Abstract

The preparation of thermochromic vanadium dioxide (VO2) films in an economical way is of interest to realizing the application of smart windows. Here, we reported a successful preparation of self-assembly VO2 nanoplate films on TiO2-buffered glass by a facile hydrothermal process. The VO2 films composed of triangle-shaped plates standing on substrates exhibit a self-generated porous structure, which favors the transmission of solar light. The porosity of films is easily controlled by changing the concentration of precursor solutions. Excellent thermochromic properties are observed with visible light transmittance as high as 70.3% and solar modulating efficiency up to 9.3% in a VO2 film with porosity of ~35.9%. This work demonstrates a promising technique to promote the commercial utilization of VO2 in smart windows.

Similar content being viewed by others

Introduction

Energy consumption in the residential, commercial and other man-made buildings accounts for nearly 40% of total global energy use, making it the largest single component of energy use1. The explosion in demand for air-conditioning units is aggravating this large energy consumption. Low-E window which exhibits high reflectivity of infrared light has been widely used in commercial buildings to achieve energy saving. However, its solar radiation reflection has no responding ability to environmental temperature change, limiting its application in different market requirements1,2. Smart windows with thermochromic thin-film coatings on building glass provide an effective way to modulate the solar energy transmitted into the interior room.

It is well known that vanadium dioxide (VO2) shows a reversible metal-insulator phase transition (MIT) at a phase-transition temperature (Tc) of 68 °C3. When temperature below Tc, VO2 is an insulator with a monoclinic structure (M phase, space group P21/c) which is transparent to infrared radiation (IR). As temperature above Tc, VO2 transforms to a metallic state with a rutile structure (R phase, space group P42/mnm) which is reflective to IR radiation while maintains visible-light transparent4. Such a MIT transition makes VO2 an attractive material for smart windows5. In order to promote the application of VO2 based smart windows, various methods have been used to achieve the VO2 coatings on transparent substrates for smart windows. However, how to enhance the visible light transmission with little sacrifice of solar modulation ability and lower the cost of large scale coating are still two major challenges for researchers. Based on the vapor-based deposition techniques6,7, multilayered structure (glass/TiO2/VO2/TiO2/VO2/TiO2)8, multifunctional TiO2(R)/VO2(M)/TiO2(A)9 and antireflection (AR) coatings on VO2 films10, were designed to meet the performance boost. But those methods were proved to be complicated and expensive due to the difficulties in controlling variable valences of V ions and costly equipment.

Recently, solution-based methods for depositing VO2 coatings on substrates have been studied extensively because of its low-cost and up-scalable. Cao et al. and Kang et al. have utilized solution methods (dip-coated with freeze-drying and spin-coated with sol-gel, respectively11,12) to obtain enhanced optical performance with high solar modulation ability. Their work demonstrated that creating tunable porosity in VO2 films was a feasible way to meet the performance requirements for practical usage. However, complex processes with high temperature crystallization treatment (500–550 °C for hours) were needed during those fabrications to limit their usability in industry.

Compared to those traditional solution-based deposition methods, hydrothermal method shows many advantages, such as easy implementation on the industrial scale, controllable porosity and crystal size, low-temperature processing, possibility to utilize a wide range of substrates, and being environmentally friendly. The hydrothermal technique has been used to grow ZnO films13, TiO2 films14 and other transition metal oxide functional thin films15,16 on glass or conductive substrate with high quality. Crystal morphologies, especially tunable porosity of films can be controlled by synthesis processes, showing great impacts on functional performance13. In previous studies, hydrothermal technique and subsequent thermal treatment were used to synthesize various VO2 (M) nanomaterials17,18, and VO2-based composite membrane were prepared by mixing VO2 (M) nanopowders with transparent polymer (e.g.,VO2/SiO2 core-shell19, VO2/ATO/polymer20 and polymer-assisted deposition21,22,23,24). However, there is no report about using the hydrothermal method to prepare VO2 (M) thin films on glass for smart windows.

To our knowledge, preparing a high quality metallic oxide thin film directly on glass by hydrothermal method is not easy25. The substrates with polarity and crystal orientations were usually used to grow fine organized thin films26,27,28. Our recent work has demonstrated that high quality epitaxial VO2 thin films can be grown on sapphire substrates by hydrothermal method29. Compared to the costly single crystal substrate, the buffer layer prepared on glass is an economic way to grow fine films. For example, Podlogar et al. prepared ZnO buffer layers on glass to grow highly adhesive crystalline ZnO films13, and Masuda et al. grew super hydrophilic TiO2 thin films on glass with SnO2:F layer (FTO)30.

Here, we successfully prepared VO2 smart windows via a facile hydrothermal process followed by a short heat treatment. High quality and porosity of obtained VO2 coatings make the films exhibit excellent thermochromic properties with good solar modulation ability and high visible light transmittance. To grow VO2 thin films on glass, TiO2 was selected as an buffer layer since TiO2 film shows stable thermal properties, high transparency to visible light and easy preparation9,31. The porosity of VO2 films was easily controlled by adjusting the concentration of the reaction solution. The possible growth mechanism was discussed based on the investigation into the effects of pH value and different precursor solutions on the growth process. The proposed simple process which is low cost and up-scalable would promote the application of VO2 in smart windows.

Experimental

Experiment section

All reagents used in the experiment were analytically pure and purchased from Sinopharm Chemical Reagent Co., Ltd. Vanadyl oxalate aqueous solution was used to grow VO2 thin films on glass substrates by the hydrothermal method. Before the growth of VO2 films, TiO2 buffers were firstly deposited on amorphous glass substrate by spin coating. A moderate-temperature treatment (400 °C) was carried out to achieve its crystallization and adhesion32. The detailed preparation process for TiO2 buffers is as follows: firstly, tetrabutyltitanate (C16H36O4Ti, 10 ml) was added into the ethanol (5 ml) at room temperature and stirred for 30 min. Then the solution was transferred into a mixed solution of nitric acid (3 ml), deionized water (6 ml) and ethanol (80 ml) and stirred for 1 h. Finally a transparent and stable TiO2 sol was obtained. The sol was spin coated at 3500 rpm for 30 s on a glass with diameter of 2 inches, which was ultrasonically cleaned for 10 min in a solution of acetone, 2-propanol and deionized water with volume ratios of 1:1:1. As-coated TiO2 precursor layer was heated under 400 °C for 1 h to produce fine grained TiO2 layer. The glass with TiO2 buffers was used for the hydrothermal growth of VO2 films. In the hydrothermal process, the vanadyl oxalate precursors were prepared by dissolving V2O5 (0.182 g) in the aqueous solution (50 ml) containing oxalic acid (1.97 g) at 70 °C. The aqueous solution was diluted into 500 ml with deionized water, forming a 4 mmol/L solution with pH value ~2.4. The PH value was controlled by NH4OH. The vanadyl oxalate aqueous solution (60 ml) was transferred into a Teflon-lined autoclave (100 ml). The chemical reaction was carried out at 230 °C in an electric oven. After heating for 4 h, the autoclave was naturally cooled down in furnace. The side of TiO2 layer was covered by a uniform film. The wafer samples were cleaned up with deionized water and alcohol, and dried by nitrogen. The thermochromic VO2 windows were obtained through annealing the as-grown VO2 films in a short annealing furnace at 400 °C for 60 s in 4 * 104 Pa of air. Unless specifically noted in the article, all samples used here are prepared as mentioned above.

Instrumentation characterization

The morphology of the reaction product was examined by using scanning electron micros-copy (SEM, Hitachi S-4800). The phase identification of the TiO2 and VO2 films was performed using X-ray diffraction (XRD, Bruker-AXS diffractometer, Model D8 ANVANCE) with Cu-Kα radiation source, Raman spectra (HR800, excitation wavelength: 633 nm, laser power: 1 mW) and Transmission Electron Microscope (TEM, FEI Tecnai G2 F20 S-TWIN). The chemical valence of vanadium ions was measured by XPS (PHI QUANTERA-II SXM) with Al-Kα radiation source (1486.6 eV). The porosity based on SEM images was calculated by using Image-Pro Plus (IPP) to compare the gray scale pixel of the area occupied by VO2 nanoplates and exposed TiO2 films. The optical transmittance spectra of samples at normal incidence from 300 to 3000 nm and were measured by using Shimadzu UV-3600 UV-VIS-NIR spectrophotometer with Heat Solid Transmission Accessory.

Result and Discussion

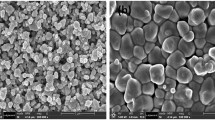

Figure 1a shows the morphology images of polycrystalline TiO2 buffers with grain size between 25 to 75 nm. The XPS full spectrum (Fig. 1b) of TiO2 reveals a high purity component. The obtained VO2 film is composed of nanoplates with an average thickness of ~40 nm, and a height of ~400 nm, which are regularly grown against substrates (Fig. 1c,d). There are smaller and more randomly oriented nanoplates close to the substrate, which is similar with the previous report for the growth of ZnO films33. As identified by XRD (Fig. 1e), the characteristic peaks agree with those of M-VO2 in monoclinic structure (JCPDS No. 65-2358) and A-TiO2 in anatase phase (JCPDS No. 21-1272) respectively. The remarkable (020) peak of VO2 indicates that the growth of VO2 films are preferentially oriented on substrates. For a randomly oriented VO2 polycrystalline sample the intensity of (020) diffraction is only ~2.4% of the strongest peak (011). The preferred orientation of the VO2 films supports the conclusion that the VO2 nanoplates are regularly grown on substrates as shown in the cross-section structure of VO2 films in Fig. 1d. The XRD pattern of TiO2 buffers indicates the (004)-preferred orientation of anatase TiO2. It is known that the close-packed planes in anatase-TiO2 (112) and rutile-VO2 (200)/(020) are equivalent34, so we can infer that there is a lattice-matching relationship between anatase TiO2 and rutile VO2 with A-TiO2 (112)//R-VO2 (200)/(020). In this case, it is possible for VO2 to grow in a preferred orientation manner guided by the A-TiO2 buffer under hydrothermal growth temperature (230 °C). The M-VO2 is a polymorphic phase transformed from R-VO2 through a small distortion35. The R-VO2 {200} planes correspond to the (020) and (002) planes in the M-VO2 phase36. For the (004)-preferred orientation of anatase TiO2 as determined by XRD, the preferred orientation of M-VO2 should be (011)M considering the crystal distortion induced by the mismatch between TiO2 and VO2. The angle between (112) and (004) in A-TiO2 is ~61° and no good lattice-match relation exist along other directions, therefore, the inclined growth of plate-like VO2 nanocrystals are observed in Fig. 1c,d. While the VO2 nanoplates show the strong preferred orientation of (020)M, it should be related to other orientations of TiO2, i.e. (110) or (112) orientations of A-TiO2. For A-TiO2 (110) or (112) orientations the VO2 nanoplates would grow perpendicular or parallel to the substrate. The corresponding growth of VO2 nanoplates can be observed in Fig. 1c,d. The existence of (110)-orientation TiO2 is verified by TEM in Fig. 2. XPS measurements were performed to examine the oxidation states of V ions in VO2 thin films (Fig. 1f)37. It is shown that the VO2 thin films contain partial V5+ ions together with V4+ ions. The presence of V5+ ions could be attributed to surface oxidization in the annealing process or storage in air and exist only on the surface as proved5.

(a) Compact TiO2 thin films are composed of equiaxed grains with size distribution between 25 to 75 nm. (b) The XPS full spectrum of prepared TiO2 thin film. (c,d) SEM images of the obtained VO2 thin films and the corresponding cross section morphology, revealing a nanoplate structure. (e) XRD patterns of VO2 thin films compared to TiO2 thin films, indicating the orientated growth of the monoclinic VO2 on anatase TiO2 phase. (f) XPS spectrum of VO2 thin films.

(a,b) Cross-sectional TEM images of the VO2/TiO2 films on glass substrate, (a) shows the shape of the VO2 nanoplates, (b) a VO2 grain grown on the TiO2 thin film, (c,e) High resolution TEM (HRTEM) images taken from different layers as marked by squares in (b). (d,f) FFT patterns correspond to (c) VO2 nanoplate and (e) TiO2 thin film respectively.

In order to understand more details about the oriented growth of VO2 and TiO2 layers, a cross-section sample of VO2/TiO2 films was prepared and investigated by TEM. TEM images (Fig. 2a,b) show the well-connected 3-layer structure. The TiO2 thin film has a thickness ~12.8 nm (Fig. 2b). Two TiO2 grains exist in the observation region, and they have different orientations as shown by the HRTEM images in Fig. S1 (supporting information). The VO2 nanoplates show a triangle-like shape in Fig. 2a, which stand on the substrate. HRTEM images taken from two layers in Fig. 2c,e show clear lattice fringe, indicating good crystallinity of VO2 and TiO2 films. The interplanar spacing of 0.331 nm in Fig. 2c corresponds to the plane distance of (1–10) of monoclinic VO2 (Fig. 2d). The interplanar spacings of 0.270 nm and 0.358 nm in Fig. 2e belong to the (−110) plane and (011) plane of anatase TiO2 (Fig. 2f), respectively. For the present orientations of A-TiO2 and M-VO2 as shown in Fig. 2(c–f), the equivalent planes, i.e. A-TiO2 (112) and M-VO2 (002)/(020) are not in the matching orientations. However, the right-hand grain of A-TiO2 as shown in Fig. 2(b) and Fig. S1(c) exhibits an orientation that the left-hand grain rotates about 15° clockwise. In this case, the M-VO2 (002) plane is parallel to the A-TiO2 (112) plane of the right-hand grain, indicating the growth of VO2 in Fig. 2 is guided by the left-hand TiO2. The corresponding crystallographic relationship of VO2 and A-TiO2 is schematically shown in Fig. S2. The TEM analysis demonstrates the guided growth of VO2 by buffer TiO2.

To investigate the possible growth mechanism of VO2 films, controllable hydrothermal processes were designed. Different precursor solutions and pH values were found to be key factors to affect the reaction process. The role of precursors in the hydrothermal process for preparing the VO2 films were investigated, i.e. precursor solutions obtained from V(OH)2NH2 dissolved in HNO3 38, hydrazine hydrate reacted with VOSO4 39, NH4VO3 with 1,3-propylene glycol reduced in H2SO4 40, and V2O5 dissolved in oxalate acid solution41. It is found that VO2 films can be grown only in the vanadyl oxalate solution, which suggests that oxalate acid solution is a suitable solvent for the formation of VO2 thin films.

The pH value of vanadyl oxalate solution was modulated by adding droplets of NH4OH. Figure 3(a–e) show the SEM images of VO2 films prepared at different pH values. The morphology of VO2 nanoplates greatly changes with increasing pH values. Obviously, the growth of VO2 is greatly influenced by the pH value. At pH 3.46, the VO2 nanoplates in Fig. 3a are twice thicker than those grown at pH 2.4 (Fig. 1c), making the nanoplates more like nanorods (length was ~300 nm). When the pH value rises up to 4.56, the nanorods become shorter (length is 250 nm) and wider (Fig. 3b). As the PH value equals to 6.21, nanorods disappear instead of rectangle-like grains distribute randomly on the film (Fig. 3c). At pH 7.45, irregularly shaped particles are loosely attached to substrates. At PH 8.12, more area of substrate is exposed. Furthermore, experiments revealed that nothing could be grown on the substrate while pH values ≥ 8.5. Dobson et al. have examined the adsorption of low molecular weight (LMW) carboxylic acids to TiO2 in aqueous solutions by infrared spectroscopic analysis, and reported the existence of strong adsorption of dicarboxylic acids (such as oxalic acid) to TiO2 42. This result was demonstrated by Mendive et al., who pointed out that the pH value played an important role in the adsorption behavior43. The strong adsorption of oxalate organic species on TiO2 occurred only as the pH value less than IEP (the isoelectric point, a pH value at which a particular molecule or surface carries have no net electrical charge)26,44,45. Bandura et al. investigated the adsorption of H2O on TiO2, and reported that for adsorption of H2O onto the surface of TiO2, H+ and OH− would produce positive (-O-H+) and negative (-Ti-OH−) surface sites, respectively46. The IEP of TiO2 is close to 6.2 as reported by Parks47. When PH is lower than 6.2, positive charge sites should dominate on the surface, whereas negative charge sites would be in majority. The adsorption affinity decreased rapidly as the pH value larger than IEP. Although the concentration of oxalate acids and the presence of metal cations in solution can influence the IEP, the pH dependence of adsorption does not change. It indicates that the protonated surface of TiO2 thin films is required for adsorption of organic anions. Our experimental results of different vanadic acid solutions and pH values are in consistence with the reported adsorption features of the organic acid solutions, indicating the chemical solution growth of VO2 on TiO2 is of adsorption dependence. The TiO2 buffer is a key factor for adsorption and consequently for interface reactions in the chemical solution environment because its surface chemical state at low pH values facilitates adsorption of carboxyl group.

(a–e) SEM images of VO2 thin films grown in different PH value, (a, 3.46; b 4.56; c, 6.21; d, 7.45; e, 8.12). The image insert in (e) is high magnification, scale bar is 300 nm. (f) Photos of reaction solution with different PH value, the color of solution changes from light blue to dark brown reveals the vanadyl oxalate gradually decrease and eventually disappear. (g) Schematic illustration of process for fabricating VO2 film following an adsorption and dehydration process.

In the oxalic acid solution, the possible surface reaction would be like that: 1) the vanadyl oxalate species were adsorbed on the TiO2 buffer. It is known that oxalate can form organic metallic cation complexes through the coordinating ability of the carboxyl group48. In that case, the negatively charged organic vanadium complexes ([(VO)x(C2O4)y]x−y) should be adsorbed on the positive surface sites through the carboxylic group. 2) Undergoing the water shrinkage reaction between the adsorbed vanadyl oxalate and the neighboring hydrogen ions on the protonated surface, VO2+ were adsorbed on the TiO2 substrate, and then crystallized to VO2 thin films. The schematic diagram of the growth process is shown in Fig. 3g. The different vanadic precursor solutions mentioned above have no carboxylic group, so there is no effective species to play the role of bridge between vanadium ions and positive charge-terminated surface of the TiO2 thin films for achieving the growth of highly adhesive VO2 films.

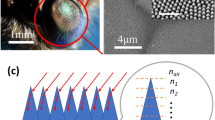

The optical modulation properties of the prepared VO2 films were investigated to evaluate its potential for the smart windows. For realizing the application of VO2 in smart window a technological challenge is to improve the maximum visible transmittance (T-vis) to an acceptable value (>60%), while maintain the high solar modulating efficiency ( ) of VO2 49. To improve T-vis, one way is to fabricate porous films6,12,49, and another way is to deposit an antireflection film or reduce the thickness of the continuous films of VO2 to less than 80 nm12,24. In this work, the standing nanoplate structure facilitates the penetration of solar light, namely apt to achieve high T-vis. The obtained VO2 films are in fact self-generated porous films, which would produce excellent combination thermochromic property. Cao et al. reported a nanoporous VO2 film exhibiting good thermochromic properties, the highest value of T-vis and

) of VO2 49. To improve T-vis, one way is to fabricate porous films6,12,49, and another way is to deposit an antireflection film or reduce the thickness of the continuous films of VO2 to less than 80 nm12,24. In this work, the standing nanoplate structure facilitates the penetration of solar light, namely apt to achieve high T-vis. The obtained VO2 films are in fact self-generated porous films, which would produce excellent combination thermochromic property. Cao et al. reported a nanoporous VO2 film exhibiting good thermochromic properties, the highest value of T-vis and  were 75% and 7.9% respectively11. In our work, the T-vis can be easily adjusted by changing the porosity of VO2 films through diluting the concentration of vanadyl oxalate in solution (Fig. S3). The porosity of VO2 films on glass increases with decreasing the concentration of vanadyl oxalate. By comparing the area occupied by VO2 nanoplates and exposed TiO2 films, the calculated porosities for the VO2 films grown in different concentration vanadyl oxalate solutions are shown in Fig. 4a. The samples are marked as: #1, 0.73 mmol/L; #2, 1.1 mmol/L; #3, 1.5 mmol/L; #4, 2.2 mmol/L; #5, 4.0 mmol/L (as in Fig. 1c), respectively. The sample #1 has the largest porosity of ~54.9%, it suggests that higher T-vis could be achieved.

were 75% and 7.9% respectively11. In our work, the T-vis can be easily adjusted by changing the porosity of VO2 films through diluting the concentration of vanadyl oxalate in solution (Fig. S3). The porosity of VO2 films on glass increases with decreasing the concentration of vanadyl oxalate. By comparing the area occupied by VO2 nanoplates and exposed TiO2 films, the calculated porosities for the VO2 films grown in different concentration vanadyl oxalate solutions are shown in Fig. 4a. The samples are marked as: #1, 0.73 mmol/L; #2, 1.1 mmol/L; #3, 1.5 mmol/L; #4, 2.2 mmol/L; #5, 4.0 mmol/L (as in Fig. 1c), respectively. The sample #1 has the largest porosity of ~54.9%, it suggests that higher T-vis could be achieved.

(a) Effect of concentration on the porosity of VO2 thin films, black and pink ball indicate the concentration and porosity respectively. (b) Transmittance spectra of different VO2 thin films from 300 nm to 3000 nm at 30 °C (solid dots line) and 100 °C (solid line), the right inserted photos from up to down are corresponding to the different samples: #1, #2, #3, #4, #5, respectively. (c) Thermal hysteresis loops of transmittance at 2000 nm for different VO2 thin films. The red arrow and black arrow indicate the heating and cooling respectively, and transition temperatures were defined as the center of the hysteresis loops. (d) Optical properties of typical samples with different precursor concentration. (The concentration of each sample as below: #1, 0.73 mmol/L; #2, 1.1 mmol/L; #3, 1.5 mmol/L; #4, 2.2 mmol/L; #5, 4.0 mmol/L, respectively).

Such self-generated porous nanostructures exhibit a good combination property of thermochromism (combining visible light transmittance and solar modulating efficiency). Figure 4b shows temperature-dependent transmittance of the porous VO2 nanoplates thin films. The right insets are the corresponding coating photos. The hysteresis loops of transmittance at 2000 nm for different VO2 thin films are shown in Fig. 4c, the Tc and hysteresis loop width (ΔT) of #5 is 70.1 °C and 12.9 °C respectively. Both of Tc and ΔT are increased as the porosity of thin films increasing, which is considered that the discontinuity of grain in thin films causes a loose grain boundaries limit propagation of MIT, and results higher Tc and wider ΔT50. The T-vis,  , and near-infrared (NIR) switching efficiency (

, and near-infrared (NIR) switching efficiency ( ) are shown in Fig. 4d, T-vis monotonously increases with the porosity of thin films as predicted. While the

) are shown in Fig. 4d, T-vis monotonously increases with the porosity of thin films as predicted. While the  shows a plateau for samples #2-#4. Pleasurable thermochromic properties are observed in the sample #2 with 35.9% porosity, the T-vis value is as high as ~70.3% with the

shows a plateau for samples #2-#4. Pleasurable thermochromic properties are observed in the sample #2 with 35.9% porosity, the T-vis value is as high as ~70.3% with the  up to 9.3%. The results are even better than those of periodic and aperiodic porous VO2(M) films fabricated by complicated chemical and physical processes6,24,49, the multilayered TiO2(or SiO2)/VO2/substrate films9, and the VO2-based composite thin films20,51. The excellent thermochromic properties of our VO2 films benefit from the special nanoplates structure which provides pores to solve the issue of low visible transmittance, meanwhile keep the thickness of films up to ~400 nm.

up to 9.3%. The results are even better than those of periodic and aperiodic porous VO2(M) films fabricated by complicated chemical and physical processes6,24,49, the multilayered TiO2(or SiO2)/VO2/substrate films9, and the VO2-based composite thin films20,51. The excellent thermochromic properties of our VO2 films benefit from the special nanoplates structure which provides pores to solve the issue of low visible transmittance, meanwhile keep the thickness of films up to ~400 nm.

The integrated solar transmittance (Tsol, 300–2500 nm) and the  values are obtained from the following equation:

values are obtained from the following equation:

where Tλ denotes transmittance at wavelength λ, φsol is the solar irradiance spectrum for air mass 1.5 (corresponding to the sun standing 37° above the horizon)52.

Conclusion

In summary, we have successfully fabricated nanoplates VO2 films on glass substrates with TiO2-buffers, for the first time, by a facile hydrothermal method. The obtained VO2 films show unique self-assembly porous structure with the porosity controllable by the concentration of the precursor solution. Excellent thermochromic properties are achieved with a visible light transmittance of 70.3% and a solar modulating efficiency of 9.3%. The investigation of growth process reveals that the appropriate adsorbent media, such as oxalate groups adsorbing on TiO2 buffers, are necessary for the preparation of VO2 thin films on glass by the hydrothermal technique. The preparation process of thermochromic VO2 films adopted in this work is facile, low-cost and up-scalable. The experiments proved its potential in promoting the practical application of VO2 in smart windows.

Additional Information

How to cite this article: Zhang, J. et al. Hydrothermal growth of VO2 nanoplate thermochromic films on glass with high visible transmittance. Sci. Rep. 6, 27898; doi: 10.1038/srep27898 (2016).

Change history

12 August 2016

A correction has been published and is appended to both the HTML and PDF versions of this paper. The error has not been fixed in the paper.

References

Chen, S. et al. The visible transmittance and solar modulation ability of VO2 flexible foils simultaneously improved by Ti doping: an optimization and first principle study. Phys. Chem. Chem. Phys. 15, 17537–17543 (2013).

Granqvist, C. G. Transparent conductors as solar energy materials: A panoramic review. Energ. Mat. Sol. C. 91, 1529–1598 (2007).

Qazilbash, M. M. et al. Mott transition in VO2 revealed by infrared spectroscopy and nano-imaging. Science 318, 1750–1753 (2007).

Zhou, J. et al. VO2 thermochromic smart window for energy savings and generation. Sci. Rep. 3, 1–5 (2013).

Zhang, Z. et al. Thermochromic VO2 thin films: solution-based processing, improved optical properties, and lowered phase transformation temperature. Langmuir 26, 10738–10744 (2010).

Sun, Y. M. et al. Anisotropic vanadium dioxide sculptured thin films with superior thermochromic properties. Sci. Rep. 3, 1–10 (2013).

Qureshi, U., Manning, T. D., Blackman, C. & Parkin, I. P. Composite thermochromic thin films: (TiO2)–(VO2) prepared from titanium isopropoxide, VOCl3 and water. Polyhedron 25, 334–338 (2006).

Mlyuka, N. R., Niklasson, G. A. & Granqvist, C. G. Thermochromic VO2-based multilayer films with enhanced luminous transmittance and solar modulation. Phy. Status Solidi A 206, 2155–2160 (2009).

Zheng, J., Bao, S. & Jin, P. TiO2(R)/VO2(M)/TiO2(A) multilayer film as smart window: Combination of energy-saving, antifogging and self-cleaning functions. Nano Energy 11, 136–145 (2015).

Jin, P., Xu, G., Tazawa, M. & Yoshimura, K. A VO2-based multifunctional window with highly improved luminous transmittance. Jpn. J. Appl. Phys. 41, L278 (2002).

Cao, X. et al. Nanoporous Thermochromic VO2 (M) Thin Films: Controlled Porosity, Largely Enhanced Luminous Transmittance and Solar Modulating Ability. Langmuir 30, 1710–1715 (2014).

Kang, L. et al. Nanoporous thermochromic VO2 films with low optical constants, enhanced luminous transmittance and thermochromic properties. ACS Appl. Mater. Inter. 3, 135–138 (2011).

Podlogar, M. et al. Growth of Transparent and Conductive Polycrystalline (0001)-ZnO Films on Glass Substrates Under Low-Temperature Hydrothermal Conditions. Adv. Funct. Mater. 22, 3136–3145 (2012).

Wu, W.-Q. et al. Hydrothermal fabrication of hierarchically anatase TiO2 nanowire arrays on FTO glass for dye-sensitized solar cells. Sci. Rep. 3, 1–7 (2013).

Jiao, Z., Sun, X. W., Wang, J., Ke, L. & Demir, H. V. Hydrothermally grown nanostructured WO3 films and their electrochromic characteristics. J. Phy. D: Appl. Phys. 43, 285501 (2010).

Cha, H. G. et al. Facile preparation of Fe2O3 thin film with photoelectrochemical properties. Chem. Commun. 47, 2441–2443 (2011).

Cao, C., Gao, Y. & Luo, H. Pure single-crystal rutile vanadium dioxide powders: synthesis, mechanism and phase-transformation property. J. Phys. Chem. C 112, 18810–18814 (2008).

Chen, Z., Cao, C., Chen, S., Luo, H. & Gao, Y. Crystallised mesoporous TiO2 (A)–VO2 (M/R) nanocomposite films with self-cleaning and excellent thermochromic properties. J. Mater. Chem. A 2, 11874–11884 (2014)

Gao, Y. et al. Enhanced chemical stability of VO2 nanoparticles by the formation of SiO2/VO2 core/shell structures and the application to transparent and flexible VO2-based composite foils with excellent thermochromic properties for solar heat control. Energ. Environ. Sci. 5, 9947–9947 (2012).

Gao, Y. F. et al. VO2-Sb:SnO2 composite thermochromic smart glass foil. Energ. Environ. Sci. 5, 8234–8237 (2012).

Li, M. et al. Defect-mediated phase transition temperature of VO2(M) nanoparticles with excellent thermochromic performance and low threshold voltage. J. Mater. Chem. A 2, 4520–4523 (2014).

Zhong, L. et al. Star-shaped VO2(M) nanoparticle films with high thermochromic performance. CrystEngComm 17, 5614–5619 (2015).

Shi, Q. et al. Giant Phase Transition Properties at Terahertz Range in VO2 films Deposited by Sol-Gel Method. ACS Appl. Mater. Inter 3, 3523–3527 (2011).

Chen, Z. et al. Fine crystalline VO2 nanoparticles: synthesis, abnormal phase transition temperatures and excellent optical properties of a derived VO2 nanocomposite foil. J. Mater. Chem. A 2, 2718–2727 (2014).

Hosono, E., Fujihara, S., Kakiuchi, K. & Imai, H. Growth of submicrometer-scale rectangular parallelepiped rutile TiO2 films in aqueous TiCl3 solutions under hydrothermal conditions. J. Am. Chem. Soc. 126, 7790–7791 (2004).

Kim, J. H. et al. Growth of Heteroepitaxial ZnO Thin Films on GaN‐Buffered Al2O3 (0001) Substrates by Low-Temperature Hydrothermal Synthesis at 90 °C. Adv. Funct. Mater. 17, 463–471 (2007).

Yang, H. et al. Large-scale growth of highly oriented ZnO nanorod arrays in the Zn-NH3·H2O hydrothermal system. Cryst. Growth Des. 8, 1039–1043 (2008).

Yan, D. et al. Fabrication, in-depth characterization, and formation mechanism of crystalline porous birnessite MnO2 film with amorphous bottom layers by hydrothermal method. Cryst. Growth Des. 9, 218–222 (2008).

Zhang, J. et al. Self-Assembling VO2 Nanonet with High Switching Performance at Wafer-Scale. Chem. Mater. 27, 7419–7424 (2015).

Masuda, Y. & Kato, K. Liquid-Phase Patterning and Microstructure of Anatase TiO2 Films on SnO2: F Substrates Using Superhydrophilic Surface. Chem. Mater. 20, 1057–1063 (2007).

Fan, L. et al. Strain dynamics of ultra-thin VO2 film grown on TiO2 (001) and the associated phase transition modulation. Nano lett. 14, 4036–4043 (2014).

Wang, Z., Helmersson, U. & Käll, P.-O. Optical properties of anatase TiO2 thin films prepared by aqueous sol–gel process at low temperature. Thin Solid Films 405, 50–54 (2002).

Park, H. K. et al. Charge‐Generating Mode Control in High‐Performance Transparent Flexible Piezoelectric Nanogenerators. Adv. Funct. Mater. 21, 1187–1193 (2011).

Shannon, R. D. & Pask, J. A. Topotaxy in the Anataserutile Transformation. J. A. Am. Mineral 49, 1707– 1717 (1964).

Whittaker, L., Jaye, C., Fu, Z., Fischer, D. A. & Banerjee, S. Depressed phase transition in solution-grown VO2 nanostructures. J. Am. Chem. Soc. 131, 8884–8894 (2009).

Yan, J. Z., Huang, W. X., Zhang, Y., Liu, X. J. & Tu, M. J. Characterization of preferred orientated vanadium dioxide film on muscovite (001) substrate. J. Phys. Status Solidi. A. 205, 2409–2412, (2008).

Silversmit, G., Depla, D., Poelman, H., Marin, G. B. & De Gryse, R. Determination of the V2p XPS binding energies for different vanadium oxidation states (V5+ to V0+). J. Electron Spectrosc. 135, 167–175 (2004).

Wu, C. et al. Direct hydrothermal synthesis of monoclinic VO2(M) single-domain nanorods on large scale displaying magnetocaloric effect. J. Mater. Chem. 21, 4509–4517 (2011).

Son, J.-H., Wei, J., Cobden, D., Cao, G. & Xia, Y. Hydrothermal synthesis of monoclinic VO2 micro-and nanocrystals in one step and their use in fabricating inverse opals. Chem. Mater. 22, 3043–3050 (2010).

Li, S. T. et al. Preparation and Characterization of Self-Supporting Thermochromic Films Composed of VO2(M)@SiO2 Nanofibers. ACS Appl. Mater. Inter. 5, 6453–6457 (2013).

Liu, P. et al. Ultra-long VO2(A) nanorods using the high-temperature mixing method under hydrothermal conditions: synthesis, evolution and thermochromic properties. CrystEngComm 15, 2753–2760 (2013).

Dobson, K. D. & McQuillan, A. J. In situ infrared spectroscopic analysis of the adsorption of aliphatic carboxylic acids to TiO2, ZrO2, Al2O3, and Ta2O5 from aqueous solutions. J. Spectrochim. Acta A 55, 1395–1405 (1999).

Mendive, C. B., Bredow, T., Blesa, M. A. & Bahnemann, D. W. ATR-FTIR measurements and quantum chemical calculations concerning the adsorption and photoreaction of oxalic acid on TiO2 . Phys. Chem. Chem. Phys. 8, 3232–3247 (2006).

Lewis, J. A. Colloidal processing of ceramics. J. Am. Ceram. Soc. 83, 2341–2359 (2000).

Young, A. G. & McQuillan, A. J. Adsorption/desorption kinetics from ATR-IR spectroscopy. Aqueous oxalic acid on anatase TiO2 . Langmuir 25, 3538–3548 (2009).

Bandura, A. et al. Adsorption of water on the TiO2 (rutile)(110) surface: a comparison of periodic and embedded cluster calculations. J. Phys. Chem. B 108, 7844–7853 (2004).

Parks, G. A. The isoelectric points of solid oxides, solid hydroxides, and aqueous hydroxo complex systems. Chem. Rev. 65, 177–198 (1965).

Mehrotra, R. C., Bohra, R. & Gaur, D. Metal carboxylates Vol. 9 (Academic Press London, 1983).

Zhou, M. et al. Periodic Porous Thermochromic VO2(M) Film with Enhanced Visible Transmittance. Chem. Commun. 49, 6021–6023 (2013).

Kang, L. et al. Effects of annealing parameters on optical properties of thermochromic VO2 films prepared in aqueous solution. J. Phys. Chem. C 114, 1901–1911 (2010).

Li, M. et al. Defects-mediated phase transition temperature of VO2(M) nanoparticles with excellent thermochromic performance and low threshold voltage. J. Mater. Chem. A 2, 4520–4523 (2014).

ASTM G173-03 Standard Tables of Reference Solar Spectral Irradiances: Direct Normal and Hemispherical on a 37° Tilted Surface, Annual Book of ASTM Standards, Vol. 14.04, American Society for Testing and Materials, Philadelphia, PA, USA, http://rredc.nrel.gov/solar/spectra/am1.5.

Acknowledgements

The authors gratefully acknowledge the financial support from the National Science Foundation of China (Grant Nos 51132002, 51372024, 51172026 and 51572027) and Key Project of Chinese Ministry of Education (Grant No. 313007).

Author information

Authors and Affiliations

Contributions

J.L., J.Z. and H.J. supervised and coordinated all aspects of the project. J.Z. synthesized and characterized the materials. P.C. carried out the measurement of electronic and optical properties. F.R. carried out the XRD and Raman characterizations and crystal structure analysis. Y.J., M.C. and Y.Z. carried out the TEM characterization and image analysis. All authors contributed to the writing of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Zhang, J., Li, J., Chen, P. et al. Hydrothermal growth of VO2 nanoplate thermochromic films on glass with high visible transmittance. Sci Rep 6, 27898 (2016). https://doi.org/10.1038/srep27898

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep27898

This article is cited by

-

Advanced liquid crystal-based switchable optical devices for light protection applications: principles and strategies

Light: Science & Applications (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.