Abstract

A nominal GeOx (x ≤ 2) compound contains mixtures of Ge, Ge suboxides and GeO2, but the detailed composition and crystallinity could vary from material to material. In this study, we synthesize GeOx nanoparticles by chemical reduction of GeO2 and comparatively investigate the freshly prepared sample and the sample exposed to ambient conditions. Although both compounds are nominally GeOx, they exhibit different X-ray diffraction patterns. X-ray absorption fine structure (XAFS) is utilized to analyse the detailed structure of GeOx. We find that the two initial GeOx compounds have entirely different compositions: the fresh GeOx contains large amorphous Ge clusters connected by GeOx, while after air exposure; the Ge clusters are replaced by a GeO2-GeOx composite. In addition, the two GeOx products undergo different structural rearrangement under H2 annealing, producing different intermediate phases before ultimately turning into metallic Ge. In the fresh GeOx, the amorphous Ge remains stable, with the GeOx being gradually reduced to Ge, leading to a final structure of crystalline Ge grains connected by GeOx. The air-exposed GeOx on the other hand, undergoes a GeO2→GeOx→Ge transition, in which H2 induces the creation of oxygen vacancies at intermediate stage. A complete removal of oxides occurs at high temperature.

Similar content being viewed by others

Introduction

Ge is one of the promising candidates for anode materials in Li-ion batteries1,2. It has a theoretical capacity as high as 1600 mA h g−1 (upon formation of a Li4.4Ge alloy) and excellent Li+ diffusion rate at room temperature1. However, the drastic volume expansion in crystalline Ge that occurs after Li insertion leads to capacity fading which limits its use in practical Li-ion devices3. Researchers have been seeking methods to enhance the stability of Ge anodes, such as minimizing the size of Ge4,5, surface functionalization2,6, morphology engineering7,8 and forming a composite structure by coating Ge with a layer of carbon9,10. Recently, amorphous GeOx (x < 2) structures have attracted great interest due to their ability to enhance the cycling life of Li-ion batteries11,12,13,14. Compared to crystalline Ge, oxidized Ge is lower cost, has better chemical stability and improved cyclability. In fact, it has been reported that GeO2 is able to deliver a capacity up to 2152 mA h g−1 if it reversibly stores 8.4 Li+ (reactions (1) and (2))14,15,16.

It has been proposed that presence of Ge0 in GeO2 has a unique role in that it can serve as a catalyst to drive reaction (1) in the inverse direction, hence the formation of LiO2 is reversible17. This catalytic effect of Ge has been demonstrated by Seng et al. using a GeO2/Ge/C nanocomposite as an anode for a Li battery test17. A nominal GeOx structure contains a mixture of Ge dioxides and sub-oxides, as well as elemental Ge. It is critical to understand the composition and the structure of GeOx to achieve better control of the crystallinity and grain size of the different constituents in terms of improving the battery performance.

Although there has been a large amount of work on synthesizing nanostructured GeOx with new configurations12,14,18, less attention has been given to understanding the starting material itself before introducing it into a battery test. GeOx contains a mixture of Ge, GeOx and GeO2 and in an oxidizing (or reducing) environment, these three components can transform from one species to another19,20,21. In fact, GeOx has been deliberately synthesized and served either as the precursor for making Ge nanocrystals and/or GeO2 nanostructures for the purpose of fabricating electronic and optical devices22,23,24. Although there have been relatively large amount of early studies done on Ge nanocrystal embedded GeOx or SiOx thin films for the purpose of electronic devices fabrication, few reports are available on the structure characterization of the free-standing Ge/GeOx/GeO2 nanocomposite in terms of battery applications. In particular, since amorphous Ge and GeOx are more promising for Li-ion anodes than their crystalline counterparts, the standard crystal structure analysis tool X-ray diffraction (XRD) is no longer capable of characterizing the crystal structure of GeOx. Transmission electron microscopy (TEM) with high resolution can tell the crystallinity of individual nanoparticles. However, for amorphous structure, distinguishing different components (e.g. Ge and GeOx) almost entirely relies on the contrast of the image. In addition, the small sampling size of TEM lacks information on the averaged chemical composition of the material.

Aside from the crystal structure, understanding the chemical components in GeOx from the electronic structure perspective is also important. GeOx contains Ge in various oxidation states, from Ge0 up to Ge4+. The conventional characterization technique for studying the electronic structure of GeO2/Ge materials is photoelectron spectroscopy21. This technique requires the samples to have a clean surface and be in good electrical contact with the substrate. However, nanostructured GeOx for Li-ion battery applications are more often in the form of powder. The GeOx therefore have irregular surfaces, which makes removing surface impurities and ensuring good electrical contact very difficult. Consequently, characterizing the electronic structure of these materials with photoelectron spectroscopy is very challenging. X-ray absorption spectroscopy, on the other hand, is an alternative tool for electronic structure characterization that is flexible in terms of sample preparation. X-ray absorption fine structure (XAFS) probes the local environment of an element of interest in the material. The spectrum originates from the interference between incoming and outgoing electrons after single and/or multiple scattering. As a result, it is a local structure probe and doesn’t require the sample to be crystalline. By measuring the Ge K-edge XAFS, the chemical environment of Ge, such as its oxidation state (from the X-ray absorption near-edge structure, XANES), the coordination number and the bond distance between Ge and the nearest neighbors (from the extended X-ray absorption fine structure, EXAFS) can be obtained14,25,26,27.

GeOx nanostructures can be synthesized using various approaches, such as hydrothermal methods13, hydrolysis17 and by chemical reduction2,11. Herein we study the electronic structure of GeOx nanoparticles synthesized by simple chemical reduction. Such method produces GeOx which contains GeO2, Ge sub-oxides and most interestingly, Ge11. This serves as a good starting point to investigate the electronic structure of the GeOx and the transitions between the three components under various conditions. We first compare the freshly prepared GeOx and the one stored in ambient condition for 3 days. These two samples were then used as starting materials and were annealed in H2 at various temperatures. The change in the chemical environment of Ge under different annealing temperatures is studied.

Results and Discussion

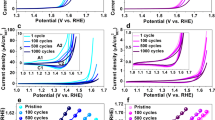

The freshly prepared GeOx nanoparticles have an average size of 50 nm. Figure 1a shows a representative transmission electron microscopy (TEM) image of these particles. X-ray diffraction (XRD) measurement reveals that the fresh GeOx and air-exposed GeOx have very different crystal structure (Fig. 1b–d). The fresh GeOx only contains two broad peaks, indicating its amorphous nature. The air-exposed GeOx, on the other hand, shows well-resolved features that resemble crystalline GeO2 with a quartz structure. After annealing in H2 at 300 °C, the XRD patterns of both fresh GeOx and air-exposed GeOx are both broadened to some extent, however, the features characteristic of GeO2 are still present in the latter. When the annealing temperature is increased to 500 °C, fresh GeOx crystallizes into an fcc structure, with diffraction peaks matching cubic-phase metallic Ge. These features are further sharpened under annealing at 700 °C. As for air-exposed GeOx, the 500 °C annealing results in a mixed phase containing both GeO2 and Ge. From the intensity of the two peak series, the GeO2 is still the major component. A full conversion from GeO2 to Ge is observed at 700 °C annealing.

(a) TEM image of as-prepared fresh GeOx nanoparticles. (b–d) XRD patterns of GeOx nanoparticles before and after annealing in comparison with standards. (b) fresh GeOx (sample series 1); (c) air-exposed GeOx (sample series 2); (d) standard XRD patterns of cubic Ge and quartz GeO233,34. Labels in (b) and (c): (a) as-prepared samples; (b) samples annealed at 300 °C; (c) samples annealed at 500 °C; (d) samples annealed at 700 °C. The intensity of 1-d is reduced in half to fit the panel.

We analyse the crystalline grain size of our samples using the Scherrer equation (Eq. 3),

in which τ is the crystalline size, K is the shape factor, λ is the wavelength of the incident X-ray, β is the full width at half maximum. In this case, the values of β for 700 °C annealed fresh GeOx and air-exposed GeOx are 0.0055 rad (0.318) and 0.0065 rad (0.370), respectively. Taking K=0.89 (the typical value of the shape factor) and λ = 1.5406 Å, we can obtain the averaged crystalline sizes for annealed fresh GeOx and air-exposed GeOx are 26 nm and 22 nm, respectively. The crystalline domain size of metallic Ge by annealing fresh GeOx is slightly larger than that of air-exposed GeOx.

Although after the final annealing, the two GeOx possess very similar XRD patterns, the initial and intermediate phases are significantly different. Since XRD is only sensitive to structure of long-range order (i.e. crystalline), we then turn to XAFS to further examine the local structure of GeOx nanoparticles.

Figure 2 shows the Ge K-edge XANES for all GeOx samples, before and after annealing, in comparison with commercial GeO2 powder. As a fully oxidized Ge standard, the XANES of GeO2 is dominated by one sharp peak (marked by the dashed line in Fig. 2), which corresponds to the transition of an electron from the Ge 1s core level to an unoccupied 4p state. Compared to GeO2, both GeOx samples, with or without heat treatment, have additional features at lower energy (marked by the dotted line in Fig. 2), indicating the presence of Ge with an oxidation states lower than that in GeO2. Recall from the XRD pattern in Fig. 1 that the fresh GeOx is amorphous until annealed at a temperature above 500 °C. From XANES, we can see that there are both Ge- and GeO2-like structures in the fresh GeOx and the lack of diffraction peaks in the XRD suggests that they are amorphous. Under annealing at 500 °C and 700 °C, crystalline Ge appears (as confirmed by XRD, refer back to Fig. 1), although there is still amorphous GeO2 present as evidenced by XANES. On the other hand, air-exposed GeOx is dominated by GeO2. A slight broadening at the lower energy side of the main peak is caused by the presence of Ge sub-oxides and Ge. A sudden transition occurs after annealing at 700 °C, in which almost all the GeO2 disappears and the spectrum is dominated by a low-valent species Ge (spectrum 2-d). The energy onset and the spectral profile resembles the previously reported metallic Ge2,28. Unlike the fresh GeOx which has a mixture of metallic Ge and amorphous GeO2, air-exposed GeOx after 700 °C turns almost completely to metallic Ge. We note that the XRD patterns for the fresh and air-exposed samples after annealing at 700 °C are essentially the same, but the metallic Ge-related feature in the XANES is more intense for the air-exposed sample than the fresh sample, suggesting that in the air exposed sample, a larger fraction of the available Ge is converted to cubic Ge than in the fresh sample. This is further corroborated by noting that the air-exposed sample lacks a clear GeO2-related feature in the XANES; suggesting that so much Ge has been converted to metallic Ge that a distinct GeO2 phase is unable to form. Recall that the air-exposed sample annealed at 700 °C exhibits a smaller grain size for metallic Ge than the fresh sample annealed at 700 °C. If any Ge oxide remaining in these samples after annealing at 700 °C occupies the space between the grains, if these grains are close-packed then the smaller grains in the air-exposed sample will lead to smaller domains of Ge oxide; possibly too small for a distinct GeO2 lattice to form.

A closer examination of the oxidation states in Ge can be performed by examining the 1st derivative of the XANES spectra. The plots are shown in Fig. 3 and the peak positions (the edge jump) correspond to the oxidation states of Ge in the samples. This method allows us to obtain the evolution of Ge oxidation states during annealing in detail. The lower energy dashed line marks the edge jump of Ge0 and the higher energy line marks the one of Ge4+. Interestingly, the evolution of the edge jump positions as a function of annealing temperature is quite different between the two sets of GeOx.

Ge K-edge XANES of GeOx nanoparticles plotted in 1st derivatives.

The legend is the same as the one shown in Fig. 2.

For fresh GeOx at room temperature (spectrum 1-a in Fig. 3), the edge jump is at energy slightly higher than Ge0, while after annealing, all the edge jumps are aligned to the position of Ge0 regardless of temperature. Instead of Ge0, the Ge in fresh GeOx are slightly oxidized (i.e. 0 < x ≤ 2). After annealing at 300 °C, GeOx undergoes a disproportionation reaction, producing Ge and GeO2 (reaction (4)), leading to the lower-energy shift of the main peak position and a better-defined GeO2 edge jump.

The disproportionation reaction of GeOx into Ge and GeO2 is commonly observed in Ge nanostructure synthesis. The reaction takes place when GeOx is annealed in a non-oxidizing environment and is considered as one of the intermediate stages in forming a Ge-GeO2 complex22. It has been observed experimentally using XANES that annealing GeOx thin films under N2 results in a low-energy shift in the shoulder feature and an intensity increase in GeO2 feature27,29. At 500 °C annealing, the GeO2 decreases noticeably, while Ge remains almost unchanged. At this temperature, the reduction of GeOx starts to take place and O is being removed out of the system. The amorphous Ge clusters starts to crystalize. At 700 °C, phase separation takes place, Ge forms large crystalline grains and the left over GeO2 migrates to the grain boundary.

As for air-exposed GeOx, the one at room temperature contains both fully oxidized GeO2 and Ge sub-oxide. The Ge sub-oxide component exhibit a progressive shift at alleviated annealing temperature until it becomes Ge0, while the edge jump of the GeO2 component remains stable but the intensity decrease until it totally disappears as the temperature reaches 700 °C.

The results above demonstrate that the fresh GeOx and air-exposed GeOx has distinct compositions and because of this, they undergo different crystallization processes under H2 annealing, even though the ultimate products have identical XRD patterns. The fresh GeOx is always a mixture of Ge and GeO2, while air-exposed GeOx is dominated by GeO2 at low and intermediate temperatures with a gradual emergence of Ge and GeO2 is fully converted to Ge0 at high annealing temperature.

The Fourier transformed EXAFS spectra of GeOx are shown in Fig. 4. The amplitude was fitted using the IFFEFIT package at the R-range between 1.0 Å and 2.5Å (first shell). Detailed structural parameters, such as the Ge coordination number (CN), Ge-O and Ge-Ge bond distance (R), Debye Waller factor (σ2) and inner potential shift (ΔE) are listed in Table 1.

Fourier transforms of Ge K-edge k3-weighted EXAFS data in R-space with first-shell fits.

Solid lines: experimental spectra; dotted lines: fitted spectra. Sample series 1: fresh GeOx, series 2: air-exposed GeOx. The labels are the same as the ones in Fig. 2.

It can be clearly seen from Fig. 4 that the fresh GeOx contains significant amount of Ge-Ge bonding, with bond distance of ~2.45Å. This bond length is consistent with previous EXAFS studies of Ge-Ge bonding30. The CNGe-Ge is less than the one of metallic Ge, indicating its amorphous nature. As for the oxide component, Ge-O bonds are present in the material with bond lengths close to that of GeO2. Compared to GeO2, only the first shell Ge-O is present in GeOx; the features from second shell (features around 2.5Å to 3.2Å) are missing. The low CNGe-O means GeOx are highly under-coordinated compared to GeO2.This further confirms that the GeOx components in the fresh samples lack long range order. The as-prepared GeOx contains both GeOx and Ge clusters in an amorphous form.

Under annealing at 300 °C, the CNGe-O remains almost unchanged (within the error range), while the CNGe-Ge increases. The values deduced from the fitting further supports our proposed reaction of GeOx disproportionation at 300 °C (reaction 4). During the reaction, O atom is transferred from one Ge to another Ge, leaving one Ge with dangling bond and then two adjacent Ge joined together to form Ge-Ge bond. A similar reaction scheme was proposed by Wang et al. on vacuum annealed GeO film21 and our result is consistent with their observation.

The Ge-O bond almost disappears after annealing at 500 °C, while there is a slight decrease in CNGe-Ge. At this stage, reduction of GeOx (reaction (5)) becomes the dominant reaction in the system. This reaction leads to the consumption of GeOx, hence a significant decrease of CNGe-O.

As the temperature further increases, thermal induced crystallization takes place, the Ge clusters becomes highly coordinated, with CNGe-Ge approaches metallic Ge.

We should note that CNGe-Ge, CNGe-O and the intensity of the XANES features are smaller for the sample annealed at 500 °C than for the other samples (refer back to Fig. 2 and Table 1). There are two possible explanations for this: One is that at 500 °C disproportionation into cubic Ge and amorphous GeO2 is complete, but these phases exist as finely mixed nanoscale domains (this is supported by the rather broad XRD pattern of cubic Ge from the sample annealed at 500 °C, refer back to Fig. 1(b)). These very small domains indicate a relatively large amorphous boundary region, in which the general lack of structure would lead to a more intense background in the XAFS spectrum that reduces the relative amplitude of the fine structure features related to the Ge and GeO2 and phases. After annealing at 700 °C the respective cubic Ge and amorphous GeO2 domains are large enough to be resolved separated in the XAFS spectrum. On the other hand, it is possible that the pellet prepared from the 500 °C sample was slightly too thick for XAFS and consequently the XANES features and coordination numbers are reduced by the “thickness effect”31. We would like to stress that the ratio of CNGe-O to CNGe-Ge is the same for the samples annealed at 500 °C and 700 °C (~0.3) and both are lower than those for the samples annealed at 300 °C (0.46) and as-prepared (0.65). The thickness of the XAFS sample would affect CNGe-O and CNGe-Ge equally, so this observation is independent of possible measurement artefacts. Therefore regardless of whether the anomalous aspects of the XANES and EXAFS from the sample annealed at 500 °C are due to nanoscale GeO2, Ge phase separation, or are due to a measurement artefact, the discussion above shows that the disproportionation reaction (4) is largely complete after annealing at 500 °C and that higher temperatures simply improve phase separation and growth of larger crystals of Ge. We should also point out that a previous report shows that high temperature (above 500 °C) annealing induces the crystallization of GeOx23, which would lead to O migration to the edges of the cubic Ge domains. This could also lead to the increase in the CNGe-O from the sample annealed at 500 °C to the one annealed at 700 °C.

As for the air-exposed GeOx, the material retains GeO2-like features from room temperature up to 500 °C. The room temperature sample contains mostly undercoordinated GeO2 and the CNGe-O is much closer to GeO2 compared to fresh GeOx. The second shell component of radial distance above 2.4Å is also present, so that air-exposed GeOx is more of a GeO2-like crystalline structure. This also explains why GeO2-like pattern only appears in the XRD of air-exposed GeOx but not the fresh ones. Small amounts of Ge-Ge bonds are present in the sample too, but from their low CN and long Ge-Ge distance, they are unlikely to be Ge clusters. Instead, the system is more like GeO2 with oxygen vacancies, in which Ge is present as dangling bonds.

Unlike fresh GeOx, the disproportionation reaction does not happen in the air-exposed GeOx sample system. From Table 1, we see a decrease in CNGe-O, while CNGe-Ge remains almost constant at 300 °C. Annealing the GeOx in a reduced environment only partially removes O atoms (i.e. amorphorization), following the reaction (6), which produces a highly oxygen-deficient GeO2 structure. Meanwhile, the Ge-Ge distance gets shorter, indicating the formation of amorphous Ge cluster.

At 500 °C, the decrease of CNGe-O slows down. Recall from Fig. 1, metallic Ge features start to appear in the XRD, so at this stage, structural rearrangement start to occur. Note the Ge-O long-range order also improves as seen in Fig. 4. A system with many oxygen vacancies is not thermodynamically stable, so O migrates and produces GeO2 and adjacent Ge start to join each other forming Ge-Ge bonds. At 700 °C, the high temperature leads to a total reduction of GeOx (reaction (7)), leading to a sudden transition from GeOx to Ge. Upon the removal of almost all O in GeOx, the Ge grows into cubic crystallites. The relative rapidity of this transition may explain why these crystallites are somewhat smaller than those that form during the more gradual crystallization during annealing in the fresh GeOx samples. As the O is almost all removed, a distinct GeOx phase no longer exists. This is evidenced by the lack of a clear GeO2-related feature in the XANES spectrum from the air-exposed sample annealed at 700 °C (refer back to Fig. 2), as well as the anomalously short Ge-O bond length obtained from EXAFS fitting (see Table 1). The remaining O is likely only found as a capping layer on the Ge crystallites.

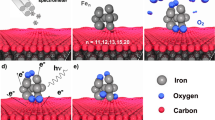

The structures of the two GeOx samples and their behaviour under H2 annealing can be summarized in the scheme shown in Fig. 5. The fresh GeOx contains both elemental Ge and GeOx (x closes to 1), both are amorphous and present in comparable amounts. H2 annealing induces the disproportionation and reduction of GeOx, forming more Ge clusters. Ge clusters crystalize at high annealing temperatures and grain boundaries are filled with GeOx. Air-exposed GeOx, on the other hand, can be modelled as GeO2 crystallites with O vacancies. Ambient air introduces oxygen and the initial product is mostly crystalline GeO2 with GeOx where x closes to 2. H2 annealing gradually creates more oxygen vacancies, reducing the presence of crystalline GeO2 and leading to the formation of more Ge dangling bonds. The GeOx structure is completely eliminated at the temperature of 700 °C, when a transition to crystalline Ge occurs due to the H2 reduction reaction.

Illustration of the structure of GeOx nanoparticles, fresh (1-a) and air-exposed (2-a) and their compositions under H2 annealing.

The labels are the same as the ones in Fig. 2.

Conclusion

As nominal GeOx compounds, the actual compositions could vary significantly from material to material, depending on the synthesis strategies and post-treatment conditions. We have demonstrated that the exact composition and structure of GeOx and its structural evolution during annealing can be successfully analyzed using XAFS. In our model system, GeOx nanoparticles were synthesized by chemical reduction of GeO2, freshly prepared GeOx is found consisting of Ge clusters and GeOx (x closes to 1), both in amorphous forms. Such GeOx undergoes disproportionation when annealed in a reducing environment. The amount of amorphous Ge increases and finally crystallizes into metallic Ge, with GeOx presents at the grain boundaries. However, if the GeOx is exposed to ambient conditions, the elemental Ge domains are quickly replaced by oxides and the nanoparticles turn into a GeO2-like structure. Once such structure formed, the GeOx (x closes to 2) can be slowly reduced by H2, under mild temperature, producing small Ge crystallites embedded in GeOx matrix. Once the temperature reaches 700 °C, there is a complete conversion of GeOx to Ge. The composition of GeOx can change significantly from its initial composition after exposure to oxygen and this exposure also affects how the structural rearrangement takes place during post-treatment. These findings are of paramount importance to developing GeOx anodes for Li-ion batteries. In particular, they highlight the importance of carefully controlled synthesis of GeOx anodes – as even under identical preparation conditions, the composition and crystal structure can completely change based on whether or not the samples are exposed to ambient conditions. A controlled regime of air exposure followed by annealing in H2 can further tailor the composition of the material. All the samples investigated here have nominal GeOx structures, but each of them possesses unique structures, which are identified by XAFS. With this in mind, the next step of the research includes the examination of Li battery performance with integration of these materials. The device performance can then be related to the fundamental structures of the GeOx. Amorphous Ge is preferable to crystalline Ge for Li-storage, but smaller clusters are also preferable to larger clusters. If the composition of the GeOx is tunable, we will be able to find which configuration is desired as an anode material.

Methods

Material Synthesis

GeOx nanoparticles were prepared using a chemical reduction method11,24. 2.0 g of GeO2 (99.99%, Aladdin) was first dissolved in 36 mL deionized water and 7 mL of NH4OH (28%-30% NH3, Aladdin) was added. Freshly prepared NaBH4 (98%, Aladdin) solution (3.616 g in 20 mL deionized water) was quickly added to the mixture. The solution was vigorously stirred for 20h at room temperature. The resulting product was then filtered, washed with deionized water and dried under vacuum at 50 °C. The freshly prepared GeOx was divided into two parts, one sealed in a glass vial and kept in a glove box filled with N2 (denoted as fresh GeOx) and the other one was kept in a desiccator (humidity <3%) for 3 days (denoted as air-exposed GeOx). H2 annealing was conducted in a tube furnace. GeOx was placed in a combustion crucible at the centre of the tube and 2% H2 was introduced to the tube at a rate of 50 sccm (standard-state cubic centimetre per minute). The samples were annealed at 300 °C, 500 °C and 700 °C, respectively, under the H2 flow. The temperature was increased at a rate of 2.1 °C/min and held at the desired temperature for 30 min. After annealing, the samples were cooled down to the room temperature.

Characterization

X-ray diffraction (XRD) and transmission electron microscopy (TEM) characterization was performed at the Institute of Functional Nano and Soft Materials (FUNSOM), Soochow University. XRD was done using a PANalytical (Empyrean) apparatus with Cu Kα as the probing source. The morphology of the as-prepared GeOx was examined using TEM (Tecnai G2 F20, FEI). The Ge K-edge XAFS experiments were conducted at beamlines BL01C1 at National Synchrotron Radiation Research Center (NSRRC), Taiwan and BL12B1 at SPring8, Japan. NSRRC is a 1.5 GeV storage ring operating at the beam current of 360 mA in top-up mode. The beamline, BL01C1 has energy range of 6–33 keV and a resolution ΔE/E of 2.3 × 10−4. SPring-8 is an 8 GeV ring operating at the beam current of 100 mA in top-up mode. BL12B1 has an energy range of 5–25 keV with resolution ΔE/E of 10−4. The GeOx powder was pressed into thin pellets and sealed in Kapton tape. The spectra were measured using transmission mode. Commercially obtained GeO2 powder (99.99%, Aladdin) was used as a reference.

XAFS data analysis

XAFS data was processed following the standard procedure using the IFFEFIT software package32. Briefly, in the pre-edge region, the spectrum was fitted to a straight line and the post-edge background was fitted with a cubic spline. The EXAFS function, χ, was obtained by subtracting the post-edge background from the overall absorption and then normalizing with respect to the edge jump step. The EXAFS fitting was performed in R-space between 1.0 Å and 2.6 Å (the Fourier transform from k-space was performed over a range of 3.0 to 14.0 Å−1), taking both Ge-O and Ge-Ge shells into consideration. The amplitude reduction factor S02 was determined to be 0.85 (±0.09), using GeO2 powder of quartz-phase and assuming Ge is fully coordinated with a coordination number (CN) of 4. Structural parameters of the GeOx samples, such as coordination numbers, bond distance (R), Debye-Waller factor (σ2) and inner potential shift (E0) were fitted using the IFEFFIT code.

Additional Information

How to cite this article: Zhao, J. et al. Reduced GeO2 Nanoparticles: Electronic Structure of a Nominal GeOx Complex and Its Stability under H2 Annealing. Sci. Rep. 5, 17779; doi: 10.1038/srep17779 (2015).

References

Graetz, J., Ahn, C. C., Yazami, R. & Flultz, B. Nanocrystalline and thin film germanium electrodes with high lithium capacity and high rate capabilities. J. Electrochem. Soc. 151, A698–A702, (2004).

Lee, H. et al. Surface-stabilized amorphous germanium nanoparticles for lithium-storage material. J. Phys. Chem. B 109, 20719–20723, (2005).

Kim, M. G. & Cho, J. Nanocomposite of amorphous Ge and Sn nanoparticles as an anode material for Li secondary battery. J. Electrochem. Soc. 156, A277–A282, (2009).

Lee, H., Kim, H., Doo, S.-G. & Cho, J. Synthesis and optimization of nanoparticle Ge confined in a carbon matrix for lithium battery anode material. J. Electrochem. Soc. 154, A343–A346, (2007).

Kennedy, T. et al. High-performance germanium nanowire-based lithium-ion battery anodes extending over 1000 cycles through in situ formation of a continuous porous network. Nano Lett. 14, 716–723, (2014).

Park, M. H., Kim, K., Kim, J. & Cho, J. Flexible dimensional control of high-capacity Li-ion-battery anodes: from 0D hollow to 3D porous germanium nanoparticle assemblies. Adv. Mater. 22, 415–418, (2010).

Park, M. H. et al. Germanium nanotubes prepared by using the Kirkendall effect as anodes for high-rate lithium batteries. Angew. Chem. Int. Ed. 50, 9647–9650, (2011).

Xue, D. J. et al. Improving the electrode performance of Ge through Ge@C core-shell nanoparticles and graphene networks. J. Am. Chem. Soc. 134, 2512–2515, (2012).

Cui, G. et al. A germanium-carbon nanocomposite material for lithium batteries. Adv. Mater. 20, 3079–3083, (2008).

Wang, X. L. et al. Amorphous hierarchical porous GeOx as high-capacity anodes for Li ion batteries with very long cycling life. J. Am. Chem. Soc. 133, 20692–20695, (2011).

Choi, S. H., Jung, K. Y. & Kang, Y. C. Amorphous GeOx-coated reduced graphene oxide balls with sandwich structure for long-life lithium-ion batteries. ACS Appl. Mater. Interfaces 7, 13952–13959, (2015).

Lin, Y.-M., Klavetter, K. C., Heller, A. & Mullins, C. B. Storage of lithium in hydrothermally synthesized GeO2 nanoparticles. J. Phys. Chem. Lett. 4, 999–1004, (2013).

Hwang, J. et al. Mesoporous Ge/GeO2/carbon lithium-ion battery anodes with high capacity and high reversibility. ACS Nano 9, 5299–5309, (2015).

Pena, J. S. et al. Electrochemical reaction between lithium and β-quartz GeO2 . Electrochem. Solid-State Lett. 7, A278–A281, (2004).

Feng, J. K., Lai, M. O. & Lu, L. Influence of grain size on lithium storage performance of germanium oxide films. Electrochimica Acta 62, 103–108, (2012).

Seng, K. H., Park, M. H., Guo, Z. P., Liu, H. K. & Cho, J. Catalytic role of Ge in highly reversible GeO2/Ge/C nanocomposite anode material for lithium batteries. Nano Lett. 13, 1230–1236, (2013).

Fang, Z. et al. 3D hollow framework of GeOx with ultrathin shell for improved anode performance in lithium-ion batteries. Electrochimica Acta 151, 453–458, (2015).

Wu, J. et al. In situ structural evolution from GeO nanospheres to GeO/(Ge, GeO2) core-shell nanospheres and to Ge hollow nanospheres. CrystEngComm 13, 4611, (2011).

Shinde, S. L. & Nanda, K. K. Thermal oxidation strategy for the synthesis of phase-controlled GeO2 and photoluminescence characterization. CrystEngComm 15, 1043–1046, (2013).

Wang, S. K., Liu, H.-G. & Toriumi, A. Kinetic study of GeO disproportionation into a GeO2/Ge system using x-ray photoelectron spectroscopy. Appl. Phys. Lett. 101, 061907, (2012).

Zhang, Y. F. et al. Germanium nanowires sheathed with an oxide layer. Phys. Rev. B 61, 4518–4521, (2000).

Vijayarangamuthu, K. et al. Ge nanocrystals embedded in a GeOx matrix formed by thermally annealing of Ge oxide films. J. Vac. Sci. Technol. A 27, 731, (2009).

Jing, C., Zang, X., Bai, W., Chu, J. & Liu, A. Aqueous germanate ion solution promoted synthesis of worm-like crystallized Ge nanostructures under ambient conditions. Nanotechnology 20, 505607, (2009).

Peng, M. et al. Electronic structure and photoluminescence origin of single-crystalline germanium oxide nanowires with green light emission. J. Phys. Chem. C 115, 11420–11426, (2011).

Ridgway, M. C. et al. EXAFS characterisation of Ge nanocrystals in silica. Nucl. Instrum. Meth. Phys. Res. B 218, 421–426, (2004).

Sahle, C. J. et al. Phase separation and nanocrystal formation in GeO. Appl. Phys. Lett. 95, 021910, (2009).

Ge XRD pattern from ICSD (ICDD 01-089-4164), from Smakula, A. & Kalnajs, J. Precision Determination of Lattice Constants with a Geiger-Counter X-ray Diffractometer. Phys. Rev. 99, 1737, (1955).

Schacht, A. et al. Temperature-induced obliteration of sub-oxide interfaces in amorphous GeO. J. Non-Crystalline Solids 355, 1285–1287, (2009).

Little, W. et al. Structural origin of light emission in germanium quantum dots. Scientific Reports 4, 7372, (2014).

Stern, E. A. & Kim, K. Thickness effect on the extended-x-ray-absorption-fine-structure amplitude. Phys. Rev. B, 23, 3781–3787, (1981).

Yuan, F.-W., Yang, H.-J. & Tuan, H.-Y. Alkanethiol-passivated Ge nanowires as high-performance anode materials for lithium-ion batteries: the rold of chemical surface functionalization. ACS Nano 6, 9932–9942, (2012).

Newville, M. IFEFFIT: interactive EXAFS analysis and FEFF fitting. J. Synchrotron Rad. 8, 322–324, (2001).

GeO2 XRD pattern from ICSD (ICDD 01-083-2476), from Jorgensen, J. D., Compression mechanisms in α-quartz structures – SiO2 and GeO2 . J. Appl. Phys. 49, 5473, (1978).

Gerion, D. et al. Solution synthesis of germanium nanocrystals: success and open challenges. Nano Lett. 4, 597–602, (2004).

Acknowledgements

This work is funded by National Natural Science Foundation of China (NSFC) (project numbers 21403147, 11404232 and U1432106). The authors acknowledge the support from Soochow University-Western University Center for Synchrotron Radiation Research and Collaborative Innovation Center of Suzhou Nano Science and Technology (NANO-CIC), Soochow University. J. Z. acknowledges the help from Mr. Mo Sha for the H2 annealing experiment.

Author information

Authors and Affiliations

Contributions

L.L. conceived and designed the experiments. J.Z. synthesized GeOx nanoparticles and performed the preliminary characterization. L.Y. and J.Z. conducted the XAFS measurements. J.A.M. and L.L. performed the spectra analysis and wrote the manuscript. All authors discussed and commented on the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Zhao, J., Yang, L., McLeod, J. et al. Reduced GeO2 Nanoparticles: Electronic Structure of a Nominal GeOx Complex and Its Stability under H2 Annealing. Sci Rep 5, 17779 (2015). https://doi.org/10.1038/srep17779

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep17779

This article is cited by

-

Atomic-scale combination of germanium-zinc nanofibers for structural and electrochemical evolution

Nature Communications (2019)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.