Abstract

Today, the world’s climate change is a growing problem, plant carbon sequestration is one of the effective ways to mitigate climate change by reducing greenhouse gases, mostly carbon gases. Dicranopteris linearis (D. linearis), a common fern species in the tropic or subtropic ecoregions, has been recently recognized as a potential feedstock to produce highly porous biochar. This study aims to enhance the specific surface area (SSA) and pore volumes of biochars derived from the D. linearis by H3PO4 activation and examine electrical properties of the activated biochars and their possible usage for the electric double-layer capacitor (EDLC) electrode. The treated raw fern was activated with H3PO4 85% by the three different mixing ratios 1:0, 1:1, and 1:3 (w/w) and then pyrolysis under N2 flow maintained at 500 °C for 1 h. The performance as the electrode for an EDLC was evaluated in 1 mol L−1 H2SO4 solution for the H3PO4-activated samples. The SSA and pore volumes were drastically increased after activation. The maximum SSA and pore volume were 1212 m2 g−1 and 1.43 cm3 g−1, respectively for the biochar activated at 400 °C with a weight mixing ratio 1:3 (w/w) between the fern and H3PO4 acid while these values of the biochar at 400 °C were 12 m2 g−1 and 0.02 cm3 g−1, respectively. The biochar activated at 600 °C with the mixing ratio 1:1 (w/w) showed the maximum capacitance value, ca. 108 F g−1 at 1 mV s−1. The activation using H3PO4 showed a positive tendency to enhance electrochemical properties and it could be a premise toward a higher performance of EDLC from the D. linearis derived activated biochar.

Similar content being viewed by others

Introduction

Today, the world’s climate change is a growing problem, increasing ocean depth, changing plant and animal habitats, and making storm stronger and more dangerous1. Climate change is caused by greenhouse gases, mostly carbon gases that build up in our atmosphere trapping the heat from the sun and stopping it from escaping into space. Carbon gases such CO2 and CO are mainly released when people use fossil fuels such as gas diesel and coal. It is important to take carbon out of the air to reduce the impact of greenhouse effects. The process of removing carbon from the air and storing is called carbon sequestration. One effective and natural method of carbon sequestration that tree suck in carbon and converted into wood which they bury deep underground in the form of roots which can be turn into charcoal by controlled or naturally burns. However, one major challenge of using biomass as an energy carrier is the treatment of such emissions during the thermal process (combustion/pyrolysis). Nitrogen oxides (NOx), are considered one of the main gas emissions during the thermal processes of biomass and NOx family gases are often recognized to cause acid rain2. Therefore, these kinds of emissions need to be controlled to reduce their impact on the environment and human health3. Hence, there are more and more researchers use biomass as a precursor material for producing biochars or activated biochars in controlled conditions.

Fern Dicranopteris linearis (D. linearis) is known as one of the most serious weed species due to their widespread from tropical to subtropical ecoregions4. Nevertheless, their economic value has received little attention. In many remote regions, this fern is burned to fertile soils (slash-and-burn agriculture) or used as a material for covering soil surface or earlier it has been an important fuel for local minorities. More recently, D. linearis has been more intensively studied and the findings suggested this fern species as a potential material for biochar production5 or soil improvement6,7. This encourages more research works to get the advantages from this type of species economically and efficiently5,6,7,8,9,10.

Activated carbon has a wide range of applications in reality such as medicine, industry, agriculture, and the environment due to its ability of adsorption and desorption. Activated carbon is known as purified charcoal, treated physically or chemically to generated micro-fissures that vastly increase its SSA, thereby enhancing exposure for adsorption or chemical reactions11. Chemical activation usually provides activated carbon with higher SSA than that of activated carbon prepared by physical activation. Chemical substance as phosphoric acid (H3PO4) is a highly recommended activator for the preparation of activated carbon due to its benefits of relatively lower activation temperature than other typical alkali activators such as KOH, K2CO3, NaOH, etc. For example, Hayashi et al., reported that in comparison with other alkali activators, H3PO4 allowed to obtain the high SSA (> 1000 m2 g−1) and total pore volumes at the lower temperature range (400–600 °C) while the effective temperature for alkali activators was 800 °C12. The lower temperature activation means safer, more economical, and more convenient for practical uses. Moreover, H3PO4 has a relatively lower toxicity than other common activators such as ZnCl2 and KOH. Many researchers have paid attention to H3PO4 activation to enhance SSA and total pore volumes of their carbon material12,13,14,15,16,17,18. Abdenaeim and De Yuso reported that the main mechanisms of activation with phosphoric acid are the depolymerization, dehydration and redistribution of biopolymers in lignocellulosic materials19,20 to created tunnel-shaped and generally have a honeycomb structure on the surface of activated carbon21,22. Activated carbon with large SSA and suitable pore size, which also leads to high electrical conductivity and enhance the performance of the electric double-layer capacitor (EDLC) electrode, a well-known electric power storage device nowadays23,24,25.

The electric power storage in EDLC is performed by utilizing the interlayer between electrode surfaces and electrolytes. So far, many kinds of agricultural wastes such as pine cones, coconuts shells, rice husk26, strobili fibers27, durian shells28, bamboos29, starch30 and flowers31 have been investigated as promising raw materials to create activated carbon for the EDLC electrode. Having higher SSA in comparison with other biochar prepared at the same pyrolysis condition5, fern D. linearis can also be a promising material to prepared activated biochar and use for the EDLC electrode. This study evaluated the performance of H3PO4 in activating fern D. linearis derived biochars, electrical properties of the activated biochars and the feasibility of using these activated materials for well-performed EDLC electrodes.

Material and methods

Material and sample preparation

Production of biochars

The fern D. linearis was collected in a hilly area at Pho Yen district, Thai Nguyen province, Vietnam (Long: 105.485° E; Lat: 22.762° N) was air-dried, chopped into small segments (size ~ 1 mm) and then kept in the dried and clean plastic bottles for further investigation. Detailed description of the heat treatment apparatus used in this study is shown in Supplementary Fig. S1 online. Pyrolysis of the D. linearis biomass was conducted under N2-supported at three different temperatures, i.e., 400, 600 and 800 °C in an oven (Nabertherm LT 24/12/P300). For each experiment, approximately 300 g of D. linearis was put into an airtight steel box (10 cm in height and 20 cm in diameter). The pyrolysis process was installed at a heating rate of 15 °C min−1 with N2 supporting at 3 NL min−1 (NL: Normal litter at 273 K and 1 atm) and maintained for 1 h.

Activation procedure

For activation, each 60 g of D. linearis biomass was mixed with H3PO4 (85%) by the mixing ratio 1:0, 1:1, and 1:3 (w/w) in an airtight refractory steel box 25 cm in diameter and 20 cm in height and put in an electric muffle furnace (Nabertherm LT 24/12/P300). The pyrolysis process was installed at a heating rate of 15 °C min−1 with N2 supporting at 3 NL min−1 (NL: Normal litter at 273 K and 1 atm) and maintained at 500 °C for 1 h.

Characterizations

Chemical composition of D. linearis biomass was examined by executing wet digestion with aqua regia solution and then dissolved Si was determined by molybdate blue method while other dissolved ions were analyzed by inductively coupled plasma mass spectrometry (ICP-MS, Agilent 7900). The micro-structures of the samples were observed by scanning electron microscope (SEM, JEM5310, JEOL). To characterize the SSA and pore volumes, N2 adsorption isotherms and CO2 adsorption isotherms were measured by a commercial apparatus (BELSORP mini II, MicrotracBEL Corporation instrument). The data of N2 adsorption isotherms were used for the estimation of Barrett–Brunauer–Emmett–Teller (BET) SSA, total pore volume, and micro-pore volume by using the t-plot statistical thickness method. CO2 adsorption isotherms were used for the estimation of micro-pore volume by using Dubinin–Astakhov (DA) method. To understand the properties of the samples, several methods were conducted such as CHN measurement (CHN corder MT-5, Yanako), XRF measurement (S8 TIGER, Bruker), and 13C NMR measurement (JNM-ECX400, JEOL) for understanding the kind of elements in the samples. The measurement conditions of 13C NMR were as follows, DEPTH2, CPMAS probe: 3.2 mm, MAS (Magic Angle Spinning) speed: 15 kHz. Moreover, FT-IR (Nicolet 6700, Thermo scientific) (ATR method) and XPS (AXIS-NOVA, Shimadzu/KRATOS) for defining the chemicals bonds and functional groups.

Electrochemical properties

Evaluation of the electrochemical performance as an electrode of electric double-layer capacitor was performed following the procedure suggested by Tsubota et al.29,30,31,32,33,34. The activated biochars were mixed with polytetrafluoroethylene (PTFE) and acetylene black (AB) by the mixing ratio 8:1:1 (w/w/w). PTFE played a role as a binder, while acetylene black (AB) acted as conductive agent. The mixtures were rolled to ca. 0.5 mm thickness, and then were cut into the rectangle shape 20 mm × 8 mm samples. The sheet samples were set on a Pt plate for collecting electrode, and a three-electrode cell was prepared for the electrochemical measurements. A 1 M H2SO4 aqueous solution, a Pt plate, and an Ag/AgCl electrode were used as electrolyte, a counter electrode, and reference electrode, respectively. The electrochemical measurements, such as cyclic voltammetry (CV) and galvanostatic charge–discharge measurement, were performed for the evaluation of electrochemical performance.

Results and discussion

Raw material

The elements in raw fern D. linearis were shown in Supplementary Fig. S2 online. The result shown that K, Na, Ca, Al, Si are the main inorganic elements in the chemical composition of the D. linearis fern. Alkaline metal (K, Na) and alkaline-earth metal (Ca, Mg) were main elements, but Al and Si also existed in the fern. All toxic heavy metals as Cr, Ni, As, Cd, Hg, Pb, etc. did not appear so this demonstrated the purity of raw material.

Characteristics of biochars and activated biochars

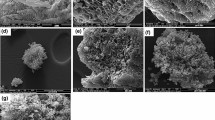

The SEM (Fig. 1) images of the carbonized samples indicated that the sizes of the particles, which had the micro-structure derived from plant issues, were independent of the carbonization temperature. Therefore, the structure of raw material was not destroyed by the carbonization at the temperature region (400–800 °C).

The N2 adsorption isotherms at 77 K of the carbonized samples are shown in Fig. 2. The adsorbed volumes of the sample carbonized at 400 °C were relatively low, while these volumes of biochars obtained at 600 °C and 800 °C were obviously higher; and increased rapidly in the region of the low relative pressure. In addition, the curves of all samples did not close in the low-pressure region, which was considered as low-pressure hysteresis. The low-pressure hysteresis appeared when the diameters of pores were near to the size of nitrogen molecule (approximate 0.35 nm). The difference between adsorption isotherm and desorption isotherm at low pressure decreased when the pyrolysis temperatures increased.

The CO2 adsorption isotherms at 298 K of the carbonized samples are shown in Supplementary Fig. S3 online. The patterns of the adsorbed volumes obtained from the biochars carbonized at 600 °C and 800 °C were similar. These volumes are much larger than that volume of the 400 °C sample. The drastic increment of the adsorbed volumes from 400 to 600 °C means that the volume of pore less than 0.7 nm in diameter classified as ultra-micropores largely increased from 400 to 600 °C. The chemical reactions for carbonization, such as pyrolysis, generate gaseous species leading to the formation of ultra-micropores progress in the region from 400 to 600 °C; and the irradiations of these gases increased significantly from 400 to 600 °C. The slight increment of adsorbed volumes from 600 to 800 °C could be reasonable due to the carbonization reactions which generate gaseous molecules until 600 °C.

The values related to SSA and pore volume estimated from N2 adsorption isotherms and CO2 adsorption isotherms are listed in Table 1. The BET SSA (SBET), total pore volume (Vtotal), and micropore volume (Vmicro) estimated from CO2 adsorption isotherms by Dubinin-Astakhov (DA) model increased with increasing the carbonization temperature. The index number of DA models depends on the pyrolysis temperature and relates to the pore size distribution, so pyrolysis temperatures should affect the pore size distribution of the samples. The change in SSA and the pore conditions such as pore volumes and pore size distribution of the samples as the follows.

-

At 400 °C, pores were poorly generated. Most of the pores had very small diameters, which cause low-pressure hysteresis at N2 adsorption isotherm.

-

At 600 °C, relatively many pores were created by the irradiation of gaseous molecules derived during the pyrolysis processes. Therefore, the volume of ultra-micropore and micropore significantly increased for both N2 and CO2 adsorption isotherms when pyrolysis temperature changed from 400 to 600 °C.

-

At 800 °C, the diameter of pores increased, which was explained by the increase of the N2 adsorbed volumes from 600 to 800 °C as shown in Fig. 2. The N2 adsorbed volumes at 800 °C were about two times higher than the value at 600 °C, while in CO2 adsorption isotherm these values were similar at both temperatures. The larger molecules are diffused into the larger pores on the sample surfaces, so the discrepancy of N2 adsorbed volumes at 800 °C and 600 °C indicated the difference of pore size. In that case, samples prepared at 800 °C has larger pore size compare to others.

The contents of C, H and N are listed in Table 2. The ash content was 9.74 wt.%. The XRF result illustrated that the ash contents of the sample mainly consist of K, Ca, Si, and Al in Table 3. In comparison with the chemical components of raw material, Na no longer appeared in the biochar samples. That means Na elements were removed during the pyrolysis process. Nguyen et al.35 reported that the relationship of pyrolysis temperature and potassium (K) which element has the highest percentage in the XRF detection. From XPS data Nguyen et al. found that the intensities of the peaks related to K decreased with increasing the heating temperature and disappeared at 800 °C so the K atoms changed to higher valence at 600 °C35.

H3PO4 activation

The SEM images (see Supplementary Fig. S4 online) indicated the micro-structure of the H3PO4-activated biochars in which the particles were independent of the activation condition such as temperature and the amount of added H3PO4. Some parts of the activated biochars were likely slagged leading to smoother surface and unified pores.

The N2 adsorption isotherms of the activated samples are shown in Fig. 3. The adsorbed volume increased with the increasing amount of H3PO4 and decreased with increasing the heating temperature. When the mixing ratio of H3PO4 to raw material was 3, the adsorbed volume rapidly increased with the relative pressure (p/p0) higher than 0.8. Because the size distributions of the activated biochars were similar each other, the origin of the rapid increment was defined by the increase of N2 diffusion not into the interparticle void but into the pores on particles. Luo et al. also reported17 that the SSA and total pore volume dramatically increased with the mixing ratio 1:3 (w/w), and then decreased in the higher mixing ratio. The reason for the decrement was presumed by Luo et al.17 that higher concentration of H3PO4 forms some phosphorus compounds which blocked the porosity of activated carbon. The N2 adsorption isotherms for H3PO4 activation reported by Luo et al.17 and by Hayashi et al.12 were different from those of this study. They reported that pore volume and SSA decreased with increasing the activation temperature at > 600 °C while this study showed the highest values at 600 °C and then decreased at the higher pyrolysis temperatures. The differences in pretreatment processes and raw biomass sources were the reasons for the distinctive results. Figure 3 showed the hysteresis loop which closed around 0.4 of p/p0 explained by the theory based on capillary condensation in pores. Because capillary condensation can occur in mesopore (2–50 nm), these samples should have mesopores.

The CO2 adsorption isotherms at 298 K are shown in Supplementary Fig. S5 online. The adsorbed CO2 volume decreased with increasing the added H3PO4 amount. Because the adsorbed CO2 volume should be related to ultra-micropore (< 0.7 nm in diameter), the decrease of the adsorbed volume should mean the reduction of the volume for very small pores such as ultra-micropore of the sample. One of the reasons lead to the decrements is the expansion of pore sizes (larger than CO2 molecule) due to the superimposing of ultra-micropores in the biochars activated by adding a higher H3PO4 amount.

The values related to SSA and pore volumes were estimated these adsorption isotherms and were listed in Table 4. The curves in Fig. 3 represent type IV adsorption isotherm. The vertical increment at the near-zero of relative pressures should indicate the existence of micropores. Because all the values of Vmicro were estimated from N2 adsorption isotherms by using the t-plot theory, the estimated pore volume roughly assigned to 0.7–2.0 nm in diameter. Vmicro (DA) was estimated from CO2 adsorption isotherm with extrapolation. Vmeso was estimated from N2 adsorption isotherm by using the BJH theory. The sample with the mixing ratio 1:3 (w/w) prepared at 400 °C had the largest SBET value (1212 m2 g−1) and all the volumes. In comparison with other biomass sources in Supplementary Table S1 online, the SBET of D. linearis activated biochar is similar while Vtotal and Vmicro are higher than most of others15,16,28,36,37,38,39,40,41,42. Therefore, fern D. linearis derived activated carbon with both micro and mesopores could be effectively prepared by H3PO4 activation.

It is obvious from the experimental results of N2 and CO2 adsorption isotherms listed in Tables 1 and 4 that both SSA and total pore volume were significantly enhanced by H3PO4 activation. Processes that occurred during activation with H3PO4 acid were the cellulose depolymerization, biopolymers dehydration, and redistribution of biopolymers in biomass43,44, which enhanced the total pore volumes and SSA. The H3PO4 added in the raw material acted as the catalyst for the cleavage of cellulose fibers and cross-links in the biomass shell to formation of gases, volatile fragments and soluble products during the activation processes28,44,45. In Supplementary Table S2 online, The C contents of the samples prepared by H3PO4 activation were lower than those of the samples that were simply prepared by carbonization, while the other remaining compounds increased with increasing the amount of added H3PO4. The reason could be presumed that the appearance of some inorganic compounds generated during H3PO4 activation such as polyphosphoric acid. The XPS (in Supplementary Fig. S6 online) demonstrated the intensive of others element like N, P, Si, etc., increase with the increase of temperature and the H3PO4 amount. 13C NMR graphs shown in the Supplementary Fig. S7 online has been shown that the activated carbon prepared with phosphoric acid has less C=O groups than the raw materials. The reduction of carbonyl groups may be due to the effect of H3PO4 hydrolysis, which decomposes these groups and other products such as volatile substances46. The FT-IR chart show (Supplementary Fig. S8 online) that the transmittance of O–H and C=O group decrease with the increase of temperature and H3PO4 doses. These experimental results indicate that the addition of H3PO4 affects the functional groups in biochar.

Electrochemical properties

The results of cyclic voltammetry (CV) (scan rate: 1 mV s−1) are shown in Supplementary Fig. S9 online. The larger area of CV graph indicates the capacitance value, and the like-rectangular shapes of CV graph show the capacitance derived from electric double layer. Therefore, the large area with rectangular shape of CV graph means the high performance of electrochemical properties of the sample. When the activation temperature was 600 °C, the CV graph of the sample tended to a larger area than that of others. The trend of the activated sample prepared at 600 °C were relatively rectangular although some peaks were still observed. Despite having larger SSA and pore volumes, the activated carbons prepared at 400 °C revealed their smaller areas of CV charts as compare to the 600 °C activated samples. In general, electrical conductivity depends on the treated temperature. The electrical conductivity of carbonized samples drastically increases from about 800 to c.a. 1000 °C. Electrical conductivity is one of the important factors which affect the capacitance values. At lower treated temperature (e.g., 400 °C) can be the reason why activated carbons at 400 °C has low capacitance while its SSA is the highest.

The pyrolysis temperatures dependence of the capacitance values at 1 mV s−1 are shown in Supplementary Fig. S10 online. The samples prepared with the mixing ratio 1:1 (w/w) had the higher capacitance values than the samples prepared with the mixing ratio 1:3 at all carbonization temperature. It was likely that H3PO4 activation were effective at the low impregnation ratio for large capacitance value. The presumed reason could be excessive phosphoric acids reacted more with organic compounds in the precursor leading to the formation of phosphate and polyphosphate bridge and esters linkage with OH− group at cellulose44 as electrical insulating layers. The sample prepared at 600 °C with the mixing ratio 1:1 (w/w) had the highest value of capacitance about 110 F g−1 (scan rate 1 mV s−1). The capacitance values are higher than the previously reported values such as 82.5 F g−1 (scan rate: 50 mV s−1) and 72 F g−1 (scan rate: 200 mV s−1) of activated biochar derived from durian prepared by H3PO4 activation28. However, the activated carbons prepared in this study was not considered as high electrochemical performances because the capacitance value per weight estimated by two-electrode cell is 1/4 times in comparison with 3-electrode system.

The patterns of charge–discharge measurement at 10 mA g−1 are shown in Fig. 4. The shapes of these graphs were nearly isosceles triangles indicating that the electric energy was stored not by redox reactions but by the electric double layer. The shape type of charge and discharge curve is usually obtained from the carbon-based electrode EDLC28,31. Therefore, the samples in the cells act as the active material of EDLC.

The capacitance values calculated from the results of charge–discharge measurements are shown in Supplementary Fig. S11 online. Recent studies have reported the capacitance values which were measured in the electrolyte of 1 M H2SO4 aqueous solution31,47,48. One of the reasons for lower capacitance values at higher current densities could be the low electrical conductivity of the activated samples. Moreover, the lower capacitance values also attributed to insufficient electrolyte ions diffusion kinetics across the micropores. The reduced accumulation amount of electrolyte ions onto porous electrode interfaced results of the reduction in specific capacitance31. The specific capacitance values of all the activated biochars of this study nearly closed to 0 at 1000 mA g−1, which is not suitable as an EDLC electrode. Chang et al.31 reported an effective result that the capacitance value of 211.6 F g−1 could remain at 10,000 mA g−1, revealing that the large capacitance value at high current density region. In spite that some of the activated biochars in the study had mesopores, the capacitance values of the samples were still low at high current density regions. The explanation is low electrical conductivity of the carbonized structure and to exist electrical insulators formed by the components generated during activation like polyphosphoric acid, oxides, and oxygen-containing functional groups as Molina-Sabio and Rodrı́guez-Reinoso recorded in his study44. Reducing the electrical resistance or remove the insulators layers is effective to improve the performance of EDLC electrodes, which might be interesting idea for future studies.

Conclusions

The present work focused on developing the SSA and total pore volume of biochar derived from fern D. linearis by H3PO4 activation and check the possibility of electrochemical performance for EDLC electrodes. All the N2 adsorption isotherms for the biochars prepared at 400–800 °C showed low-pressure hysteresis, which indicates the existence of ultra-micropores. Dominant elements in the sample carbonized at 600 °C were potassium and calcium except for the elements related to organic compounds, such as carbon, oxygen, hydrogen. The activation by H3PO4 was effective for enhancing both the SSA and pore volume. The sample activated at 400 °C with the mixing ratio 1:3 (w/w) had the maximum values. The maximum capacitance value was ca. 108 F g−1 at 1 mV s−1 for the sample activated at 600 °C with the mixing ratio 1:1 (w/w) at the weight. The research opened an idea of a new research about suppression of electrical resistance to improve of the electrochemical performance.

References

Fawzy, S., Osman, A. I., Doran, J. & Rooney, D. W. Strategies for mitigation of climate change: A review. Environ. Chem. Lett. https://doi.org/10.1007/s10311-020-01059-w (2020).

Forbes, E., Easson, D., Lyons, G. & Mcroberts, W. Physico-chemical characteristics of eight different biomass fuels and comparison of combustion and emission results in a small scale multi-fuel boiler. Energy Convers. Manage. 87, 1162–1169. https://doi.org/10.1016/j.enconman.2014.06.063 (2014).

Osman, A. I. Mass spectrometry study of lignocellulosic biomass combustion and pyrolysis with NOx removal. Renew. Energy 146, 484–496. https://doi.org/10.1016/j.renene.2019.06.155 (2020).

Tet-Vun, C. & Ismail, B. S. Field evidence of the allelopathic properties of Dicranopteris linearis. Weed Biol. Manag. 6(2), 59–67. https://doi.org/10.1111/j.1445-6664.2006.00203.x (2006).

Mai, N. T. et al. Fern Dicranopteris linearis-derived biochars: Adjusting surface properties by direct processing of the silica phase. Colloids Surf. A 583, 123937. https://doi.org/10.1016/j.colsurfa.2019.123937 (2019).

Nguyen, M. N. et al. Fern, Dicranopteris linearis, derived phytoliths in soil: Morphotypes, solubility and content in relation to soil properties. Eur. J. Soil Sci. 70(3), 507–517. https://doi.org/10.1111/ejss.12754 (2019).

Tran, C. T. et al. Phytolith-associated potassium in fern: Characterization, dissolution properties and implications for slash-and-burn agriculture. Soil Use Manag. 34(1), 28–36. https://doi.org/10.1111/sum.12409 (2018).

Zakaria, Z. A. et al. Antinociceptive, anti-inflammatory, and antipyretic properties of an aqueous extract of Dicranopteris linearis leaves in experimental animal models. J. Nat. Med. 62(2), 179–187. https://doi.org/10.1007/s11418-007-0224-x (2008).

Russell, A. E., Raich, J. W. & Vitousek, P. M. The ecology of the climbing fern Dicranopteris linearis on windward Mauna Loa, Hawaii. J. Ecol. 86(5), 765–779. https://doi.org/10.1046/j.1365-2745.1998.8650765.x (2003).

Kamisan, F. H. et al. Effect of methanol extract of Dicranopteris linearis against carbon tetrachloride-induced acute liver injury in rats. BMC Complement. Alternative Med. 14(1), 123. https://doi.org/10.1186/1472-6882-14-123 (2014).

Johnson, C. Advances in pretreatment and clarification technologies. Comprehensive Water Qual. Purif. 2, 60–74. https://doi.org/10.1016/B978-0-12-382182-9.00029-3 (2014).

Hayashi, J., Kazehaya, A., Muroyama, K. & Watkinson, A. Preparation of activated carbon from lignin by chemical activation. Carbon 38(13), 1873–1878. https://doi.org/10.1016/S0008-6223(00)00027-0 (2000).

Gao, Y. et al. Preparation of high surface area-activated carbon from lignin of papermaking black liquor by KOH activation for Ni(II) adsorption. Chem. Eng. J. 217, 345–353. https://doi.org/10.1016/j.cej.2012.09.038 (2013).

Myglovets, M. et al. Preparation of carbon adsorbents from lignosulfonate by phosphoric acid activation for the adsorption of metal ions. Carbon 80, 771–783. https://doi.org/10.1016/j.carbon.2014.09.032 (2014).

Liu, Q., Zheng, T., Wang, P. & Guo, L. Preparation and characterization of activated carbon from bamboo by microwave-induced phosphoric acid activation. Ind. Crops Prod. 31(2), 233–238. https://doi.org/10.1016/j.indcrop.2009.10.011 (2010).

Yakout, S. & El-Deen, G. S. Characterization of activated carbon prepared by phosphoric acid activation of olive stones. Arab. J. Chem. 9, S1155–S1162. https://doi.org/10.1016/j.arabjc.2011.12.002 (2016).

Luo, Y. et al. The performance of phosphoric acid in the preparation of activated carbon-containing phosphorus species from rice husk residue. J. Mater. Sci. 54(6), 5008–5021. https://doi.org/10.1007/s10853-018-03220-x (2018).

Sun, Y., Yang, G., Zhang, J., Wang, Y. & Yao, M. Activated carbon preparation from lignin by H3PO4 activation and its application to gas separation. Chem. Eng. Technol. 35(2), 309–316. https://doi.org/10.1002/ceat.201100309 (2011).

Abdelnaeim, M. Y., Sherif, I. Y., Attia, A. A., Fathy, N. A. & El-Shahat, M. Impact of chemical activation on the adsorption performance of common reed towards Cu(II) and Cd(II). Int. J. Mineral Process. 157, 80–88. https://doi.org/10.1016/j.minpro.2016.09.013 (2016).

Yuso, A. M., Rubio, B. & Izquierdo, M. T. Influence of activation atmosphere used in the chemical activation of almond shell on the characteristics and adsorption performance of activated carbons. Fuel Process. Technol. 119, 74–80. https://doi.org/10.1016/j.fuproc.2013.10.024 (2014).

Yorgun, S. & Yıldız, D. Preparation and characterization of activated carbons from Paulownia wood by chemical activation with H3PO4. J. Taiwan Inst. Chem. Eng. 53, 122–131. https://doi.org/10.1016/j.jtice.2015.02.032 (2015).

Yorgun, S., Yıldız, D. & Şimşek, Y. E. Activated carbon from paulownia wood: Yields of chemical activation stages. Energy Sources Part A Recov. Utilization Environ. Effects 38(14), 2035–2042. https://doi.org/10.1080/15567036.2015.1030477 (2016).

Qu, D. & Shi, H. Studies of activated carbons used in double-layer capacitors. J. Power Sources 74(1), 99–107. https://doi.org/10.1016/S0378-7753(98)00038-X (1998).

Burke, A. R&D considerations for the performance and application of electrochemical capacitors. Electrochim. Acta 53(3), 1083–1091. https://doi.org/10.1016/j.electacta.2007.01.011 (2007).

Sharma, P. & Bhatti, T. A review on electrochemical double-layer capacitors. Energy Convers. Manage. 51(12), 2901–2912. https://doi.org/10.1016/j.enconman.2010.06.031 (2010).

Momodu, D. et al. Transformation of plant biomass waste into resourceful activated carbon nanostructures for mixed-assembly type electrochemical capacitors. Waste Biomass Valorization 10(6), 1741–1753. https://doi.org/10.1007/s12649-017-0165-x (2017).

Su, X. et al. Superior capacitive behavior of porous activated carbon tubes derived from biomass waste-cotonier strobili fibers. Adv. Powder Technol. 29(9), 2097–2107. https://doi.org/10.1016/j.apt.2018.05.018 (2018).

Tey, J. P., Careem, M. A., Yarmo, M. A. & Arof, A. K. Durian shell-based activated carbon electrode for EDLCs. Ionics 22(7), 1209–1216. https://doi.org/10.1007/s11581-016-1640-2 (2016).

Tsubota, T. et al. Catalytic graphitization for preparation of porous carbon material derived from bamboo precursor and performance as electrode of electrical double-layer capacitor. J. Electron. Mater. 44(12), 4933–4939. https://doi.org/10.1007/s11664-015-4106-9 (2015).

Tsubota, T. et al. Capacitance property of carbon material derived from starch mixed with guanidine phosphate as electrochemical capacitor. J. Power Sources 227, 24–30. https://doi.org/10.1016/j.jpowsour.2012.11.042 (2013).

Chang, J. et al. Activated porous carbon prepared from paulownia flower for high performance supercapacitor electrodes. Electrochim. Acta 157, 290–298. https://doi.org/10.1016/j.electacta.2014.12.169 (2015).

Tsubota, T., Hohshi, Y., Ohno, T. & Kumagai, S. KOH activation of solid residue of Japanese citron after extraction by microwave process and property as EDLC electrode. J. Porous Mater. 27(3), 727–734. https://doi.org/10.1007/s10934-019-00855-2 (2020).

Tsubota, T. et al. Preparation of porous carbon material derived from cellulose with added melamine sulfate and electrochemical performance as EDLC electrode. J. Electron. Mater. 48(2), 879–886. https://doi.org/10.1007/s11664-018-6799-z (2018).

Tsubota, T., Ishimoto, K., Kumagai, S., Kamimura, S. & Ohno, T. Cascade use of bamboo as raw material for several high value products: Production of xylo-oligosaccharide and activated carbon for EDLC electrode from bamboo. J. Porous Mater. 25(5), 1541–1549. https://doi.org/10.1007/s10934-018-0567-6 (2018).

Nguyen, A. T. et al. Release kinetics of potassium from silica-rich fern-derived biochars. Agron. J. 112(3), 1713–1725. https://doi.org/10.1002/agj2.20209 (2020).

Chen, M. et al. Preparation of activated carbon from cotton stalk and its application in supercapacitor. J. Solid State Electrochem. 17(4), 1005–1012. https://doi.org/10.1007/s10008-012-1946-6 (2012).

Liu, X. et al. Net-like porous activated carbon materials from shrimp shell by solution-processed carbonization and H3PO4 activation for methylene blue adsorption. Powder Technol. 326, 181–189. https://doi.org/10.1016/j.powtec.2017.12.034 (2018).

Reffas, A. et al. Carbons prepared from coffee grounds by H3PO4 activation: Characterization and adsorption of methylene blue and Nylosan Red N-2RBL. J. Hazard. Mater. 175(1–3), 779–788. https://doi.org/10.1016/j.jhazmat.2009.10.076 (2010).

Prahas, D., Kartika, Y., Indraswati, N. & Ismadji, S. Activated carbon from jackfruit peel waste by H3PO4 chemical activation: Pore structure and surface chemistry characterization. Chem. Eng. J. 140(1–3), 32–42. https://doi.org/10.1016/j.cej.2007.08.032 (2008).

Liu, H. et al. Preparation of activated carbon from lotus stalks with the mixture of phosphoric acid and pentaerythritol impregnation and its application for Ni(II) sorption. Chem. Eng. J. 209, 155–162. https://doi.org/10.1016/j.cej.2012.07.132 (2012).

Girgis, B. S. & El-Hendawy, A. A. Porosity development in activated carbons obtained from date pits under chemical activation with phosphoric acid. Microporous Mesoporous Mater. 52(2), 105–117. https://doi.org/10.1016/S1387-1811(01)00481-4 (2002).

Li, Y., Zhang, X., Yang, R., Li, G. & Hu, C. The role of H3PO4 in the preparation of activated carbon from NaOH-treated rice husk residue. RSC Adv. 5(41), 32626–32636. https://doi.org/10.1039/C5RA04634C (2015).

Abdelnaeim, M. Y., Sherif, I. Y., Attia, A. A., Fathy, N. A. & El-Shahat, M. Impact of chemical activation on the adsorption performance of common reed towards Cu(II) and Cd(II). Int. J. Miner. Process. 157, 80–88. https://doi.org/10.1016/j.minpro.2016.09.013 (2016).

Molina-Sabio, M. & Rodrı́guez-Reinoso, F. Role of chemical activation in the development of carbon porosity. Colloids Surfaces A Physicochem. Eng. Aspects 241(1–3), 15–25. https://doi.org/10.1016/j.colsurfa.2004.04.007 (2004).

Guo, Y. & Rockstraw, D. A. Physical and chemical properties of carbons synthesized from xylan, cellulose, and Kraft lignin by H3PO4 activation. Carbon 44(8), 1464–1475. https://doi.org/10.1016/j.carbon.2005.12.002 (2006).

Baccar, R., Bouzid, J., Feki, M. & Montiel, A. Preparation of activated carbon from Tunisian olive-waste cakes and its application for adsorption of heavy metal ions. J. Hazard. Mater. 162(2–3), 1522–1529. https://doi.org/10.1016/j.jhazmat.2008.06.041 (2009).

Fan, L. et al. High electroactivity of polyaniline in supercapacitors by using a hierarchically porous carbon monolith as a support. Adv. Func. Mater. 17(16), 3083–3087. https://doi.org/10.1002/adfm.200700518 (2007).

Scorsone, E., Gattout, N., Rousseau, L. & Lissorgues, G. Porous diamond pouch cell supercapacitors. Diam. Relat. Mater. 76, 31–37. https://doi.org/10.1016/j.diamond.2017.04.004 (2017).

Acknowledgements

This work was supported by the Vingroup Innovation Foundation (VINIF) under the project code DA163_15062019/ year 2019. This work was performed under the Cooperative Research Program of “Network Joint Research Center for Materials and Devices”. Acknowledgments are made to Cooperative Studies Using Collaborative Research Facilities of Wood Composite of Research Institute for Sustainable Humanosphere of Kyoto University.

Author information

Authors and Affiliations

Contributions

T.K.T. wrote the main manuscript text and measured the samples. T.T. and M.N.N. revised the main manuscript text, and prepared figures. S.T. performed the experiments of H3PO4 activation and measured the samples. N.T.M. and N.H.N. performed the experiments of carbonization and H3PO4 activation, and elemental analysis of the samples. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Trinh, T.K., Tsubota, T., Takahashi, S. et al. Carbonization and H3PO4 activation of fern Dicranopteris linearis and electrochemical properties for electric double layer capacitor electrode. Sci Rep 10, 19974 (2020). https://doi.org/10.1038/s41598-020-77099-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-020-77099-7

This article is cited by

-

Effect of synthesis conditions on the porous texture of activated carbons obtained from Tara Rubber by FeCl3 activation

Scientific Reports (2024)

-

Mixed (organic and inorganic) contaminants removal ability of water fern biomass-based biochar on starch industry wastewater

Biomass Conversion and Biorefinery (2024)

-

Preparation, characterization and application of H3PO4-activated carbon from Pentaclethra macrophylla pods for the removal of Cr(VI) in aqueous medium

Journal of the Iranian Chemical Society (2023)

-

Mathematical analysis of the effect of process conditions on the porous structure development of activated carbons derived from Pine cones

Scientific Reports (2022)

-

Evolution of physico-chemical properties of Dicranopteris linearis-derived activated carbon under various physical activation atmospheres

Scientific Reports (2021)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.