Abstract

TiO2-coated Ag nanorods (Ag@TiO2 NRs) have been fabricated as multifunctional surface-enhanced Raman scattering (SERS) substrates. Uniform TiO2 shells could sufficiently protect the internal Ag NRs against oxidation and sulfuration, thus the temporal stability of SERS substrates was markedly improved. Meanwhile, due to the synergetic effect between crystalline TiO2 and Ag, the nanocomposites could clean themselves via photocatalytic degradation of the adsorbed molecules under ultraviolet irradiation and water dilution, making the SERS substrates renewable. Such Ag@TiO2 NRs were shown to serve as outstanding SERS sensors featuring high sensitivity, superior stability and recyclability.

Similar content being viewed by others

Introduction

As an influential spectroscopic detection method for extremely minute amounts of target molecules, surface-enhanced Raman scattering (SERS) technique is currently recognized as one of the most promising analytical tools in fields of chemistry, biology, medicine and life science1,2,3,4, with the advantages of ultrahigh sensitivity and specificity, rapid response speed as well as non-destructive determination5,6,7,8. In general, noble metal materials (in particular Au, Ag and Cu) of multiple nanostructures can render excellent SERS performance, introduced mainly by the electromagnetic (EM) resonance between the incident optical field and localized surface plasmons (LSP)9,10. In recent years, great efforts have been dedicated to fabricate various noble metal substrates as efficient Raman signal amplifiers and even to meet the requirements for single-molecule detection11,12,13,14.

However, from practical application viewpoint, not only strong enhancement but also stability, recyclability as well as cost-effective preparation methods are necessary for satisfactory SERS sensors. To this end, the fabrication of SERS-active substrates with optimized properties is still faced with numerous challenges. For example, despite the optimal plasmonic enhancement of Ag nanostructures15,16,17, their applicability is hindered by the poor stability, which is caused by the oxidation and sulfuration of silver in air18,19,20 and will greatly weaken the SERS performance. Furthermore, traditional SERS substrates with noble metals are not easily reused, thus the high costs would seriously hamper the universality of SERS technique21,22,23. For these reasons, it is significant to develop stable and recyclable SERS substrates. Lately, nanocomposites consisting of noble metals and photocatalytic materials have been elaborately designed and synthesized, which showed great potential to satisfy the above demands12,24,25,26,27,28.

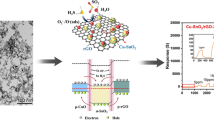

Herein, we reported the preparation of Ag nanorods coated with uniform TiO2 overlayers (Ag@TiO2 NRs), for the synthesis of sensitive, stable and recyclable SERS substrates. Slanted Ag NRs were prepared based on oblique angle vapor deposition (OAD)29,30,31 technique and were subsequently covered with TiO2 layers using atomic layer deposition (ALD)19,32. In order to achieve the recyclability of the substrates, further thermal annealing at 300 °C was employed to improve the crystallinity of TiO2, which was crucial for photocatalytic activity. The Raman enhancement originates from ordered Ag NRs and TiO2 shells function as a barrier that could protect the internal Ag NRs at elevated temperatures as well as avoid their direct contact with external environments. What’s more, the self-cleaning ability stems from the ultraviolet (UV) light-induced degradation of analytes via the synergetic effect of TiO2 shells and Ag NRs, i.e., subsequent to SERS measurements, the substrates can be purified by UV irradiation and be reused for further Raman analyses. This self-cleaning function offers an opportunity to eliminate the single-use shortcoming of most conventional SERS substrates and reduce the SERS measurement costs as well.

Results and Discussion

Characterization of Ag@TiO2 NRs

Ag NRs coated with TiO2 shells by 1, 2, 3, 4 and 5 ALD cycles are denoted hereafter as Ag@TiO2-1, Ag@TiO2-2, Ag@TiO2-3, Ag@TiO2-4 and Ag@TiO2-5, respectively. Figure 1a shows the typical top-view and side-view SEM images of Ag@TiO2-3 NRs. It could be observed that the tilted NRs are ~40 nm in diameter, ~280 nm in length and well-separated. Note that, due to the relative low-temperature ALD procedure (at 80 °C) and the generated TiO2 shells, there were no evident fusion and distortion of the underneath Ag NRs during ALD coating and the subsequent annealing treatments19,33,34. In addition, we found that the substrates coated by different ALD cycles showed no visible structure variation observed from the SEM resolution, which might be due to the ultrathin nature of the deposited TiO2 layers.

We thus used TEM analyses to provide a visual evidence of the TiO2 coatings, which were also applied to probe the thickness growth of TiO2 layers. The TEM images of Ag@TiO2 substrates coated with 1 to 5 ALD cycles are displayed in Fig. S1. It is shown that the TiO2 coatings grown at 80 °C are extremely conformal and uniform with varying thickness, fully wrapping the Ag NRs and are amorphous in structure. A linear relationship between TiO2 thickness and ALD cycles was obtained at ~0.55 nm per cycle, which was ascribed to the intrinsic characteristic of ALD process on the basis of sequential self-terminating growth32. Further, after annealing at 300 °C, Ag@TiO2-3 NRs exhibit the lattice spacing of 0.233 nm obtained from HRTEM image in Fig. 1b. This lattice spacing corresponds to the distance between the (112) crystal planes of anatase35,36 and indicates the crystallization of TiO2 at high temperature.

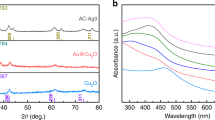

XPS measurements were conducted to further verify the surface components and valence states of Ag@TiO2 substrates. As shown in Fig. 2a, no excessive peaks other than Ag, Ti, O and C signals are observed from Ag@TiO2-3 NRs. Figure 2b plots the XPS spectrum of Ag 3d5/2 and Ag 3d3/2 double peaks from the substrate, which are centered at 367.8 and 373.8 eV, respectively. This is in good agreement with those of elemental Ag37,38 and demonstrates that there was no corrosion of Ag NRs during ALD and post-annealing procedures. Figure 2c shows the amplified Ti 2p3/2 and Ti 2p1/2 XPS peaks at 458.5 and 464.2 eV, indicating the formation of Ti4+ in TiO2 39,40. In addition, compared with TiO2 molecules, the ALD precursor tetrakis(dimethylamino)titanium (TDMAT) contains four N atoms in each molecule41, so the XPS spectrum of N element could be used to further evaluate the reaction extent of TDMAT and water. Figure 2d represents the XPS spectra of N 1 s from bare Ag and Ag@TiO2-3 NRs. No visible peaks were observed in both curves, which means that the Ti-N bonds of TDMAT were fully broken and the chemical reaction during ALD process was complete.

(a) XPS survey spectrum taken from Ag@TiO2-3 NRs. (b) HRXPS Ag 3d spectrum on Ag@TiO2-3 NRs. (c) HRXPS Ti 2p spectrum on Ag@TiO2-3 NRs. (d) HRXPS N 1 s spectra on different substrates: the spectrum above is from bare Ag NRs and the one below is from Ag@TiO2-3 NRs. All binding energies of the XPS spectra are calibrated with reference to the C1s peak at 284.8 eV.

Sensitivity and Stability of Ag@TiO2 NRs

It has been long recognized that the Raman enhancement of metal nanostructures depends strongly on the distance between metal surfaces and adsorbed molecules19,42,43. We therefore investigated the TiO2 layers’ effect on the sensitivity of SERS substrates, using crystal violet (CV) as a model analyte. The inset in Fig. 3a shows the SERS spectra of 10−5 M CV on bare Ag NRs and Ag NRs coated with TiO2 layers by 1 to 5 ALD cycles. It is observed that all spectra with distinct intensities clearly reveal several characteristic Raman bands of CV molecules44. Herein, the 1171 cm−1 Raman peak with strong intensity was chosen to quantitatively calculate the attenuation effect of TiO2 layers on SERS sensitivity. Figure 3a plots the normalized Raman intensities at 1171 cm−1 as a function of ALD cycles. As expect, due to the enhancive analyte-substrate separation introduced by TiO2, CV Raman signals decreased monotonously with the increase of ALD cycles. To be specific, the CV intensities on Ag@TiO2-1, Ag@TiO2-2 and Ag@TiO2-3 substrates occupied ~65%, ~55% and ~43%, respectively, compared with those on bare Ag NRs and then decreased mildly when further increasing the TiO2 thickness. It is noted that, although the Raman enhancement dropped to some extent when TiO2 became thicker, all coated substrates still exhibited large Raman signals with little background noises. Fig. S2 shows the Raman spectra of CV on Ag@TiO2-2 NRs at concentrations ranging from 10−5 M to 10−10 M. One sees that the Raman intensities descend along with CV concentrations, nevertheless, their Raman peaks were readily observed even when the concentration was as low as 10−9 M. Meanwhile, the detection limits for Ag@TiO2-3 and Ag@TiO2-4 NRs were down to 10−8 M (spectra not shown here), demonstrating the superior sensitivity of Ag@TiO2 nanocomposites.

(a) The normalized Raman intensities of 1171 cm−1 peak from 10−5 M CV molecules versus the ALD cycles of Ag@TiO2 NRs. The inset illustrates the Raman spectra of 10−5 M CV adsorbed on bare Ag NRs and Ag@TiO2-1, Ag@TiO2-2, Ag@TiO2-3, Ag@TiO2-4, Ag@TiO2-5 NRs, respectively. (b) The normalized Raman intensities of 1171 cm−1 peak on these substrates during aging in air for 48 days.

The temporal stability of bare Ag and Ag@TiO2 NRs was supervised via counting the SERS intensities of 10−5 M CV from the stored substrates as a function of time. Figure 3b displays the normalized Raman intensities at 1171 cm−1 band obtained from different substrates over a period of 48 days. For each sample, the 1171 cm−1 peak value was normalized to that on freshly prepared Ag NRs to facilitate comparison. As can been seen, CV signals on bare Ag NRs emerged a substantial decline even only after 8 days (~50% drop) and were more than one order smaller after 48 days. However, when the NRs were uniformly wrapped with ultrathin TiO2, their stability was dramatically enhanced. Specifically, Ag@TiO2-1 NRs presented a slight decrease in SERS performance, while the substrates covered with TiO2 by two or more cycles remained unchanged in SERS enhancement during the whole test period. As a result, the TiO2 shells could protect the internal Ag NRs against at atmospheric conditions, which were valuable in improving the corresponding stability of SERS substrates.

Recyclability of Ag@TiO2 NRs Substrates

In addition to sensitivity and stability, the recyclable property of SERS substrates is also meaningful for routine applications19,43,45. In our study, the self-cleaning performances of Ag@TiO2 NRs were investigated through UV light-assisted photocatalytic bleaching of organic molecules adsorbed on the substrates. These experiments were performed by the following setups: after SERS characterization of the analytes adsorbed on Ag@TiO2 NRs, the substrates were immersed into deionized water and were irradiated by UV light for certain times. When the organic molecules were completely decomposed, these substrates could be reused for further analyte immersion and SERS measurements. The primary results showed that the Ag NRs coated with TiO2 layers by 3, 4 and 5 cycles could degrade most of the CV molecules absorbed on them through UV radiation within 20 minutes, while Ag NRs with thinner TiO2 films could not achieve an effective decomposition of dye molecules within a short time. Hence, Ag@TiO2-3 NRs were chosen to verify the UV-assisted renewability, due to their relatively high SERS sensitivity compared with that of Ag@TiO2-4 and Ag@TiO2-5 substrates. As shown in Fig. 4a, four circulations of the “detection-UV cleaning” process were carried out. Strong Raman signals of 10−5 M CV were observed in the first round, while no obvious CV peaks were identified after UV-illumination, suggesting that the target molecules were gradually decomposed into small inorganic species such as CO2, HCl and H2O that could be removed easily by aqueous solvent26. In this way, this substrate could be reused as a new and clean SERS sensor, while it was not possible to wash the adsorbed molecules off the substrate barely by water (see Fig. S3). More importantly, the results from the subsequent three circulations showed that the Raman intensities of CV maintained almost at the same level in every detection step, which indicates that the Ag@TiO2 structure could endure multiple UV irradiations, enabling it to work as a reversible SERS substrate with high robustness.

In order to further confirm the universality of this multifunctional substrate, 5 × 10−6 M methylene blue (MB) molecules were introduced to perform the “detection-UV cleaning” routes. As shown in Fig. S4, intense MB Raman signals are carried out on Ag NRs covered with various cycles of TiO2. Typically, there was also a descending relationship between Raman intensities and TiO2 cycles, which was in accord with the results we reached before. The Ag@TiO2-3 substrate was employed again in the reusability tests. Figure 4b shows the Raman spectra of MB on the substrate before and after self-cleaning. One sees clearly that the MB signals almost vanished after 30-minute UV illumination and were fully recovered through subsequent MB soaking. Last but not least, different molecules can also be alternately examined and degraded over the same substrate. As shown in Fig. 4c, the representative vibration patterns of CV and MB were both clearly identified when dyes were adsorbed on Ag@TiO2-3 NRs, but were completely disappeared via UV irradiation and water dilution. We should note that the measurement of different molecules did not influence each other since only the Raman peaks of the adsorptive molecules were discovered other than any impurity peaks. These results suggest that the Ag@TiO2 composites were feasible to act as recyclable SERS substrates for the detection of organic species such as CV and MB and show great potential for further sensitive and reusable SERS applications13,26,28.

For comparison, this photocatalysis process was carried out on bare Ag NRs under the identical experiment conditions. From Fig. S5a, one sees that after UV irradiation for 30 minutes, the Raman peaks of MB were still clearly observed on Ag NRs and the decline of Raman signals may owing to the molecule dilution in water. Moreover, in the following three “detection-UV cleaning” cycles, when the substrate was further soaked into MB solution, the Raman signals dropped gradually time after time. Fig. S5b,c present the SEM images of Ag NRs adsorbed with MB, before and after UV irradiation for 60 minutes. Apparent coarsening was observed from the illuminated Ag NRs, i.e., the high power UV radiation gave rise to a detrimental effect on bare Ag NRs, resulting in the decrease in SERS sensitivity.

Photocatalytic Mechanism for Ag@TiO2 NRs

In the area of semiconductor-noble metal SERS substrates, TiO2 has attracted considerable attention owing to its strong chemical stability, remarkable photocatalytic activity and low-cost synthesis46,47,48. It is commonly accepted that the photocatalytic ability of TiO2 depends greatly on its crystal types and anatase is usually more active than rutile and amorphous TiO2 49,50,51. We thus annealed the Ag@TiO2 NRs at 300 °C to crystalize the amorphous TiO2 to anatase, in order to boost their photocatalytic performance. Additionally, Ag NRs in contact with TiO2 layers can act as electron traps to separate the photogenerated electron-hole pairs (e− − h+), which is beneficial for photocatalytic reactions13,52,53. Figure 5 illustrates the mechanism of such a process. When TiO2 is activated by UV light, it undergoes charge separation and the e− are excited into the conduction band of TiO2. Since the work function of Ag is lower than that of TiO2 51,53, Ag serves as an acceptor of the e− transformed from TiO2 layers, while the h+ remain in TiO2. As a consequence, Ag@TiO2 NRs provide a charge transfer channel at the metal-semiconductor interface and Ag could extensively suppress the recombination of e− − h+ pairs. The residual e− on the surface of TiO2 can be trapped via O2 to form superoxide (•O2−)54, while h+ at the valence band of TiO2 are oxidized by H2O to form surface hydroxyl radical (•OH)55. Thereafter, the organic molecules nearby will react with these active oxidative species and be decomposed into inorganic compounds. In this way, the strong interaction between Ag and TiO2 would optimize the separation of photo-excited charge carriers, resulting in a remarkable enhancement of organic molecules degradation efficiency.

Conclusion

In summary, we have developed a facile and novel approach for the fabrication of Ag NRs coated with uniform TiO2 shells as sensitive, stable and reusable SERS substrates and found that Ag NRs covered by ~2 nm TiO2 shell was optimal in our study. TiO2 overlayers could protect Ag NRs against the disturbance from air, without seriously weakening the sensitivity of SERS substrates. Moreover, due to the beneficial interaction between Ag NRs and TiO2 layers, dye molecules adsorbed on Ag@TiO2 NRs were rapidly photodegraded into inorganic species under UV irradiation, thus the renewed substrate could be used for further SERS analyses with little decline in sensitivity. This study suggests that Ag@TiO2 nanocomposites with stability and self-cleaning property can serve as superb substrates in SERS sensing fields.

Methods

Fabrication of Ag NRs

Slanted Ag NRs were grown on Si (001) substrates by OAD technique in an electron-beam system (GLAD, Thermionics Inc.) with a background vacuum level down to 10−6 Pa. During deposition, the angle between the surface normal of substrates and the incoming vapor flux was set at ~86° and the deposition rate as well as thickness were simultaneously monitored via a quartz crystal microbalance (QCM). The growth rate was fixed at ~0.75 nm/s and the deposition stopped when the QCM read 500 nm. The detailed deposition procedure can be found elsewhere56,57,58.

Fabrication of Ag@TiO2 NRs

TiO2 adhesion layers were deposited onto freshly prepared Ag NRs in an ALD reactor (MNT-100, Wuxi MNT Micro and Nanotech Co.). The TiO2 precursors, i.e., TDMAT (maintained at 110 °C) and water (maintained at 40 °C) were alternately pumped through the reaction chamber, using high purity N2 (99.999%, 15 sccm) as the carrier and purge gas. The chamber was heated and maintained at 80 °C so as to guarantee a complete chemical reaction of precursors, while not damaging the morphology of Ag NRs at the relatively low reaction temperature. Typically, one complete reaction cycle took ~38 s and consisted of four steps: (1) TDMAT reactant was pulsed for 200 ms and allowed to soak in an additional 5 s; (2) N2 gas was used to purge the chamber for 20 s; (3) water vapor was pulsed for 6 ms and soaked for an extra 3 s; and (4) the chamber was purified by N2 for 6 s. This reaction cycle repeated for 1, 2, 3, 4 and 5 times over Ag NRs and the as-prepared samples were further annealed at 300 °C for 30 minutes in a quartz tube furnace in air.

Characterization

The morphology, structure and chemical states of Ag NRs and Ag@TiO2 NRs were characterized by scanning electron microscope (SEM, JEOL-JMS-7001F), high-resolution transmission electron microscope (HRTEM, JEOL-2011) and X-ray photoelectron spectroscopy (XPS, PHI 5300) with Mg Kα as the excitation source, respectively.

Measurements of SERS Sensitivity and Recyclability

The SERS performances were evaluated by an optical fiber micro-Raman system (i-Raman Plus, B&W TEK Inc.) using CV and MB as probing molecules. Before SERS measurements, all substrates were submerged into dye aqueous solutions for 30 minutes and dried naturally in air. The Raman spectra were obtained using a 785 nm laser as the excitation source, with its beam spot focused to ~80 μm in diameter and an excitation power of 120 mW. The integration time of one spectrum was 15 s and 6 s for CV and MB, separately. For every sample, the Raman spectrum was obtained by averaging the spectra obtained from five different areas of the SERS substrate.

To test the UV-cleanable property, the photocatalytic self-cleaning experiments were performed by the following setups: after SERS characterization of the organic molecules adsorbed on Ag@TiO2 and bare Ag NRs (bare Ag NRs were used in a control experiment), these substrates were immersed into a vessel containing 50 mL deionized water and were irradiated by a 300 W Xe lamp for certain times. An ultraviolet cutoff filter was inserted between the light source and the substrates to block the UV light with the wavelength below 420 nm. The electric current was set at 15 A and the power density of the UV light was ~60 mW/cm2. Water was used to accelerate the dilution effect and get rid of the thermal energy coming from UV radiation. Then the illuminated substrates were dried in air and the following Raman spectra were executed to check the degradation degree of adsorbates. Finally, when the substrates showed no apparent Raman signals, they could be reused for further SERS trials. For the reusability characterization, the “detection-UV cleaning” cycles were repeated for four times on each sample.

Additional Information

How to cite this article: Ma, L. et al. Ag Nanorods Coated with Ultrathin TiO2 Shells as Stable and Recyclable SERS Substrates. Sci. Rep. 5, 15442; doi: 10.1038/srep15442 (2015).

References

Wang, Y. et al. Single Molecule Detection Using Surface-Enhanced Raman Scattering (SERS). Phys. Rev. Lett. 78, 1667–1670 (1997).

Anker, J. N. et al. Biosensing with Plasmonic Nanosensors. Nat. Mater. 7, 442–453 (2008).

Moskovits, M. Surface-Enhanced Raman Spectroscopy: A Brief Retrospective. J. Raman Spectrosc. 36, 485–496 (2005).

Liu, B. et al. Shell Thickness-Dependent Raman Enhancement for Rapid Identification and Detection of Pesticide Residues at Fruit Peels. Anal. Chem. 84, 255–261 (2011).

Nie, S. & Emory, S. R. Probing Single Molecules and Single Nanoparticles by Surface-Enhanced Raman Scattering. Science 275, 1102–1106 (1997).

Ko, H., Singamaneni, S. & Tsukruk, V. V. Nanostructured Surfaces and Assemblies as SERS Media. Small 4, 1576–1599 (2008).

Doering, W. E., Piotti, M. E., Natan, M. J. & Freeman, R. G. SERS as a Foundation for Nanoscale, Optically Detected Biological Labels. Adv. Mater. 19, 3100–3108 (2007).

Gunawidjaja, R., Peleshanko, S., Ko, H. & Tsukruk, V. V. Bimetallic Nanocobs: Decorating Silver Nanowires with Gold Nanoparticles. Adv. Mater. 20, 1544–1549 (2008).

Sutherland, W. S., Laserna, J. J., Angebranndt, M. J. & Winefordner, J. D. Surface-Enhanced Raman Analysis of Sulfa Drugs On Colloidal Silver Dispersion. Anal. Chem. 62, 689–693 (1990).

Ruperez, A., Montes, R. & Laserna, J. J. Identification of Stimulant Drugs by Surface-Enhanced Raman Spectrometry on Colloidal Silver. Vib. Spectrosc. 2, 145–154 (1991).

Camden, J. P. et al. Probing the Structure of Single-Molecule Surface-Enhanced Raman Scattering Hot Spots. J. Am. Chem. Soc. 130, 12616–12617 (2008).

Tan, E., Yin, P., You, T., Wang, H. & Guo, L. Three Dimensional Design of Large-Scale TiO2 Nanorods Scaffold Decorated by Silver Nanoparticles as SERS Sensor for Ultrasensitive Malachite Green Detection. ACS Appl. Mater. Inter. 4, 3432–3437 (2012).

Zhao, Y. et al. Electrospun TiO2 Nanofelt Surface-Decorated with Ag Nanoparticles as Sensitive and UV-Cleanable Substrate for Surface Enhanced Raman Scattering. ACS Appl. Mater. Inter. 6, 5759–5767 (2014).

Bachenheimer, L., Elliott, P., Stagon, S. & Huang, H. Enhanced Thermal Stability of Ag Nanorods through Capping. Appl. Phys. Lett. 105, 213104 (2014).

Cañamares, M. V., Garcia-Ramos, J. V., Gómez-Varga, J. D., Domingo, C. & Sanchez-Cortes, S. Comparative Study of the Morphology, Aggregation, Adherence to Glass and Surface-Enhanced Raman Scattering Activity of Silver Nanoparticles Prepared by Chemical Reduction of Ag+ Using Citrate and Hydroxylamine. Langmuir 21, 8546–8553 (2005).

Fernanda Cardinal, M., Rodríguez-González, B., Alvarez-Puebla, R. A., Pérez-Juste, J. & Liz-Marzán, L. M. Modulation of Localized Surface Plasmons and SERS Response in Gold Dumbbells through Silver Coating. J. Phys. Chem. C 114, 10417–10423 (2010).

Jiang, R., Chen, H., Shao, L., Li, Q. & Wang, J. Unraveling the Evolution and Nature of the Plasmons in (Au Core) - (Ag Shell) Nanorods. Adv. Mater. 24, 200–207 (2012).

Bao, L., Mahurin, S. M. & Dai, S. Controlled Layer-By-Layer Formation of Ultrathin TiO2 On Silver Island Films Via a Surface Sol-Gel Method for Surface-Enhanced Raman Scattering Measurement. Anal. Chem. 76, 4531–4536 (2004).

John, J. F., Mahurin, S., Dai, S. & Sepaniak, M. J. Use of Atomic Layer Deposition to Improve the Stability of Silver Substrates for in Situ, High-Temperature SERS Measurements. J. Raman Spectrosc. 41, 4–11 (2010).

Im, H., Lindquist, N. C., Lesuffleur, A. & Oh, S. Atomic Layer Deposition of Dielectric Overlayers for Enhancing the Optical Properties and Chemical Stability of Plasmonic Nanoholes. ACS Nano 4, 947–954 (2010).

Li, W., Camargo, P. H. C., Lu, X. & Xia, Y. Dimers of Silver Nanospheres: Facile Synthesis and their Use as Hot Spots for Surface-Enhanced Raman Scattering. Nano Lett. 9, 485–490 (2008).

Zhang, B. et al. Large-Area Silver-Coated Silicon Nanowire Arrays for Molecular Sensing Using Surface-Enhanced Raman Spectroscopy. Adv. Funct. Mater. 18, 2348–2355 (2008).

Canpean, V. & Astilean, S. Multifunctional Plasmonic Sensors on Low-Cost Subwavelength Metallic Nanoholes Arrays. Lab Chip 9, 3574–3579 (2009).

Zhang, X. et al. Multifunctional Fe3O4@TiO2@Au Magnetic Microspheres as Recyclable Substrates for Surface-Enhanced Raman Scattering. Nanoscale 6, 5971–5979 (2014).

Xu, S. C. et al. Ag-Decorated TiO2 Nanograss for 3D SERS-active Substrate with Visible Light Self-Cleaning and Reactivation. Analyst 138, 4519–4525 (2013).

Li, X., Chen, G., Yang, L., Jin, Z. & Liu, J. Multifunctional Au-Coated TiO2 Nanotube Arrays as Recyclable SERS Substrates for Multifold Organic Pollutants Detection. Adv. Funct. Mater. 20, 2815–2824 (2010).

Sinha, G., Depero, L. E. & Alessandri, I. Recyclable SERS Substrates Based On Au-coated ZnO Nanorods. ACS Appl. Mater. Inter. 3, 2557–2563 (2011).

Zou, X., Silva, R., Huang, X., Al-Sharab, J. F. & Asefa, T. A Self-Cleaning Porous TiO2-Ag Core-Shell Nanocomposite Material for Surface-Enhanced Raman Scattering. Chem. Commun. 49, 382–384 (2013).

Bantz, K. C. et al. Recent Progress in SERS Biosensing. Phys. Chem. Chem. Phys. 13, 11551–11567 (2011).

Zhou, Q., Li, Z., Yang, Y. & Zhang, Z. Arrays of Aligned, Single Crystalline Silver Nanorods for Trace Amount Detection. J. Phys. D: Appl. Phys. 41, 152007 (2008).

Driskell, J. D. et al. The Use of Aligned Silver Nanorod Arrays Prepared by Oblique Angle Deposition as Surface Enhanced Raman Scattering Substrates. J. Phys. Chem. C 112, 895–901 (2008).

George, S. M., Ott, A. W. & Klaus, J. W. Surface Chemistry for Atomic Layer Growth. J. Phys. Chem. 100, 13121–13131 (1996).

Formo, E. V., Mahurin, S. M. & Dai, S. Robust SERS Substrates Generated by Coupling a Bottom-Up Approach and Atomic Layer Deposition. ACS Appl. Mater. Inter. 2, 1987–1991 (2010).

Whitney, A. V., Elam, J. W., Stair, P. C. & Van Duyne, R. P. Toward a Thermally Robust Operando Surface-Enhanced Raman Spectroscopy Substrate. J. Phys. Chem. C 111, 16827–16832 (2007).

Meng, X., Geng, D., Liu, J., Li, R. & Sun, X. Controllable Synthesis of Graphene-Based Titanium Dioxide Nanocomposites by Atomic Layer Deposition. Nanotechnology 22, 165602–165611 (2011).

Kim, G. M. et al. Nanostructured Pure Anatase Titania Tubes Replicated from Electrospun Polymer Fiber Templates by Atomic Layer Deposition. Chem. Mater. 20, 3085–3091 (2008).

Yu, J., Xiong, J., Cheng, B. & Liu, S. Fabrication and Characterization of Ag-TiO2 Multiphase Nanocomposite Thin Films with Enhanced Photocatalytic Activity. Appl. Catal. B: Environ. 60, 211–221 (2005).

Stathatos, E., Lianos, P., Falaras, P. & Siokou, A. Photocatalytically Deposited Silver Nanoparticles on Mesoporous TiO2 Films. Langmuir 16, 2398–2400 (2000).

Chen, J. et al. 3D TiO2 Submicrostructures Decorated by Silver Nanoparticles as SERS Substrate for Organic Pollutants Detection and Degradation. Mater. Res. Bull. 49, 560–565 (2014).

Erdem, B. et al. XPS and FTIR Surface Characterization of TiO2 Particles Used in Polymer Encapsulation. Langmuir 17, 2664–2669 (2001).

Elam, J. W., Schuisky, M., Ferguson, J. D. & George, S. M. Surface Chemistry and Film Growth During TiN Atomic Layer Deposition Using TDMAT and NH3 . Thin Solid Films 436, 145–156 (2003).

Yang, K., Liu, Y., Hsu, T. & Juang, M. Strategy to Improve Stability of Surface-Enhanced Raman Scattering-Active Ag Substrates. J. Mater. Chem. 20, 7530–7535 (2010).

Mahurin, S. M., Bao, L. & Dai, S. Controlled Layer-by-Layer Formation of Ultrathin Oxide Films on Silver Island Films for Surface-Enhanced Raman Scattering Measurement. Isr. J. Chem. 46, 329–336 (2006).

Ye, Y. et al. Sea-Urchin-Like Fe3O4@C@Ag Particles: An Efficient SERS Substrate for Detection of Organic Pollutants. Nanoscale 5, 5887–5895 (2013).

Zhang, X., Zhao, J., Whitney, A. V., Elam, J. W. & Van Duyne, R. P. Ultrastable Substrates for Surface-Enhanced Raman Spectroscopy: Al2O3 Overlayers Fabricated by Atomic Layer Deposition Yield Improved Anthrax Biomarker Detection. J. Am. Chem. Soc. 128, 10304–10309 (2006).

Bian, Z., Zhu, J., Cao, F., Lu, Y. & Li, H. In Situ Encapsulation of Au Nanoparticles in Mesoporous Core-Shell TiO2 Microspheres with Enhanced Activity and Durability. Chem. Commun. 3789–3791 (2009).

Dunnill, C. W. & Parkin, I. P. Nitrogen-Doped TiO2 Thin Films: Photocatalytic Applications for Healthcare Environments. Dalton T. 40, 1635–1640 (2011).

Li, Y., Sasaki, T., Shimizu, Y. & Koshizaki, N. Hexagonal-Close-Packed, Hierarchical Amorphous TiO2 Nanocolumn Arrays: Transferability, Enhanced Photocatalytic Activity and Superamphiphilicity without UV Irradiation. J. Am. Chem. Soc. 130, 14755–14762 (2008).

Ohtani, B., Ogawa, Y. & Nishimoto, S. Photocatalytic Activity of Amorphous−Anatase Mixture of Titanium (IV) Oxide Particles Suspended in Aqueous Solutions. J Phys. Chem. B 101, 3746–3752 (1997).

Tian, Y. & Tatsuma, T. Mechanisms and Applications of Plasmon-Induced Charge Separation at TiO2 Films Loaded with Gold Nanoparticles. J. Am. Chem. Soc. 127, 7632–7637 (2005).

Xu, J. et al. Enhanced Photocatalysis by Coupling of Anatase TiO2 Film to Triangular Ag Nanoparticle Island. Nanoscale Res. Lett. 7, 1–6 (2012).

Hirakawa, T. & Kamat, P. V. Charge Separation and Catalytic Activity of Ag@TiO2 Core-Shell Composite Clusters under UV-Irradiation. J. Am. Chem. Soc. 127, 3928–3934 (2005).

Bao, Z. Y. et al. In Situ SERS Monitoring of Photocatalytic Organic Decomposition Using Recyclable TiO2-Coated Ag Nanowire Arrays. Appl. Surf. Sci. 301, 351–357 (2014).

Miyauchi, M., Nakajima, A., Hashimoto, K. & Watanabe, T. A Highly Hydrophilic Thin Film under 1 μW/cm2 UV Illumination. Adv. Mater. 12, 1923–1927 (2000).

Alberici, R. M. & Jardim, W. F. Photocatalytic Destruction of VOCs in the Gas-Phase Using Titanium Dioxide. Appl. Catal. B: Environ. 14, 55–68 (1997).

Zhang, X., Zhou, Q., Huang, Y., Li, Z. & Zhang, Z. The Regulation of Surface-Enhanced Raman Scattering Sensitivity of Silver Nanorods by Silicon Sections. J. Nanomater. 2013, 72 (2013).

Zhou, Q., Liu, Y., He, Y., Zhang, Z. & Zhao, Y. The Effect of Underlayer Thin Films on the Surface-Enhanced Raman Scattering Response of Ag Nanorod Substrates. Appl. Phys. Lett. 97, 121902 (2010).

Zhou, Q., Yang, Y., Ni, J., Li, Z. & Zhang, Z. Rapid Recognition of Isomers of Monochlorobiphenyls at Trace Levels by Surface-Enhanced Raman Scattering Using Ag Nanorods as a Substrate. Nano Res. 3, 423–428 (2010).

Acknowledgements

The authors are very grateful to the financial support by the National Basic Research Program of China (973 program, Grant No. 2013CB934301), the National Natural Science Foundation of China (Grants No. 51228101, No. 51531006, No. 51572148), the Research Project of Chinese Ministry of Education (Grant No. 113007A) and the Tsinghua University Initiative Scientific Research Program.

Author information

Authors and Affiliations

Contributions

L.W.M. and Z.J.Z. designed the study, interpreted the data and wrote the manuscript. L.W.M. performed the experiments and analyzed the data. Y.H., M.J.H. and Z.X. participated in the substrate synthesis and data analysis.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Ma, L., Huang, Y., Hou, M. et al. Ag Nanorods Coated with Ultrathin TiO2 Shells as Stable and Recyclable SERS Substrates. Sci Rep 5, 15442 (2015). https://doi.org/10.1038/srep15442

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep15442

This article is cited by

-

Synthesis of Ag nanoparticles by cathode glow discharge electrolysis using sacrificial Ag foil of anode

Colloid and Polymer Science (2023)

-

Fabrication of bioactive corrosion-resistant polyaniline/TiO2 nanotubes nanocomposite and their application in orthopedics

Journal of Materials Science (2020)

-

Recent advance in near-infrared/ultrasound-sensitive 2D-nanomaterials for cancer therapeutics

Science China Materials (2020)

-

Enhanced photocatalysis and biomolecular sensing with field-activated nanotube-nanoparticle templates

Nature Communications (2019)

-

The research progress on corrosion and protection of silver layer

SN Applied Sciences (2019)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.