Abstract

Electrospun nanofibers have received considerable attention in the field of soft electronics owing to their promising advantages and superior properties in flexibility and/or stretchability, conductivity, and transparency; furthermore, their one-dimensional nanostructure, high surface area, and diverse fibrous morphologies are also desirable. Herein, we provide an overview of electrospun nanofiber-based soft electronics. A brief introduction of the unique structure and properties of electrospun nanofiber materials is provided, and assembly strategies for flexible/stretchable electronics are highlighted. We then summarize the latest progress in the design and fabrication of representative flexible/stretchable electronic devices utilizing electrospun nanofibers, such as flexible/stretchable conductors, sensors, energy harvesting and storage devices, and transistors. Finally, a conclusion and several future research directions for electrospun nanofiber-based soft electronics are proposed.

Similar content being viewed by others

Introduction

Flexible and stretchable electronics have attracted worldwide attention in recent years due to their promising features, such as thinness, lightness, flexibility, stretchability, conformability, and compatibility1,2. Accordingly, they have been applied widely in the development of flexible displays3,4, healthcare monitoring5,6, sensors7,8,9, artificial skins10,11, energy harvesting and storage devices12,13, and implantable bioelectronics14,15. Tremendous effort has been applied to improve the performance of soft electronics by designing flexible/stretchable structures and/or finding intrinsically soft materials16,17,18,19. To this end, several advanced nanomaterials (e.g., graphene, carbon nanotubes (CNT), nanoparticles, nanowires (NW)/nanofibers, nanomembranes) have been developed to manufacture soft electronics due to their large specific surface area and excellent mechanical and electrical properties20,21,22. There are several configurations to fabricate nanomaterial-enabled soft electronics, such as wavy, prestrain, composite, and transfer23,24. Considering repeatability and large-scale fabrication, it is becoming obvious that both physical and economic factors will limit their further advances with the aforementioned techniques, in addition to the complex procedures required during the fabrication of nanomaterials25,26. However, electrospinning provides a low-cost, efficient, and large-scale method for preparing one-dimensional nanofibers with exciting mechanical and electrical characteristics, including high porosity, surface area, conductivity, transparency, and ultrahigh flexibility (Fig. 1). In addition, diverse, viable nanofiber assemblies are pivotal in devising thin, soft, lightweight, breathable, and conformable electronic devices. Moreover, the applicability of biocompatible polymers makes electrospinning ideal to fabricate substrate materials for flexible/stretchable electronic devices that directly interface with tissues, organs, or cells27,28,29.

Strain sensors (modified from ref. 57, copyright 2019 Wiley-VCH). Pressure sensors (modified from ref. 135, copyright 2017 Wiley-VCH). Chemical sensors (modified from ref. 197, copyright 2020 Elsevier). Nanogenerators (modified from ref. 139, copyright 2018 Royal Society of Chemistry). Batteries (modified from ref. 202, copyright 2019 Wiley-VCH). Supercapacitors (modified from ref. 186, copyright 2015 Elsevier). Photodetectors (modified from ref. 196, copyright 2014 Springer Nature). Light-emitting diodes (LEDs) (modified from ref. 203, copyright 2018 American Chemical Society). Transistors (modified from ref. 54, copyright 2020 Royal Society of Chemistry). Conductors (modified from ref. 96, copyright 2019 American Chemical Society). Transparent electrodes (modified from ref. 83, copyright 2014 American Chemical Society).

With the rapid development of electrospinning techniques, significant progress has been made toward functional applications of electrospun nanofibers in soft electronics (Fig. 1)30,31,32,33. Organic polymers, small molecules, colloidal particles, composites, organic/inorganic, and organic/organic systems have been successfully electrospun into nonwoven mats through modified electrospinning techniques34,35,36, further extending the application of electrospinning for flexible/stretchable electronic devices. Although electrospun nanofibers have been widely investigated for several decades, their use as building blocks for flexible and stretchable electronics is still at the early stage despite their advantageous features37,38. This review aims to introduce readers to the current development of electrospun nanofiber-based soft electronics and to suggest possibilities for several exciting developments. State-of-the-art applications in soft electronics, including flexible/stretchable conductors, transparent electrodes, strain sensors, pressure sensors, energy harvesting and storage devices, transistors, and optoelectronics, are presented in detail. Finally, an outlook on future prospects is also provided.

Electrospinning

Among the different methods for producing one-dimensional nanostructures, electrospinning is the simplest and most economically viable; furthermore, electrospinning has been a commercially successful process for the large-scale production of nanofibers with adjustable diameters (from nanometers to micrometers)39,40. Electrospinning was first studied in the 1930s and began to draw noticeable attention from the late 20th century due to growing industrial and academic interest41. To date, more than 100 different types of organic polymers, both natural and synthetic, have been successfully explored for solution electrospinning to directly produce continuous nanofibers27.

Technically, electrospinning is a process that uses a strong electrical field to draw a polymer solution or melt into fine filaments. The basic electrospinning setup, shown in Fig. 2, consists of a needle nozzle, high-voltage power supply, container for the spinning fluid, and an electrode collector. When a viscous fluid is charged at a high voltage, the electrostatic force draws the fluid into a liquid jet. Because of the interaction between the jet and the external electric field and the charge repulsion inside the jet, the charged jet undergoes bending or whipping instability to stretch it thinner. Solvent evaporation from the filaments results in solid fibers42,43. In most cases, the as-spun fibers deposit randomly on the electrode collector, forming a nonwoven, entangled nanofiber mat. While the diameters and morphologies (e.g., parallel and crossed fiber arrays, helical or wavy fibers, twisted fiber yarns, patterned fiber webs, and 3D fibrous stacks) of these electrospun nanofibers can be well adjusted by a variety of parameters, such as the intrinsic properties of the solution (e.g., the type of polymer and solvent, the conformation of the polymer chain, viscosity/concentration, elasticity, electrical conductivity, and the polarity and surface tension of the solvent), the operational conditions (e.g., the strength of the applied electric field, the distance between the spinneret and collector, and the feeding rate of the polymer solution), as well as the humidity and temperature of the surroundings44,45. Therefore, the electrospinning process should be optimized in regard to the above parameters to obtain a uniform, long, continuous fibers with a desired diameter, structure, composition, morphology, porosity, and orientation for use in developing a variety of electronic, environmental, and biomedical applications41,46,47.

a Electrospinning and electrospun nanofibers. Electrospinning setup (modified from ref. 44, copyright 2019 American Chemical Society) and b scanning electron microscopy (SEM) image of an electrospun polyurethane (PU) nanofiber mat.

Strategies for electrospun nanofibers in soft electronics

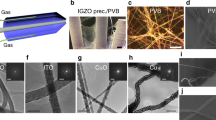

Diverse nanomaterials, such as organic polymer nanofibers, carbon nanofibers, metal nanofibers, ceramic nanofibers, and inorganic hybrid nanofibers, have been fabricated directly or indirectly by electrospinning. We have seen their increasingly growing applications in soft electronics, including transparent electrodes, conductors, transistors, optoelectronics, sensors, and energy devices48. To this end, different methods have been employed to engineer electrospun nanofibers as passive components (such as functional substrates, templates, and precursors) and active components (such as friction layers for nanogenerators, electrolyte separators for energy storage devices, and sensing layers for chemical sensors) for flexible/stretchable electronic devices49. In the following, we will introduce six main strategies to assemble electrospun nanofibers in soft electronic systems (Fig. 3).

Single semiconductor nanofiber (modified from ref. 53, copyright 2018 Wiley-VCH). Entangled porous nanofiber sheet (modified from ref. 108, copyright 2016 Wiley-VCH). Aligned nanofiber arrays (modified from ref. 69, copyright 2013 IOPscience). Yarns (modified from ref. 76, copyright 2020 American Chemical Society). Template (modified from ref. 56, copyright 2017 Springer Nature). Reinforcement (modified from ref. 90, copyright 2019 American Chemical Society).

Single semiconducting nanofiber

Single electrospun semiconducting nanofibers have been used as channel materials for flexible/stretchable transistors due to their high carrier mobility and good mechanical flexibility. Compared to conventional film-type semiconducting materials, one-dimensional nanostructures from conjugated polymers exhibit the following promising advantages: (1) a large contact area with a dielectric layer, (2) inherent flexibility, (3) the capability to engineer wrinkled or buckled structures for better stretchability, (4) easier patternability via direct printing, and (5) efficient and easy scale-up fabrication. A variety of nanofibers, such as poly(3-decylthiophene) (P3DT)/poly(3-hexylthiophene) (P3HT) copolymer50, poly(3,3′′′didodecylquarterthiophene) (PQT-12)/poly(ethylene oxide) (PEO) copolymer51, P3HT52, thiophene diketopyrrolopyrrole (FT4-DPP)/PEO copolymer53, and core-shell P3HT/PEO copolymer54, have been fabricated as single nanofiber flexible/stretchable transistors.

Entangled porous nanofiber sheet

Flexible/stretchable electronic devices are generally fabricated by depositing electrical materials onto elastomeric substrates or by embedding them into elastomeric matrixes16,55. The elastomeric materials used for soft electronics are mainly polydimethylsiloxane (PDMS), polyimide (PI), polyethylene terephthalate (PET), Ecoflex, Parylene, latex rubber, paper, etc.17. However, these polymeric substrates have inherent mechanical mismatches with commonly used electrical materials such as metals, metallic nanomaterials, and carbon-based materials18. In addition, the limited gas/liquid permeability will restrain their application in on-skin electronics for long-term continuous monitoring56. In contrast, elastomer substrates prepared from electrospun nanofiber sheets can not only provide notable mechanical flexibility but also breathability for wearable skin electronics. Furthermore, the large surface area and high pore volume of nanofiber-based substrates can benefit the loading of large amounts of electrically active materials44, resulting in highly sensitive devices. Wearable electronic devices can be lightweight, conformable, highly sensitive, flexible, and/or stretchable and breathable while using nonconducting electrospun nanofiber sheets as supporting materials57,58. Recently, a high-adhesion, biocompatible, ultrathin PDMS nano/microfiber mat was developed by using electrospun core-sheath PDMS-polyvinylpyrrolidone (PVP) nanofibers. The PDMS nano/microfiber mat was suggested to be an ideal candidate as a supporting substrate for epidermal electronics59. In addition, nonconducting electrospun nanofiber sheets can be used as other components in soft electronic devices, such as electrolytes and separators for batteries and insulating/passivation layers60,61.

Conducting (e.g., carbon, polyvinylidene fluoride (PVDF), composite) nanofiber sheets are applied as active functional materials in flexible/stretchable electrodes62, conductors63, and sensors64. Semiconducting, e.g., P3HT, metal oxide, and composite, nanofiber sheets are employed as channel materials in flexible/stretchable transistors65, active materials in flexible/stretchable sensors66, and friction layers in flexible/stretchable nanogenerators67.

Aligned nanofiber array

Highly aligned nanofibers can be easily achieved by adjusting conditions regarding the flow rate and collector during the electrospinning process68. Apart from the single semiconducting nanofibers previously mentioned in “Single semiconducting nanofiber”, aligned nanofibers from conjugated polymers have also been used as channel materials. It has been reported that the maximum on-current values can be manipulated by the number of aligned P3HT electrospun nanofibers connecting the source (S)/drain (D) electrodes52. Specifically, a transistor based on a single P3HT nanofiber has an on-current value of 0.7 mA, and the value increases to 3.8 mA when there are 10 aligned nanofibers. Therefore, this approach is promising for fabricating transistor arrays with high density.

A stretchable platinum-based transparent electrode has been made with a sheet resistance of 131 Ω/sq at T = 90% by using aligned electrospun nanofibers as templates69. Ultrafine and well-aligned PVDF-based nanofibers can be utilized to fabricate high-performance piezoelectric pressure sensors due to the enhanced piezoelectric coefficient68,70,71. Moreover, a multidirectional strain sensor was developed by orthogonally stacking two aligned carbon nanofiber layers with a remarkable selectivity of 3.8472.

Yarn

Notably, e-textiles are of great importance for wearable electronics because of their potential use in portable electronics, smart fabrics, and wearable displays73. Though other spinning methods (dry, force, melting, and wet spinning) have been developed to produce nano/microfibers for e-textile applications, they are not suitable for large-scale manufacturing74,75. To this end, diverse three-dimensional porous microfibers or yarn-shaped flexible/stretchable conductors have been prepared by wrapping conductive membranes based on electrospun nanofibers. Typically, entangled nanofibers are loaded with electrically conducting materials, such as CNTs, graphene, and silver nanoparticles (AgNPs)76,77,78,79. The as-prepared yarns are generally used as highly sensitive strain and pressure sensors with a large maximum strain (>50%) and good conductivity79,80,81,82.

Temporary template

A typical approach to fabricate transparent electrodes is to use electrospun polymer nanofiber mats as temporary templates69,83,84. After the removal of nanofibers by annealing or dissolving in solution, the porous mesh structures of the conductive metal layers are maintained. Characteristics such as the transparency and sheet resistance of the transparent electrode can be well tuned by changing the morphology of the electrospun nanofiber sheet. Furthermore, a substrate-free, breathable, on-skin conductor can be readily obtained by dissolving polyvinyl alcohol (PVA) nanofiber sheets with a water mist after attachment56,85.

Reinforcement

Inspired by reinforcement wires in concrete, numerous nanotube or nanowire-based materials have been widely used as reinforcement materials in composites to enhance mechanical performence86,87. Upon incorporating electrospun nanofibers into an elastomer matrix, the as-received elastomer substrate becomes a skin-like substrate even though the thickness is on the micrometer scale88,89. The good mechanical properties originate from the existence of randomly distributed nanofibers in the polymer matrix. In addition, the fiber reinforcing effect enhances the toughness and suppresses crack growth due to the embedded nanofibers in the composite conductor90.

Soft electronic applications of electrospun nanofibers

Because the impressive properties of electrospun nanofibers in one-dimensional nanostructures, namely, the porosity, flexibility, conductivity, transparency, and diverse fibrous morphologies are vital to designing high-performance soft electronics, a number of recently developed flexible/stretchable electronic devices are discussed and summarized in the following sections, including conductors, transparent electrodes, strain sensors, pressure sensors, nanogenerators, supercapacitors, batteries, transistors, and other applications.

Conductors

Flexible and/or stretchable conductors are indispensable components for soft electronic integrations to develop next-generation wearable electronics and soft robotics20,91,92. In this section, we introduce flexible/stretchable nontransparent conductors and transparent electrodes made from electrospun nanofibers.

Nontransparent conductors

The basic feature of a flexible and/or stretchable conductor is that it retains high conductivity under certain mechanical deformations93,94,95. Thanks to the excellent flexibility of the nanofiber-networked porous structure from electrospinning, a plethora of flexible/stretchable conductive films or yarns have been fabricated63,76,77,78,96,97. For example, carbon nanofiber (CNF)/graphene nanosheet (GNS) composite paper can be directly prepared by electrospinning after adding GNS to the electrospun polymer precursor. The flexible paper shows a specific capacitance up to 197 F/g, which is 24% higher than that of pure CNF paper, revealing its promise for application in high-performance flexible capacitors98.

By using water-dissolvable PVA electrospun polymers, Someya et al. reported substrate-free on-skin electronics56,85. The fabrication process was simple and effective. In brief, a PVA nanofiber sheet was prepared by electrospinning. Then, a 70–100-nm-thick Au layer was deposited on top using a shadow mask. When the Au/PVA conductors were placed on skin and sprayed with water, the PVA nanofibers easily dissolved, and the Au nanomesh conductor adhered to the skin (Fig. 4a). Figure 4b shows the fine ridges of the human finger, demonstrating the good conformability of the material due to the ultrathin adhesive layer produced by the dissolved PVA. Compared to conventional planar substrates, substrate-free nanomeshes offer notable gas permeability and a significant decrease in stuffiness, rashes, and other inflammatory skin reactions. Furthermore, these nanomesh conductors can survive 10,000 cycles of finger bending (~40% strain) (Fig. 4c, d). A recently published work has shown that with heat-press treatment at 180 °C, the resistance of the nanomesh conductors decrease by 76%, and the stretchability increases from 25 to 80% strain85.

a Schematic of substrate-free nanomesh conductors. The lamination process of Au nanomesh onto the skin is as follows: first, the Au layer is deposited onto electrospun PVA nanofibers; then, PVA is dissolved by being sprayed with water; final, after the removal of PVA, the nanomesh conductor adheres to the skin. b Picture of a nanomesh conductor attached to a fingertip. Scale bar, 1 mm. c SEM image of a nanomesh conductor after PVA dissolution. Scale bar, 5 µm. c Photographs showing the Au nanomesh adhered to fingers in relaxed and stretched states. d Conductance changes during 10,000 cycles of finger bending (modified from ref. 56, copyright 2017 Springer Nature).

Flexible/stretchable conductors have also been fabricated when electrospun nanofibers are used as supporting scaffolds for electrical materials. Someya et al. presented an ultrasoft Au/Parylene/PU conductor and employed it to monitor dynamically pulsing cardiomyocytes99. The PU nanofiber (diameter: 800–900 nm) sheet was ultrathin and flexible and had a coverage of 10–20%. The Parylene layer (200-nm-thick) was deposited via chemical vapor deposition to uniformly cover the PU nanofibers. Finally, the conductor was completed by depositing a 100-nm-thick Au layer on top (Fig. 5a). The effective Young’s modulus of the PU nanosubstrate was estimated to be 0.274 ± 0.039 MPa, which was two to three orders of magnitude lower than that of a uniform pure Parylene layer. The Au/Parylene/PU nanomesh conductor could be stretched to 30% strain while remaining highly conductive (211.6 ± 63.4 Ω) (Fig. 5b). Moreover, this conductor exhibited stable electrical responses under repetitive stretching (up to 20% strain) and releasing despite their ultrasoftness (Fig. 5c). To increase stretchability and conductivity, electrospun polymer nanofibers can also function as reinforcements57,90. A porous AgNW/PU nanofiber elastic conductor can be prepared with a layer-by-layer structure of nanofibers/nanowires due to interfacial hydrogen bonding57. The resultant nanofiber-based conductor exhibits a conductivity of up to 9190 S/cm, good stretchability of 310% strain, and high cycling durability at 70% strain. The as-prepared conductor also demonstrates good breathability for continuous on-skin electrophysiological signal recording.

a Optical image of the Au/Parylene/PU nanofiber-based device. Scale bar, 2mm. Insets show the schematic structure of the fabricated nanomesh conductor. b Resistance change of a nanomesh conductor from 0 to 30% strain. c Cyclic stretch test under 20% strain (modified from ref. 99, copyright 2019 Springer Nature).

Transparent electrodes

Flexible transparent electrodes, which combine high electrical conductivity, optical transparency, and mechanical flexibility, play a fundamental role in soft electronic applications, including transparent heaters, photovoltaics, supercapacitors, light-emitting diodes, and batteries100. Although transparent conductive oxides are universally used as conducting materials, their brittleness and required high-pressure vacuum processes during fabrication limit their applications in flexible/stretchable electronics101. Considerable efforts have been directed toward manufacturing flexible transparent electrodes with one-dimensional nanowires or nanofibers owing to their outstanding physical properties48,102. Owing to electrospinning, a low-cost and high-throughput method, diverse materials such as metals, polymers, and composites have been manufactured directly or with other techniques to construct flexible/stretchable transparent electrodes69,83,103,104,105,106.

A representative example is a metal nanotrough network-based transparent electrode developed by Cui et al.84. First, water-soluble PVA and PVP are electrospun into polymer nanofibers as templates. Then, a thermal evaporator is employed to deposit metals onto the porous nanofiber sheet. Finally, the transparent electrode is obtained by dissolving the underlying polymer nanofiber support (Fig. 6a). Various materials have been used via this approach to fabricate transparent electrodes, including silicon, indium tin oxide (ITO) and metals, such as gold, silver, copper, platinum, aluminum, chromium, nickel, and their alloys. After the polymer nanofiber is removed, the nanotroughs are found to be connected at junctions and exhibit concave cross-sections (Fig. 6b). The sheet resistance (Rs) values of copper nanotrough networks have the best performance: 2 Ω/sq at T = 90%, 10 Ω/sq at T = 95%, and 17 Ω/sq at T = 97%, comparable to that of state-of-the-art device-grade ITO (Fig. 6c). Furthermore, the nanotrough networks show good adhesion after attaching to flexible substrates such as PET plastic and paper (Fig. 6d)84. After introducing an in-plane sinusoidal wavy structure, an Au nanotrough networks can be stretched to more than 300% strain107. This buckled Au nanotrough electrode exhibits fatigue-free (>100% strain) properties and presents high optical transparency of 91% with a sheet resistance of 10 Ω/sq.

a Schematic of the polymer-nanofiber templating process for fabricating nanotrough networks. b SEM images of a junction between two nanotroughs (right) and the cross-section of a single gold nanotrough (left). c Sheet resistance versus optical transmission (at 550nm) for copper, gold, silver, and aluminum nanotrough networks. d Photographs of ‘conducting paper’, demonstrating the reversible flexibility of nanotrough network-based transparent electrodes (modified from ref. 84, copyright 2013 Springer Nature).

Transparent self-junctioned metal electrodes can also be made by seeding metal ions or nanoparticles onto electrospun polymer nanofibers and subsequently performing electroplating or oxidation105,108,109,110. In addition to thermal evaporation and electroless deposition, the direct coating of functional materials onto electrospun polymer nanofiber scaffolds is also effective in creating percolation networks for transparent electrodes106,111,112. After immersion in a highly concentrated dispersion of single-walled CNTs, the electrospun nylon 6 membrane becomes a conductive transparent film with a sheet resistance of 2100 Ω/sq at T = 77.4%106. These flexible or stretchable transparent electrodes have been demonstrated in applications such as solar cells109,111,113, flexible touch screens84, batteries111, electrophysiological sensors112, and LEDs110,114,115.

Sensors

Various highly sensitive flexible/stretchable sensors have been developed using electrospun nanofibers owing to their high surface area and ultraflexibility. Strain sensors and pressure sensors, the two most studied sensors using electrospun nanofibers, are reviewed in this section.

Strain sensors

Stretchable strain sensors have been extensively developed over the past two decades and have been employed in various applications, such as human activity monitoring and soft robotics116,117. The working mechanism is that mechanical deformations induce electrical responses in terms of resistance, capacitance or voltage118,119. Electrospun nanofiber-based train sensors exhibit lightness, flexibility/stretchability, and gas permeability, all of which are significant in wearable electronic applications. An effective way to fabricate strain sensors from electrospun nanofibers is to decorate or deposit functional materials onto nanofiber scaffolds due to their high surface area79,120,121,122,123,124. A typical example is the use of a hybrid ZnNW/polysteryne (PS) nanofiber network as the functional material of a strain sensor125. The ZnNW/PS nanofiber porous structure is fabricated by attaching ZnO seeds onto electrospun PS nanofibers and subsequently growing ZnO NWs. The fabricated sensor can be stretched up to 50% strain with a gauge factor of ~116 (Fig. 7a–c).

a Schematic fabrication process of ZnO NW/PS nanofibers from electrospun PS nanofibers. b High-resolution SEM image of ZnO NW/PS nanofibers. c Resistance-strain curve of the ZnO NW/PS nanofiber-based strain sensor (modified from ref. 125, copyright 2011 Wiley-VCH). d Photograph showing the nanomesh sensor attached to a fingerprint, demonstrating good conformability. e Microscopic images of nanomeshes on the surface of artificial skin, showing distinguishable sweat pores. f Facial strain monitoring during the speech. The nanomesh-attached face (right side) exhibits skin strain mapping comparable to that of a face (left side) without nanomeshes (Modified from ref. 126, copyright 2020 American Association for the Advancement of Science).

To continuously monitor skin strain without disturbing natural skin motions, Someya et al.126 developed a breathable, ultrathin, and soft nanomesh skin-strain gauge. The nanomeshes were fabricated by reinforcing electrospun PU nanofibers formed by an electrospinning method with extremely thin PDMS. The sensor was ultralightweight (0.012 mg/cm2) and extremely thin (430 nm), which allowed it to adhere to the skin and detect minute skin strains (Fig. 7d). The ultraconformability was also demonstrated by the distinguishable sweat pores shown in Fig. 7e while laminating the nanomeshes onto the surface of artificial skin. The as-fabricated sensor exhibited high mechanical durability (a resistance degradation of <3% after 5000 repetitive stretching and releasing cycles under 60% strain) and excellent sustainability (under 40% strain for 12 h with a <0.053 electrical drift error). The reliable electrical responses were independent of the stretch frequencies, and its thin geometry and softness provided minimum mechanical interference on natural skin motions. Hence, the skin strain could be quantitatively measured without affecting the natural movement of the skin. By attaching the developed nanomesh sensor to the face, they succeeded in measuring mapping facial strains during speech (Fig. 7f). The measured strain from the attached sensors on the right side of the face was asymmetric to that of the left side of the face with black markers. They also succeeded in mapping facial skin strains during a speech even after 3.5 h of wearing the device. This nanomesh sensor is expected to be used in smart facial masks that can accurately recognize facial microexpressions such as joy, anger, sadness, and fear.

Other strategies to fabricate stretchable strain sensors include the following: (1) directly electrospinning polymer nanofibers and carbonizing72,127; (2) directly electrospinning functional nanofibers, such as PVDF nanofibers64,71,128; and (3) adding functional materials to the polymer solution for electrospinning80. When any of these three strategies are used, the alignment, density, and diameter of the electrospun nanofibers are tuned to obtain the best performance of the stretchable strain sensor. Table 1 illustrates examples of electrospun nanofiber-based stretchable strain sensors using the aforementioned strategies.

Pressure sensors

The measurement of small normal pressures is critical to accurately evaluate external stimuli on curvilinear and dynamic surfaces such as human skin and natural tissues129,130,131. Electrospun nanofiber mats have high tolerance for repetitive external pressing due to their porous structures and high flexibility. Therefore, a large number of wearable pressure sensors have been constructed using electrospun nanofibers. Among these sensors, there are four types of working mechanisms: capacitive132, resistive66, triboelectric133, and piezoelectric134. Based on this, electrospun nanofibers are applied as dielectric layers, conductive layers, or electrode materials in pressure sensor assemblies. For example, Zhang et al.135 used carbonized silk nanofibers as a conductive layer and fabricated a resistive pressure sensor. The developed pressure sensor had a rapid response time of <16.7 ms, a low detection limit of only 0.8 Pa, and a sensitivity of up to 34.47 kPa−1. These outstanding performances were attributed to the unique N-doped silk nanofiber mats. To optimize piezoelectric responses, a highly aligned P(VDF-TrFe) nanofiber array has been fabricated into a flexible and freestanding sheet by electrospinning on a fast-rotating collector68. A flexible pressure sensor can be simply formed by adding two electrical contacts at the ends of the as-fabricated sheet, and the resulting pressure sensor can detect pressure signals that are as low as 0.1 Pa. In addition, the device exhibits an excellent response under an extremely low-pressure regime, which suggests its potential utility as a sensor-energy harvesting component for applications in human motion detection and robotics68. Table 2 provides a summary of recently reported electrospun nanofiber-based flexible/stretchable pressure sensors.

Energy harvesting and storage devices

Wearable energy generation and storage devices are prerequisites to implement independent wearable electronic platforms. In this section, we present the development of soft energy harvesting devices (e.g., nanogenerators, batteries) and storage devices such as supercapacitors based on electrospun nanofibers.

Nanogenerators

There has been an increasing demand for renewable energy due to the rapid consumption of fossil fuels as well as environmental issues. Hence, mechanical energy harvesting systems that can convert small-scale energy from vibrations and motions into electrical power have been developed to solve this problem49. To date, there are two major types of nanogenerators: piezoelectric nanogenerators (PENGs) and triboelectric nanogenerators (TENGs). PENGs have attracted extensive attention since 2006 and are mainly fabricated from PVDF-based materials due to their large piezoelectric coefficients136. TENGs were first demonstrated in 2012 by Wang et al., in which they coupled the triboelectric effect and electrostatic induction137,138. With the introduction of piezoelectric, triboelectric, and/or pyroelectric electrospun nanofibers, a flexible/stretchable electronic system can realize self-powered operation with attractive mechanical and electrical performances139,140,141,142,143,144.

For example, a breathable, all-nanofiber TENG has been fabricated for effective mechanical energy harvesting and whole-body physiological signal detection145. The device is composed of a top polylactic-co-glycolic acid (PLGA) triboelectric layer, a bottom PVA nanofiber substrate, and an AgNW layer in between. This one-electrode TENG shows a high power density of 130 mW/m2 and pressure sensitivity of up to 0.011 kPa−1 owing to the high surface area provided by the three-dimensional micro-to-nano hierarchical pores. TENG-based e-skin can be used to monitor whole-body physiological signals with good breathability, biodegradability, and antibacterial properties145. By anchoring piezoelectric barium titanate nanoparticles onto P(VDF-TrFE) nanofibers, the as-achieved PENG exhibits a significantly enhanced output of 6 V and 1.5 μA. The values for the PENG made from only P(VDF-TrFE) membranes are only 1.25 V and 0.6 μA146. Moreover, various pressure/tactile sensors have been developed by piezoelectric and/or triboelectric electrospun nanofibers for manufacturing wearable energy-sustainable electronic devices for monitoring human motion103,134,140,147,148,149,150,151,152.

Batteries

Lithium (Li)-ion batteries play a pivotal role in energy storage systems for fast-growing demands in hybrid/full electric vehicles, portable devices, and power tools153,154. A Li-ion battery consists of a cathode, electrolyte, separator, and Li anode155. The separator is sandwiched between the two electrodes and immersed in the electrolyte. Li is the lightest metal in electrochemical energy storage and has the lowest reduction potential and an excellent theoretical specific capacity of 3860 mAh/g60. Owing to their large surface area, high porosity, and good conductivity, electrospun nanofibers have shown great potential for the development of flexible/stretchable Li-ion batteries44. To date, various electrodes, separators, and electrolytes have been developed using electrospun nanofibers to improve the electrochemical, mechanical, and safety performances of Li-ion batteries156,157,158,159,160.

Free-standing Li2S paper electrodes based on electrospun carbon nanofibers have been fabricated for flexible high-energy Li-ion batteries161. The free-standing conductive electrode also largely lowers the cost and manufacturing complexity of Li2S cathodes. The flexible paper electrode is composed of N-doped carbon nanofibers (NCNFs) decorated with ultrafine Li2S nanoparticles (Fig. 8a–c). These mechanically robust paper electrodes allow a high content of Li2S loading through layer-by-layer stacking. This highly opened but microscopically confined design enhances structural stability, reaction kinetics, and areal specific capacities. In addition, high performance with a high capacity of 520 mAh/g (4.68 mAh/cm2) is maintained with a stable capacity retention of over 65% for 200 cycles when utilizing a very high Li2S loading of 9.0 mg/cm2 (Fig. 8d); additionally, an approximately 100% coulombic efficiency is achieved. Electrodes with a Li2S loading of 6.0 mg/cm2 can deliver high capacities of 650, 540, 505, and 490 mAh/g (3.9, 3.24, 3.03, and 2.94 mAh/cm2, respectively) at current rates of 0.2, 0.5, 0.1, and 2.0C, respectively. The high rate capacity is retained with multilayered Li2S@NCNF electrodes (Fig. 8e, f). The high initial capacity of Li2S@NCNF//Fe3O4 full cells can power an LED array consisting of 11*44 diodes (Fig. 8g). Figure 8h, i shows that the as-obtained prototype battery exhibits excellent flexibility while powering an LED161. Recently, Jeong et al. reported an intrinsically stretchable Li-ion battery that exhibited a high capacity of 91.8 mAh/g at 100% strain using an electrospun poly(styrene-b-butadiene-b-styrene) (SBS) block copolymer nanofiber mat as the separator membrane162. The developed stretchable rechargeable battery was successfully used to power stand-alone intrinsically stretchable electronic device platforms.

a Flexibility and SEM image of the Li2S@NCNF paper electrode. b High-resolution SEM image of the Li2S@NCNF paper electrode. c High-resolution transmission electron microscopy image showing the decoration of single-crystalline Li2S nanoparticles in carbon nanofibers with disordered structures. d Cycling test and coulombic efficiency of Li2S@NCNF electrodes with different Li2S loadings at a current rate of 0.1C. e Rate capacities and f areal specific capacities with different Li2S loadings at current rates ranging from 0.2 to 2.0C. g LED array illuminated by coin-type cells based on the Li2S@NCNF paper electrode. h, i Flexible Li-ion battery based on a Li2S@NCNF paper electrode (modified from ref. 161, copyright 2017 Wiley-VCH).

In addition to Li-ion batteries, other batteries, such as sodium-ion and zinc-air batteries, can also be achieved with electrospun nannofibers163,164,165. For example, by loading S1−xSex on porous carbon nanofibers, a flexible cathode electrode is achieved, which delivers a high reversible capacity of 840 mAh/g after 100 cycles at 0.1 A/g for Li-S batteries and 762 mAh/g after 100 cycles at 0.1 A/g for Na–S batteries166.

Supercapacitors

Supercapacitors, i.e., electrochemical capacitors, are energy storage devices that possess advantageous properties, such as fast charging/discharging capacities, high power and energy densities, long-term cycling, and safe operation167,168. A supercapacitor consists of two electrodes with a sandwiched ion-permeable electrolyte layer/seperator169,170. To integrate a supercapacitor into a soft electronic system, it should maintain high performance under repeated mechanical deformations171,172. Following this target, the development of flexible/stretchable supercapacitors mainly focuses on designing highly flexible/stretchable capacitive materials for electrodes173,174. As a novel class of electrode materials, porous electrospun capacitive nanofibers are able to provide (1) mechanical flexibility, (2) a large surface area accessible to the electrolyte, (3) efficient ion transport kinetics, and (4) structural stability62,160. Consequently, high capacitive performance can be readily realized by engineering the pore size distribution of interconnected nanofibers175,176.

Electrospun carbon nanofiber-based electrodes are one of the most important components of supercapacitors because of their large specific surface area and good conductivity and chemical stability177. Strategies such as dopants, hollow structures, and composites have been applied to enhance electrochemical activity178,179,180. For instance, vanadium (V)/cobalt monoxide (CoO) has been introduced with conductive carbon nanofibers to produce extra reaction sites, accelerate electron transfer, and stabilize the electrode structure with good mechanical flexibility and accessibility for real applications181. VCO/carbon nanofibers are achieved by electrospinning PAN, which is subsequently annealed (carbonization process) (Fig. 9a). The above electrode yields a high areal capacitance of 1.83 F/cm2 at a current density of 8 mA/cm2. A binder-free, nonpolar asymmetric flexible supercapacitor is then assembled with PVA/KOH gel as the electrolyte and separator between the two binder-free VCO/carbon nanofiber electrodes (Fig. 9b). The supercapacitor yields an areal energy density up to 44.2 μWh/cm2 at a power density of 2.8 mW/cm2 (Fig. 9c). The device also exhibits good mechanical flexibility and is able to survive a high bending angle of 180° with a small capacitance decay of 5.5%181.

a SEM characterization of VCO/carbon nanofibers. b Schematic diagram and photograph of the assembled flexible supercapacitor. c Ragone plots of the flexible supercapacitor compared with previously reported values. Inset is a photograph of the three-series supercapacitor powering an LED indicator (modified from ref. 181, copyright 2020 Elsevier). d Configuration of the dynamically stretchable supercapacitor. e Capacitive performance of the dynamic stretching/release (DSR) states. f Stability performance under different strain rates (modified from ref. 182, copyright 2020 Elsevier).

Electrospun nanofiber mats can also be employed as a separator in a supercapacitor182,183. Wei et al. demonstrated a fully stretchable supercapacitor with an electrospun membrane made of PU nanofibers as a separator, buckled SWNT films as electrodes, and an organic electrolyte consisting of tetraethylammonium tetrafluoroborate in propylene carbonate182. The resultant supercapacitor exhibited full stretchability up to 31.5% strain and retained 94.6% capacitance even after 2521 cycles of dynamic stretching and release under a high strain rate of 4.46% strain/s (Fig. 9d–f).

In addition, porous entangled nanofibers can enhance the capacitive performance by loading a high content of active capacitive materials due to the high surface area of these materials184,185. For example, an SWCNT-coated electrospun SBS nanofiber mat has been employed to fabricate a high-performance fully stretchable supercapacitor. The as-obtained supercapacitor delivers a volumetric capacitance of 15.2 F/cm3 at 0.021 A/cm3 and can maintain this performance under strains of up to 40%185. Specifically, an all-textile-based flexible supercapacitor has been fabricated by using electrospun PEDOT nanofibers as electrodes, a PAN electrospun nanofibrous membrane as a separator, and carbon fabric cloths as current collectors186. The as-prepared supercapacitor is totally flexible and demonstrates high cyclability under ambient conditions.

Transistors

A field-effect transistor (FET) is generally regarded as an electrical switch that uses an external electric field to control the charge transport behaviors in a device. It consists of three electrodes (source, drain, and gate); a semiconductor, i.e., an active channel; and a dielectric utilized as a thin insulating layer between the channel and gate electrode187,188. When a voltage is applied at the gate electrode, charge carriers move from the source to the drain to generate a source-drain current. Therefore, by adjusting the gate voltage, the source-drain current can be well controlled189. Flexible/stretchable transistors are of high importance in soft electronic integrations, and are capable of effectively manipulating and processing electrical signals190,191. However, polymer semiconductors made from film-type materials or nanofibril composites usually suffer from degraded charge carrier transport and limited flexibility. These issues can be overcome by the application of electrospun organic semiconducting nanofibers, where charge carrier transport can be enhanced by the preferential orientation of the polymer chains along the longitudinal direction of the fibers. It has been reported that the charge carrier mobility of P3HT electrospun nanofibers is dramatically improved by over 3 orders of magnitude192. In addition, electrospun semiconductors can avoid complex lithography-based patterning procedures by being directly aligned on polymeric substrates.

For instance, a single electrospun semiconducting NW with a diameter of 675 ± 40 nm has been used as an active channel, which is composed of a fused thiophene diketopyrrolopyrrole-based polymer semiconductor and high-molecular-weight polyethylene oxide as both the molecular binder and deformability enhancer (Fig. 10a)53. SBS elastomer films are applied as stretchable substrates for the transistor. CNT percolating networks are transferred to SBS films to fabricate S/D electrodes. Then, a straight semiconducting NW was transferred on top of the S/D electrodes. The transistor fabrication is completed by subsequently transferring nonionic SEBS dielectric and eutectic gallium-indium gate electrodes on the NW. The original mobility and maximum drain current of the device are 0.78 ± 0.21 cm2/Vs and −6.7 ± 1.88 nA at a gate/drain voltage of −100 V, respectively. When stretching along the channel length structure to 100% strain, the elongated NWs become wrinkled after release. Thus, both the mobility and drain current vary by <20% during cyclic stretching. In contrast, along the perpendicular direction, both the mobility and drain current remain almost the same up to a strain of 100%. The reason is that NWs do not actually experience stress but wrinkle in the channel length direction. By applying prestrain to the NWs to obtain a serpentine geometry, the mechanical durability of the transistor can be largely enhanced (Fig. 10b). The electrical performance can be easily maintained when stretched in both the length and width directions to ≥100% strain (Fig. 10c–e). When attached to a rubber balloon, the deformable transistor can survive a three-dimensional volume change of 1735% with a constant current output.

a Schematic illustration of the semiconducting NW FET. Top left: chemical structure of the semiconducting NW. Top right: microscopy images of the semiconducting NW. b Schematic illustration of the fabrication process of a stretchable transistor with the serpentine semiconducting NW. Insets are microscopy images of the semiconducting NW before and after stretching. Mobility and maximum drain current under c various strains and d repeated stretching cycles of 100% strain in the channel length direction. e Mobility and maximum drain current under a width-directional strain and after strain release at various strains (modified from ref. 53, copyright 2018 Wiley-VCH).

In addition to single nanofibers50,51,54,193, entangled or aligned electrospun semiconductor nanofibers are applicable as channel materials52,194. An entirely stretchable transistor has been developed by using electrospun SBS nanofibers as the substrate, P3HT nanofibers as the active channel, an ion-gel dielectric layer, S/D electrodes, and gate materials made of Au-nanosheet networks (Fig. 11a)65. The SBS nanofiber mat has a thickness of ~500 μm, and the average diameter of a nanofiber is ~300 nm. Au nanosheets are first transferred to PDMS and then to SBS membranes to form S/D electrodes with a size of 100*800 μm. The active channel is fabricated by directly collecting electrospun P3HT nanofiber (diameter: 2.5 μm) sheets between the S/D electrodes. The dielectric layer is also made from stretchable materials, namely, ion gels, and bridges the S/D electrodes. Finally, the Au-nanosheet network is transferred to the ion-gel dielectric layer to form a gate electrode (Fig. 11b). Figure 11c shows that a 15*17 transistor array can be stably operated up to 70% strain. The device mobility experiences a light decrease to 15.5 cm2/Vs after 500 cycles under 70% strain and recovers to 18 cm2/Vs after 1500 cycles of stretching and releasing under 70% strain (Fig. 11d). This decrease may be because of the change in position of P3HT fibers under repeated stretching. Notably, the on-off current and threshold voltage remain the same during the cycling test.

a Schematic illustration of the transistor. The S/D electrodes made of Au nanosheets are transferred to the electrospun SBS nanofiber mat, and P3HT electrospun nanofibers are directly collected in between. The ion-gel dielectric layer is formed and bridges the S/D electrodes. The gate electrode is then fabricated by transferring the Au nanosheets to the dielectric layer. b SEM images of the device. c Photograph showing the device array at a strain of 70%. d Changes in the transfer curves under repeated stretching at 70% strain (modified from ref. 65, copyright 2014 Wiley-VCH).

Other applications

Other applications, such as flexible/stretchable heaters195, photodetectors196, chemical sensors88,197, optically encoded sensors198, solar cells199, and organic LEDs114,115, have also been developed with electrospun nanofibers. For example, a fully transparent and flexible ultraviolet-visible photodetector has been fabricated using the photoelectric effect of electrospun ZnO/CdO (cadmium oxide) nanofibers200. ZnO/CdO nanofibers have been fabricated by fusing ZnO and CdO nanoparticles into individual nanofibers. These highly aligned ZnO/CdO nanofibers, i.e., channel materials, can be exposed to light and induce a change in conductivity. The hybrid photodetector shows a transparency of up to 95% in the spectral range of 400–800 nm and a good mechanical durability of 200 bending cycles, as shown in Fig. 12a–c. The as-achieved fibrous membranes can be used as chemiresistors for wearable chemical sensing applications by incorporating CNTs or graphene on electrospun fibrous scaffolds197,201. A stretchable and highly sensitive chemical sensor has been manufactured by utilizing multilayered PU nanofiber/RGO networks (Fig. 12d)201. The conductance of the device increases upon exposure to NO2 (oxidizing gas) and decreases upon exposure to NH3 (reducing gas). Here, RGO is the p-type semiconductor, while NO2 molecules are the electron acceptors and NH3 molecules are the electron donors. The device exhibits a responsivity of ~40% toward a 2.5 ppm exposure of NO2 (Fig. 12e). The current responses to NO2 exposure show very small changes even after 5000 cyclic stretching/releasing tests at 50% strain (Fig. 12f–h)201.

a Photograph of the transparent and flexible ZnO nanofiber array photodetector array. b Microscopic image of the device. Scale bar: 50μm. c Electrical responses at the 1st and 200th bending cycles (modified from ref. 200, copyright 2015 Wiley-VCH). d Schematic structure of the R-GO/PU nanofiber-based chemical sensor. e Electrical responses of a rigid RGO device under exposure to 2.5 ppm NO2 and 25 ppm NH3 diluted in dry air. f Electrical response of the chemical sensor under 2.5 ppm NO2 at strains of 0, 30, and 50%. Test C denotes 5000 cycles of 50% strain. g Electrical responses at different concentrations of NO2 at room temperature. h Electrical responses at different concentrations of NO2 under 50% strain after 5000 stretching cycles (modified from ref. 201, copyright 2017 IOPscience).

Summary and outlook

In this review, we first introduced the basic electrospinning technique for nanofiber fabrication. The advantageous electrical and mechanical properties of electrospun nanofibers include high transparency, good conductivity, a large surface area, diverse porous structures, excellent flexibility and/or stretchability, a one-dimensional nanostructure, and easy scale-up, all of which provide strong benefits in the development of high-performance flexible/stretchable electronics. Generally, there are six strategies for the design of soft electronic devices: (1) single semiconducting nanofibers, (2) entangled porous nanofiber sheets, (3) aligned nanofiber arrays, (4) yarn, (5) temporary templates, and (6) reinforcement. Both single nanofibers and assembled nanofibers have been proven to be superior candidates for use in soft electronic applications. We then presented recent advances in electrospun nanofiber-based soft electronic devices, such as flexible/stretchable conductors, transparent electrodes, strain sensors, pressure sensors, nanogenerators, supercapacitors, batteries, and transistors. Nevertheless, to approach cost-effective, daily life applications, there are several remaining challenges regarding nanofiber fabrication and assembly, device performance, and system integration.

-

(1)

It is difficult to electrospin organic conducting and semiconducting polymers, which are commonly used for conventional transistors, energy devices, and optoelectronics. Although some electrospun conducting (e.g., PPy and PANI) and functional (e.g., PEDOT: PSS and P3HT) nanofibers have been utilized for soft electronic devices, spinnable active polymers are still limited. The basic requirements for solution electrospinning are a sufficiently high molecular weight of the polymer and an appropriate solvent. The electrical conductivity of the polymer also influences the electrospinnability. Hence, advances in lowering electrospinning requirements and developing novel polymers and polymer blends are highly desired to achieve electrospinnable organic functional polymers for flexible/stretchable electronic applications.

-

(2)

It is still crucial to improve the flexibility and stretchability of electrospun nanofibers. Existing electrospun nanofiber-based soft electronics endow a certain degree of mechanical flexibility owing to the inherent flexibility of nanofibers. However, some electrospun nanomaterials, such as carbon nanofibers and metallic oxide nanofibers, have limited mechanical flexibility, resulting in inferior mechanical properties of the as-fabricated devices. It is necessary to precisely control the density, orientation, and porosity of the nanofibers in an effort to improve the flexibility/stretchability while maintaining the electrical performance of the devices. In addition, different nanofiber assembly methods should be combined, and new device assembly techniques are needed to realize soft electronics with desirable flexibility/stretchability.

-

(3)

As fundamental breakthroughs in individual electrospun nanofiber-based soft electronic devices have already been achieved over the past 10 years, these successes will lead to particularly promising achievements when combining two or more of the as-developed devices. Due to tremendous advancements in the flexible/stretchable electronic field, it is highly necessary to develop integrated and portable soft electronics. An appropriate combination of sensors and energy harvesting and storage devices can achieve a fully flexible/stretchable system based on electrospun nanofibers. For instance, a textile format, self-powered integrated wearable system can be prepared by using as-fabricated yarn sensors80, all-textile flexible supercapacitors186, and all-nanofiber-based ultralight TENG151. We believe that the assembly of existing components into smart soft systems will bring new opportunities both in the market and in academic research.

References

Someya, T. & Amagai, M. Toward a new generation of smart skins. Nat. Biotechnol. 37, 382–388 (2019).

Wang, C., Wang, C., Huang, Z. & Xu, S. Materials and structures toward soft electronics. Adv. Mater. 30, 1801368 (2018).

Choi, M. et al. Full-color active-matrix organic light-emitting diode display on human skin based on a large-area MoS2 backplane. Sci. Adv. 6, eabb5898 (2020).

Sekitani, T. et al. Stretchable active-matrix organic light-emitting diode display using printable elastic conductors. Nat. Mater. 8, 494–499 (2009).

Ho, M. D. et al. Percolating network of ultrathin gold nanowires and silver nanowires toward “invisible” wearable sensors for detecting emotional expression and apexcardiogram. Adv. Funct. Mater. 27, 1700845 (2017).

Koh, A. et al. A soft, wearable microfluidic device for the capture, storage, and colorimetric sensing of sweat. Sci. Transl. Med. 8, 366ra165 (2016).

Someya, T., Bao, Z. & Malliaras, G. G. The rise of plastic bioelectronics. Nature 540, 379–385 (2016).

Tao, W., Liu, T., Zheng, R. & Feng, H. Gait analysis using wearable sensors. Sensors 12, 2255–2283 (2012).

Lee, Y. et al. Graphene-based stretchable/wearable self-powered touch sensor. Nano Energy 62, 259–267 (2019).

Chortos, A., Liu, J. & Bao, Z. Pursuing prosthetic electronic skin. Nat. Mater. 15, 937–950 (2016).

Ramuz, M., Tee, B. C. K., Tok, J. B. H. & Bao, Z. Transparent, optical, pressure‐sensitive artificial skin for large‐area stretchable electronics. Adv. Mater. 24, 3223–3227 (2012).

Park, S. et al. Self-powered ultra-flexible electronics via nano-grating-patterned organic photovoltaics. Nature 561, 516–521 (2018).

Fukuda, K., Yu, K. & Someya, T. The future of flexible organic solar cells. Adv. Energy Mater. https://doi.org/10.1002/aenm.202000765 (2020).

Park, S. I. et al. Soft, stretchable, fully implantable miniaturized optoelectronic systems for wireless optogenetics. Nat. Biotechnol. 33, 1280–1286 (2015).

Song, Y., Min, J. & Gao, W. Wearable and implantable electronics: moving toward precision therapy. ACS Nano. 13, 12280–12286 (2019).

Rogers, J. A., Someya, T. & Huang, Y. Materials and mechanics for stretchable electronics. Science 327, 1603–1607 (2010).

Wagner, S. & Bauer, S. Materials for stretchable electronics. MRS Bull. 37, 207–213 (2012).

Wang, Y., Gong, S., Wang, S. J., Simon, G. P. & Cheng, W. Volume-invariant ionic liquid microbands as highly durable wearable biomedical sensors. Mater. Horiz. 3, 208–213 (2016).

Dickey, M. D. Stretchable and soft electronics using liquid metals. Adv. Mater. 29, 1606425 (2017).

Yao, S. & Zhu, Y. Nanomaterial‐enabled stretchable conductors: strategies, materials and devices. Adv. Mater. 27, 1480–1511 (2015).

Wang, Y. et al. Standing enokitake-like nanowire films for highly stretchable elastronics. ACS Nano. 12, 9742–9749 (2018).

Yao, S., Swetha, P. & Zhu, Y. Nanomaterial‐enabled wearable sensors for healthcare. Adv. Healthc. Mater. 7, 1700889 (2018).

Choi, S., Lee, H., Ghaffari, R., Hyeon, T. & Kim, D. H. Recent advances in flexible and stretchable bio‐electronic devices integrated with nanomaterials. Adv. Mater. 28, 4203–4218 (2016).

Huang, Q. & Zhu, Y. Printing conductive nanomaterials for flexible and stretchable electronics: A review of materials, processes, and applications. Adv. Mater. Technol. 4, 1800546 (2019).

Kim, D.-H., Lu, N., Ghaffari, R. & Rogers, J. A. Inorganic semiconductor nanomaterials for flexible and stretchable bio-integrated electronics. NPG Asia Mater. 4, e15 (2012).

Wang, Y. et al. Unconventional Janus properties of enokitake-like gold nanowire films. ACS Nano. 12, 8717–8722 (2018).

Ding, J. et al. Electrospun polymer biomaterials. Prog. Polym. Sci. 90, 1–34 (2019).

Wu, T. et al. Resorbable polymer electrospun nanofibers: History, shapes and application for tissue engineering. Chin. Chem. Lett. 31, 617–625 (2020).

Xu, S.-C. et al. A battery-operated portable handheld electrospinning apparatus. Nanoscale 7, 12351–12355 (2015).

Cho, H., Min, S. Y. & Lee, T. W. Electrospun organic nanofiber electronics and photonics. Macromol. Mater. Eng. 298, 475–486 (2013).

Wang, X. et al. Tactile-sensing based on flexible PVDF nanofibers via electrospinning: a review. Sensors 18, 330 (2018).

Santangelo, S. Electrospun nanomaterials for energy applications: recent advances. Appl. Sci. 9, 1049 (2019).

Wang, B. et al. Flexible and stretchable metal oxide nanofiber networks for multimodal and monolithically integrated wearable electronics. Nat. Commun. 11, 1–11 (2020).

Ramaseshan, R., Sundarrajan, S., Jose, R. & Ramakrishna, S. Nanostructured ceramics by electrospinning. J. Appl. Phys. 102, 7 (2007).

Long, Y.-Z., Yu, M., Sun, B., Gu, C.-Z. & Fan, Z. Recent advances in large-scale assembly of semiconducting inorganic nanowires and nanofibers for electronics, sensors and photovoltaics. Chem. Soc. Rev. 41, 4560–4580 (2012).

Liu, Z., Xu, J., Chen, D. & Shen, G. Flexible electronics based on inorganic nanowires. Chem. Soc. Rev. 44, 161–192 (2015).

Lee, Y., Zhou, H. & Lee, T.-W. One-dimensional conjugated polymer nanomaterials for flexible and stretchable electronics. J. Mater. Chem. C 6, 3538–3550 (2018).

Liu, Q., Ramakrishna, S. & Long, Y.-Z. Electrospun flexible sensor. J. Semicond. 40, 111603 (2019).

Fang, J., Wang, X. & Lin, T. Functional applications of electrospun nanofibers. Nanofibers-Prod., Prop. Funct. Appl. 14, 287–302 (2011).

Navarro-Pardo, F., Martinez-Hernandez, A. L. & Velasco-Santos, C. Carbon nanotube and graphene based polyamide electrospun nanocomposites: a review. J. Nanomater. 2016, 3182761 (2016).

Thenmozhi, S., Dharmaraj, N., Kadirvelu, K. & Kim, H. Y. Electrospun nanofibers: New generation materials for advanced applications. Mat. Sci. Eng. B-Adv. 217, 36–48 (2017).

Wendorff, J. H., Agarwal, S. & Greiner, A. Electrospinning: Materials, Processing, and Applications. (John Wiley & Sons, 2012).

Luzio, A., Canesi, E. V., Bertarelli, C. & Caironi, M. Electrospun polymer fibers for electronic applications. Materials 7, 906–947 (2014).

Xue, J., Wu, T., Dai, Y. & Xia, Y. Electrospinning and electrospun nanofibers: Methods, materials, and applications. Chem. Rev. 119, 5298–5415 (2019).

Schiffman, J. D. & Schauer, C. L. A review: electrospinning of biopolymer nanofibers and their applications. Polym. Rev. 48, 317–352 (2008).

Choi, S. J. et al. Electrospun nanostructures for high performance chemiresistive and optical sensors. Macromol. Mater. Eng. 302, 1600569 (2017).

Lee, J. K. Y. et al. Polymer-based composites by electrospinning: Preparation & functionalization with nanocarbons. Prog. Polym. Sci. 86, 40–84 (2018).

Sun, B. et al. Recent advances in flexible and stretchable electronic devices via electrospinning. J. Mater. Chem. C 2, 1209–1219 (2014).

Gong, M., Zhang, L. & Wan, P. Polymer nanocomposite meshes for flexible electronic devices. Prog. Polym. Sci. https://doi.org/10.1016/j.progpolymsci.2020.101279 (2020).

Manuelli, A., Persano, L. & Pisignano, D. Flexible organic field-effect transistors based on electrospun conjugated polymer nanofibers with high bending stability. Org. Electron. 15, 1056–1061 (2014).

Lee, M. Y. et al. Highly flexible organic nanofiber phototransistors fabricated on a textile composite for wearable photosensors. Adv. Funct. Mater. 26, 1445–1453 (2016).

Lee, S. W. et al. Periodic array of polyelectrolyte-gated organic transistors from electrospun poly(3-hexylthiophene) nanofibers. Nano Lett. 10, 347–351 (2010).

Lee, Y. et al. Deformable organic nanowire field‐effect transistors. Adv. Mater. 30, 1704401 (2018).

Chen, J. Y. et al. Electrospinning-induced elastomeric properties of conjugated polymers for extremely stretchable nanofibers and rubbery optoelectronics. J. Mater. Chem. C 8, 873–882 (2020).

Zhu, B., Gong, S. & Cheng, W. Softening gold for elastronics. Chem. Soc. Rev. 48, 1668–1711 (2019).

Miyamoto, A. et al. Inflammation-free, gas-permeable, lightweight, stretchable on-skin electronics with nanomeshes. Nat. Nanotechnol. 12, 907 (2017).

Jiang, Z. et al. Highly stretchable metallic nanowire networks reinforced by the underlying randomly distributed elastic polymer nanofibers via interfacial adhesion improvement. Adv. Mater. 31, 1903446 (2019).

Nayeem, M. O. G. et al. All-nanofiber–based, ultrasensitive, gas-permeable mechanoacoustic sensors for continuous long-term heart monitoring. Proc. Natl Acad. Sci. USA 117, 7063–7070 (2020).

Brown, M. S. et al. Electronic‐ECM: a permeable microporous elastomer for an advanced bio-integrated continuous sensing platform. Adv. Mater. Technol., https://doi.org/10.1002/admt.202000242 (2020).

Peng, S. & Ilango, P. R. in Electrospinning of Nanofibers for Battery Applications 101–120 (Springer, 2020).

Liu, M. et al. A review: electrospun nanofiber materials for lithium‐sulfur batteries. Adv. Funct. Mater. 29, 1905467 (2019).

Zhang, F. et al. Flexible films derived from electrospun carbon nanofibers incorporated with Co3O4 hollow nanoparticles as self‐supported electrodes for electrochemical capacitors. Adv. Funct. Mater. 23, 3909–3915 (2013).

Boubée de Gramont, F. et al. Highly stretchable electrospun conducting polymer nanofibers. Appl. Phys. Lett. 111, 093701 (2017).

Yu, G.-F. et al. Patterned, highly stretchable and conductive nanofibrous PANI/PVDF strain sensors based on electrospinning and in situ polymerization. Nanoscale 8, 2944–2950 (2016).

Shin, M. et al. Highly stretchable polymer transistors consisting entirely of stretchable device components. Adv. Mater. 26, 3706–3711 (2014).

Gao, Q., Meguro, H., Okamoto, S. & Kimura, M. Flexible tactile sensor using the reversible deformation of poly(3-hexylthiophene) nanofiber assemblies. Langmuir 28, 17593–17596 (2012).

Wang, X. et al. A highly stretchable transparent self‐powered triboelectric tactile sensor with metallized nanofibers for wearable electronics. Adv. Mater. 30, 1706738 (2018).

Persano, L. et al. High performance piezoelectric devices based on aligned arrays of nanofibers of poly (vinylidenefluoride-co-trifluoroethylene). Nat. Commun. 4, 1–10 (2013).

Fuh, Y.-K. & Lien, L.-C. Pattern transfer of aligned metal nano/microwires as flexible transparent electrodes using an electrospun nanofiber template. Nanotechnology 24, 055301 (2013).

Wang, A., Hu, M., Zhou, L. & Qiang, X. Self-powered wearable pressure sensors with enhanced piezoelectric properties of aligned P(VDF-TrFE)/MWCNT composites for monitoring human physiological and muscle motion signs. Nanomaterials 8, 1021 (2018).

Wu, C.-M., Chou, M.-H. & Zeng, W.-Y. Piezoelectric response of aligned electrospun polyvinylidene fluoride/carbon nanotube nanofibrous membranes. Nanomaterials 8, 420 (2018).

Lee, J. H. et al. Highly aligned, anisotropic carbon nanofiber films for multidirectional strain sensors with exceptional selectivity. Adv. Funct. Mater. 29, 1901623 (2019).

Stoppa, M. & Chiolerio, A. Wearable electronics and smart textiles: a critical review. Sensors 14, 11957–11992 (2014).

Zhao, Y. et al. Highly stretchable and strain-insensitive fiber-based wearable electrochemical biosensor to monitor glucose in the sweat. Anal. Chem. 91, 6569–6576 (2019).

Wang, R. et al. Stretchable gold fiber-based wearable electrochemical sensor toward pH monitoring. J. Mater. Chem. B. 8, 3655–3660 (2020).

Xu, Q., Liu, H., Zhong, X., Jiang, B. & Ma, Z.-j Permeable weldable elastic fiber conductor for wearable electronics. ACS Appl. Mater. Interfaces 12, 36609–36619 (2020).

Yun, Y. J., Hong, W. G., Kim, W. J., Jun, Y. & Kim, B. H. A novel method for applying reduced graphene oxide directly to electronic textiles from yarns to fabrics. Adv. Mater. 25, 5701–5705 (2013).

Guan, X. et al. Carbon nanotubes-adsorbed electrospun PA66 nanofiber bundles with improved conductivity and robust flexibility. ACS Appl. Mater. Interfaces 8, 14150–14159 (2016).

Qi, K. et al. Weavable and stretchable piezoresistive carbon nanotubes-embedded nanofiber sensing yarns for highly sensitive and multimodal wearable textile sensor. Carbon 170, 464–476 (2020).

Yan, T., Wang, Z., Wang, Y.-Q. & Pan, Z.-J. Carbon/graphene composite nanofiber yarns for highly sensitive strain sensors. Mater. Des. 143, 214–223 (2018).

Li, Y. et al. Continuously prepared highly conductive and stretchable SWNT/MWNT synergistically composited electrospun thermoplastic polyurethane yarns for wearable sensing. J. Mater. Chem. C 6, 2258–2269 (2018).

Pan, J. et al. Highly sensitive and durable wearable strain sensors from a core-sheath nanocomposite yarn. Compos. B Eng. 183, 107683 (2020).

He, T., Xie, A., Reneker, D. H. & Zhu, Y. A tough and high-performance transparent electrode from a scalable and transfer-free method. ACS Nano 8, 4782–4789 (2014).

Wu, H. et al. A transparent electrode based on a metal nanotrough network. Nat. Nanotechnol. 8, 421 (2013).

Okutani, C., Yokota, T. & Someya, T. Interconnected heat-press-treated gold nanomesh conductors for wearable sensors. ACS Appl. Nano Mater. 3, 1848–1854 (2020).

Mersha, A. & Fujikawa, S. Mechanical reinforcement of free-standing polymeric nanomembranes via aluminosilicate nanotube scaffolding. ACS Appl. Polym. Mater. 1, 112–117 (2019).

Esawi, A. M. & Farag, M. M. Carbon nanotube reinforced composites: potential and current challenges. Mater. Des. 28, 2394–2401 (2007).

Hanif, A. et al. A skin‐inspired substrate with spaghetti‐like multi‐nanofiber network of stiff and elastic components for stretchable electronics. Adv. Funct. Mater. 30, 2003540 (2020).

Hanif, A., Trung, T. Q., Siddiqui, S., Toi, P. T. & Lee, N.-E. Stretchable, transparent, tough, ultrathin, and self-limiting skin-like substrate for stretchable electronics. ACS Appl. Mater. Interfaces 10, 27297–27307 (2018).

Jin, H. et al. Highly durable nanofiber-reinforced elastic conductors for skin-tight electronic textiles. ACS Nano 13, 7905–7912 (2019).

Lacour, S. P., Wagner, S., Huang, Z. & Suo, Z. Stretchable gold conductors on elastomeric substrates. Appl. Phys. Lett. 82, 2404–2406 (2003).

Ge, J. et al. Stretchable conductors based on silver nanowires: improved performance through a binary network design. Angew. Chem. Int. 52, 1654–1659 (2013).

Matsuhisa, N., Chen, X., Bao, Z. & Someya, T. Materials and structural designs of stretchable conductors. Chem. Soc. Rev. 48, 2946–2966 (2019).

Cheng, W., Simon, G. P. & Wang, Y. (Google Patents, 2020).

Jin, H. et al. Enhancing the performance of stretchable conductors for e‐textiles by controlled ink permeation. Adv. Mater. 29, 1605848 (2017).

Tang, P. et al. Intrinsically stretchable and shape memory conducting nanofiber for programmable flexible electronic films. ACS Appl. Mater. Interfaces 11, 48202–48211 (2019).

Presser, V. et al. Flexible nano‐felts of carbide‐derived carbon with ultra‐high power handling capability. Adv. Energy Mater. 1, 423–430 (2011).

Tai, Z., Yan, X., Lang, J. & Xue, Q. Enhancement of capacitance performance of flexible carbon nanofiber paper by adding graphene nanosheets. J. Power Sources 199, 373–378 (2012).

Lee, S. et al. Ultrasoft electronics to monitor dynamically pulsing cardiomyocytes. Nat. Nanotechnol. 14, 156–160 (2019).

Kim, S. & Lee, J.-L. Design of dielectric/metal/dielectric transparent electrodes for flexible electronics. J. Photon. Energy 2, 021215 (2012).

Langley, D. et al. Flexible transparent conductive materials based on silver nanowire networks: a review. Nanotechnology 24, 452001 (2013).

Sannicolo, T. et al. Metallic nanowire‐based transparent electrodes for next generation flexible devices: a review. Small 12, 6052–6075 (2016).

Guo, W. et al. Wireless piezoelectric devices based on electrospun PVDF/BaTiO3 NW nanocomposite fibers for human motion monitoring. Nanoscale 10, 17751–17760 (2018).

Hsu, P.-C. et al. Passivation coating on electrospun copper nanofibers for stable transparent electrodes. ACS Nano 6, 5150–5156 (2012).

Hsu, P.-C. et al. Electrolessly deposited electrospun metal nanowire transparent electrodes. J. Am. Chem. Soc. 136, 10593–10596 (2014).

Bak, H., Cho, S. Y., Yun, Y. S. & Jin, H.-J. Electrically conductive transparent films based on nylon 6 membranes and single-walled carbon nanotubes. Curr. Appl. Phys. 10, S468–S472 (2010).

Huang, S., Liu, Y., Guo, C. F. & Ren, Z. A highly stretchable and fatigue‐free transparent electrode based on an in‐plane buckled Au nanotrough network. Adv. Electron. Mater. 3, 1600534 (2017).

An, S. et al. Self‐junctioned copper nanofiber transparent flexible conducting film via electrospinning and electroplating. Adv. Mater. 28, 7149–7154 (2016).

Yang, X. et al. Large-scale stretchable semiembedded copper nanowire transparent conductive films by an electrospinning template. ACS Appl. Mater. Interfaces 9, 26468–26475 (2017).

Jiang, D.-H. et al. Facile preparation of Cu/Ag core/shell electrospun nanofibers as highly stable and flexible transparent conductive electrodes for optoelectronic devices. ACS Appl. Mater. Interfaces 11, 10118–10127 (2019).

Liu, S. et al. A flexible TiO2 (B)‐based battery electrode with superior power rate and ultralong cycle life. Adv. Mater. 25, 3462–3467 (2013).

Qiu, J. et al. A bioinspired, durable and non-disposable transparent graphene skin-electrode for electrophysiological signal detection. ACS Mater. Lett. 2, 999–1007 (2020).

Wu, H. et al. Electrospun metal nanofiber webs as high-performance transparent electrode. Nano lett. 10, 4242–4248 (2010).

Choi, J. et al. Ag fiber/IZO composite electrodes: improved chemical and thermal stability and uniform light emission in flexible organic light-emitting diodes. Sci. Rep. 9, 1–7 (2019).

Choi, J. et al. Junction‐free electrospun Ag fiber electrodes for flexible organic light‐emitting diodes. Small 14, 1702567 (2018).

Lu, Y., Biswas, M. C., Guo, Z., Jeon, J.-W. & Wujcik, E. K. Recent developments in bio-monitoring via advanced polymer nanocomposite-based wearable strain sensors. Biosens. Bioelectron. 123, 167–177 (2019).

Yamada, T. et al. A stretchable carbon nanotube strain sensor for human-motion detection. Nat. Nanotechnol. 6, 296 (2011).

Ryu, S. et al. Extremely elastic wearable carbon nanotube fiber strain sensor for monitoring of human motion. ACS Nano 9, 5929–5936 (2015).

Ma, Z. et al. Liquid-wetting-solid strategy to fabricate stretchable sensors for human-motion detection. ACS Sens. 1, 303–311 (2016).

Qi, K. et al. A highly stretchable nanofiber-based electronic skin with pressure-, strain-, and flexion-sensitive properties for health and motion monitoring. ACS Appl. Mater. Interfaces 9, 42951–42960 (2017).

Gao, J. et al. Electrically conductive and fluorine free superhydrophobic strain sensors based on SiO2/graphene-decorated electrospun nanofibers for human motion monitoring. Chem. Eng. J. 373, 298–306 (2019).

Wang, Y. et al. Flexible electrically resistive-type strain sensors based on reduced graphene oxide-decorated electrospun polymer fibrous mats for human motion monitoring. Carbon 126, 360–371 (2018).

Park, M., Im, J., Park, J. & Jeong, U. Micropatterned stretchable circuit and strain sensor fabricated by lithography on an electrospun nanofiber mat. ACS Appl. Mater. Interfaces 5, 8766–8771 (2013).

Wang, N. et al. A tunable strain sensor based on a carbon nanotubes/electrospun polyamide 6 conductive nanofibrous network embedded into poly (vinyl alcohol) with self-diagnosis capabilities. J. Mater. Chem. C 5, 4408–4418 (2017).

Xiao, X. et al. High‐strain sensors based on ZnO nanowire/polystyrene hybridized flexible films. Adv. Mater. 23, 5440–5444 (2011).

Wang, Y. et al. A durable nanomesh on-skin strain gauge for natural skin motion monitoring with minimum mechanical constraints. Sci. Adv. 6, eabb7043 (2020).

Ding, Y., Yang, J., Tolle, C. R. & Zhu, Z. Highly stretchable strain sensor based on electrospun carbon nanofibers for human motion monitoring. RSC Adv. 6, 79114–79120 (2016).

Cao, R., Zhao, S. & Li, C. Free deformable nanofibers enhanced tribo-sensors for sleep and tremor monitoring. ACS Appl. Electron. Mater. 1, 2301–2307 (2019).

Lee, S. et al. A transparent bending-insensitive pressure sensor. Nat. Nanotechnol. 11, 472–478 (2016).

Dagdeviren, C. et al. Conformable amplified lead zirconate titanate sensors with enhanced piezoelectric response for cutaneous pressure monitoring. Nat. Commun. 5, 1–10 (2014).

Shao, Q. et al. High‐performance and tailorable pressure sensor based on ultrathin conductive polymer film. Small 10, 1466–1472 (2014).

Zhao, S. et al. 3D dielectric layer enabled highly sensitive capacitive pressure sensors for wearable electronics. ACS Appl. Mater. Interfaces 12, 32023–32030 (2020).

Lou, M. et al. Hierarchically rough structured and self-powered pressure sensor textile for motion sensing and pulse monitoring. ACS Appl. Mater. Interfaces 12, 1597–1605 (2019).

Mandal, D., Yoon, S. & Kim, K. J. Origin of piezoelectricity in an electrospun poly (vinylidene fluoride‐trifluoroethylene) nanofiber web‐based nanogenerator and nano‐pressure sensor. Macromol. Rapid Commun. 32, 831–837 (2011).

Wang, Q., Jian, M., Wang, C. & Zhang, Y. Carbonized silk nanofiber membrane for transparent and sensitive electronic skin. Adv. Funct. Mater. 27, 1605657 (2017).

Pi, Z., Zhang, J., Wen, C., Zhang, Z.-b. & Wu, D. Flexible piezoelectric nanogenerator made of poly(vinylidenefluoride-co-trifluoroethylene)(PVDF-TrFE) thin film. Nano Energy 7, 33–41 (2014).

Wu, C., Wang, A. C., Ding, W., Guo, H. & Wang, Z. L. Triboelectric nanogenerator: a foundation of the energy for the new era. Adv. Energy Mater. 9, 1802906 (2019).

Liu, W. et al. Integrated charge excitation triboelectric nanogenerator. Nat. Commun. 10, 1–9 (2019).

You, M.-H. et al. A self-powered flexible hybrid piezoelectric–pyroelectric nanogenerator based on non-woven nanofiber membranes. J. Mater. Chem. A 6, 3500–3509 (2018).

Ji, S. H., Lee, W. & Yun, J. S. All-in-one piezo-triboelectric energy harvester module based on piezoceramic nanofibers for wearable devices. ACS Appl. Mater. Interfaces 12, 18609–18616 (2020).

Qin, Z. et al. Flexible Janus electrospun nanofiber films for wearable triboelectric nanogenerator. Adv. Mater. Technol. 5, 1900859 (2019).

Qiu, H.-J. et al. A calibration-free self-powered sensor for vital sign monitoring and finger tap communication based on wearable triboelectric nanogenerator. Nano Energy 58, 536–542 (2019).

Wang, X. et al. Bionic single-electrode electronic skin unit based on piezoelectric nanogenerator. Acs Nano 12, 8588–8596 (2018).

Lu, L., Yang, B., Zhai, Y. & Liu, J. Electrospinning core-sheath piezoelectric microfibers for self-powered stitchable sensor. Nano Energy 76, 104966 (2020).

Peng, X. et al. A breathable, biodegradable, antibacterial, and self-powered electronic skin based on all-nanofiber triboelectric nanogenerators. Sci. Adv. 6, eaba9624 (2020).

Guan, X., Xu, B. & Gong, J. Hierarchically architected polydopamine modified BaTiO3@P(VDF-TrFE) nanocomposite fiber mats for flexible piezoelectric nanogenerators and self-powered sensors. Nano Energy 70, 104516 (2020).

Deng, W. et al. Cowpea-structured PVDF/ZnO nanofibers based flexible self-powered piezoelectric bending motion sensor towards remote control of gestures. Nano Energy 55, 516–525 (2019).

Zhao, G. et al. Ultrathin biocompatible electrospun fiber films for self-powered human motion sensor. Int. J. Pr. Eng. Man-GT. https://doi.org/10.1007/s40684-020-00246-y (2020).

Gheibi, A., Latifi, M., Merati, A. A. & Bagherzadeh, R. Piezoelectric electrospun nanofibrous materials for self-powering wearable electronic textiles applications. J. Polym. Res. 21, 469 (2014).

Garain, S., Jana, S., Sinha, T. K. & Mandal, D. Design of in situ poled Ce3+-doped electrospun PVDF/graphene composite nanofibers for fabrication of nanopressure sensor and ultrasensitive acoustic nanogenerator. ACS Appl. Mater. Interfaces 8, 4532–4540 (2016).