Abstract

We demonstrate a new refuelable lithium cell using lithium solvated electron solution (Li-SES) as anolyte and iodine solutions as catholyte. This cell shows a high OCV (~3 V). Unlike conventional rechargeable Li batteries, this kind of cell can be re-fueled in several minutes by replacing the spent liquids. We also show for the first time, that Li-SES/I2 cells which operate at room temperature, can be prepared in a fully discharged state (~0 V OCV) for safe handling, transportation and storage. Li-SES and iodine are then electrochemically generated during charge as is confirmed by UV-VIS and a qualitative test. We have also conducted proof-of-concept tests for an “indirect lithium-air” cell in which iodine is reduced at the cathode and subsequently is catalytically re-oxidized by oxygen dissolved in the catholyte.

Similar content being viewed by others

Introduction

The current focus of research into and development of anode materials for lithium ion batteries (LIBs) is on solid-state anodes such as graphite, carbonaceous materials and carbon-silicon composites1,2,3,4,5. Attempts to incorporate both the advantages of the LIB’s high energy density as well as the redox flow batteries’ dual refueling/recharging options, led to the use of alkali-metals (Li or Na) in semi-solid rechargeable lithium flow cells6,7,8,9,10. However, these types of cells possess serious disadvantages. Semi-solid flow batteries circulate viscous slurry suspensions from external storage tanks through the cells during operation. The suspensions contain non-conducting lithium-based oxide materials (LiFePO4, LiCoO2, etc) which require a large quantity of additives to improve their conductivity. Moreover, there is a possibility for solid particles to agglomerate and clog the circulatory system during operation. Present redox-flow cells also have a low energy density. Lastly, solid anode material such as metallic lithium poses a safety concern and must be replaced when depleted.

In this work, we demonstrate a new kind of cell operating at ambient temperature which consists of a liquid-state active anode material (anolyte) and liquid-state active anode material (catholyte) separated by a solid-state Li-ion conducting glass ceramic membrane. Lithium Solvated Electron Solution (Li-SES) is the active material in the anolyte. There are several novel aspects offered by this new chemistry:

-

(1)

A low operation OCV of Li-SES versus metallic lithium (<600 mV).

-

(2)

High OCV achieved with Li-SES based anode in full cells (>3 V).

-

(3)

Cells can be prepared either in the charged state (>3 V), complete discharged state at ~0 V OCV or in the intermediary charged state.

-

(4)

The cell uses true liquid solutions which is different from semi-solid flow energy storage devices that utilize slurry-based suspensions of solids as catholyte and anolyte, thus eliminating the issue of particle agglomeration8, 10.

-

(5)

The depleted cell can be recharged in a variety of methods, one of which is by replacing the spent liquids with fresh ones. This allows the cell to be replenished in minutes, i.e. just like refuelling of cars at a petrol station.

In the initial discharged state, the cell does not have any solvated electrons and iodine to begin with and can be charged to electrochemically produce solvated electrons in the anode and iodine in the cathode as demonstrated in this work.

The LiSES anolyte solution has two main advantages as compared to a solid-state anode or a slurry based anolyte. Firstly, it possesses fast ion transport capability. Secondly, it is able to achieve a physically stable anolyte/ceramic membrane electrolyte interface.

The Iodine/Iodide mixture is dissolved in methanol to form a catholyte solution which can serve as the active material at the cathode11 Similar to the anolyte, the catholyte is able to achieve a fast ion transport and stable catholyte/ceramic membrane electrolyte interface.

Our experimental work details the preparation and testing of a charged full cell, a discharged full cell and the FTIR and UV-VIS analysis of anolyte and catholyte solutions, the results of which will be discussed. Also, we introduce the concept of indirect lithium-air cells.

Results and Discussion

This section is divided into five parts. Part I describes the preparation of anolyte solutions for the charged cell. Part II describes the OCV measurement and discharge profile of a Li-SES//I2 full cell loaded in the charged state11. Part III describes the CV measurement of an uncharged full cell without the initial presence of both Li-SES in the anolyte and I2 in the catholyte, the subsequent generation of the Li-SES and I2 from the LiI in both anolyte and catholyte via cyclic voltammetry and finally a qualitative test to check for the presence of Li-SES by dropping a small quantity of the solution in dilute HCl. Part IV covers the FTIR and UV/Vis test results on the anolyte and the catholyte before and after CV charging to verify the formation of Li-SES and iodine. Finally, Part V presents the concept of an indirect Li-Air cell by exposing the catholyte chamber to oxygen.

Part I: Anolyte Preparation

The LiSES anolyte is prepared chemically for the cell in the charged state.

The LiSES for the charged cell is \({{\rm{Li}}}_{1.0}\beta {({\rm{THF}})}_{12.3}\), where β denotes biphenyl and Li: β:THF denotes a molar ratio of 1:1:12.3. For clarity, the LiSES will also be referred to subsequently as a solution of 1 M LiSES.

As discussed in our previous study12, \({{\rm{Li}}}_{x}\beta {({\rm{THF}})}_{{n}_{1}}\) can be formed in a two-step process according to x value of Li. With x < 1, \({{\rm{Li}}}_{1}\beta {({\rm{THF}})}_{{n}_{1}}\) forms first together with unlithiated \(\beta {({\rm{THF}})}_{{n}_{2}}\):

With x > 1, the system consists of a mixture of \({{\rm{Li}}}_{1}\beta {({\rm{THF}})}_{{n}_{1}\text{'}}\) and \({{\rm{Li}}}_{2}\beta {({\rm{THF}})}_{{n}_{2}\text{'}}\):

where 1 < x < 2.

Separately, a Li-SES solution of the molar composition \({{\rm{Li}}}_{2.0}\beta {({\rm{THF}})}_{22.2}\) is also prepared chemically for FTIR and UV-VIS analysis as well as for a qualitative test using dilute HCl. The results will be covered in Part IV. The reader can refer to the supplementary video clip to see the reactions described above.

Part II: Chemically Prepared Cell

A schematic diagram of the cell is shown in Fig. 1A. Details of the cell preparation are covered in the Experimental Methods section. The Li-SES anolyte and the Iodine catholyte are separated by a Li-ion conducting solid electrolyte membrane (Ohara, Japan). The initial OCV with 1 M LiSES anolyte and 0.1 M I2 catholyte of the cell just before discharge is 2.83 V. The cell is then discharged across a 1 kΩ resistor. A low concentration of iodine in methanol is used because maximum solubility of I2 in CH3OH is 0.1 M, beyond which additional iodine in the solution exists in solid form13.

(A) Schematic diagram of cell in 100% state-of-charge (S.O.C.)11. (B) Schematic diagram of cell in 0% state-of-charge (S.O.C). The entire cell sits on two magnetic stirring plates which keep the stirrer bars in the cell stirring.

There is a noticeable drop from 2.83 V to 1.61 V when the cell is first connected to the resistor. This drop could be attributed to the internal resistance of the whole cell in particular in the Ohara thick membrane. Figure 2 shows the open-circuit voltage (OCV) and closed-circuit voltage (CCV) profile of a cell consisting of 1 M LiSES, 0.1 M of I2 in methanol and 0.1 M of LiI in both anolyte and catholyte.

Open-circuit voltage (OCV) and closed-circuit voltage (CCV) profiles11.

Each OCV reading was obtained by disconnecting the cell from the load during discharge and reconnecting back after ~5 min. Two plateaus can be clearly seen in both the OCV versus t and the V versus t graphs. By the end of the first plateau, the catholyte has become colourless, indicating all the I2 (or I3 −) has been converted to I−.

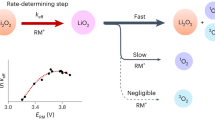

The electrochemical reactions taking place during discharge and charge of a Li-SES//I2 cell can be schematized as follows:

Anode:

Cathode:

Overall cell reaction:

where Θ in Equations (3) and (5) denotes the PAH/solvent solution11.

Since iodine can be in the form of I3 −, the cell reaction may also be written as:

Though the subject of using iodine as the liquid-based active cathode material in lithium cells have been explored in the past14,15,16,17,18,19,20,21,22,23,24, this is the first time iodine in methanol has been used in conjunction with Li-SES anolyte in a liquid-based cell at ambient temperature11. The use of Li-SES as an anolyte was proposed by Sammells25, who used liquid ammonia as the electron receptor. However, during discharge, liquid ammonia will convert to gas which will lead to a pressure build-up in the cell. Hence, ammonia-based Li-SES cells are not suitable for use at ambient temperatures. In recent years, we patented poly-aromatic hydrocarbons (PAH) as electron receptors for Li-SES26. Our recent studies have indicated that Li-SES prepared using simple PAHs such as biphenyl and naphthalene are stable at ambient temperature27.

Part III: Electrochemically Prepared Cell

In the charged state, both the Li-SES and I2 are prepared chemically and loaded into the cell, whereas in the uncharged state, the cell is loaded with LiI in both the catholyte and the anolyte which give a ~0 V initial OCV, then charged to form iodine and Li-SES. The rationale for preparing cells in the uncharged state is the convenience and safety of the system. The cell can also be prepared in a partial charged state depending on the needs.

A schematic diagram of the uncharged cell is shown in Fig. 1B. The initial OCV of the cell is ~0 V. When the cell is subjected to cyclic voltammetry between 0.8 V and 4.4 V, the colourless catholyte gradually turns dark orange with each cycle, indicating the formation of I2 (or I3 −) from I− in methanol according to Eq. (2) (See Supplementary Material Figure S1). The colourless anolyte becomes a very pale amber colour indicating a low concentration Li-SES is formed. With each charge/discharge cycle, the colours of the solutions intensify, suggesting the possibility of some irreversible processes occurring during each cycle. This goes on until the 9th cycle whereby cycling is stopped at 4.4 V. The OCV of the cell is 2.97 V at the end of the 9th charging cycle. The CV profiles are shown in Fig. 3. Earlier studies on electrochemical generation of solvated electrons have shown that solvated electrons that are thus formed are stable at ambient temperature in several types of solvents28,29,30,31.

From Fig. 3, it can be seen that the cell becomes more stable by the 4th cycle. The current profile during charging after the 3rd cycle (activation) shows change in slope (peak?) followed by steep increase with voltage. The “peak” should be attributed to the I− → I2 conversion and the steep increase may come from the liquid electrolyte oxidation (electrolyte wall).

Figure 3 shows the current versus time profile from the CV data. From the areas under each cycle curve, we can determine the amount of charge transferred during each charge/discharge cycle. The Coulombic efficiency during the first cycles is quite low, but increases after the third cycle to above 50%. Hence the first three cycles can be considered as the formation cycles. Integration of the CV data show, at the end of the 9th cycle charge, the Li-SES formed in the anolyte is 7.43 × 10−3 M and the I2 formed in the catholyte is 3.72 × 10−3 M, which is about half of the concentration of the Li-SES formed, as stated by Equation (5).

A direct proof of Li-SES formation is given by the following test: Cell at its charged state up to 4.4 V is removed from the glovebox and a few drops of the anolyte are added to a dilute aqueous HCl solution. The immediate observed evolution of gas bubbles, most likely H2 gas, indicates Li-SES is formed in the anolyte solution:

The same results have been obtained when a few drops of chemically prepared \({{\rm{Li}}}_{2.0}\beta {({\rm{THF}})}_{22.2}\) is added to dilute HCl.

Part IV: UV-VIS Analysis of Anolyte and Catholyte solutions before and after CV

To provide additional evidence of the electrochemical generation of solvated electrons, UV-VIS spectroscopy measurements are carried out on the anolyte solutions before 1st charging (S1) and after 9th charging to 4.4 V (S2) and are presented in Fig. 4. S3, the spectrum of the chemically prepared Li-SES matches the one of S2. Thus the emerging of the single absorbance peak centred at 306.5 nm in S2 is believed to be caused by the solvated electrons.

For the catholyte, FT-IR is not able to conclusively distinguish between iodide and iodine unlike UV-VIS, which is able to do so. As presented in the UV-VIS spectra in Fig. 5, S4, (charged catholyte solution at the 6th cycle CV) is different from S6 (lithium iodide dissolved in methanol - uncharged catholyte). In the range of 280 nm to 600 nm studied, spectrum S4 (electrochemically prepared iodine in methanol from charging LiI in methanol) has two peaks at 291 nm and 358 nm in spectrum S4 which are attributed to I3 −. These two peaks matches that of S5 (iodine dissolved in methanol) which indicates that tri-iodide is formed electrochemically via charging32. The additional third peak at 443 nm for S5 is attributed to I2 33. In fact, S5 is the characteristic spectrum of iodine dissolved in methanol. The absence of all three peaks (291 nm, 358 nm, and 443 nm) indicates that the LiI/methanol solution consists of only I- in methanol which does not have any peaks in the range studied33.

FT-IR analysis has been conducted on the anolyte of the uncharged cell before and after charging and on a chemically prepared \({{\rm{Li}}}_{2.0}\beta {({\rm{THF}})}_{22.2}\) solution as described in Part I. However, the amount of solvated electrons formed from our electrochemical process is too small to be detected by FTIR for any meaningful comparison.

Part V: Indirect Li-Air Cell

A possible further application of iodine-based catholyte is to use it in the presence of oxygen by exposing the catholyte chamber to air during charge/discharge. Our initial tests show that when the catholyte chamber of a chemically prepared cell (Fig. 2) is exposed to air after discharge for a few minutes, the OCV is observed to rise slightly. Also, for an electrochemically prepared cell charged to 4.4 V, its orange catholyte darkened after exposure to air over some time. This colour change suggests the formation of I2 perhaps due to oxidation of I− by O2. The addition of CuSO4 seems to catalyse I− → I2 conversion in O2 presence because brown solution is formed instantly when CuSO4 is added to a solution of colourless LiI in methanol. The I2 formed is converted quickly to I3 − in the solution via the following reaction34:

This is confirmed by UV-VIS (See Spectrum1 which has only the two peaks due to I3 − at 291 nm and 358 nm from Supplementary Material Figure S2). The formation of I3 − occurs when solid I2 is dissolved in methanol as supported also by the UV-VIS spectrum S5 in Fig. 5 described earlier.

A possible reaction mechanism for the catholyte in ‘indirect’ Li-air battery is as follows:

Reaction (8) takes place at the cathode current-collector whereas (9) and (10a) occurs in the solution. Even though the catholyte has both I3 − and O2 as oxidants, I3 − is kinetically more favoured for reduction as compared to O2. The Li2O2 product is formed chemically in the solution as evidenced by the white precipitate at the bottom of the catholyte chamber and not on the cathode as is the case in direct lithium-air cells. Accordingly, the cell reaction in indirect Li-air battery is:

where Θ in (10b) denotes the PAH/solvent solution.

Based on these preliminary results, the cell can be used as an indirect Li-SES/ Air cell in which I3 − can prevent the formation of passivating Li2O2 on the cathode current collector during discharge.

Experimental Methods

Preparation of Li-SES//I2 cell

For the cell set up in the charged state, the liquid-state active anode material (anolyte) is made up of metallic lithium dissolved in a solution of biphenyl in THF. The LiSES anolyte is prepared in its molar composition of \({{\rm{Li}}}_{1.0}\beta {({\rm{THF}})}_{12.3}\), where β denotes biphenyl and Li: β:THF denotes a molar ratio of 1:1:12.3. The preparation of the Li-SES is carried out in an Ar-filled glove box at ambient temperature. Details of the preparation process are provided in our previous studies12, 27. The liquid-state active cathode material (catholyte) is made up of 0.1 M of I2 in methanol.

Both the anolyte and the catholyte are separated by a Li-ion conducting ceramic membrane, LATP (Ohara, Japan).

In the uncharged state, the anolyte is made up of a solution of 0.5 M biphenyl with 0.9 M lithium iodide in THF and the catholyte is made up of 0.9 M lithium iodide dissolved in methanol.

In both charged and uncharged cases, lithium iodide serves as supporting electrolyte in both the anolyte and the catholyte.

Lithium foil, iodine, anhydrous methanol, anhydrous THF, biphenyl and copper (II) sulphate were purchased from Sigma Aldrich. Lithium iodide was purchased from Alfa Aesar. All materials were used without further purification.

The completed cells have configurations as follows:

Charged Cell:

(−) Ni mesh/LiSES + THF + LiI//LATP//I2 + LiI/Ni mesh (+)

Uncharged Cell (OCV ~0 V)

(−) Ni mesh/ Biphenyl + THF + LiI//LATP//CH3OH + LiI/Ni mesh (+)

The plastic components of the cell were machined from PEEK (Polyether-ether-ketone). Both the anolyte and catholyte chambers were made from glass.

Chemically Prepared Cell

In both anolyte and catholyte, the concentration of the LiI salt (supporting electrolyte) is 0.50 M (Fig. 1A). The initial OCV of the cell is 2.83 V, which is close to the expected value of 2.89 V. This is because the standard electrode potential of biphenyl-based Li-SES is 0.68 V versus Li35 and that of I2/I− redox couple is close to 3.57 V versus Li.

Electrochemically Prepared Cell

For this experiment, the anolyte used is 0.9 M of lithium iodide in a solution of 0.5 M Biphenyl in THF (Fig. 1B). The catholyte used is 0.9 M of lithium iodide dissolved in methanol. 25 ml of each solution is used for the cell. Initially, both anolyte and catholyte are colourless. Cyclic voltammetry is conducted on the cell in argon atmosphere. Glass coated magnetic stirrers are placed in both anolyte and catholyte chambers to aid the mass transport of the ions in the solutions. The cell is first charged to 4.4 V and then cycled between 0.8 V and 4.4 V for 8 cycles.

Electrochemical measurements

A ceramic 1 kΩ resistor is used for constant load cell discharge.

An APPA 505 True RMS Multimeter cum data-logger is used to register the data points for the constant load discharge.

A Basytec Battery Tester is used for the cyclic voltammetry of the initially uncharged cell.

FTIR and UV-VIS Analysis

An FT-IR spectrophotometer (Perkin-Elmer Spectrum One Spectrometer) with KBr window kit is used. Loading of samples into the KBr window is done in the glove box. After each test, the KBr window is cleaned using Chloroform and dried in a vacuum oven at 80 °C.

UV-VIS spectroscopy measurements are carried out with a Shimadzu UV-2450 spectrometer using a scan speed of 400 nm/min. The baseline correction procedure is executed prior to each measurement session.

Indirect Li-Air Cell

The catholyte chamber’s cap is unscrewed (loosened) to allow for air to enter the chamber.

CuSO4 is added to LiI in air.

Conclusion

In summary, we have demonstrated for the first time the concept of a liquid cell in the initial charged and discharged states that can operate at ambient temperature. Secondly, we have successful demonstrated the electrochemical formation of Li-SES anolyte and I2 catholyte from a discharged cell of 0 V OCV in a full cell configuration. The presence of Li-SES was confirmed by two ways. The first is by qualitative test of adding the charged solution to dilute HCl to produce hydrogen gas. The second way is by UV-VIS which confirms the formation of iodine in the catholyte. This discovery allows us to build a Li-SES//I2 cell that has purely liquid based anode and cathode and a solid state electrolyte membrane in either charged or discharged states for refuelable lithium battery applications. Thirdly, we have also introduced iodine in methanol as a solution that can function solely as catholyte. Finally, we have used the iodine catholyte in oxygen to prove the new concept of indirect Li-SES//Air cell.

We are extending our investigations by testing PAHs with more than 2 rings such as 1,3,5-triphenylbenzene derivatives, corranulene35 and cyclopenta-2,4-dienone derivatives36 as suitable electron receptors for preparing LiSES for use in similar batteries.

A new generation of solid state membranes with enhanced lithium ion conductivity at the ambient temperatures has been developed by us. The new membranes should reduce the ohmic drop in the cell for improved charge/discharge rates37.

References

Chen, J. Recent progress in advanced materials for lithium ion batteries. Materials 6, 156–183 (2013).

Casas, C. D. L. & Li, W. A review of application of carbon nanotubes for lithium ion battery anode material. Journal of Power Sources 208, 74–85 (2012).

Goodenough, J. B. & Kim, Y. Challenges for rechargeable batteries. Journal of Power Sources 196, 6688–6694 (2011).

Park, M., Zhang, X., Chung, M., Less, G. B. & Sastry, A. M. A review of conduction phenomena in Li-ion batteries. Journal of Power Sources 195, 7904–7929 (2010).

Scrosati, B. & Garche, J. Lithium batteries: Status, prospects and future. Journal of Power Sources 195, 2419–2430 (2010).

Hamelet, S. et al. Non-Aqueous Li-Based Redox Flow Batteries. Journal of the Electrochemical Society 159, A1360–A1367 (2012).

Wang, Y., He, P. & Zhou, H. Li-redox flow batteries based on hybrid electrolytes: At the cross road between Li-ion and redox flow batteries. Advanced Energy Materials 2, 770–779 (2012).

Duduta, M. et al. Semi-Solid Lithium Rechargeable Flow Battery. Advanced Energy Materials 1, 511–516 (2011).

Lu, Y. & Goodenough, J. B. Rechargeable alkali-ion cathode-flow battery. Journal of Materials Chemistry 21, 10113–10117 (2011).

Presser, V. et al. The electrochemical flow capacitor: A new concept for rapid energy storage and recovery. Advanced Energy Materials 2, 895–902 (2012).

Rinaldi, A., Tan, K. S., Wijaya, O., Wang, Y., Yazami, R. Advances in batteries for large- and medium-scale energy storage applications in power systems and electric vehicles (eds Menictas, C. et al.) Ch 11, 387–440 (Woodhead Publishing Ltd, 2014).

Tan, K. S., Grimsdale, A. C. & Yazami, R. Synthesis and Characterisation of Biphenyl-Based Lithium Solvated Electrons Solutions. The Journal of Physical Chemistry B 116, 9056–9060 (2012).

Browne, D. L., Deadman, B. J., Ashe, R., Baxendale, I. R. & Ley, S. V. Continuous flow processing of slurries: Evaluation of an agitated cell reactor. Org. Process Res. Dev. 15, 693–697 (2011).

Bragg, A. E. & Schwartz, B. J. Ultrafast charge-transfer-to-solvent dynamics of iodide in tetrahydrofuran. 2. Photoinduced electron transfer to counterions in solution. Journal of Physical Chemistry A 112, 3530–3543 (2008).

Greatbatch, W. & Holmes, C. F. The lithium/iodine battery: A historical perspective. Pacing and Clinical Electrophysiology 15, 2034–2036 (1992).

Kontos, A. G. et al. Morphology, ionic diffusion and applicability of novel polymer gel electrolytes with LiI/I 2. Physical Chemistry Chemical Physics 8, 767–776 (2006).

Liu, F.-C., Liu, W.-M., Zhan, M.-H., Fu, Z.-W. & Li, H. An all solid-state rechargeable lithium-iodine thin film battery using LiI(3-hydroxypropionitrile)2 as an I- ion electrolyte. Energy & Environmental Science 4, 1261–1264 (2011).

J. R. Moser. Solid state lithium-iodine primary battery. (US Patent 3,660,163, US, 1972).

Phipps, J. B., Hayes, T. G., Skarstad, P. M. & Untereker, D. F. In-situ formation of a solid/liquid composite electrolyte in Li/I2 batteries. Solid State Ionics 18-19, 1073–1077 (1986).

Stevenson, G. R. & Hashim, R. T. Polyacene dianion heats of generation and solvation. Journal of Physical Chemistry 90, 1896–1899 (1986).

Wang, Y. L., Sun, Q. L., Zhao, Q. Q., Cao, J. S. & Ye, S. H. Rechargeable lithium/iodine battery with superior high-rate capability by using iodine-carbon composite as cathode. Energy and Environmental Science 4, 3947–3950 (2011).

Weinstein, L., Yourey, W., Gural, J. & Amatucci, G. G. Electrochemical impedance spectroscopy of electrochemically self-assembled lithium-iodine batteries. Journal of the Electrochemical Society 155, A590–A598 (2008).

Zhao, Y. & Byon, H. R. High-performance lithium-iodine flow battery. Advanced Energy Materials 3, 1630–1635 (2013).

A. A. Schneider. Primary Cells and Iodine Containing Cathodes Therefor. (US Patent 3660163, US, 1972).

A. F. Sammells. Solvated electron lithium electrode for high energy density battery. (US Patent 4,684,590, US, 1987).

R. Yazami. Hybrid Electrochemical Generator With A Soluble Anode. (US Patent 20100141211A1, US, 2010).

Tan, K. S. & Yazami, R. Physical-Chemical and Electrochemical Studies of the Lithium Naphthalenide Anolyte. Electrochimica Acta 180, 629–635 (2015).

N. Alpatova, L. Krishtalik & Y. Pleskov. In Organolithium Compounds/Solvated Electrons. (Springer Berlin/Heidelberg, 1987), vol. 138, pp. 149–219.

Avaca, L. A. & Bewick, A. The cathodic generation of solvated electrons in the LiCl/hexamethylphosphoramide system. Journal of Electroanalytical Chemistry and Interfacial Electrochemistry 41, 395–403 (1973).

Kanzaki, Y. & Aoyagui, S. Electrode kinetics of solvated electrons in hexamethylphosphoric triamide. Journal of Electroanalytical Chemistry and Interfacial Electrochemistry 36, 297–310 (1972).

Krivenko, A. G., Komarova, N. S. & Piven, N. P. Electrochemical generation of solvated electrons from nanostructured carbon. Electrochemistry Communications 9, 2364–2369 (2007).

N. Li, L. Shi, X. Wang, F. Guo, C. Yan, Experimental study of closed system in the chlorine dioxide-iodide-sulfuric acid reaction by UV-vis spectrophotometric method. International journal of analytical chemistry 2011 (2011).

Wei, Y. J., Liu, C. G. & Mo, L. P. Ultraviolet absorption spectra of iodine, iodide ion and triiodide ion. Guang Pu Xue Yu Guang Pu Fen Xi/Spectroscopy and Spectral Analysis 25, 86–88 (2005).

Kireev, S. V. & Shnyrev, S. L. Study of molecular iodine, iodate ions, iodide ions, and triiodide ions solutions absorption in the. Laser Physics 25, 075602 (2015).

K. S. Tan, A. V. Lunchev, M. C. Stuparu, A. C. Grimsdale, R. Yazami 1,3,5-Triphenylbenzene and Corannulene as Electron Receptors for Lithium Solvated Electron Solutions. Journal of Visualized Experiments e54366 (2016).

Lim, Z. B. et al. Synthesis and assessment of new cyclopenta-2,4-dienone derivatives for energy storage applications. Synthetic Metals 200, 85–90 (2015).

R. Yazami, N. Gupta. Glass ceramic electrolyte system. (Patent WO 2013180658 A1, 2013).

Acknowledgements

The authors would like to thank Dr Wang Yuxi for his help in the FTIR & UV-VIS experiments for LiSES as well as for helping to video-tape part of the raw footage for the supplementary video (Movie S1), and Miss Hanyi Chen for her help in the UV-VIS measurements on the catholyte samples. Funding for this project from the Singapore Ministry of Education through the Academic Research Fund (Tier2 grant MOE2013-T2-002) is gratefully acknowledged.

Author information

Authors and Affiliations

Contributions

K.S.T. performed most of the experiments and wrote the first draft of the manuscript. R.Y. is behind the concept of LiSES for lithium battery application. Both A.C.G. and R.Y. revised the whole manuscript and commented on it. K.S.T. – Kim Seng Tan. R.Y. – Rachid Yazami. A.C.G. – Andrew Clive Grimsdale.

Corresponding author

Ethics declarations

Competing Interests

The authors declare that they have no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Tan, K., Grimsdale, A.C. & Yazami, R. A room-temperature refuelable lithium, iodine and air battery. Sci Rep 7, 6502 (2017). https://doi.org/10.1038/s41598-017-06321-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-017-06321-w

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.