This article is cited by

-

Engineering of antisolvent dripping for large-area perovskite solar cell fabrication under air ambient conditions

Journal of Materials Science: Materials in Electronics (2024)

-

Pivotal avenue for hybrid electron transport layer-based perovskite solar cells with improved efficiency

Scientific Reports (2023)

-

Numerical simulation study on the photovoltaic performance of tin-based perovskite solar cell using CuSCN as a hole transport layer giving 32% theoretical efficiency

Indian Journal of Physics (2023)

-

Cotton soot derived carbon nanoparticles for NiO supported processing temperature tuned ambient perovskite solar cells

Scientific Reports (2021)

-

Low-temperature-deposited SnO2 films for efficient planar CH3NH3PbI3 photovoltaics

Journal of Materials Science (2021)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.