Abstract

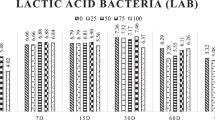

Improving the nutrition of livestock is an important aspect of global food production sustainability. This study verified whether lactic acid bacteria (LAB) inoculant could promote ensiling characteristics, nutritive value, and in vitro enteric methane (CH4) mitigation of forage sorghum (FS) mixture silage in attacking malnutrition in Zebu beef cattle. The FS at the soft dough stage, Cavalcade hay (CH), and cassava chip (CC) were obtained. The treatments were designed as a 4 × 2 factorial arrangement in a completely randomized design. Factor A was FS prepared without or with CH, CC, and CH + CC. Factor B was untreated or treated with Lactobacillus casei TH14. The results showed that all FS mixture silages preserved well with lower pH values below 4.0 and higher lactic acid contents above 56.4 g/kg dry matter (DM). Adding LAB boosted the lactic acid content of silages. After 24 h and 48 h of in vitro rumen incubation, the CC-treated silage increased in vitro DM digestibility (IVDMD) with increased total gas production and CH4 production. The LAB-treated silage increased IVDMD but decreased CH4 production. Thus, the addition of L. casei TH14 inoculant could improve lactic acid fermentation, in vitro digestibility, and CH4 mitigation in the FS mixture silages.

Similar content being viewed by others

Introduction

The use of locally available natural resources to improve the nutrition of livestock is an important aspect of global food production sustainability. In ruminant production, feeding partial mixed rations as the sole diet is a strategy to eliminate malnutrition. In tropical countries, sorghum (Sorghum bicolor) cultivation generates a major fodder crop1,2. Forage sorghum (FS) harvested at the optimal stage of 75 days has 31.0% dry matter (DM) content, consisting of 60.7% neutral detergent fiber (NDF) with 5.1% crude protein (CP)3. With concentrate-free diets, FS resulted in insufficient total digestible nutrients and negative nitrogen balance in ruminants4. Therefore, FS is ideal for silage production, providing a roughage source. Pholsen et al.1 demonstrated FS-mixture silage production by adding two neighboring crops, Cavalcade hay (CH) at 15% inclusion rate and dry cassava chip (CC) at 10% inclusion rate, to improve the nutritive levels, such as CP and metabolizable energy (ME) contents for maintaining animals’ requirements. Taking mixture silages into the account, the beneficial effect of adding unusual components into the silo on ensiling should be ensured to eliminate unpredictable spoilage.

The addition of lactic acid bacteria (LAB) inoculants is known to increase the initial LAB numbers of silages, prohibiting the growth of enterobacteria and clostridia5. LAB application was also reported to reduce enteric methane (CH4) production, a major source of energy loss and contributor to ruminants’ greenhouse gas emissions, because it could be a rumen fermentation enhancer6,7. When silage is prepared from tropical forages, improved silage quality was verified with Lactobacillus casei TH14 inoculant isolated from corn silage8,9.

The comparison of silage quality with animal requirements has practical relevance to ensuring livestock performance. This paper hypothesizes that alternative ingredients and LAB additive might alter ensiling characteristics and in vitro ruminal utilization of FS mixture silage, leading to enhanced Zebu beef cattle by improving indigenous materials. Therefore, the purpose of this study was to evaluate the ensiling characteristics, nutritive value, and in vitro CH4 production of FS mixture silages (FS, FS + CH, FS + CC, and FS + CH + CC) prepared without and with strain TH14.

Results

Microbial population and chemical composition of ensiling material

Microbial counts were reported in colony-forming units (cfu)/g in fresh matter (FM; Table 1). All ensiling materials showed low LAB counts (ranging from 103 to 104) but high counts of aerobic bacteria (108) and yeast (106 to 108). The coliform bacteria were found only in FS (107). The molds were below detection level (< 102). The DM content of FS was 25.97%, whereas those of CH and CC were greater than 88.73%. The CP, NDF, acid detergent fiber (ADF), acid detergent lignin (ADL), and nonfiber carbohydrates (NFC) contents of FS were in between those of CC and CH. The gross energy (GE) contents ranged from 16.22 to 18.00 MJ/kg DM.

Fermentation quality of silage

The highest DM content (p < 0.05) was FS + CH + CC silage, followed by FS + CH (Table 2). The highest pH value was found in either FS + CH silage (p < 0.05) or LAB-untreated (control) silage (p < 0.05). The lactic acid contents did not differ (p = 0.45) among materials but increased (p < 0.05) in LAB-treated silage. The butyric acid content of FS silage was greater (p < 0.05) than that of FS + CH + CC silage. The LAB inoculation tended to affect (p = 0.064) the butyric acid content of silage. The interaction effect (materials × LAB inoculation) was detected (p < 0.05) in the acetic acid, propionic acid, and ammonia nitrogen (NH3-N) concentrations.

Microbial population of silage

The LAB and aerobic bacteria counts of silage ranged from 107 to 108 cfu/g FM (Table 3). The FS + CH + CC silage showed lower (p < 0.05) yeasts than FS + CH, or FS + CC silage did. Moreover, LAB-treated silage decreased (p < 0.05) the yeast counts. In all silages, the coliform bacteria and molds were below detection level (< 102 cfu/g FM). The LAB and aerobic bacteria counts were affected (p < 0.05) by interaction.

Chemical composition and energy content of silage

The highest CP content (p < 0.05) was found in FS + CH, followed by FS + CH + CC, FS, and FS + CC silages (Table 4). The CP content was greater (p < 0.05) in LAB inoculated silage than that of control. The ADL contents were the highest (p < 0.05) in FS + CH silage. Silage prepared with LAB had a lower (p < 0.05) GE content than control. The FS and FS + CH silages had greater (p < 0.05) GE contents than the other two silages. The predicted ME (pME) contents of silage ranged from 9.21 to 10.58 MJ/kg DM (p < 0.05), with the superior values appearing in the order of FS + CC, FS + CH + CC, FS, and FS + CH silages, respectively. The pME contents of LAB-treated silage were greater (p < 0.05) than those of control. Interaction influenced (p < 0.05) the organic matter (OM), NDF, and ADF contents of silage.

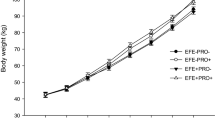

Based on a synthesized comparison (Fig. 1), when compared to FS and FS + CC silages, the FS + CH and FS + CH + CC silages provided pME and CP contents above maintenance levels required by Zebu beef cattle in the growth stage.

The nutritive values of the tested forage sorghum (FS) mixture silages estimated to supply the maintenance requirements of Zebu beef cattle in the growth stage according to current feeding standards3. CH Cavalcade hay (15% inclusion rate), CC dry cassava chip (10% inclusion rate).

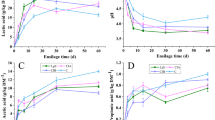

In vitro digestibility, total gas production, and methane production

After 24 h of incubation, the in vitro DM digestibility (IVDMD) in FS + CC and FS + CH + CC silages were higher (p < 0.05) than that in FS, and FS + CH silages (Table 5). The in vitro OM digestibility (IVOMD) was the highest (p < 0.05) in FS + CC silage, followed by FS + CH + CC, FS, and FS + CH silages. The total gas production and CH4 production (L/kg DM and % GE) were the highest (p < 0.05) in FS + CC silage. Compared to control silage, the LAB-treated silage increased IVDMD and IVOMD with decreased (p < 0.05) total gas and CH4 production. Interaction did not affect (p > 0.05) all parameters. When incubation was prolonged to 48 h, the effects of LAB inoculation were consistent with the findings at 24 h (Table 6). The FS + CC silage had greater (p < 0.05) IVDMD, IVOMD, total gas production, and CH4 production than the other silages.

Discussion

The dynamic changes of microbial species and numbers during ensiling are important indicators that affect the fermentation quality and feed nutrient of silage. The abundance of epiphytic LAB of ≥ 105 cfu/g FM is mostly preferred to promote lactic acid fermentation9. In this study (Table 1), the counts of LAB in FS, CH, and CC were lower than aerobic bacteria and yeast counts were. These results agreed with Cai et al.5, who indicated FS had low LAB counts (< 104 cfu/g FM). This fact suggests the numbers of harmful bacteria should be controlled during silage fermentation by adding LAB inoculants10.

In this study, the addition of CH, CC, and CH + CC increased the DM content of FS mixture silage by 4 to 15% and could be an important factor that maintained its fermentation quality, as indicated by pH drops (< 3.9) and low butyric acid concentration (< 10 g/kg DM; Table 2). The results showed that the addition of CH increased silage pH value, which may be partly attributed to the influence of high buffering capacity in legume forage. Usually, the addition of legume CH increases the pH value of mixed silage. The TH14 displayed a higher lactic acid concentration and tended to have lower (p = 0.06) butyric acid concentrations than control. However, Khota et al.11 reported that strain TH14 could also increase acetic acid and propionic acid contents, and decrease butyric acid and NH3-N contents of FS silage. Understandably, natural bacteria present in FS may produce a different amount of short-chain fatty acids during ensiling.

The results showed that both LAB and aerobic bacteria counts were higher (p < 0.05) in FS + CH + CC + TH14 silages (Table 3). This interaction effect should associate with adding TH14, and some epiphytic LAB can survive in a low-pH condition of silage with different materials. This finding is contrary to the results of previous research; good quality silage generally reduces aerobic bacteria counts11,12. The reason for this is not very clear. Perhaps the aerobic spore-containing bacilli can grow in a relatively low pH environment such as silage. Future research needs to explore the relationship between spore forming aerobic bacteria and silage fermentation.

With an estimated DM intake of 2.3% body weight, Zebu beef cattle in the growth stage require about 75 g CP/kg DM and 6.62 MJ ME/kg DM3. Only FS + CH and FS + CH + CC silages could result in adequate levels needed to maintain healthy herds (Table 4). Although the sufficiency in ME supply is likely to exist in all FS mixture silages, both FS and FS + CC silages need to be supplemented with CP when used as feed (Fig. 1). Animals produced in these circumstances continually require protein levels above their maintenance requirement; otherwise, their body tissue degrades due to disease stemming from chronic malnutrition. In addition, such a practice emits extremely high-intensity CH4 due to negative production of beef cattle. Thus, our results strongly suggest considering protein supplements rather than NFC in FS. In this study, the NDF and ADF contents’ reducing effect on strain TH14 was influenced by interaction (p < 0.05; Table 4). Generally, LAB find it impossible to decompose plant fiber directly9,11. Perhaps other fiber-decomposing microbes that degrade fiber during silage fermentation could be found, which might lead to a reduction in fibrous contents.

The potential digestibility of forages for ruminants could be estimated with reasonable accuracy by using rumen fluid in vitro13. Therefore, in vitro tests have become important in qualifying whether to apply desirable treatments to in vivo experiments with animals. The results indicated FS + CC silage had consistently higher IVDMD, IVOMD, total gas production, and CH4 production than the other silages had (Tables 5 and 6). These findings largely associate with incorporated forage fiber in the NFC substrates of the CC portion, which lead to increased amounts of fermentable substrates in the in vitro rumen. The results agree with Chaudhry and Khan14, who reported that higher starch content in feeds could result in higher CH4 production than high fiber content could. Albores-Moreno et al.15 reported that the lower CH4 production could be due to the lower in vitro digestibility. Moreover, the addition of crude glycerol (a sugar alcohol) to a forage was recently reported to increase the in vitro CH4 production16. Given CC is ultimately important as a major energy feed source for ruminant production in these circumstances3, our results implied that it could be an attractive point for CH4-mitigation in this area.

The results showed TH14 decreased in vitro CH4 production with increased IVDMD and IVOMD compared to the control silage (Tables 5 and 6). We suspect the low pH value and the high lactic acid concentration of the LAB-treated silage may have led to a breakdown of the lignifications bound to the structural carbohydrates, which might be an action that improved the in vitro digestibility of FS mixture silage. The reduced methanogenesis due to LAB inoculation could stem from an abundance of ruminal lactic acid concentrations, which stimulates lactate-utilizing bacteria such as Megasphaera elsdenii, Selenomonas ruminantium, and Veillonella parvula to become hydrogen and CO2 sinks in the conversion of lactate to propionate7. In previous in vitro works, the effects of LAB additive on CH4 production were different among studies that mostly used different LAB species; probably because the LAB species have different modes of action to enhance rumen fermentation. Cao et al.7 found L. plantarum did not affect IVDMD of vegetable silages but did decrease the CH4 production. In addition, Ellis et al.6 suggested that the effects depended on the substrates and that most LAB inoculations were effective on grass silage but not corn silage, in addition to suggesting that some LAB strains can increase IVDMD with concurrent increased CH4 production.

In conclusion, the results suggest the addition of either CH or CH + CC makes this FS mixture silage type a promising candidate as an accessible dietary strategy for avoiding malnutrition in cattle. Understandably, when using FS or FS + CC, feeding cattle a concentrated protein supplement is strongly recommended. The addition of L. casei TH14 inoculant could help improve lactic acid production of these FS mixture silages and could modulate in vitro digestibility and in vitro enteric CH4 production. Determining the real CH4-mitigating potential of LAB additive in cattle feed requires evaluating the additive’s performance in vivo.

Methods

The Animal Care and Use Committee of Khon Kaen University, Khon Kaen, Thailand, approved all experimental protocols. All methods were carried out in accordance with relevant guidelines and regulations.

Experimental design and silage production

This experiment was conducted as a 4 × 2 factorial arrangement of treatments in a completely randomized design. In Factor A, the FS was prepared without or with CH 15% (FS + CH), CC 10% (FS + CC), and CH 15% + CC 10% (FS + CH + CC) on an FM basis. In Factor B, FS was left untreated (control) or was treated with L. casei TH14 at 1.0 × 105 cfu/g FM. The aim of adding CH and CC was to balance the CP and ME contents, respectively, as recommended by Pholsen et al.1. The FS and CH were planted and harvested at 75 days on an experimental farm run by the Faculty of Agriculture, Khon Kaen University, Khon Kaen, Thailand. The CC was obtained from a local feedstuff supplier. The CH was prepared by wilting for 3 days in the field. The FS, CH, and CC were chopped separately at a theoretical length of 1 cm. Three replications of each treatment were prepared via plastic bags (100-g FM sample/bag) for the silage evaluations based on a small-scale silo technique according to previous studies7,17. Before packing and sealing, sample consisting of ensiling materials was prepared for each bag, which the LAB additive was added by spraying. The contents were mixed together. The silos were opened after 30 days of ensiling (23–32 °C) to enter a stable phase.

Analytical procedures

The samples of materials and silages were analyzed for their microbial populations, including LAB, coliform bacteria, aerobic bacteria, yeast, and mold, using the plate count method as described by Kaewpila et al.17. The counts were reported in cfu/g FM. Silage fermentation products were analyzed from cold-water extracts18. Their pH was measured via a glass electrode. The NH3-N content was analyzed spectrophotometrically19. Acetic acid, propionic acid, butyric acid, and lactic acid concentrations were measured using high-performance liquid chromatography18.

Ensiling materials and silage samples were dried at 60 °C for 48 h, and then grinded (1 mm). The chemical composition was analyzed following the standard AOAC20 method, including DM, OM, CP, and ether extract (EE). The NDF and ADF were analyzed21 via a fiber analyzer (ANKOM 200, ANKOM Technology, NY, USA). The ADL was measured by solubilization with sulfuric acid22. The GE content was analyzed using an adiabatic bomb calorimeter (AC 500, LECO Corp., MI, USA). The NFC content of ensiling materials was calculated as the opposite fraction of ash, CP, EE, and NDF contents23. The pME content of silages was calculated using the equation by Thiputen and Sommart24:

where IVOMD was obtained at 24 h of in vitro incubation.

An in vitro gas production technique was used following the method of Makkar et al.25. The cattle were fed a basal diet comprised of a 70:30 ratio of rice straw to concentrate on a DM basis. The concentrate ingredients were CC, rice bran, coconut kernel cake, palm kernel cake, urea, and a vitamin–mineral mixture at 500, 300, 110, 60, 10, and 20 g/kg, respectively, on a DM basis. Cattle were fed daily at 8:30 am and 4:00 pm. A stomach-tube sucker collected the rumen fluid before morning feeding from 3 heads of Bos indicus (181 ± 11.1 kg of body weight). Stomach tubing to obtain rumen fluid is a widely used alternative when such cannulated cattle are not available and does not invalidate the results of the comparison within this experiment. The rumen fluid was filtered through 4 layers of cheesecloth into prewarmed (39 °C) thermos bottles and transported immediately to the laboratory. Rumen fluid was diluted to 1:4 (v/v) with a buffer solution25. The serum bottles (50-mL capacity) containing ground silage sample (0.5 g) were closed via rubber stoppers and aluminum caps, injected with 40 mL of the rumen inoculums under CO2, and incubated at 39 °C in a water-bath checker (WNB22, Memmert GmbH + Co. KG, Schwabach, Germany). Incubations were in 2 batches for in vitro evaluations at 24 or 48 h of incubation with different flasks of rumen inoculum. Within each batch, 75 bottles were incubated, corresponding to 8 silage treatments × 3 silo replicates × 3 in vitro replicates + 3 blanks. The blanks were bottles consisting of only rumen inoculum. The gas produced was measured every 2 h using a 25-mL calibrated glass syringe. The piston was painted by graphite powder and petroleum jelly to ensure it was gastight. For each bottle, the gas measured in the glass syringe was stored in a gas bag (0.5-L capacity) via an air connector (1.68-mL capacity). After incubation, gas produced in a bottle’s headspace was purged into a gas bag by injecting 100-mL N2. The gas sample in each gas bag was analyzed for CH4 concentration (% v:v) via gas chromatography (GC8A, Shimadzu Corp., Kyoto, Japan). The CH4 production was calculated using the following equation:

where TGP is the total gas production, AC is the air connector volume (20.16 and 40.32 mL for 24 and 48 h of incubation, respectively), and N2 = 100 mL. The CH4 production was calculated as L/kg DM of substrate minus blanks and 39.54 kJ/L. The undigested sample was filtered through a glass filter crucible, washed by a pepsin solution, dried at 100 °C in a forced-air oven for 24 h, and weighed for IVDMD calculation. To measure IVOMD, the dried residues were burned in a muffle furnace at 550 °C for 3 h. Within each silage sample, 3 in vitro replications were screened to reveal the errors using a coefficient of variance criteria prior to averaging as the representative value.

Statistical analysis

The data were analyzed for variance via the ANOVA procedure in SAS Version 6.12 (SAS Institute Inc., Cary, NC, USA) using the following model:

where Yijk = observation, μ = overall mean, αi = material effect (i = FS, FS + CH, FS + CC, and FS + CH + CC), βj = LAB inoculation effect (j = without and with TH14), αβij = the interaction effect (materials × LAB inoculation), and εijk = error. The differences among treatment means were assessed by Duncan’s new multiple range test and the significance level was accepted at p < 0.0526.

Change history

07 April 2021

A Correction to this paper has been published: https://doi.org/10.1038/s41598-021-87311-x

References

Pholsen, S., Yoottasanong, C. & Higgs, D. E. B. Effect of cassava chips on quality of silage from fresh forage sorghum plus Cavalcade forage legume hay mixtures. Trop. Grassl. 2, 262–270 (2014).

Kearl, L. C. Nutrient Requirements of Ruminants in Developing Countries (International Feedstuffs Institute, Utah, 1982).

WTSR. Nutrient Requirement of Beef Cattle in Indochinese Peninsula (Klungnanavitthaya Press, Khonkaen, 2010).

Mahanta, S. K. & Pachauri, V. C. Nutritional evaluation of two promising varieties of forage sorghum in sheep fed as silage. Asian-Australas. J. Anim. Sci. 18, 1715–1720 (2005).

Cai, Y., Pang, H., Tan, Z. & Wang, Y. Application of lactic acid bacteria for animal production. In Lactic Acid Bacteria (eds Zhang, H. & Cai, Y.) 443–491 (Springer, Dordrecht, 2014).

Ellis, J. L. et al. The effect of lactic acid bacteria included as a probiotic or silage inoculant on in vitro rumen digestibility, total gas and methane production. Anim. Feed Sci. Technol. 211, 61–74 (2016).

Cao, Y. et al. Effect of lactic acid bacteria inoculant and beet pulp addition on fermentation characteristics and in vitro ruminal digestion of vegetable residue silage. J. Dairy Sci. 94, 3902–3912 (2011).

Khota, W., Pholsen, S., Higgs, D. & Cai, Y. Natural lactic acid bacteria population of tropical grasses and their fermentation factor analysis of silage prepared with cellulase and inoculant. J. Dairy Sci. 99, 9768–9781 (2016).

Pholsen, S., Khota, W., Pang, H., Higgs, D. & Cai, Y. Characterization and application of lactic acid bacteria for tropical silage preparation. Anim. Sci. J. 87, 1202–1211 (2016).

Cai, Y., Benno, Y., Ogawa, M. & Kumai, S. Effect of applying lactic acid bacteria isolated from forage crops on fermentation characteristics and aerobic deterioration of silage. J. Dairy Sci. 82, 520–526 (1999).

Khota, W., Pholsen, S., Higgs, D. & Cai, Y. Fermentation quality and in vitro methane production of sorghum silage prepared with cellulase and lactic acid bacteria. Asian-Australas. J. Anim. Sci. 30, 1568–1574 (2017).

Liu, B. et al. Impact of molasses and microbial inoculants on fermentation quality, aerobic stability, and bacterial and fungal microbiomes of barley silage. Sci. Rep. 10, 1–10 (2020).

Madsen, J., Hvelplund, T. & Weisbjerg, M. R. Appropriate methods for the evaluation of tropical feeds for ruminants. Anim. Feed Sci. Technol. 69, 53–66 (1997).

Chaudhry, A. S. & Khan, M. M. H. Impacts of different spices on in vitro rumen dry matter disappearance, fermentation and methane of wheat or ryegrass hay based substrates. Livest. Sci. 146, 84–90 (2012).

Albores-Moreno, S. et al. Effect of tree foliage supplementation of tropical grass diet on in vitro digestibility and fermentation, microbial biomass synthesis and enteric methane production in ruminants. Trop. Anim. Health Prod. 51, 893–904 (2019).

Echavarria, D. M. V., Valderrama, L. A. G. & Gómez, A. M. In vitro fermentation of Pennisetumclandestinum Hochst. Ex Chiov increased methane production with ruminal fluid adapted to crude glycerol. Trop. Anim. Health Prod. 52, 565–571 (2020).

Kaewpila, C., Khota, W., Gunun, P., Kesorn, P. & Cherdthong, A. Strategic addition of different additives to improve silage fermentation, aerobic stability and in vitro digestibility of Napier grasses at late maturity stage. Agriculture 10, 262 (2020).

Cai, Y. Analysis method for silage Japanese Society of Grasland Science. In Field and Laboratory Methods for Grassland Science (ed. Japanese Society of Grasland Science) 279–282 (Tosho Printing Co. Ltd., Tokyo, 2004).

Fawcett, J. K. & Scott, J. E. A rapid and precise method for the determination of urea. J. Clin. Pathol. 13, 156–159 (1960).

AOAC. Official Methods of Analysis (Association of Official Analytical Chemists, Arlington, 1995).

Van Soest, P. J., Robertson, J. B. & Lewis, B. A. Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition. J. Dairy Sci. 74, 3583–3597 (1991).

Faichney, G. & White, G. Methods for the Analysis of Feeds Eaten by Ruminants (Division of Animal Production, Ian Clunies Ross Animal Research Laboratory, Commonwealth Scientific and Industrial Research Organization, Sydney, 1983).

Mertens, D. R. Creating a system for meeting the fiber requirements of dairy cows. J. Dairy Sci. 80, 1463–1481 (1997).

Thiputen, S. & Sommart, K. Prediction equations of metabolisable energy content in beef cattle diets. Khon Kaen Univ. Res. J. 17, 35–44 (2012).

Makkar, H. P., Blümmel, M. & Becker, K. Formation of complexes between polyvinyl pyrrolidones or polyethylene glycols and tannins, and their implication in gas production and true digestibility in in vitro techniques. Br. J. Nutr. 73, 897–913 (1995).

Steel, R. G. D. & Torrie, J. H. Principles and Procedures of Statistics: A Biometrical Approach (McGraw-Hill Book Co. Inc., New York, 1980).

Acknowledgements

This study was funded by the National Research Council of Thailand (NRCT, Funding no. 572103) and the Increase Production Efficiency and Meat Quality of Native Beef and Buffalo Research Group, Department of Animal Science, Faculty of Agriculture, Khon Kaen University. The authors thank Rajamangala University of Technology Isan, Sisaket Rajabhat University, Sakon Nakhon Rajabhat University, and Japan International Research Center for Agricultural Sciences (Japan) for the infrastructure and laboratory facilities.

Author information

Authors and Affiliations

Contributions

C.K., W.K., A.C., S.P. and Y.C. designed the experiments. C.K., W.K., A.C., S.T., S.S., P.G. and P.K. performed the experiments. C.K. and W.K. were mainly responsible for analyzing the data and writing the manuscript. All authors read and critically revised drafts for intellectual content and provided approval for publication.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this Article was revised: The Acknowledgements section in the original version of this Article was incomplete.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kaewpila, C., Gunun, P., Kesorn, P. et al. Improving ensiling characteristics by adding lactic acid bacteria modifies in vitro digestibility and methane production of forage-sorghum mixture silage. Sci Rep 11, 1968 (2021). https://doi.org/10.1038/s41598-021-81505-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-021-81505-z

This article is cited by

-

The isolation of rumen enterococci strains along with high potential utilizing cyanide

Scientific Reports (2023)

-

Effect of phenyllactic acid on silage fermentation and bacterial community of reed canary grass on the Qinghai Tibetan Plateau

BMC Microbiology (2022)

-

Assessment of organic acid salts on fermentation quality, aerobic stability, and in vitro rumen digestibility of total mixed ration silage

Tropical Animal Health and Production (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.