Abstract

We estimated ruminal crude protein degradation of twelve feedstuffs commonly used in China using in vitro and in vivo methods. The in vivo net protein utilization (NPU) levels of corn, sorghum, barley, wheat, Chinese wild rye grass, corn stalk, rice straw, soybean straw, soybean meal, distillers’ dried grains with solubles (DDGS), Brewers’ spent grains, and sunflower meal were 52.57, 49.68, 65.38, 72.58, 82.41, 72.26, 68.57, 76.95, 54.75, 56.27, 29.03 and 41.88%, respectively. The linear regression between NH3-N incorporated into microbial proteins and gas production after incubation (6, 12, and 24 h) was significant (r = 0.9948 and P < 0.001, r = 0.9874 and P < 0.01, and r = 0.9912 and P < 0.01, respectively). Based on the linear regression equations, we estimated in vitro protein degradability (IVPD) and generated the regression equations between IVPD and NPU. The linear regression equations between IVPD and NPU after 6 h incubation in the energy, protein, and roughage feed groups were Y = 0.5633X + 33.20 (R2 = 0.8517, P < 0.05), Y = 0.8482X+ 34.81 (R2 = 0.8650, P < 0.05), and Y = 1.6295X − 17.70 (R2 = 0.909, P < 0.05), respectively. The in vitro gas production method is useful for the determination of protein degradation in feedstuffs.

Similar content being viewed by others

Introduction

Protein supply is a key factor that determines the economic success of the beef cattle industry. Due to lack of information on the protein quality of beef cattle feedstuffs in China, the beef cattle industry relies on accurate analyses. The degradation rate of feedstuff protein in rumen is an essential characteristic for the determination of the protein value of feeds1,2,3 and an important feed characteristic in nutritional models4,5,6. Particularly, cereal grains such as maize, sorghum, barely and wheat which are rich in starch have long become an important component of the diet in high-producing beef cattle in China, and they also are a valuable source of proteins, while chemical structure and protein matrix leads to large variations in the protein degradation capabilities of the cereal grains7. Similarly, chinese wild rye grass, corn stalk, rice straw and soybean straw were important forages commonly used for beef cattle production in China especially districts of with less availability of feed resources due to their advantages of large-scale production and high nutritional value8,9,10. Besides, soybean meal, DDGS, brewers’ spent grains and sunflower meal are special source of protein for beef cattle feeds in China due to economic and environmental concerns, and these by-products usually have high protein contents and can provide competitive alternatives to more traditional protein sources11.

Amongst all methods used to evaluate protein quality in ruminant feedstuffs, in vivo estimates are the most reliable. Even though the in vivo method is expensive, time consuming, and laborious, it provides accurate information on the animal response to feedstuffs. In addition, data from in vivo studies are used to validate the accuracy of in situ and in vitro methodologies12,13. The in vitro gas production technique14,15 has been use to evaluate rumen CP degradability of feeds via ammonia-N and gas production measurements recorded by incubating feedstuffs in buffered rumen fluid. By improving this technique (e.g., through method innovation, instrument upgrades, and data handling), the in vitro gas production technique has been widely used to predict digestibility of ruminant feedstuffs16,17,18,19. Even though in vivo and in vitro methods have been widely researched, there are few comparisons between in vitro and in vivo measurements of feedstuff protein degradation.

In order to make the evaluation of relationship between IVPD and NPU more accurate, we choosed three types (forages, energy feed and protein feed) with large range of the content of protein. And the objectives of this study were to (1) determine the chemical composition of twelve common beef cattle feedstuffs commonly used in China and (2) predict protein digestibility by using in vitro gas production technique and in vivo data derived from digestion trials in an attempt to assess the accuracy of the in vitro gas production technique.

Results

The chemical composition of twelve feedstuffs is shown in Table 1. Starch content in corn, sorghum, barley, and wheat was 66.69%, 52.40%, 55.14%, and 59.46%, respectively. Meals (soybean meal and sunflower meal) and by-products (DDGS and Brewers’ spent grain) contained more CP than cereals and roughages, less NDF and ADF than roughages, and less starch than cereals. Among the protein feed group, CP concentration was higher in soybean meal and sunflower meal than in DDGS and Brewers’ spent grain. NDF, ADF, and starch were higher in Brewers’ spent grain than in soybean meal, sunflower meal, and DDGS. Sunflower meal had the highest CF content among the protein feed group. The roughage feed group contained high levels of NDF and ADF. Soybean straw had higher CP than Chinese wild rye grass, corn stalk, and rice straw.

Protein intake, fecal protein, urinary protein, and NPU of the twelve feedstuffs are shown in Table 2. Protein intake consist of proteins provided by mixed feeds (energy feed group and protein feed group) or single feeds (roughage feed group). The type of feedstuff affected the amount of protein intake. Higher protein intake was observed in the protein feed group (1.9069 kg/d for soybean meal, 1.2455 kg/d for DDGS, 1.2198 kg/d for Brewers’ spent grains, and 0.9115 kg/d for sunflower meal), and lower protein intake was observed in the roughage feed group (0.3976 kg/d for Chinese wild rye grass, 0.6919 kg/d for soybean straw, 0.4322 kg/d for corn stalk, and 0.4779 kg/d for rice straw). Fecal protein was the highest for sorghum (0.3537 kg/d) and lowest for Chinese wild rye grass (0.1508 kg/d). Urinary protein was the highest for soybean meal (141.86 g/d) and lowest for corn stalk (18.19 g/d). NPU varied among the feedstuffs. In the protein feed group, the highest and lowest NPU values were obtained in soybean meal (82.41%) and Brewers’ spent grain (68.37%), respectively. Among the cereal grains, NPU was higher for wheat (72.58%) and barley (65.38%) than for corn (52.57%) and sorghum (49.68%). For roughages, soybean straw had the highest NPU (56.27%).

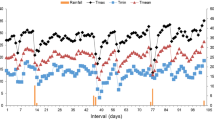

Figure 1 shows a linear regression between NH3-N incorporated into microbial proteins and gas production after 6, 12, and 24 h of incubation. The linear regression was significant, indicating that gas production from feedstuffs is an accurate estimate of incorporated ammonia N. The highest correlation coefficient was observed at 6 h, Y = 0.1331X + 0.133, R2 = 0.9896 (P < 0.05). The linear regression equations at 12 and 24 h were Y = 0.1502X – 0.7054 (R2 = 0.9750, P < 0.05) and Y = 0.0718X + 0.2872 (R2 = 0.9825, P < 0.05), respectively.

Based on the linear regression equations, estimates of IVPD were calculated (Table 3). Protein degradation during the first 6 h of in vitro incubation varied from 68.43% (wheat) to 25.65% (sorghum). After 12 h of in vitro incubation, CP degradation ranged from 80.12% (wheat) to 36.6% (corn stalk). IVPD after 24 h of in vitro incubation was the highest for wheat (87.56%) and the lowest for corn stalk (44.42%).

The relationship between IVPD and NPU after 6, 12, and 24 h of incubation are presented in Fig. 2. Regression analyses demonstrated that the linear regression equations in the three feed groups (energy feed group, protein feed group, and roughage feed group) were significant (P < 0.05) after 6 h of incubation (R2 of 0.8517, 0.8650, and 0.8909, respectively). However, increased incubation time decreased the R2 value. At 12 h, the R2 values of IVPD and NPU in the energy feed group and roughage feed group were 0.8316 and 0.8435, respectively. Additionally, there was no correlation between IVPD and NPU in the protein feed group after 12 h of incubation. Similarly, no relationship was observed between IVPD and NPU in the energy feed group, protein feed group, and roughage feed group at 24 h. When IVPD and NPU were analyzed together, the linear regression equations at 6, 12, and 24 h of incubation revealed no correlation. The equations were described by Y = 0.9848X + 16.25 with R2 = 0.5171 and P > 0.05 (6 h of incubation), Y = 0.7043X+ 20.55 with R2 = 0.3704 and P > 0.05 (12 h of incubation), and Y = 0.5958X + 19.11 with R2 = 0.2695 and P > 0.05 (24 h of incubation).

Discussion

The starch content of cereals (corn, sorghum, barley, and wheat) obtained in this study was lower than that reported by Nutrient Requirements of Beef Cattle (eighth revised edition, 2016), probably due to difference in cereal origin and growing conditions. Wheat and barley are two of the most readily degradable cereals due to their higher rate of ruminal starch fermentation and more extensive ruminal nitrogen fermentation compared with corn and sorghum20,21. The lower degradation rate of corn compared to that of wheat can be explained by the different nature of the protein components, particularly zeins in the former and gliadins in the latter22. The main potential limitation of sorghum is its poor digestibility due to the presence of dense proteinaceous matrix in the peripheral endosperm layer of the kernel, which renders protein inaccessible23. Soybean meal is a major contributor of protein to beef cattle. The CP, ADF, and NDF of soybean meal obtained in this study were similar to those reported by NRBC6. The utilization of feed protein in ruminants depends not only on total protein and amino acid content but also on the type of feed protein24 and its molecular structure25. Highest NPU values were observed in SBM, possibly due to the structure and solubility characteristics of SBM protein26,27. Brewers’ spent grain is a valuable protein source with higher levels of starch, NDF, and ADF than soybean meal, DDGS, and sunflower meal. Several studies have shown that Brewers’ spent grain, which consists of husks, pericarp parts, and seed coat layers of grains, is a rich source of fiber, protein, and carbohydrate28,29. In addition, early studies on sunflower meal have reported that it is high in fiber30 and a potential source of protein in beef rations31. Uniquely in beef cattle, the process of ruminal degradation of protein converts dietary protein of low biological value in low quality roughage into microbial protein of high biological value32. The CP content of soybean straw was higher than those reported by Maheri-Sis et al. and NRBC6,33. Soybean straw, which consists of stems, leaves, and pod husks, is a major source of roughage for beef cattle. Similar NPU values of soybean straw were reported by Gupta et al. (1978), who concluded that protein digestibility depends on variations in the pod-to-stem ratio and on maturity stage of harvested soybeans34. The presence of high levels of silica in rice straw may contribute to the resistance of rice straw to ruminal degradation35. The NPU of corn stalks and Chinese wild rye grass is low due to the formation of cross-links between lignin polymers and polysaccharides in the plant cell wall through phenolic acids (predominantly ferulic and p-coumaric acids) and arabinoxylans, that provide cell wall integrity and resistance against microbial enzymatic degradation36,37.

The approach we used in this study aimed to analyze the correlation between gas production and NH3-N incorporation into microbial proteins as an indicator of protein degradation. Gas production can be used to evaluate metabolisable energy content of feedstuffs15, which in turn determines the synthesis of rumen microbial protein. Dietary protein is eventually degraded into ammonia N in the rumen via enzymatic activity of ruminal microorganisms. However, ammonia from protein degradation and microbial catabolism, which occur simultaneously in the rumen, make it difficult to identify IVPD of feedstuffs from ammonia release. To eliminate the effect of ruminal microbial protein synthesis during fermentation, we used a method to eliminate the effect of ruminal microbial protein synthesis during fermentation. Raab et al. (1983) reported that the amount of NH3-N released when no fermentable carbohydrates are available and consequently no bacterial protein synthesis can take place can be represented by the intercept of the linear regression between NH3-N concentration and gas production. The results can be corrected by the difference between this intercept and NH3-N content in the blank (rumen fluid without substrate14. In our earlier studies, we attempted to determine protein degradability using techniques described by Broderick (1987) and Raab et al.14,38. However, the methods were complicated and cumbersome and had limitations on the batch culture used. In this study, we classified ruminal ammonia N into (1) incorporated ammonia N, which is used for microbial degradation of protein, and (2) free ammonia N. There was a high correlation between ammonia N incorporated into microbial proteins and gas production, suggesting that gas production of feedstuffs is an accurate estimate of incorporated ammonia N. Therefore, we hypothesize that free ammonia N and incorporated ammonia N represent the N obtained from feeds.

We obtained a significant correlation between IVDP and NPU of each type of feed; however, there was no correlation between IVDP and NPU when we conducted a unified analysis of all feeds. Different types of feedstuff differ substantially in their physical and chemical characteristics and are metabolized differently in animals. Falahatizow et al. (2015) reported that gas production rate might be related to structural carbohydrates of feedstuffs; consequently, gas production rate may affect IVDP39. Additionally, degradability is not only related to the type of feed but also to the residence time of feedstuffs in the rumen14. It is important to be aware of the retention time of feedstuffs to select the appropriate incubation time for the in vitro gas production technique. In the present study, IVDP increased with incubation time, and the highest correlation coefficient between feed protein degradation rate determined by in vitro gas production method and in vivo NPU was observed at 6 h of incubation in the three feed groups (energy, protein, and roughage). The in vitro gas production technique used in this study determined the end-point fermentability of feedstuffs by recording plunger displacement at frequent intervals. With increasing incubation time, IVDP increased and regression coefficient decreased. This observation is in agreement with the findings reported by Lorenz et al. (2011), who observed that increasing IVDP indicates higher NH3 released from protein degradation as opposed to bacterial uptake due to an energy shortage for bacterial synthesis40. Furthermore, with increasing in vitro culture time, fermentation products gradually accumulate due to the non-outflow of fermentation contents, thereby impacting the living conditions of microorganisms and fermentation. Eventually, these factors would be expected to interfere with normal microbial protein degradation. Mota et al. (2005) reported that underestimation of N degradation due to microbial synthesis that increases the proportion of N in the residue negatively affects the accuracy of the method41. Besides, the degradation degree of proteins contained in microorganisms increases with incubation time. Meng et al. (1991) reported that when the blank culture was performed in vitro, the concentration of free NH3-N increased gradually with time, and the concentration of NH3-N at 24 h was 1.54 times higher than the initial concentration of NH3-N42. Similarly, Cone et al. (1998) noted that microbial turnover in the blank sample resulted in a gas production rate that was different from that of feed samples and this could increase the ammonia concentration43. In addition, Karlsson et al. (2009) have speculated that different amounts of added carbohydrates affect the microbial turnover during longer incubation intervals. Pre-incubation with carbohydrates is essential for standardizing rumen fluid by increasing microbial activity and equilibrating the initial ammonia (NH3) concentration44. In previous experiments designed to study a optimum carbohydrate source, we observed that artificial rumen fluid with 25 mg of soluble starch and 25 mg of maltose was optimum42. However, the factor that corrects rumen fluid may be different for different feedstuffs, resulting in different regression coefficients. Therefore, it is important to set up a regression equation by choosing the feed itself as the nitrogen source and adding the starch by grades.

The in vivo method is the gold standard for determining ruminal CP degradability. The weak correlation between the in vivo and in vitro methods is due to variations in the latter. The quality of rumen fluid has a great impact on in vitro gas production technology. Our previous studies found that different sources of rumen fluid and sampling time had no effect on IVPD. However, in this study, feedstuffs were not incubated in defaunated rumen fluid. Ignoring the presence of protozoa in rumen fluid may influence in vitro measurements of feedstuff. Lorenz et al. (2011) reported that when soybean meal was incubated as a protein source, the removal of protozoa in vitro by centrifugation minimized the recirculation of bacterial protein by protozoa40. However, Rymer et al. (2005) observed that rumen fluid continuously flushed with CO2 during incubation may adversely affect gas production by excluding adherent cellulolytic bacteria from the rumen inoculum45. Furthermore, protein degradability has been generally estimated at the end-point of incubation, which provides inadequate information of the degradation pattern over time. To compare the ruminal degradability of feedstuffs, we need to obtain kinetic parameters, which could be offered by modified gas production instruments. Pellikaan et al. (2011) and Elberg et al. (2018) modified the in-vitro gas production instrument and reported total gas production and a precise description of in-vitro gas kinetics44,46. There is a need to generate a standardized approach of the in vitro gas production technique.

In summary, there were significant correlation between IVPD and NPU in the same feed type, and in vitro gas production method could be used for rapid determination of protein digestibility. More samples are needed for building more accurate relationship between IVPD and NPU in different feed type prediction for further study.

Methods

Feed samples

Twelve feedstuffs were obtained from Beijing (Hebei Province, P. R. China), air-dried, and ground in a hammer mill to pass through a 2-mm sieve for chemical analysis. In the in vivo method, the feedstuffs were divided into three groups: (1) energy feed group (cereals): corn, sorghum, barley, and wheat; (2) roughage feed group: Chinese wild rye grass, corn stalk, rice straw, and soybean straw; (3) protein feed group (meal and by-products): soybean meal, distillers’ dried grains with soluble (DDGS), Brewers’ spent grains, and sunflower meal.

Chemical analysis

Feeds and animal feces were analyzed for dry matter (DM), ash, and ether extract (EE) according to AOAC (2012) methods. Crude protein (CP), acid detergent insoluble N (ADIN), and neutral detergent insoluble N (NDIN) were determined by the Dumas method using an N Analyzer (Rapid N III, Elementar, Germany) and a nitrogen-to-protein conversion factor of 6.25. Neutral detergent fiber (NDF), acid detergent fiber (ADF), and acid detergent lignin (ADL) were analyzed using an A220 Fiber Analyzer (ANKOM Technology Corp., Macedon, NY, USA). NDF was assayed using alpha-amylase. Both NDF and ADF contained no residual ash. Urinary N was analyzed according to AOAC (2012) methods.

In-vitro Gas production method

Rumen fluid was collected from three Angus steers (approximately 320 kg body weight) fitted with permanent rumen cannulas. The animals were fed a total mixed ration which consisted of 40% steam-flaked corn, 40% corn stalk silage, 4.5% cottonseed meal, and 13.5% brewer’s grains (DM basis) and 0.5% salt and 0.5% premix (2.4 g/kg Mg, 7.6 g/kg K, 12.0 g/kg Fe, 1.0 g/kg Cu, 200 mg/kg Mn, 650 mg/kg Zn, 2 mg/kg Se, 22 mg/kg I, 9 mg/kg Co, 121,000 IU/kg vitamin A, 37,400 IU/kg vitamin D, and 55 IU/kg vitamin E) twice a day with ad libitum access to water. Animal care and use were approved and conducted according to standards established by the College of Animal Science and Technology, CAU, Beijing, P. R. China (permit number DK1402006). In vitro incubation was carried out according to the procedure reported by Menke et al. (1979). Samples of rumen fluid were collected prior to the morning feeding, passed through four layers of cheesecloth into a pre-warmed vacuum bottle, and transported immediately to the laboratory of Beef Cattle Research Center of China Agricultural University. The rumen fluid was mixed with buffer solution in a 1:1 (v/v) ratio (Menke et al., 1979) under a continuous flux of CO2 to maintain anaerobic conditions and maintained at 39 °C.

Five levels of substrate were prepared based on the amount of soluble starch: 0 mg DM, 40 mg DM, 80 mg DM, 120 mg DM, and 160 mg DM. An equal amount of (NH4)2SO4 (10 mg N) was added to a glass syringe. Artificial rumen culture solution (30 mL, containing 25 mg of soluble starch and 25 mg of maltose) was added and incubated at 39 °C. Gas production was measured at 6, 12, and 24 h incubation. The syringe was transferred to an ice bath to prevent further microbial activity. The fermentation mixture was centrifuged at 1,000 g for 10 min. The resulting supernatant was used for the determination of incorporated NH3-N.

The feed samples in each syringe contained 200 mg DM and <10 mg N. If the N content of the sample was >5%, the additional supplementation of corn starch would result in a DM content of 200 mg; conversely, if the N content of the feed sample was <5%, only 200 mg of this sample needed to be weighed separately. Incubations were performed in triplicate. Blank samples consisted of three syringes with artificial rumen culture solution.

In vivo Method

Twelve Angus steers (320 ± 20 kg body weight) fitted with permanent rumen cannulas (CAU Beef Cattle Research Center, Beijing, P. R. China) were kept individually in cages. The animals had ad libitum access to water and were assigned to one of three groups (each group consisted of four steers) based on their body weight in a 4 × 4 Latin square design. An adaptation period (15 d) was followed by a sample collection period (5 d). During the collection period, fecal and urine samples were collected after the morning feeding. Animal care and use were approved and conducted according to standards established by the College of Animal Science and Technology, CAU, Beijing, P. R. China (permit number DK1402006).

The steers were fed the experimental diets at 1.9% BW on a DM basis in two equal portions at 08.00 and 16.00. To prevent the occurrence of digestive abnormalities such as rumen acidosis by feeding a single feed, the first group (energy feed group) and the third group (protein feed group) were fed a mixed diet of 4.2 kg of feed and 1.8 kg of Chinese wild rye grass; the second group (roughage feed group) was fed the single feed. To meet nutrient balance, 2% rumen buffer (NaHCO3:MgO = 2:1), 0.5% stone powder, and 0.5% salt of feed intake on a DM basis and 30 mg/kg Rumensin was added to ensure normal ruminal fermentation.

Fecal samples were collected on sampling days, and 20% of the total fecal weight was collected. Fecal samples were collected into bags containing 10% tartaric acid to prevent the loss of ammonia nitrogen (N) and stored at −20 °C. At the end of each collection period, fecal samples were pooled and weighed. The pooled fecal samples were naturally air-dried, ground to a 1-mm screen size, and stored at 0–4 °C. Urine samples were collected in urinary bags. The bag, which was designed by a research team at the China Agricultural University (CAU; Beijing; P. R. China), consists of a funnel, a catheter, and latex tubes. Urine volume was measured daily, and the urine samples were passed through a gauze. The urine samples were collected in 600 mL of 6 N HCl to prevent the loss of ammonia nitrogen (N) and stored at 4 °C.

Statistical analysis

IVPD was estimated for each feed after each incubation period in the GP experiment via linear regression of incorporated ammonia N (y, mg) vs. gas production (x, mL) (Meng et al.). The relationship between ammonia N incorporated into microbial proteins and gas production was quantitatively reflected by the regression coefficient b. IVPD was calculated at 6, 12, and 24 h using the following equation,

Data obtained from the in vitro and in vivo methods were statistically analyzed using EXCEL while taking into account the net protein utilization (NPU) of the four roughage samples (Chinese wild rye grass, soybean straw, corn stalk, and rice straw) according to the following statistical model,

Protein degradation data obtained from corn, sorghum, barley, wheat, soybean meal, DDGS, Brewers’ spent grain, and sunflower meal were analyzed according to the concentration of CP in Chinese wild rye grass using the follow equation,

\(\begin{array}{c}{\rm{NPU}}=\frac{({\rm{Intake}}\,{\rm{CP}}-{\rm{Fecal}}\,{\rm{CP}}-{\rm{Urine}}\,{\rm{CP}}+\mathrm{Chinese}\,\,{\rm{wildrye}}\,{\rm{grass}}\,{\rm{CP}}\times (1-{\rm{Chinese}}\,{\rm{wildrye}}\,{\rm{grass}}\,\mathrm{CP} \% ))}{({\rm{Intake}}\,{\rm{CP}}-\mathrm{Fecal}\,\,{\rm{CP}})}\\ \,\times \frac{({\rm{Intake}}\,{\rm{CP}}-{\rm{Fecal}}\,{\rm{CP}})}{\mathrm{Intake}\,\,{\rm{CP}}}\end{array}\)The regression analysis between the two methods was determined by the CORR and REG procedures of SAS(version 9.4). Duncan’s significant difference test procedure was used to determine differences among means. Significance was set at P ≤ 0.05.

References

Masiero, M. M., Landers, A. L. & Kerley, M. S. Rumen protein degradation characteristics among six protein feed sources using a batch culture system. Journal of Animal Science 95, 180–180 (2017).

González, J., Mouhbi, R., Guevara-González, J. A., Rodríguez, C. A. & Arroyo, J. M. Protein value of cereals and cereal by-products for ruminants: a comparison between crude protein and protein-based estimates. Archives of Animal Nutrition 69, 237–250 (2015).

De Boever, J. L., Blok, M. C., Millet, S., Vanacker, J. & De Campeneere, S. The energy and protein value of wheat, maize and blend DDGS for cattle and evaluation of prediction methods. Animal 8, 1839–1850 (2014).

Sniffen, C. J., O’Connor, J. D., Van Soest, P. J., Fox, D. G. & Russell, J. B. A net carbohydrate and protein system for evaluating cattle diets: II. Carbohydrate and protein availability. J Anim Sci 70, 3562–3577 (1992).

Kebreab, E., Dijkstra, J., Bannink, A. & France, J. Recent advances in modeling nutrient utilization in ruminants1. Journal of Animal Science 87, E111–E122 (2009).

E. National Academies of Sciences, Medicine, Nutrient Requirements of Beef Cattle. (The National Academies Press, Washington, DC, 2016).

Humer, E. & Zebeli, Q. Grains in ruminant feeding and potentials to enhance their nutritive and health value by chemical processing. Animal Feed Science and Technology 226, 133–151 (2017).

Hao, X. Y., Gao, H., Wang, X. Y., Zhang, G. N. & Zhang, Y. G. Replacing alfalfa hay with dry corn gluten feed and Chinese wild rye grass: Effects on rumen fermentation, rumen microbial protein synthesis, and lactation performance in lactating dairy cows. Journal of Dairy Science 100, 2672–2681 (2017).

He, L., Wu, H., Wang, G., Meng, Q. & Zhou, Z. The effects of including corn silage, corn stalk silage, and corn grain in finishing ration of beef steers on meat quality and oxidative stability. Meat Science 139, 142–148 (2018).

Wei, M., Cui, Z.-H., Li, J.-W. & Yan, P.-S. Estimation of metabolisable energy and net energy of rice straw and wheat straw for beef cattle by indirect calorimetry. Archives of Animal Nutrition 72, 275–289 (2018).

Oishi, K., Kumagai, H. & Hirooka, H. Application of the modified feed formulation to optimize economic and environmental criteria in beef cattle fattening systems with food by-products. Animal Feed Science and Technology 165, 38–50 (2011).

Vanzant, E. S. et al. In vivo and in situ measurements of forage protein degradation in beef cattle2. Journal of Animal Science 74, 2773–2784 (1996).

Di Marco, O. N., Ressia, M. A., Arias, S., Aello, M. S. & Arzadún, M. Digestibility of forage silages from grain, sweet and bmr sorghum types: Comparison of in vivo, in situ and in vitro data. Animal Feed Science and Technology 153, 161–168 (2009).

Raab, L., Cafantaris, B., Jilg, T. & Menke, K. H. Rumen protein degradation and biosynthesis. I. A new method for determination of protein degradation in rumen fluid in vitro. Br J Nutr 50, 569–582 (1983).

Menke, K. H. et al. Estimation of the Digestibility and Metabolizable Energy Content of Ruminant Feedingstuffs from the Gas-Production When They Are Incubated with Rumen Liquor Invitro. J Agr Sci 93, 217–222 (1979).

Ding, S. et al. In vitro gas production and dry matter digestibility of malting barley grain sown with different seeding and nitrogen fertilization rates in Canada. Animal Feed Science and Technology 199, 146–151 (2015).

Westreicher-Kristen, E., Blank, R., Schulz, F. & Susenbeth, A. Replacing maize silage with red clover silage in total mixed rations for dairy cows: In vitro ruminal fermentation characteristics and associative effects. Animal Feed Science and Technology 227, 131–141 (2017).

Böttger, C. & Südekum, K. H. European distillers dried grains with solubles (DDGS): Chemical composition and in vitro evaluation of feeding value for ruminants. Animal Feed Science and Technology 224, 66–77 (2017).

Tahir, M. N., Hetta, M., Larsen, M., Lund, P. & Huhtanen, P. In vitro estimations of the rate and extent of ruminal digestion of starch-rich feed fractions compared to in vivo data. Animal Feed Science and Technology 179, 36–45 (2013).

Benninghoff, J., Paschke-Beese, M. & Sudekum, K. H. In situ and in vitro ruminal degradation of maize grain and untreated or xylose-treated wheat, barley and rye grains. Animal Feed Science and Technology 210, 86–93 (2015).

Nikkhah, A. Barley grain for ruminants: A global treasure or tragedy. J Anim Sci Biotechno 3 (2012).

Fahmy, W. G., Aufrère, J., Graviou, D., Demarquilly, C. & Elshazly, K. Comparison between the mechanism of protein degradation of two cereals by enzymatic and in situ methods, using gel electrophoresis. Animal Feed Science &. Technology 35, 115–130 (1991).

Gonzalez, A. et al. A comparison of processed sorghum grain using different digestion techniques. vol. 0, pp. 0 (2016).

Sniffen, C. J. et al. Carbohydrate and Protein System for Evaluating Cattle Diets.2. Carbohydrate and Protein Availability. Journal of Animal Science 70, 3562–3577 (1992).

Peng, Q., Khan, N. A., Wang, Z. & Yu, P. Relationship of feeds protein structural makeup in common Prairie feeds with protein solubility, in situ ruminal degradation and intestinal digestibility. Animal Feed Science and Technology 194, 58–70 (2014).

Mahadevan, S., Erfle, J. D. & Sauer, F. D. Degradation of soluble and insoluble proteins by Bacteroides amylophilus protease and by rumen microorganisms. J Anim Sci 50, 723–728 (1980).

Promkot, C. & Wanapat, M. Ruminal Degradation and Intestinal Digestion of Crude Protein of Tropical Protein Resources Using Nylon Bag Technique and Three-step in Vitro Procedure in Dairy Cattle. Visualization Techniques for Intrusion Detection, (2004).

Mussatto, S. I. Brewer’s spent grain: a valuable feedstock for industrial applications. J Sci Food Agric 94, 1264–1275 (2014).

Ikram, S., Huang, L., Zhang, H., Wang, J. & Yin, M. Composition and Nutrient Value Proposition of Brewers Spent Grain. J Food Sci 82, 2232–2242 (2017).

Senkoylu, N. & Dale, N. Sunflower meal in poultry diets: a review. World’s Poultry Science Journal 55, 153–174 (2007).

Richardson, C. R., Beville, R. N., Ratcliff, R. K. & Albin, R. C. Sunflower Meal as a Protein Supplement for Growing Ruminants. Journal of Animal Science 53, 557–563 (1981).

Getachew, G., Makkar, H. P. S. & Becker, K. The in vitro gas coupled with ammonia measurement for evaluation of nitrogen degradability in low quality roughages using incubation medium of different buffering capacity. Journal of the Science of Food and Agriculture 77, 87–95 (1998).

Maheri-Sis, N. et al. Determining nutritive value of soybean straw for ruminants using nylon bags technique. Pak. J. Nutr 10, 838–841 (2011).

Gupta, B. S., Johnson, D. E. & Hinds, F. C. Soybean Straw Intake and Nutrient Digestibility by Sheep. Journal of Animal Science 46 (1978).

Nader, G. A. & Robinson, P. H. Effects of maceration of rice straw on voluntary intake and performance of growing beef cattle fed rice straw-based rations. Animal Feed Science and Technology 146, 74–86 (2008).

Awawdeh, M. S., Titgemeyer, E. C., Drouillard, J. S., Beyer, R. S. & Shirley, J. E. Ruminal degradability and lysine bioavailability of soybean meals and effects on performance of dairy cows. Journal of Dairy Science 90, 4740–4753 (2007).

Yang, H. J. & Xie, C. Y. Assessment of fibrolytic activities of 18 commercial enzyme products and their abilities to degrade the cell wall fraction of corn stalks in in vitro enzymatic and ruminal batch cultures. Animal Feed Science & Technology 159, 110–121 (2010).

Broderick, G. A. Determination of Protein-Degradation Rates Using a Rumen Invitro System Containing Inhibitors of Microbial Nitrogen-Metabolism. British Journal of Nutrition 58, 463–475 (1987).

Falahatizow, J., Mesgaran, M. D., Vakili, A. R., Tahmasbi, A. M. & Nazari, M. R. The estimation of ruminal protein degradation parameters of various feeds using in vitro modified gas production technique. Iran J Vet Res 16, 47–52 (2015).

Lorenz, M. M., Karlsson, L., Hetta, M. & Uden, P. Recycling of microbial N and estimation of protein degradation by in vitro gas production. Animal Feed Science and Technology 170, 111–116 (2011).

Mota, M., Rodriguez, R., Solanas, E. & Fondevila, M. Evaluation of four tropical browse legumes as nitrogen sources: Comparison of in vitro gas production with other methods to determine N degradability. Animal Feed Science and Technology 123, 341–350 (2005).

Meng, Q. A new in vitro procedure for estimation of ruminal protein degradation. (1991).

Cone, J. W. The development, use and application of the gas production technique at the DLO Institute for animal science and health (ID-DLO), Lelystad, The Netherlands. In: In vitro techniques for measuring nutrient supply to ruminants/Edited by E. R. Deaville [et al.]. - s.l.: British society for animal science, 1998. - (Occasional publication; 22). - p. 65-78, 22 (1998).

Elberg, K. et al. A small scale in vitro system for high throughput gas production analysis – A comparison with the Hohenheim gas test. Animal Feed Science and Technology 241, 8–14 (2018).

Rymer, C., Huntington, J. A., Williams, B. A. & Givens, D. I. In vitro cumulative gas production techniques: History, methodological considerations and challenges. Animal Feed Science and Technology 123, 9–30 (2005).

Pellikaan, W. F. et al. A novel method to determine simultaneously methane production during in vitro gas production using fully automated equipment. Animal Feed Science and Technology 168, 196–205 (2011).

Author information

Authors and Affiliations

Contributions

The study was designed by Zhenming Zhou, Qingxiang Meng and Hao Wu. Sample processing was carried out by Chang Liu, Wanbao Chen and Yan Li. Data analysis was done by Chang Liu and Deyong Li. The manuscript was written by Chang Liu, assisted by all co-authors.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Liu, C., Li, D., Chen, W. et al. Estimating ruminal crude protein degradation from beef cattle feedstuff. Sci Rep 9, 11368 (2019). https://doi.org/10.1038/s41598-019-47768-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-019-47768-3

This article is cited by

-

Influence of Tied-Ridge with Maize Straw Biochar on Alfalfa Fodder Yield, Nutritional Quality, and Production Economics

Journal of Soil Science and Plant Nutrition (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.