Abstract

Understanding carrier loss mechanisms at microscopic regions is imperative for the development of high-performance polycrystalline inorganic thin-film solar cells. Despite the progress achieved for kesterite, a promising environmentally benign and earth-abundant thin-film photovoltaic material, the microscopic carrier loss mechanisms and their impact on device performance remain largely unknown. Herein, we unveil these mechanisms in state-of-the-art Cu2ZnSnSe4 (CZTSe) solar cells using a framework that integrates multiple microscopic and macroscopic characterizations with three-dimensional device simulations. The results indicate the CZTSe films have a relatively long intragrain electron lifetime of 10–30 ns and small recombination losses through bandgap and/or electrostatic potential fluctuations. We identify that the effective minority carrier lifetime of CZTSe is dominated by a large grain boundary recombination velocity (~104 cm s−1), which is the major limiting factor of present device performance. These findings and the framework can greatly advance the research of kesterite and other emerging photovoltaic materials.

Similar content being viewed by others

Main

Photovoltaics have been identified as the most attractive renewable energy that can be used to mitigate escalating global climate change1. Large-scale deployments of photovoltaic energy require stable, abundant and low-toxic materials similar to silicon (Si) (ref. 2), which has stimulated the worldwide interest in new inorganic photovoltaic materials such as chalcogenides, oxides, pnictides and halides3,4,5. Kesterite Cu2ZnSn(S,Se)4 (CZTSSe) has emerged as one of the most compelling candidates due to its stable structure, abundancy, environmental benefits and its large potential for high power conversion efficiency (PCE)6,7. Although CZTSSe solar cells have reached the highest PCE (12.6% to 13.0%) among the thermodynamically stable emerging inorganic materials8,9,10, their PCE is still far from a commercialization-viable level.

To allow low-cost processing, CZTSSe, like many other emerging inorganic solar cells, often uses polycrystalline thin films as light absorbers and follows the heterojunction architecture3. This device architecture accommodates a significant amount of imperfect crystalline structures, mainly grain boundaries and grain surfaces. At these regions, dangling bonds, elastic strain fields and atomic composition segregations may introduce electronic states within the energy bandgap with higher density than that in the grain interiors. These bandgap states may act as carrier traps and/or effective recombination centres depending on their transition energy level and relative capture cross-section for holes and electrons, thus imposing serious limitations to the minority carrier lifetime and carrier mobilities11. Consequently, the photovoltaic performance of polycrystalline absorbers is usually inferior to that of crystalline absorbers12, unless the grain boundaries and grain surfaces are electrically benign, such as the case of hybrid halide perovskite13, or can be well passivated, such as in the cases of CdTe and CuInGa(S,Se)2 (CIGSSe)14,15. Therefore, understanding the carrier loss mechanisms at these microscopic regions is imperative for achieving high-performance CZTSSe and other emerging inorganic thin-film solar cells.

Despite the critical importance of these microscopic carrier loss mechanisms in inorganic materials, the number of investigations regarding these processes is rather limited. For CZTSSe, due to the multiple competitive secondary phases and complex intrinsic defect system16, most efforts have been directed to the bulk and heterojunction interfaces17,18,19,20. Although some properties of the grain interiors and grain boundaries, such as intragrain crystallinity defects and band bending at the grain boundaries, have been investigated using high-resolution structural and electrical analysis, respectively21,22, detailed loss mechanisms in these microscopic regions, especially grain boundary recombination and grain interior carrier lifetime and their impact on the device performance, remain unknown. This, as a critical gap between the understanding of CZTSSe and its mature cousins CdTe and CIGSSe, can be one of the key origins of the efficiency stagnation of CZTSSe in recent years, thus requiring urgent comprehensive investigation.

Herein, we unveil the microscopic carrier loss mechanisms in state-of-the-art efficiency selenide-kesterite Cu2ZnSnSe4 (CZTSe) solar cells by establishing a framework that integrates multiple micro-structural and macroscopic optoelectronic characterizations with three-dimensional (3D) device simulations, building on a recent approach demonstrated by Krause et al. for CIGSSe solar cells23. We show that the grain boundary recombination limits the effective carrier lifetime of bulk kesterite. The associated grain boundary recombination velocity of kesterite, at a level of 104 cm s−1, is one to two orders of magnitude larger than that of CIGSSe and CdTe23,24. The intragrain minority carrier lifetime is estimated to be 10–30 ns, while the net carrier density is around 1.8 × 1015 cm−3. It seems that the well-recognized open-circuit voltage (VOC) losses due to bandgap fluctuation and/or electrostatic potential fluctuation are small. Instead, the dominating loss mechanisms of current state-of-the-art CZTSe solar cells are associated with the severe non-radiative recombination at grain boundaries. Further efficiency improvement towards 20% requires substantial grain boundary passivation and increase of net carrier density.

Photovoltaic performance and device structure

We used CZTSe absorbers fabricated by the same method used for our reported 12.5% record CZTSe cells25. Details of the fabrication processes can be found in the Methods section. The solar cells fabricated on these absorbers achieve PCEs between 11.0% and 12.5% and an average PCE of 11.8% (Supplementary Fig. 1), representing state-of-the-art performance. Figure 1a,b shows the current density–voltage (J–V) and external quantum efficiency (EQE) of one of the best devices used for characterizations in this study. The total area (0.24 cm2) efficiency is 12.45 %, with a VOC of 479 mV, a fill factor (FF) of 70.45% and a short-circuit current density (JSC) of 36.9 mA cm−2 (integrated JSC from EQE is 37.0 mA cm−2). The diode ideality factor (A) extracted from corresponding dark J–V data is 1.4 and the diode reverse saturation current (J0) is 8.1 × 10−8 A cm−2 (Supplementary Fig. 2). The JSC is much lower than the previous 11.6% efficiency record CZTSe device from IBM (40.6 mA cm−2) (ref. 26), which could be attributed to the relatively low transmittance of the window layer at the long-wavelength region, as discussed in our previous work25 and the recombination in the microscopic regions as will be discussed in the following sections.

a,b, J–V (a) and EQE (b) measurements of one of the best CZTSe cells with total area (0.24 cm2) efficiency of 12.45% with anti-reflection coating. c, Cross-sectional SEM image of a CZTSe device. The device structure from bottom to top is soda lime glass (SLG)/Mo/MoSe2/CZTSe/CdS/i-ZnO/ZnO:Al. d, Element SIMS depth profile of the CZTSe absorber. e, The cross-sectional TEM image and the corresponding EDS element mapping of Cu, Zn, Sn, Se, Mo, Cd and Mg. The cross-sectional STEM sample was prepared with a focused ion beam.

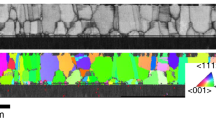

On the top, the CZTSe absorber shows large and compact grains (>1 μm), while at the bottom, the grains are smaller and voids can be seen (Fig. 1c). The secondary ion mass spectroscopy (SIMS) depth profile (Fig. 1d) indicates the CZTSe absorber has a high Zn concentration at the surface and high Sn concentration at the bottom. Segregations of Zn (probably ZnSe) could be observed at both the top and the bottom of the CZTSe film in the scanning transmission electron microscopy coupled with energy-dispersive X-ray spectroscopy (STEM-EDS) mapping (Fig. 1e). Many Sn-rich and Cu-rich small grains (probably SnSex, Cu2-xSe or Cu2SnSe3) can be noticed at the bottom region near the MoSe2 layer, in agreement with the SIMS profile. The signal of Cd is fully confined between CZTSe and ZnO, showing no significant diffusion into the CZTSe absorber or grain boundaries.

Carrier transport at front and rear interfaces

Results of surface Raman mapping on a 40 × 40 μm2 bare CZTSe absorber indicate that most of the front surface is covered with a ZnSe layer (Fig. 2a–c). This ZnSe layer is in situ grown, which could be correlated to the excessive Zn of the Zn-rich and Cu-poor local chemical environment in the surface region during the synthesis of CZTSe25. Further high-resolution STEM (HR-STEM; Fig. 2d) shows the presence of a locally epitaxially grown 8–12 nm thick ZnSe nanolayer (also observed by EDS line scan, Supplementary Fig. 3) along with the (200) orientation. With the almost identical (200) interplanar spacing between CZTSe and ZnSe (0.283 nm, Fig. 2d), no dislocation is observed at the CZTSe/ZnSe interface, showing a near-perfect heterointerface with largely suppressed interfacial lattice defects. In comparison, the CZTSe absorber without ZnSe nanolayer shows a high density of dislocations at the CZTSe/CdS heterointerface (Supplementary Fig. 4). Additionally, ZnSe has a wide bandgap of 2.7 eV with a conduction band minimum 0.86 eV higher and a valence band maximum 0.78 eV lower than that of CZTSe27. These large electron and hole barriers could repel electrons and holes, respectively, preventing them from recombining at the heterojunction interface, thus effectively suppressing interfacial recombination. On the other hand, due to the large ‘spike-like’ conduction band offset (0.86 eV) at the ZnSe/CZTSe interface, transport of the photogenerated electrons across this interface may rely on the tunnelling and/or thermionic emission processes depending on the device temperature. It is noted that a continuous ZnSe layer with 8–12 nm thickness may be too thick for tunnelling, which may block the electron current28. In another HR-STEM image (Supplementary Fig. 5), the thickness of ZnSe varies in a region of 4.7–12 nm. The thin ZnSe-layer (<5 nm) regions may provide the main electron transport channels across the CZTSe/ZnSe/CdS interface if tunnelling is dominating. On the other hand, according to Mendis’ model29, at room temperature, the large spike-like conduction band offset at the ZnSe/CZTSe interface can be greatly suppressed because the ZnSe nanolayer can be easily fully depleted, enabling thermionic emission of the photocurrent across the junction interface.

a,b, Colour-coded Raman intensity mapping at peak positions of 196 cm−1 (A mode of CZTSe) (a) and 250 cm−1 (A1 mode of ZnSe) (b), respectively (without baseline subtraction). The Raman mapping was performed using a 441 nm He–Cd laser as excitation. c, Average Raman spectrum of the mapping and the corresponding baseline. The unit cps. means count per second. The baseline-subtracted Raman spectrum is shown in Supplementary Fig. 6. d, HR-STEM image and the colour-coded inverse fast Fourier transformation images of the selected reflections revealing the dislocations (T marked) at the CZTSe/ZnSe/CdS heterointerface. The interplanar spacings are indicated in the HR-STEM figure. The yellow dashed lines roughly indicate the boundaries of different phases. The length of all the three scale bars is 2 nm. e, Temperature-dependent series resistance (Rs) and diode ideality factor extracted from temperature-dependent J–V curves (Supplementary Fig. 7). For each metric, the line on top of data is a guide to the eye. The black dashed line indicates the boundary between the ideal device region and non-ideal device region. The horizontal dashed blue line indicates where the diode ideality factor is 2. f, Plot of VOC versus temperature and the linear fit (dashed blue line) of the recombination activation energy EA. The data points coded with blue are selected for the linear fitting. The red line on top of data is a guide to the eye. g, Plot of ln (RST) versus 1 / T and the linear fitting showing back contact barrier height. Rs is the series resistance and T is the temperature.

Figure 2e shows the temperature-dependent diode ideality factor, A, extracted from the dark J–V curves (Supplementary Fig. 7). A is larger than 2 when the temperature is lower than 200 K, suggesting that the device does not behave as an ideal diode in this temperature region30 and that the tunnelling process at the CZTSe/ZnSe interface dominates the current transport in this temperature region31. Contrastingly, A is around 1.5 without significant change when the temperature is in the range of 260–320 K, indicating the dominating current transport mechanism is likely to be thermionic emission in this temperature region, where it is possible to extract the recombination activation energy, EA, using the one-diode model32:

where q is the unit charge, kB is the Boltzmann’s constant, T is the temperature, J00 is the prefactor of diode current and JL is the photocurrent. Here J00, JL and EA are assumed to be weakly temperature-dependent in the temperature region used for fitting32. The temperature-dependent VOC shows good linear behaviour in this temperature region (Fig. 2f), and the fitted EA is 1.025 ± 0.005 eV, well-aligned to the bandgap of the CZTSe absorber (Eg = 1.02 eV, as shown in Fig. 3e). This indicates that the EA deficit compared with Eg is no longer a limitation in these CZTSe devices, owing to the passivated heterojunction interface by the epitaxial ZnSe nanolayer and the suppressed bandgap/potential fluctuation as reported previously25.

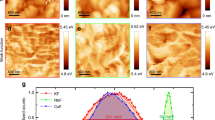

a,b, Topology image measured with AFM (a) and the corresponding KPFM image (b) of a fresh cleaved CZTSe cell. The blue dashed lines labelled with numbers indicate where the grain boundary profiles were extracted. The yellow (horizontal) dashed line in b indicates where the line scan was performed. c, Contact potential difference (CPD) and topology profiles (Z) extracted along the yellow (horizontal) dashed line in b. Here CPD = (ΦP − ΦS) / q, where ΦP and ΦS are the work function of the probe and the measured sample, respectively, meaning CPD increases linearly with the decrease of work function of the measured sample. The inset shows the statistical CPD distribution and the Gaussian fit of the horizontal CPD scan, showing a mean CPD of 237.2 mV and a standard deviation of 5.4 mV. d, The CPD and topology profiles of grain boundary (GB) 1 (indicated in a and b). The blue shade is a guide to the eye showing where the grain boundary is located. Each dashed black line is a guide to the eye roughly indicating the mean CPD around the grain boundary, which is used to define the ΔCPD. The band bending at GB1 is about −8 meV (upward). The CPD and topology profiles of GB2–GB5 are shown in Supplementary Fig. 10. e, IQE spectrum (black line), first derivative of IQE (red dashed line) and normalized PL spectrum (blue line) of the high efficiency CZTSe cell. The vertical dashed blue and red lines indicate the PL peak position and the peak position of −dIQE / dλ, respectively. λ is the wavelength. f, Plot and fitting of electrostatic potential fluctuation, γopt (red) using the Shklovskii and Efros model below the bandgap energy and the fitting of the Urbach tail energy, Eu (blue). Detailed fitting models are described in Supplementary Discussion 1.

The blocking barrier height of the back contact interface is derived from the temperature-dependent series resistance (RS) over the 200 K to ~320 K temperature range where the device behaves consistently with the thermal emission model33. The fitted barrier height is only 11 ± 5 meV (Fig. 2g), much smaller than the previously reported value34, indicating a quasi-ohmic contact at the back contact interface. The result of cross-sectional Kelvin probe force microscope (KPFM) measurements also confirms that the fine grain layer and the MoSe2 layer do not introduce a hole-transporting barrier at the back contact interface (Supplementary Figs. 8 and 9).

Potential fluctuations

We investigated the lateral electrostatic potential fluctuation between grains and the band bending at grain boundaries by means of combining atomic force microscopy (AFM) and Kelvin probe force microscopy (KPFM) on a fresh cleaved cross-section, as shown in Fig. 3a,b. The horizontal line scan of contact potential difference (CPD) (Fig. 3c) indicates a relatively uniform electrostatic potential distribution between the grains even though the topology fluctuation is large, highlighting that the impact of the topology on the CPD is small. The electrostatic potential fluctuation is only 5.4 meV, which is negligible compared with the resolution of CPD (~10 mV). The band bending at GB1 is 8 meV (Fig. 3d), which is also negligible, the same as the band bending of GB2 to GB5 (Supplementary Fig. 10). The local chemical composition near grain boundaries was investigated using an EDS line scan. A small Cu peak is observed at the grain boundary region (Supplementary Fig. 11), which has also been observed in other CZTSe and CIGS solar cells35,36, and has been deemed detrimental for device performance.

The potential fluctuation is further investigated by analysis of the internal quantum efficiency (IQE, Supplementary Fig. 12) and photoluminescence (PL) spectra. The PL emission energy, EPL (1.01 eV), is only slightly lower than the bandgap (1.02 eV) determined from the inflection of the IQE curve (peak of −dIQE / dλ, Fig. 3e). The PL peak is quite broad, though no obvious red shift is observed. This PL peak broadening can be attributed to band tailing states arising from bandgap and/or electrostatic potential fluctuation, both of which can be estimated using the absorption edge derived from the tail of the IQE curve (Supplementary Discussion 1) (ref. 37). Bandgap fluctuations can be described by a Gaussian distribution of local absorption coefficient with a standard deviation of σg (ref. 37). The fitted σg is 48 meV (Supplementary Fig. 13), which is significantly lower than some previous analysis37 but in good agreement with more recent findings38. Because the local bandgap fluctuation observed in cathodoluminescence (CL) mapping is within 5 meV, these fluctuations would have to occur on length scales smaller than the spatial resolution of CL measurement (several 100 nm). Alternatively, average electrostatic fluctuations, γopt, can be estimated from the Shklovskii and Efros model39, yielding a value of 20 meV (Fig. 3f), which also agrees with the estimated Urbach tail energy (Eu). The loss of radiative limit VOC (VOC,rad,loss) due to the lateral potential fluctuation can be estimated to be 44 mV or 7.7 mV due to either σg or γopt, respectively, by the following equation40:

where γ is either σg or γopt. Nevertheless, the VOC loss due to these fluctuations in our cells is rather small compared with the non-radiative loss mechanisms that will be discussed in the following sections.

Carrier collection and free carrier density

We performed electron beam-induced current (EBIC) measurement to investigate the carrier collection in the CZTSe solar cell. Figure 4a,b shows the SEM and EBIC images of the corresponding cross-section of the CZTSe solar cell at a beam energy of 5 keV. Figure 4c shows a representative cross-sectional line scan extracted from a reasonably flat region without near-horizontal grain boundary and the fitting using the analytical approach described by Nichterwitz et al.41. The fitted electron diffusion length is around 250 nm. As the excitation depth of the acceleration voltage used in EBIC (at 5 kV) is estimated to be only about 100 nm (Supplementary Fig. 14), it can be expected that the decay of EBIC in the quasi-neutral region (QNR) may be significantly enhanced by recombination at the unpassivated cross-section surface, thus underestimating the electron diffusion length. For a given fitted electron diffusion length, the upper limit of the intragrain electron diffusion length is estimated to be 1.0 μm using the upper limit of surface recombination velocity (107 cm s−1), according to the method described by Nichterwitz et al.41. However, we note that this approach is not very accurate given that the cross-section surface is not very flat. The intragrain diffusion length will be further estimated using 3D device simulation.

a,b, Cross-sectional SEM image (a) and EBIC image (b) of a cleaved CZTSe device. The beam energy was 5 keV. c, Normalized EBIC Intensity (IEBIC,norm) profile (blue dots) along the dashed yellow arrows shown in a and b and the fitting with analytical model (red line). The space charge region (SCR) and QNR are separated with the vertical dashed lines. The fluctuation of the EBIC signal is induced by the rough morphology. The regions with protrusions show weak EBIC because of the higher reflection of electron beam, and vice versa. The EBIC signal at the SCR region is severely altered by the non-flat morphology, which may lead to a large error in fitting of depletion region width. The QNR region shows a relatively flat morphology and thus is used for fitting diffusion length in this region. d, Carrier density profiles measured with capacity voltage (CV) and drive-level capacity profile (DLCP) with junction area before (blue) and after (red) modification. NCV and NDLCP are apparent carrier densities measured by CV and DLCP, respectively. f is the modulation frequency used for the CV and DLCP measurements. εr is the relative dielectric constant of CZTSe. Aj is the junction area. The inset shows the plain view SEM image of a CZTSe absorber.

Considering the large surface roughness of the CZTSe absorber (inset of Fig. 4d), the effective junction interface area can be significantly larger than the device area. On the basis of the AFM measurement (Supplementary Fig. 15), the effective junction interface area is about 1.3 times of the device area. Using the single-side abruption junction mode (ignoring the depletion region in the n-type buffer and window layer), the doping density (NDL) of the CZTSe absorber can be calculated as following42:

where Aj is the junction interface area and C0 and C1 are the static capacitance and the first-order differential capacitance, respectively. With the estimated junction interface area, NDL is calibrated from 3.1 × 1015 cm−3 to 1.8 × 1015 cm−3 (Fig. 4d). The NDL is the number of bulk acceptor defects that can contribute to the free carrier density. According to the defect activation energy measured using admittance from a similar sample (130 meV) (ref. 25), the electrical neutral condition and the Fermi–Dirac distribution, these defects are fully ionized (detailed analysis in Supplementary Discussion 2). We thus get an average free carrier density of 1.8 × 1015 cm−3.

In addition, the high spatial resolution of the EBIC image enables us to further investigate the electron transport across the grain boundaries. It is noteworthy that the CZTSe grains underneath near-horizontal grain boundaries, not directly connected to the buffer layer (Supplementary Fig. 16), do not contribute to the EBIC signal. This indicates significant recombination and/or a carrier transport barrier may exist near these grain boundaries or inside these grains, which may be responsible for the additional JSC loss in the long-wavelength region.

Carrier recombination at grain boundaries and grain interiors

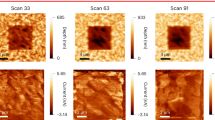

The non-radiative recombination velocity at grain boundaries and grain interiors is first qualitatively compared by performing cathodoluminescence (CL) mapping on a directly cleaved cross-section sample. In the measured region, all the grain boundaries show pronouncedly lower CL intensity compared with the grain interiors (Supplementary Fig. 17), which indicates grain boundaries have much larger non-radiative recombination velocity compared with the grain interiors. To exclude the effect of morphology and quantify the non-radiative recombination velocity at the grain boundaries, SGB, we further performed CL mapping of a focused ion beam (FIB)-prepared cross-section sample. As shown in Fig. 5a, the grains at the top and bottom of the CZTSe layer show comparable CL intensities while the CL intensities at the grain boundaries are much lower compared with the grain interiors. This verifies that the poor carrier collection efficiency in the bottom grains observed in EBIC can be attributed to their relatively larger SGB rather than to the recombination inside the grain interiors. Figure 5b shows CL line scans across two representative grain boundaries. No obvious CL peak energy variation is observed at the grain boundaries (Fig. 5c), indicating the bandgap does not change at the grain boundaries. The value of SGB can be estimated using the decay of CL intensities between grain boundaries and grain interiors, according to the model described by Mendis et al.43:

where \(\Delta I(x)\) is the relative CL intensity between the grain boundaries and grain interiors, L is the apparent electron diffusion length, S the reduced recombination velocity (S = SGB τGI / L, where τGI is the minority carrier lifetime of grain interior) and x is the position of the electron beam. The linear fittings of S and L are shown in Fig. 5d. Here we adopt the value of τGI of 10–30 ns based on the 3D device simulations as will be shown below.

a, Hyperspectral and intensity-combined CL map acquired at 10 keV from an FIB-prepared cross-sectional sample of CZTSe absorber. The SEM image is shown in Supplementary Fig. 18. The white arrows labelled with grain boundary numbers are where CL profiles are extracted for further analysis.The horizontal and vertical blue dash arrows indicate where line scans are taken. b, Spectro-, spatial- and intensity-resolved CL maps of the two representative grain boundaries indicated in a. c, Extracted CL intensity and peak energy profiles across the two grain boundaries. d, ln[ΔI] plots of the CL intensity profiles of GB1 and GB2 for positive distance values. The red and blue solid lines are linear regressions. The ln[ΔI] plots of GB3–6 are shown in Supplementary Fig. 19. e, Extracted CL peak energy profiles along the horizontal and vertical blue dashed arrows indicated in a. f, TRPL measured with a 532 nm laser and its corresponding double exponential decay fit. The unit cps. means count per second.

The values of SGB extracted from six grain boundaries (marked in Fig. 5a) are in a range of (0.15–3.8) × 104 cm s−1, one to two orders of magnitude larger than the value reported for high efficiency CIGSSe and CdTe solar cells23,24. As the band bending at grain boundaries is negligible, the effective grain boundary recombination velocity is not affected by band bending and should be close to the SGB. It is noteworthy that the high recombination velocity at the grain boundaries may also exist in sulfur-mixed CZTSSe and CZTS materials, indicating that more pertinent research efforts, such as grain boundary chemistry and passivation strategies are urgently needed for kesterite solar cells.

In addition, we further investigated the bandgap fluctuation in the CZTSe absorber by horizontal and vertical line scans of CL peak energies. The positions of these line scans are indicated in Fig. 5a, and the results are shown in Fig. 5e. The horizontal CL emission peak fluctuation at the region near the junction interface is rather small (<5 meV). In contrast, the front and rear surface regions show slightly increased CL peak energy compared with the bulk by 20–40 meV, which could be attributed to an increased bandgap correlating with the relatively high sodium concentration at the top and bottom (Supplementary Fig. 20). The incorporation of Na is known to slightly increase the bandgap of kesterite44. The minimum CL peak energy at the bulk is 1.00 eV (Supplementary Fig. 21), 0.01 eV and 0.02 eV lower than the PL peak energy and bandgap energy, respectively.

To evaluate how the large SGB impacts the optoelectronic quality of CZTSe absorber, we quantitatively correlated the effective minority carrier lifetime to the SGB and the grain size d (Supplementary Discussion 3):

where n is the number of passivated faces of cubic-like grains. Equation (5) suggests that grain size d could also be a critical factor that determines τeff. Using the value of SGB extracted from CL mapping, the calculated value of τGB of our CZTSe absorber with a grain size of 1.1 μm is 0.6–4.7 ns, with an average value of 2.5 ns, comparable to the fast decay time measured from time-resolved PL (TRPL) (3.3 ns, Fig. 5f), which is believed to be a key parameter determining VOC45,46. Using equation (5), the statistical average SGB in the cells is estimated to be 6.7 × 103 cm s−1 for the CZTSe absorbers with effective minority carrier lifetime of 3.3 ns (measured from TRPL) and grain size of 1.1 μm.

3D device simulations

To further investigate the critical intragrain material parameters (carrier lifetimes and mobilities) and how the microscopic carrier recombination mechanisms impact the device performance, we link the above characterizations into 3D device simulations. The simulations were based on a 3D unit cell established using the equivalent topology extracted from the morphology in the SEM and STEM images (Supplementary Figs. 22–24). The experimentally obtained photo-electronic parameters, including free carrier density, potential fluctuation, bandgap grading and the statistical average SGB, are integrated into the simulation model as fixed parameters (details in Methods and Supplementary Table 1).

Under a reasonable precondition that the minority carrier electrons should have a longer lifetime and mobility than holes, we can get a set of values of intragrain electron and hole lifetimes and mobilities by matching the experimental J–V and EQE data of the 12.45% efficient CZTSe cell. Meanwhile, the radiative loss due to potential fluctuations is simulated and shown to be rather small (Supplementary Fig. 25). Starting from this point, we can first estimate the region of intragrain carrier mobilities by fitting the value of FF and JSC because FF and JSC are sensitive to carrier mobilities while VOC is not. As shown in Fig. 6a, to match the value of FF (70~70.5%), the mobilities of electron and hole have to be in a range of 80–100 cm2 V−1 s−1 and 30–50 cm2 V−1 s−1, respectively, which fall within the same regions as that determined by fitting the JSC (Supplementary Fig. 26). The fitted electron mobility is comparable to that measured using time-resolved terahertz spectroscopy (128 cm2 V−1 s−1) (ref. 47), while the hole mobility is several times higher than that measured from time-resolved terahertz spectroscopy. Then we can estimate the value of electron and hole lifetimes under fixed electron and hole mobility (Supplementary Fig. 27). Figure 6b shows the overlapped region (dark brown) where experimental VOC, FF and JSC can be all well fitted within 1% deviation. The estimated intragrain electron and hole lifetimes are 10–30 ns and 0.3–0.7 ns, respectively. This shows that the intragrain minority carrier lifetime is significantly higher than the effective carrier lifetime. The electron diffusion length thus is estimated to be 1.4–2.8 μm, comparable with the value measured using bias dependent IQE26.

a, The simulated contour of FF versus electron and hole mobilities under fixed electron and hole lifetime of 15 ns and 0.3 ns, respectively, which are obtained from fitting J–V and EQE curves. The simulated JSC and VOC under the same conditions are shown in Supplementary Fig. 26. b, Simulated VOC (light yellow), FF (light purple) and JSC (light blue) versus electron and hole lifetimes within ±1% deviation compared with the experimental baseline. The full contours are shown in Supplementary Fig. 27. The overlapped region coloured in dark brown indicates where the electron and hole lifetime can well fit experimental VOC, FF and JSC simultaneously. The other overlapped regions indicate where VOC and JSC (green), JSC and FF (dark blue) and VOC and FF (military green) are well fitted. c,d, Simulated contours of efficiency against carrier lifetime and grain boundary recombination velocity under hole density of 2 × 1015 cm−3 (c) and 5 × 1016 cm−3 (d), respectively. The red star in c indicates the current state-of-the-art CZTSe cells. The optical loss is reduced in d to an extent that maximum JSC can achieve 40 mA cm−2. The efficiency contours under hole density of between 5 × 1015 cm−3 and 2 × 1016 cm−3 are shown in Supplementary Fig. 28.

To identify the efficiency limiting factors and associated step-change directions for further efficiency improvement, we simulated how the efficiency changes with intragrain electron lifetime, grain boundary recombination velocity and hole density. As shown in Fig. 6c,d, if the grain boundary recombination remains at 104 cm s−1, the efficiency can hardly be improved by increasing carrier lifetime or carrier density, suggesting that the large grain boundary recombination velocity is the current limiting factor. Additionally, if the carrier density can be improved to 5 × 1016 cm−3, a typical carrier density level for >20% efficient CIGS and CdTe solar cells23,48, the efficiency can be more easily improved, and ~20% efficiency can be achieved by reducing grain boundary recombination velocity to <102 cm s−1 and increasing electron lifetime to 100 ns. On the other hand, larger grain size will also lead to better performance (Supplementary Table 2) because both τGB and τeff linearly increase with grain size as described by equation (5).

Discussion

The above results indicate the device performance of the investigated 12.45% efficient CZTSe solar cells is mainly limited by the large grain boundary recombination velocity and the relatively low net carrier density. There are reported strategies to increase the net carrier density without introducing secondary phases, such as indium and lithium doping49,50. However, investigation of grain boundary passivation for kesterite materials is rather limited. The grain interior carrier lifetime is in a range of 10–30 ns, much higher than expected. Device simulations have shown that further improving grain interior carrier lifetime would not give any improvement in device performance if grain boundary recombination cannot be reduced. This may explain why various extrinsic doping/alloying strategies that are anticipated to improve bulk qualities can improve device performance when the baseline efficiency is low (probably because grain interior lifetime is too low) but hardly further improve the efficiency if baseline efficiency is at a level of 12–13%. Therefore, strategies for effective grain boundary passivation are urgently needed. On the other hand, as long as the density of acceptor-like interface defects can be kept low, higher net carrier density will not lead to significant interfacial recombination51. Considering the radiatively limited lifetime versus carrier density of CZTSe materials (Supplementary Fig. 29), an increase in carrier density to about 5.0 × 1016 cm−3 would be beneficial for the VOC and efficiency when the intragrain lifetime can be increased to 100 ns, which is an essential direction to improve the efficiency towards 20% and beyond.

For sulfide Cu2ZnSnS4 (CZTS) solar cells, the microscopic carrier loss mechanisms can be investigated using the same framework, though some optoelectronic characterization such as EBIC and CL mapping could be more challenging. It is worth noting that the dominant loss mechanisms in CZTS may be different from that of CZTSe. The carrier density in CZTS is usually high (>1016 cm−3), which, however, may impose more interfacial recombination even if the conduction band alignment is optimized51. Another important issue for CZTS is the significant PL red shift due to the dominating free-to-bound transition52. The impact of these loss mechanisms on the device performance needs to be carefully estimated and compared with non-radiative recombination losses at grain boundaries and grain interiors.

Conclusion

We have successfully unveiled most of the important microscopic loss mechanisms in our ≥12% efficiency CZTSe solar cells. The results indicate that the junction interface is well passivated by an epitaxial ZnSe nanolayer, the radiative recombination loss through bandgap fluctuation and/or electrostatic potential fluctuation is small and that the intragrain minority carrier lifetime is between 10 ns and 30 ns, all of which are encouraging characteristics for high efficiency solar cells. Instead, the high effective recombination velocity at grain boundaries (≥104 cm s−1) and the relatively low net carrier density (~2 × 1015 cm−3) are the current main limiting factors of our CZTSe solar cells. This provides clear direction for improving the performance of Se-based kesterite solar cells. We believe the established framework to reveal the important microscopic loss mechanisms of thin-film solar cells could also be applicable to other emerging materials such as perovskite and antimony chalcogenides.

Methods

Cu–Zn–Sn metal precursor

CZTSe films were fabricated with sputtering stacked Cu–Zn–Sn metallic precursors on Mo-coated glass substrates, followed by a selenization growth process. The target composition of the CZTSe absorber is Cu/(Zn + Sn) ≈ 0.75 and Zn/Sn ≈ 1.1, measured with X-ray fluorescence spectrometer (ARL Perform’X 4200, Thermo Fisher Scientific, with Uniquant analysis software). The Cu, Zn and Sn targets have 99.999% purity. The precursor stacking order was Mo/Sn/Cu/Zn/Sn/Cu, and the sputtering pressure was about 0.2 Pa.

CZTSe selenization process

The metallic precursors were pre-alloyed at 250 °C for 15 min, followed by a soft selenization at 250–280 °C for 15 min in controlled low Se partial pressure. Then the substrates were ramped to 550 °C in 15 min and stayed at 550 °C for 8–10 min. The details of the annealing profile are described elsewhere25. All these annealing processes were performed in a custom-made furnace that can have independent temperature control of Se source, substrates and Se cracking barrel (schematic diagram in Supplementary Fig. 30). The controlling Se atmosphere by adjusting the Se source temperature and Se cracking barrel temperature was detailed in our early publication53. Some key points for the selenization processes are summarized as follows: (1) before selenization start, a pre-alloying treatment with temperature higher than 250 °C is important to fabricate compact films and also important to control the Sn loss and the thickness of MoSe2 layer54; (2) a sufficient soft selenization with temperature below 300 °C (to prevent Sn loss) is important to control the bulk defects by turning Sn to Sn4+ and facilitating Zn diffusing to the top region before the synthesis of the CZTSe phase start at 350–400 °C (ref. 25). This Zn diffusion process enabled by the soft selenization may be a key step for the formation of the epitaxial ZnSe nanolayer. The formation of a near-continuous ZnSe nanolayer may also require a slightly high Zn/Sn ratio (close to 1:1). For example, the ZnSe layer cannot be observed in the sample with Zn/Sn ratio lower than 1.05 (Supplementary Fig. 31). In this soft selenization, it is very important to use a reactive micro-molecule Se vapour (Se2) under low Se partial pressure. High Se partial pressure will lead to poor Se diffusion55. (3) Sufficient Se partial pressure during high temperature annealing is important for grain growth.

CZTSe device fabrication

The CZTSe devices were fabricated with an architecture of Mo/CZTSe/CdS/i-ZnO/ZnO:Al/Ni/Al/MgF2. A 20–50 nm CdS buffer layer was deposited at 85 °C using the chemical bath deposition method. A 50 nm i-ZnO layer and a 400–450 nm ZnO:Al layer were subsequently deposited using radio frequency and direct current sputtering, respectively, with an Ar working pressure of 0.2 Pa. The Ni/Al grids and 110 nm MgF2 anti-reflector coating were deposited using electron beam evaporation. The total area of each device is about 0.24 cm2 defined by mechanical scribing. Total area efficiencies are reported.

SEM, STEM and EDS

Morphological analysis was performed using a SEM (FEI Apreo LoVac). The TEM-ready samples were prepared using the in situ FIB lift-out technique on an FEI Dual Beam FIB/SEM. The samples were capped with sputtered C and e-Pt/I-Pt before milling. The transmittance electron microscopy (TEM) lamella thickness was ~100 nm. The samples were imaged on a Hitachi HD2700 STEM with high-resolution TEM mode and a JEOL JEM-F200. EDS spectra were acquired on Oxford INCA, Bruker Quantax EDS system.

J–V and EQE measurement

The J–V curves were performed using a solar simulator (ABET IV Tester) with AM 1.5 G illumination (100 mW cm–2) at room temperature in open air. The light intensity was calibrated with a Fraunhofer World PV Scale (WPVS) reference cell (KG3 filter). The scan was from −0.1 V to 0.5 V with a step of 4 mV and a dwell time of 2 ms. The temperature-dependent J–V data were measured using a vacuumed cryostat with quartz windows. The light intensity was adjusted according to the JSC measured at standard condition (AM 1.5 G without cryostat). EQE data were acquired by measuring the short-circuit current with spectrally resolved monochromatic beam and locked-in amplifier, using calibrated Si and Ge photodiodes as references.

SIMS and ultraviolet photoelectron spectroscopy

The element depth profiles were recorded by SIMS (IMS-6F, CAMECA). A primary Cs+ beam was used for 500 µm × 500 µm sampling area. Ultraviolet photoelectron spectroscopy was performed on Thermo Fisher ESCALAB 250Xi. A He I light source (21.2 eV) was used as excitation source. The spot size is 500 μm. The spectrometer was calibrated using Au 4f7 = 83.96 eV, Ag 3d5 = 368.21 eV and Cu 2p3 = 932.62 eV. The data was recorded at 0 V sample bias without etching process.

Raman mapping and Raman spectrum

Raman spectroscopy mapping was performed using a Renishaw inVia Raman microscope fitted with a 441 nm He–Cd laser as the excitation source, 1,800 l mm−1 grating and measured using a 100× objective. The focal point was above the surface of the sample to collect more signals from the surface. The pixel size was 2 μm × 2 μm. Raman spectrum on MoSe2 back contact was performed using a 514 nm laser as the excitation, 1,800 l mm−1 grating and measured using a 100× objective. The focal point was on the surface of the sample.

EBIC

The EBIC measurements were performed on the cross-section of the finished device using an SEM (Zeiss ΣIGMA) extended with a tunable current amplifier. The devices were connected to a circuit that provided tunable bias. The EBIC images were obtained with a splitting mode, which was combined with SEM images of the same scanned region. The electron beam energy was 5 keV.

Cross-section KPFM and AFM

The cross-sectional KPFM measurements were conducted on a fresh cleaved CZTSe cell using atomic force microscopy (Bruker Dimension ICON SPM) with a scan rate of 0.200 Hz in a scan size of 8.5 μm (W) × 4.25 m (H). A brand new PtSi probe (Bruker SCM-PTSI) was used in these measurements, and the samples were measured using a two-pass scan (one for topography in contact mode and another for CPD maps in non-contact mode). The system deviation of CPD is about ± 10 mV. Surface AFM measurement was performed on an as-grown CZTSe sample using the same scan rate. In cross-section KPFM measurements, to prevent probe damage, we start the rough topology scan from the glass region, which is far from the cliff region of the cross-section, and gradually approach the glass/Mo interface. The glass/Mo interface can be identified by the sudden change of surface roughness because the cleaved glass is much smoother than the cross-section of Mo and CZTSe films. When reaching the Mo and CZTSe interface, we slow the approach rate and then scan at the same rate until reaching the CZTSe/window layer. Once part of the window layer appears in the projected area, we stop approaching and focus on a relatively flat region for high-resolution KPFM measurements.

PL and TRPL

PL and TRPL were measured using a microscope customized for micro-PL measurements. The excitation source was a 532 nm pump from an EKSPLA PT210 laser at 1 MHz repetition rate and 10 ps pulse width. The TRPL signal was detected using a fibre-coupled InGaAs avalanche photodiode (ID210) and processed using the time-correlated single photon counting board (TimeHarp 260). The time binning is 25 ps.

CL mapping

A cross-section sample was prepared for CL by a plasma FIB (Thermo Fisher Helios G4 PFIB) with an in situ lift-out platform. The electron excitation profile was simulated by the Monte Carlo method using the CASINO software55 (Supplementary Fig. 14) to determine the suitable thickness of the sample and acceleration voltage used in the CL measurement. On the basis of the simulation and considering that the average grain size is around 1 μm, 10 kV and 1 μm were used for the voltage and targeting thickness of the FIB milled sample, respectively. The sample was transferred and mounted on an in situ TEM grid with Pt welding after rough milling to about 2 μm thick. The sample was further polished using low beam current (0.3 nA) after lift out to achieve ~1 μm thickness. Before CL measurement, the sample received a final ion beam polish on both faces (Fischione NanoMill 1040) at low voltage (500 V) to ensure a clean and fresh surface for analysis. Analysis was conducted using a Delmic SPARC spectral cathodoluminescence system coupled to an FEI Nova Nano SEM 450 field-emission SEM.

3D device simulation

A commercial software package, Sentaurus technology computer-aided design was used to numerically examine the device physics. In this study, a 3D unit cell shown in Supplementary Fig. 24a was established in the simulator. In this unit cell, the absorber consists of five grains, one is larger (1.1 µm) and the other four are smaller with the same size (0.5 µm). The sizes of these grains were averaged from the TEM and SEM results (Supplementary Figs. 22 and 23). After all constitutional regions were generated in the simulator, the whole structure went through a meshing process to break down into millions of small elements, that is, cuboids. A smaller element allows for a higher accuracy to compute the spatial distribution of key fields such as carrier concentration. Meanwhile, it demands more computer resources as well. Hence the element size was refined only where the field variation is significant to balance between speed and accuracy. Afterwards, photogeneration was computed with the simple optical beam absorption method using the Beer–Lambert law. The complex refractive index of each layer was obtained from in-house characterization. The key semiconductor material parameters for electron simulation are listed in Supplementary Table 1 and obtained from either in-house characterization or the literature56,57,58. The ambient temperature in simulation is also 298.15 K to match the standard test condition. The carrier lifetime and mobility values are tuned to fit the experimental baseline.

After initialising all important fields and model parameters, the thermal equilibrium condition was first computed by solving five semiconductor equations, that is, the Poisson, drift-diffusion and carrier continuity equations, numerically. A well-established mesh and suitable solver help reach self-consistency fast. Subsequently, the impact of carrier generation and bias voltage was investigated by ramping these parameters dynamically. For each ramping step, the steady state was computed so that key fields can be extracted for further analysis. If necessary, a snapshot at a ramping step can also be saved to preserve spatial distribution of fields. Following this practice, the champion cell was reproduced by matching key performance characteristics. Afterwards, the impact of grain lifetime, carrier density, grain size and grain boundary recombination on cell performance was predicted, providing a guideline for future cell improvement.

Reporting summary

Further information on research design is available in the Nature Research Reporting Summary linked to this article.

Data availability

The datasets analysed and generated during the current study are included in the paper and its Supplementary Information. Source data are provided with this paper.

Code availability

The codes used for simulation within this paper are available from the corresponding author upon reasonable request.

References

Creutzig, F. et al. The underestimated potential of solar energy to mitigate climate change. Nat. Energy 2, 1–9 (2017).

Green, M. A. Third Generation Photovoltaics, Springer (2006).

Liu, F. et al. Emerging inorganic compound thin film photovoltaic materials: progress, challenges and strategies. Mater. Today 41, 120–142 (2020).

Zakutayev, A. et al. Emerging inorganic solar cell efficiency tables (version 2). J. Phys. Energy 3, 032003 (2021).

Osbel Almora, D. B. et al. Device performance of emerging photovoltaic materials (version 2). Adv. Energy Mater. 11, 2102526 (2021).

Giraldo, S. et al. Progress and perspectives of thin film kesterite photovoltaic technology: a critical review. Adv. Mater. 31, e1806692 (2019).

Walsh, A., Chen, S., Wei, S.-H. & Gong, X.-G. Kesterite thin-film solar cells: advances in materials modelling of Cu2ZnSnS4. Adv. Energy Mater. 2, 400–409 (2012).

Son, D. H. et al. Effect of solid-H2S gas reactions on CZTSSe thin film growth and photovoltaic properties of a 12.62% efficiency device. J. Mater. Chem. 7, 25279–25289 (2019).

Wang, W. et al. Device characteristics of CZTSSe thin-film solar cells with 12.6% efficiency. Adv. Energy Mater. 4, 1301465 (2014).

Best research-cell efficiency chart. NREL https://www.nrel.gov/pv/cell-efficiency.html (2022).

Siebentritt, S., Igalson, M., Persson, C. & Lany, S. The electronic structure of chalcopyrites-bands, point defects and grain boundaries. Prog. Photovolt. Res. Appl. 18, 390–410 (2010).

Green, M. A. et al. Solar cell efficiency tables (version 59). Prog. Photovolt. Res. Appl. 30, 3–12 (2021).

Yun, J. S. et al. Benefit of grain boundaries in organic–inorganic halide planar perovskite solar cells. J. Phys. Chem. Lett. 6, 875–80 (2015).

Li, C. et al. Grain-boundary-enhanced carrier collection in CdTe solar cells. Phys. Rev. Lett. 112, 156103 (2014).

Lin, T.-Y. et al. Alkali-induced grain boundary reconstruction on Cu(In,Ga)Se2 thin film solar cells using cesium fluoride post deposition treatment. Nano Energy 68, 104299 (2020).

Chen, S., Walsh, A., Gong, X. G. & Wei, S. H. Classification of lattice defects in the kesterite Cu2ZnSnS4 and Cu2ZnSnSe4 earth-abundant solar cell absorbers. Adv. Mater. 25, 1522–39 (2013).

Martinho, F. et al. Persistent double-layer formation in kesterite solar cells: a critical review. ACS Appl. Mater. Interfaces 12, 39405–39424 (2020).

Li, J., Wang, D., Li, X., Zeng, Y. & Zhang, Y. Cation substitution in earth-abundant kesterite photovoltaic materials. Adv. Sci. 5, 1700744 (2018).

Romanyuk, Y. E. et al. Doping and alloying of kesterites. J. Phys. Energy 1, 044004 (2019).

He, M., Sun, K., Suryawanshi, M. P., Li, J. & Hao, X. Interface engineering of p–n heterojunction for kesterite photovoltaics: a progress review. J. Energy Chem. 60, 1–8 (2021).

Fonoll-Rubio, R. et al. Insights into interface and bulk defects in a high efficiency kesterite-based device. Energy Environ. Sci. 14, 507–523. (2021).

Vishwakarma, M. et al. A direct measurement of higher photovoltage at grain boundaries in CdS/CZTSe solar cells using KPFM technique. Sol. Energy Mater. Sol. Cells 183, 34–40 (2018).

Krause, M. et al. Microscopic origins of performance losses in highly efficient Cu(In,Ga)Se2 thin-film solar cells. Nat. Commun. 11, 4189 (2020).

Zhao, Y. et al. Monocrystalline CdTe solar cells with open-circuit voltage over 1 V and efficiency of 17%. Nat. Energy 1, 1–7 (2016).

Li, J. et al. Defect control for 12.5% efficiency Cu2ZnSnSe4 kesterite thin‐film solar cells by engineering of local chemical environment. Adv. Mater. 32, 2005268 (2020).

Lee, Y. S. et al. Cu2ZnSnSe4 thin-film solar cells by thermal co-evaporation with 11.6% efficiency and improved minority carrier diffusion length. Adv. Energy Mater. 5, 1401372 (2015).

Li, J. et al. Tailoring the defects and carrier density for beyond 10% efficient CZTSe thin film solar cells. Sol. Energy Mater. Sol. Cells 159, 447–455 (2017).

Timo Wätjen, J., Engman, J., Edoff, M. & Platzer-Björkman, C. Direct evidence of current blocking by ZnSe in Cu2ZnSnSe4 solar cells. Appl. Phys. Lett. 100, 173510 (2012).

Mendis, B. G. Fully depleted emitter layers: a novel method to improve band alignment in thin-film solar cells. Semicond. Sci. Technol. 34, 055008 (2019).

Hages, C. J., Carter, N. J., Agrawal, R. & Unold, T. Generalized current-voltage analysis and efficiency limitations in non-ideal solar cells: case of Cu2ZnSn(SxSe1−x)4 and Cu2Zn(SnyGe1−y)(SxSe1−x)4. J. Appl. Phys. 115, 234504 (2014).

Rau, U. Tunneling-enhanced recombination in Cu(In,Ga)Se2 heterojunction solar cells. Appl. Phys. Lett. 74, 112–114 (1999).

Hegedus, S. S. & Shafarman, W. N. Thin-film solar cells: device measurements and analysis. Prog. Photovolt. Res. Appl. 12, 155–176 (2004).

Wang, K. et al. Thermally evaporated Cu2ZnSnS4 solar cells. Appl. Phys. Lett. 97, 143508 (2010).

Barkhouse, D. A. R., Gunawan, O., Gokmen, T., Todorov, T. K. & Mitzi, D. B. Device characteristics of a 10.1% hydrazine-processed Cu2ZnSn(Se,S)4 solar cell. Prog. Photovolt. Res. Appl. 20, 6–11 (2012).

Schwarz, T. et al. Atom probe tomography study of internal interfaces in Cu2ZnSnSe4 thin-films. J. Appl. Phys. 118, 095302 (2015).

Cojocaru-Mirédin, O., Schwarz, T. & Abou-Ras, D. Assessment of elemental distributions at line and planar defects in Cu(In,Ga)Se2 thin films by atom probe tomography. Scr. Mater. 148, 106–114 (2018).

Gokmen, T., Gunawan, O., Todorov, T. K. & Mitzi, D. B. Band tailing and efficiency limitation in kesterite solar cells. Appl. Phys. Lett. 103, 103506 (2013).

Rey, G. et al. On the origin of band-tails in kesterite. Sol. Energy Mater. Sol. Cells 179, 142–151 (2018).

Shklovskii, B. I. & Efros, A. L. Electronic Properties of Doped Semiconductors vol. 45 (Springer, 2013).

Rau, U. & Werner, J. H. Radiative efficiency limits of solar cells with lateral band-gap fluctuations. Appl. Phys. Lett. 84, 3735–3737 (2004).

Nichterwitz, M., Caballero, R., Kaufmann, C. A., Schock, H.-W. & Unold, T. Generation-dependent charge carrier transport in Cu(In,Ga)Se2/CdS/ZnO thin-film solar-cells. J. Appl. Phys. 113, 044515 (2013).

Heath, J. T., Cohen, J. D. & Shafarman, W. N. Bulk and metastable defects in CuIn1−xGaxSe2 thin films using drive-level capacitance profiling. J. Appl. Phys. 95, 1000–1010 (2004).

Mendis, B. G., Bowen, L. & Jiang, Q. Z. A contactless method for measuring the recombination velocity of an individual grain boundary in thin-film photovoltaics. Appl. Phys. Lett. 97, 092112 (2010).

Gershon, T. et al. The role of sodium as a surfactant and suppressor of non-radiative recombination at internal surfaces in Cu2ZnSnS4. Adv. Energy Mater. 5, 1400849 (2015).

Tampo, H., Kim, K. M., Kim, S., Shibata, H. & Niki, S. Improvement of minority carrier lifetime and conversion efficiency by Na incorporation in Cu2ZnSnSe4 solar cells. J. Appl. Phys. 122, 023106 (2017).

Hages, C. J. et al. Identifying the real minority carrier lifetime in nonideal semiconductors: a case study of kesterite materials. Adv. Energy Mater. 7, 1700167 (2017).

Hempel, H., Hages, C. J., Eichberger, R., Repins, I. & Unold, T. Minority and majority charge carrier mobility in Cu2ZnSnSe4 revealed by Terahertz Spectroscopy. Sci. Rep. 8, 14476 (2018).

Metzger, W. K. et al. Exceeding 20% efficiency with in situ group V doping in polycrystalline CdTe solar cells. Nat. Energy 4, 837–845 (2019).

Kim, J. et al. High efficiency Cu2ZnSn(S,Se)4 solar cells by applying a double In2S3/CdS emitter. Adv. Mater. 26, 7427–31 (2014).

He, M. et al. High efficiency Cu2ZnSn(S,Se)4 solar cells with shallow LiZn acceptor defects enabled by solution‐based Li post‐deposition treatment. Adv. Energy Mater. 11, (2021).

Li, J. et al. Interface recombination of Cu2ZnSnS4 solar cells leveraged by high carrier density and interface defects. Sol. RRL 5, 2100418 (2021).

Levcenko, S. et al. Deep defects in Cu2ZnSn(S,Se)4 solar cells with varying Se content. Phys. Rev. Appl. 5, (2016).

Li, J. et al. Growth of Cu2ZnSnSe4 film under controllable Se vapor composition and impact of low Cu content on solar cell efficiency. ACS Appl. Mater. Interfaces 8, 10283–92 (2016).

Li, J. et al. Barrier effect of the alloy layer during selenization: tailoring the thickness of MoSe2 for efficient Cu2ZnSnSe4 Solar Cells. Adv. Energy Mater. 5, 1402178 (2015).

Drouin, D. et al. CASINO V2. 42—a fast and easy‐to‐use modeling tool for scanning electron microscopy and microanalysis users. Scanning 29, 92–101 (2007).

Pu, A. et al. Sentaurus modelling of 6.9% Cu2ZnSnS4 device based on comprehensive electrical & optical characterization. Sol. Energy Mater. Sol. Cells 160, 372–381 (2017).

Jones, G. & Woods, J. The electrical properties of zinc selenide. J. Phys. D 9, 799 (1976).

El Otmani, R., El Manouni, A., & Al Maggoussi, A. Numerical simulation of CZTSe based solar cells using different back surface field layers: improvement and comparison. J. Electron. Mater. 50, 2021–2033 (2021).

Acknowledgements

J.L., J.H., X.H. and M.A.G. acknowledge the financial support of the Australian government through the Australian Renewable Energy Agency (ARENA) (grant number 2017/RND006), Baosteel (grant number LP150100911). X.H. acknowledges the financial support of the Australian Research Council (ARC) Future Fellowship (FT190100756). J.L. acknowledges the support from Australian Centre of Advanced Photovoltaics (ACAP, RG200768-A). T.U. acknowledges support by the European Union’s Horizon 2020 research and innovation programme under grant agreement numbers 777968 (INFINITE-CELL project) and 952982 (Custom-Art project). Responsibility for the views, information or advice expressed herein is not accepted by the Australian government. We thank C. Jiang from the US National Renewable Energy Laboratory for the discussion of KPFM measurements. We thank C. Li for the reflectance measurements. We acknowledge the facilities and the scientific and technical assistance of Microscopy Australia at the Electron Microscope Unit (EMU), the Spectroscopy Laboratory and the Solid State and Elemental Analysis Unit within the Mark Wainwright Analytical Centre (MWAC) at UNSW Sydney.

Author information

Authors and Affiliations

Contributions

J.L. and X.H. conceived the idea. X.H. and M.A.G. supervised the project. J.L. fabricated the CZTSe films and solar cells; conducted J–V, EQE, J–V–T, CV/DLCP, Raman mapping, SEM, EBIC measurements and most of the data analysis; and wrote the manuscript. J.H. analysed the HR-STEM, EBIC and CL data. F.M. developed the 3D device simulation model. F.M. and J.L. performed the 3D simulation. Y.Y., J.L. and H.S. conducted KPFM measurements. J.H. and J.C. fabricated the FIB sample for CL mapping and STEM-EDS measurements. K.P., J.H., R.D.T. and J.L. conducted the CL mapping. R.F.W., S.C., R.D.T. and J.H. conducted the STEM-EDS measurements. R.L.C., Z.H. and J.L. conducted the PL and TRPL measurements. X.Y. did the Raman measurements. M.H. and K.S. assisted in precursor and window layer fabrication. H.L. assisted in EBIC measurements. All authors discussed and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Energy thanks the anonymous reviewers for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–31, Discussions 1–3 and Tables 1 and 2.

Supplementary Data 1

Source data for Supplementary Figs. 1–3, 6–14, 19–21, 23, 25–29 and 31.

Source data

Source Data Fig. 1

Unprocessed J–V, EQE and SIMS source data.

Source Data Fig. 2

Unprocessed Raman mapping, Raman scan, temperature-dependent Rs, A, Voc and the source data for the fit of back contact barrier.

Source Data Fig. 3

Topology and CPD scans, IQE and normalized PL spectrum and the absorption data at the band edge.

Source Data Fig. 4

EBIC profile and simulation, CV and DLCP profiles.

Source Data Fig. 5

CL line scan profiles, data for the fit of reduced recombination velocity, TRPL decay data and its fitting data.

Source Data Fig. 6

Simulated FF versus electron and hole mobilities, simulated efficiency versus electron lifetime and grain boundary recombination velocity at different doping densities.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Li, J., Huang, J., Ma, F. et al. Unveiling microscopic carrier loss mechanisms in 12% efficient Cu2ZnSnSe4 solar cells. Nat Energy 7, 754–764 (2022). https://doi.org/10.1038/s41560-022-01078-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41560-022-01078-7

This article is cited by

-

Controlling Selenization Equilibrium Enables High-Quality Kesterite Absorbers for Efficient Solar Cells

Nature Communications (2023)

-

Phase evolution under pressure

Nature Energy (2023)

-

Control of the phase evolution of kesterite by tuning of the selenium partial pressure for solar cells with 13.8% certified efficiency

Nature Energy (2023)

-

Emergence of flexible kesterite solar cells: progress and perspectives

npj Flexible Electronics (2023)