Abstract

With diameter close to the wavelength of the guided light and high index contrast between the fiber and the surrounding, an optical micro-fiber shows a variety of interesting waveguiding properties, including widely tailorable optical confinement, strong evanescent fields and waveguide dispersion. Among various micro-fiber applications, optical sensing has been attracting increasing research interest due to its possibilities of realizing miniaturized fiber optic sensors with small footprint, high sensitivity and low optical power consumption. Typical micro-fiber based sensing structures, including Michelson interferometer, Mach-Zenhder interferometer, Fabry-Perot interferometer, micro-fiber ring resonator, have been proposed. The sensitivity of these structures heavily related to the fraction of evanescent field outside micro-fiber. In this paper, we report the first theoretical and experimental study of a new type of refractometric sensor based on micro-fiber three-beam interferometer. Theoretical and experimental analysis reveals that the sensitivity is not only determined by the fraction of evanescent field outside the micro-fiber but also related to the values of interferometric arms. The sensitivity can be enhanced significantly when the effective lengths of the interferometric arms tends to be equal. We argue that this has great potential for increasing the sensitivity of refractive index detection.

Similar content being viewed by others

Introduction

Micro-fiber based refractometric sensors are currently in the spotlight of research as basic functional elements for physical1,2,3, chemical4,5 and biological6,7 sensing. Due to the small dimension for light confinement, a wave-guiding micro-fiber leaves a considerable fraction of the guided field outside the micro-fiber as evanescent waves, making it sensitivity to the change of ambient refractive index (RI). During the past few years, a number of micro-fiber based refractometric sensors have be developed using Michelson interferometer8, Mach-Zenhder interferometer9,10, Fabry-Perot interferometer11, micro-fiber ring resonator12,13 and micro-fiber coil resonator14, et al. The sensitivity of these types of sensor relies on the interaction between the evanescent field and and external medium. It is believed that the most feasible approach to improve the sensitivity is to enhance the evanescent wave15,16. Many efforts have previously been made by decreasing the radius of micro-fiber17, twisting or bending the micro-fiber18, et al. However, precise adjustment of evanescent field is a challenge task in practice.

In this paper, we propose a new type of micro-fiber based refractometric sensor by using three-beam interferometer (TBI) construction. Comparing with the conventional micro-fiber based refractometric sensors, the sensitivity of the proposed sensor is not only originated from the evanescent field outside the fiber but also determined by the lengths of the two arms of the proposed interferometer. The sensitivity can be enhanced significantly when the effective length difference of the two arms approaches zero. This suggests a new technical means for increasing the sensitivity. The operating principle and theoretical model of the TBI will be explained in the context of its use as a refractometric sensor. The variation of sensitivity with the fraction of evanescent field and the lengths of interferometric arms will be highlighted. In addition, we will demonstrate our discovery by experimental results.

Results

Concept and operating principle of TBI

Figure 1(a) shows schematically the proposed TBI. The interferometer consists of a Mach-Zehnder interferometer and a Sagnac loop. The operating principle can be explained with the aid of Fig. 1 and Fig. 2. When the incident light is launched into the input port of TBI as shown in Fig. 1(b), this beam will be split into two by the first coupler. The two resultant beams are transmitted and reected by the second coupler and Sagnac loop and then back to the first coupler. The total light field at the output port of TBI is a summation of four components corresponding the four paths as shown in Fig. 2. Since the third path (as shown in Fig. 2(c)) and the fourth path (as shown in Fig. 2(d)) are the same, light beams travelling in these two paths experience the same phase delay and phase shift, thus the total light field at the output port of the TBI is a summation of three components, exactly.

(a) Schematic design for micro-fiber based three-beam interferometer architecture. T1, T2, snd T3 stand for the transformation matrix in different sections of TBI. c1 and c2 represent the effective lengths of the first and the second coupler, respectively. (b) Schematic illustration of the light wave forward propagation in the TBI. The black arrow indicates the direction of light propagation. (c) Schematic illustration of the light wave backward propagation in the TBI. The red arrow indicates the direction of light propagation.

Theoretical model of TBI

The optical paths followed by the incident light are indicated by the arrows shown in Fig. 1(b) and Fig. 1(c). We consider the case in which an optical beam with power  is injected into the input port of the TBI (as shown in Fig. 1(b)). Here we assume that both of the upper and lower arms have the same waveguide structures; that is, the outputs of the first coupler are given by19,20

is injected into the input port of the TBI (as shown in Fig. 1(b)). Here we assume that both of the upper and lower arms have the same waveguide structures; that is, the outputs of the first coupler are given by19,20

where T1 is the transfer matrix of the first coupler, A1 = A0, B1 = 0. κ1 and c1 denote the coupling coefficient and coupling length of the first coupler, respectively.

After passing through the straight arms of TBI, A3 and B3 become

where T2 is a diagonal matrix which represents the phase shift in the straight region of TBI (as shown in Fig. 1(a)). ϕ1 and ϕ2 stand for the phase shift in the upper and lower arms (as shown in Fig. 1(b) and Fig. 1(c)), respectively. The phase shift ϕ1 and ϕ2 can be expressed as

and

where neff1 and neff2 are the effective index of the propagating mode guided along the upper and lower arms. L1 and L2 are the lengths of the two arms (as shown in Fig. 1(a)). λ denotes the wavelength of light in vacuum.

Then the output of the second coupler A4 and B4 can be obtained by

where κ2 and c2 denote the coupling coefficient and coupling length of the second coupler, respectively. T3 is the transfer matrix of the second coupler.

When lights enter into the loop, the lights will pass through the loop and back to the right ends of the second coupler (as shown in Fig. 1(c)). During the lights passing through the loop, the two beams of light in opposite angular directions experience a same phase delay

where neff3 denotes the effective index of the propagating mode guided along the loop and L3 represents the length of the loop.

Then A5 and B5 (as shown in Fig. 1(c)) can be expressed as21

When the reected lights launched from the right ends of the second coupler, the lights will propagate along the micro-fiber and finally arrive at the output port of the proposed TBI. The overall transformation matrix for this progress can be computed by concatenating the three transfer matrices T1, T2 and T3. Therefore, the light field A8 and B8 can be calculated by

Combining Eqs. (1) to (8), we obtain the light field at the output port, B8, as

where

It can be seen from the above equations that the output light field is a summation of three field components, which is in accordance with the operating principle analyzed in the former section.

Here, we may note the following special cases:

-

One of κ 1 c 1 and κ 2 c 2 is

and the other one is not

and the other one is not

, m is a positive integer, simultaneously.

, m is a positive integer, simultaneously.

In this case, from Eq. (9) we can find that the component

is zero. Thus the output field B8 only contain two components (as shown in Fig. 2(a) and Fig. 2(b)), the proposed TBI becomes a Michelson interferometer.

is zero. Thus the output field B8 only contain two components (as shown in Fig. 2(a) and Fig. 2(b)), the proposed TBI becomes a Michelson interferometer. -

One of κ1c1and κ2c2equals to

. In this case,

and

and  become zero. This result indicates that the TBI behaves like an optical switch. When the other of κ1c1 and κ2c2 equals to

become zero. This result indicates that the TBI behaves like an optical switch. When the other of κ1c1 and κ2c2 equals to  the resulting output field B8 is zero. Otherwise

the resulting output field B8 is zero. Otherwise  , represents the output light contain only one component.

, represents the output light contain only one component.

However, we are not concerned with the above particular cases. The work of this paper, as an effort and achievement on the route of improvement the sensing sensitivity of micro-based refractometric sensors, focuses on the issues of the operating principle and theoretical model of the proposed TBI as a three-beam interferometer.

The total light intensity at the output port of TBI can be obtained from Eq. (9)

where  is the complex conjugate of B8. The output spectrum as a function of wavelength is depicted in Fig. 3(a).

is the complex conjugate of B8. The output spectrum as a function of wavelength is depicted in Fig. 3(a).

(a) The calculated output spectra from output port of TBI under different κ1 · c1 and κ2 · c2. (b) The calculated output spectra of TBI with different ambient RIs. The parameters of TBI are γ = 0.5, κ1 · c1 = κ2 · c2 = π/6, L1 = 10 mm and L2 = 9 mm. (c) Theoretical sensitivity of TBI as a function of the fraction of evanescent field outside the micro-fiber under different values of L1 and L2. The ambient RI is around 1.33000 and the RIU here is the abbreviation for refractive index unit. (d) Dependence of the sensitivity of TBI for RI sensing on L1 under the condition L2 = 10 mm.

Refractive index sensitivity of TBI

If the RI of the environment surrounding the micro-fiber in the sensing area (as shown in Fig. 1(a)) is changed, the effective index neff1 will be changed accordingly, which will result in the shifts of the output spectra. Figure 3(b) plots several output spectra under different ambient RIs. From the figure we can find the peak-wavelength will shift with the variation of ambient RI. For the ambient RI measurement using spectral shift, the sensitivity can be defined as

where nam and nf denote the RI of ambient medium and micro-fiber, respectively and γ is a value in the range among 0 and 1 which characterizes the fraction of the evanescent field outside the micro-fiber. For the slight variations of the RI of ambient materials, γ can be approximately regarded as a constant.

As shown in Eq. (11), the sensitivity is not only determined by the fraction of evanescent field, γ, but also related to the values of L1 and L2. The sensitivity as a function of the fraction of evanescent, γ, is illustrated in Fig. 3(c). From this figure, we can see:

-

If and only if nf · L1 < neff2 · L2 or neff2 · L2 < nam · L1 the sensitivity will increase with the fraction of evanescent field, γ, monotonously;

-

In the case of nam · L1 < neff2 · L2 < nf · L1, the sensitivity increases with γ when neff1 · L1 > neff2 · L2 and decreases under the condition neff1 · L1 < neff2 · L2;

-

The sensitivity can be enhanced significantly when the effective lengths of the two arms of TBI approaches equal (here, we define neff1 · L1 and neff2 · L2 as the effective lengths of the upper and lower arms of TBI, respectively).

The above theoretical analysis shows that the sensitivity of the proposed TBI is not only determined by the fraction of evanescent field, but also related to the values of L1 and L2. Fig. 3(d) indicates the sensitivity of TBI as the function of L1 under the condition γ and L2 are constant. We can find that the sensitivity increases rapidly as the length of L1 tends to  .

.

In general, precise adjustment of the fraction of evanescent field is challenging task. As a result the sensitivity of micro-fiber based RI sensor can hardly meet the requirement by adjusting γ. However, precise adjustment of L1 and L2 can be achieved quite easily. This suggests a new technical means for increasing the sensitivity of micro-fiber based refractometric sensor.

We further demonstrate our discovery by experiments. We measure the spectral response of the TBI to ambient RI by immersing the upper arm into an aqueous solution of alcohol (as shown in Fig. 1(a)), with the solution's RI modified by changing the concentration of alcohol. Figure 4(a) gives the measured peak-wavelengths as a function of ambient RI ranging from 1.33000 to 1.33020. Figure 4(b) records the relationship between the peak-wavelength and ambient RI under difference values of L1 under the condition L2 remains a constant value. Comparing the sensitivity of the proposed TBI in different values of L1, we can see that when L1 is 3 mm longer than L2, the sensitivity is only 2000 nm/RIU (refractive index unit). With the decrease of the value of L1, the sensitivity will become higher and higher. For instance, when L1 decreased to be 11 mm, the sensitivity achieve to 10 000 nm/RIU. This reveals that the sensitivity of TBI heavily relies on the values of L1 and L2. The experimental results are in accordance with the theoretical analysis.

Discussion

For the measurement of an ambient RI change of Δnam, the corresponding peak-wavelength shift Δλ is given by

where FSR stands for the free spectral range of the output spectrum of proposed TBI.

From Eq. (12) we can see that the sensitivity of TBI to ambient RI changes depends on two factors: the phase changes Δϕ1 and the free spectral range of the output spectrum FSR.

The phase changes Δϕ1 associated with variations in ambient refractive index, Δnam, is given by

From Eq. (12) and Eq. (13), we may get the conclusion that the sensitivity can be increased by increasing the fraction of evanescent γ. However, as shown in Fig. 3(c), the sensitivity varies non-monotonically with γ when nam · L1 < neff2 · L2 < nf · L1. Therefore, in general, higher sensitivity cannot be obtained simply by increasing γ. This is mainly due to the fact that FSR of the TBI also related to γ. From Eq. (9) and Eq. (10), the FSR can be expressed as

As shown in Eq. (14), FSR may decreases as γ increased. Consequently, from Eq. (12) we can see that it is difficult to get the conclusion whether the sensitivity is increased according to the increase of γ. This is the reason why the sensitivity increases with γ when neff1 · L1 > neff2 · L2 and decreases under the condition neff1 · L1 < neff2 · L2 in the case of nam · L1 < neff2 · L2 < nf · L1 (as shown in Fig. 3(c)). If γ satisfies a certain condition to make neff1 · L1 ≈ neff2 · L2, the FSR will reach its maximum value. Consequently, the sensitivity can be enhanced significantly. However, it would be a challenging to fabricate such a micro-fiber with desired γ in practice.

If the the fraction of evanescent field γ remain unchanged, the phase changes Δϕ1 associated with Δnam will be a constant. Therefore the sensitivity of TBI only determined by FSR. In this case, the sensitivity can be easily enhanced by regulating the lengths of refractometric arms of TBI. When the effective lengths of the two arms approaches equal, the FSR will become significantly large. Consequently, the sensitivity can be enhanced significantly. Figure 5(a) depicts the spectra of two TBI under different values of L1 and L2 under the condition the fraction of evanescent equals to 0.5. From this figure we can find that the FSR is heavily rely on the values of L1 and L2. Figure 5(b) shows the output spectra of the two TBI under different ambient RIs. Comparing the peak-wavelength changes of the two TBI, we can see that under the condition of L1 = 11 mm and L2 = 9 mm, the peak-wavelength changes 0.125 nm when the ambient RI changes from 1.33000 to 1.33005. When L1 = 10 mm and L2 = 9 mm, the peak-wavelength changes 0.261 nm as the ambient RI changes from 1.33000 to 1.33005. This means that the sensitivity will be doubled when the values of L1 decreases from 11 mm to 10 mm. If we further decrease L1, the sensitivity will be further improved. When the values of L1 and L2 satisfied the condition neff1 · L1 ≈ neff2 · L2, the sensitivity of TBI will be enhanced significantly. Figure 3(d) indicates the dependence of the sensitivity of TBI for RI sensing on the values of L1 and L2. We can see from the figure that the sensitivity increases rapidly as the length of L1 tends to  . From the above analysis, we can find that the sensitivity can be enhanced significantly by adjusting the lengths of the two arms of TBI.

. From the above analysis, we can find that the sensitivity can be enhanced significantly by adjusting the lengths of the two arms of TBI.

In conclusion, a refractometric sensor based on a micro-fiber three-beam interferometer was theoretically and experimentally demonstrated. In contrast to the earlier proposed micro-fiber based refractometric sensor, we have discovered that the sensitivity of this type of sensor is not only determined by the fraction of evanescent field outside micro-fiber but also related to the lengths of TBI's arms. The sensitivity can be enhanced significantly when the effective length difference of the two arms approaches zero. This suggests a new means for increasing the sensitivity. It can be foreseen that a micro-fiber based refractometric sensor using TBI architecture may be beneficial for improving the sensitivity significantly by adjusting the lengths of both arms of TBI.

Methods

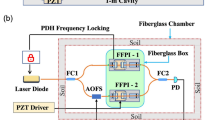

Fabrication and package of TBI

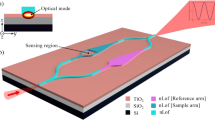

First a micro-fiber with 1 μm in radius and 65 mm in length was fabricated from a standard single mode fiber (SMF-28, Corning) using the ame brushing method16,22. Then, the architecture of the proposed TBI as shown in Fig. 1(a) was constructed by adopting the micro-fiber. A plate of glass is adopted as the substrate to support the proposed TBI and ambient medium. In order to avoid evanescent field leaking from TBI into the glass substrate whose RI is higher than micro-fiber, a layer of low-index polymer (here, we use silica gel as the polymer, the RI of silica gel is 1.401, which is smaller than micro-fiber and glass substrate) was first coated on the glass plate. After this low-index polymer is cured, we put the fabricated TBI on the substrate. Then we coated the TBI expect for the sensing region by the same silica gel. After the silica is cured, the package is complete. The package would not only make the TBI robust, but also ensure the evanescent field is able to access the external medium. Figure 6 shows the schematic diagram of the packaged TBI.

Description of experimental setup

The spectral characterization of TBI was carried out by connecting a broadband light source (SLED 1550) to the input port and an optical spectrum analyzer (Yokogawa AQ6370B) to the output port. We measure the spectral response of the TBI to ambient RI by immersing the upper arm into an aqueous solution of alcohol (as shown in Fig. 6), with the solution's RI modified by changing the concentration of alcohol. During the experiment, the temperature of laboratory is kept constant (25°C).

References

Ishizaki, K. & Noda, S. Manipulation of photons at the surface of three-dimensional photonic crystals. Nature. 460, 367–370 (2009).

Pevec, S. & Donlagic, D. Nanowire-based refractive index sensor on the tip of an optical fiber. Appl. Phys. Lett. 102, 213114 (2013).

Pengfei, W. et al. High-sensitivity, evanescent field refractometric sensor based on a tapered, multimode fiber interference. Opt. Lett. 36, 2233–2235 (2011).

Vollmer, F. et al. Protein detection by optical shift of a resonant microcavity. Appl. Phys. Lett. 80, 4057–4059 (2002).

Cui, Yi. et al. Nanowire nanosensors for highly sensitive and selective detection of biological and chemical species. Science. 293, 1289–1292 (2001).

Tazawa, H., Kanie, T. & Katayama, M. Fiber-optic coupler based refractive index sensor and its application to biosensing. Appl. Phys. Lett. 91, 113901 (2007).

Gu, F. et al. Polymer single-nanowire optical sensors. Nano Lett. 8, 2757–2761 (2008).

Zhaobing, T., Scott, S.-H. Yam. & Hans-peter, L. Refractive index sensor based on an abrupt taper Michelson interferometer in a single-mode fiber. Opt. Lett. 33, 1105–1107 (2008).

Xu, L., Li, Q. & Li, B. Nonadiabatic fiber taper-based Mach-zehnder interferometer for refractive index sensing. Appl. Phys. Lett. 101, 153510 (2012).

Wo, J. et al. Refractive index sensor using micro-fiber-based Mach-Zehnder interferometer. Opt. Lett. 37, 67–69 (2012).

Zhang, J. et al. Microfiber Fabry-Perot interferometer fabricated by taper-drawing technique and its application as a radio frequency interrogated refractive index sensor. Opt. Lett. 37, 2925–2927 (2012).

Fei, X. et al. An embedded optical nanowire loop resonator refractometric sensor. Opt. Express. 16, 1062–1067 (2008).

Xianli, Li. & Hui, D. All-fiber magnetic-field sensor based on microfiber knot resonator and magnetic uid. Opt. Lett. 37, 5187–5189 (2012).

Fei, X. & Brambilla, G. Demonstration of a refractometric sensor based on optical microfiber coil resonator. Appl. Phys. Lett. 92, 101126 (2008).

Tong, L., Lou, J. & Mazur, E. Single-mode guiding properties of subwavelength-diameter silica and silicon wire waveguides. Opt. Express. 12, 1025–1035 (2004).

Tong, L. et al. Subwavelength-diameter silica wires for low-loss optical wave guiding. Nature. 426, 816–819 (2003).

Haddock, H. S., Shankar, P. M. & Mutharasan, R. Evanescent sensing of biomolecules and cells. Sensor. Actuat. B- Chem. 88, 67–74 (2003).

Zhu, H., Wang, Y. & Li, B. Tunable refractive index sensor with ultracompact structure twisted by poly (trimethylene terephthalate) nanowires. ACS nano. 3, 3110–3114 (2009).

Iizuka, T. & Sterke, C. M. Corrections to coupled mode theory for deep gratings. Phys. Rev. E. 61, 4491–4499 (2000).

Verslegers, L., Yu, Z. & Ruan, Z. et al. From Electromagnetically Induced Transparency to Supercattering with a Single Structure: A Coupled-Mode Theory for Doubly Resonant Structures. Phys. Rev. Lett. 108, 083902 (2000).

Post, E. J. Sagnac Effect. Rev. Mod. Phys. 39, 475–493 (1967).

Brambilla, G., Finazzi, V. & Richardson, D. Ultra-low-loss optical fiber nanotapers. Opt. Express. 12, 2258–2263 (2004).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Nos. 51377125 and 51077107).

Author information

Authors and Affiliations

Contributions

D.H. supervised the project; H.C.Y. developed the concept and conceived the design; H.C.Y. performed the simulation and calculation; D.H., H.C.Y. and L.F.X. performed the experiments; L.F.X. prepared the samples; H.C.Y. and D.H. discussed the results and wrote the manuscript; All authors reviewed the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article's Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder in order to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Han, C., Ding, H. & Lv, F. Demonstration of a refractometric sensor based on an optical micro-fiber three-beam interferometer. Sci Rep 4, 7504 (2014). https://doi.org/10.1038/srep07504

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep07504

This article is cited by

-

Semi-reciprocal polarization maintaining fibre coupler with distinctive transmission characteristics

Scientific Reports (2015)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.

and the other one is not

and the other one is not

, m is a positive integer, simultaneously.

, m is a positive integer, simultaneously.

is zero. Thus the output field B8 only contain two components (as shown in

is zero. Thus the output field B8 only contain two components (as shown in

and

and  become zero. This result indicates that the TBI behaves like an optical switch. When the other of κ1c1 and κ2c2 equals to

become zero. This result indicates that the TBI behaves like an optical switch. When the other of κ1c1 and κ2c2 equals to  the resulting output field B8 is zero. Otherwise

the resulting output field B8 is zero. Otherwise  , represents the output light contain only one component.

, represents the output light contain only one component.