Abstract

We have found that poly (4-vinylpyridine) (P4VP) and poly (methylmethacrylate) thin films can be etched with ultraviolet A (UVA) radiation. Furthermore, we also found that dermal fibroblasts could be cultured successfully on the P4VP polymer, with a doubling time comparable to tissue culture Petri dish standards. Consequently, we were able to grow tissue on P4VP substrates, this could easily be lifted using UVA radiation. The cell sheets that were removed were then re-plated at a lower density and a series of assays was performed at 3 and 6 days. Although only a small amount of damage was discernable at day 3 nearly complete recovery was observed at day 6. The technique was used to pattern areas within the tissue, where other types of cells could be inserted. To demonstrate the technique, a hybrid tissue layer was produced, in which the dermal fibroblasts in a circular area at the center of the sample were removed by exposure through a mask. A keratinocyte layer was inserted, which adhere to the fibroblast layer forming a tissue with integrated layers of two distinct cell types.

Similar content being viewed by others

Introduction

A significant shortcoming of conventional tissue engineering methods is the loss of differentiated cell functions during cell collecting. Typical cell collecting techniques use proteolytic enzymes such as trypsin or dispase, which irreversibly damage cell surface proteins, such as growth factor receptors, ion channels and cell-to-cell junction proteins.1 This result in an inability to assemble constructs from multiple cell types, which is an important requirement in tissue engineering.

To address these shortcomings, cell sheet engineering has been proposed as a new methodology to facilitate the non-invasive collect of cultured cells as intact cell sheets.2 As the cell sheets collected through this technique are recovered with intact cell-to-cell junctions and deposited extracellular matrix whole-cell sheets can be transferred to other tissue surfaces to produce versatile two-dimensional or three-dimensional tissues.3 Cell sheet engineering advanced rapidly with the development of culture dishes covalently grafted with temperature-responsive polymers. These culture surfaces allowed whole, contiguous cell sheets to spontaneously detach from the surface simply by briefly decreasing the temperature.4, 5 This technique was also used to culture four layers of cardiomyocytes, which successfully formed pulsatile myocardial tissue in vitro and in vivo.6 Other studies using epidermal keratinocytes have shown that it was possible to maintain the differentiated functions after the cell sheets were collected.7

However, although thermoresponsive culture surfaces have shown success in producing whole sheets of hard, cell-dense tissues such as myocardium, the technique is not suitable for tissue patterning and for soft tissue. For example, biological soft tissue like brain and adipose are difficult to manipulate (for the mechanical shock that is applied briefly to the hydrogel substrate to dislodge the sheets, may cause soft tissue to collapse rather than dislodge or detach).8 Therefore, the creation of blood vessels to facilitate vascularization would not be possible using thermoresponsive culture surfaces due to the characteristic softness of the tissue,9, 10, 11 It is also sometimes desirable to grow tissue with different types of cells in a prescribed pattern formation. For example, one may want to place cells that promote angiogenesis among cells that promote other types of tissue. This is not possible with the thermoresponsive surfaces, as the thermal response cannot be concentrated in any specific region and thermal conduction does not allow exposure through a mask. On the other hand, specific patterns can be created on photo-cleavable surfaces using focused beams of light. Hence, cells can be selectively removed and others inserted in a controlled manner.

We therefore propose a new methodology for cell sheet collecting and patterning, which uses photo-cleavable polymers. The major advantage of this technique is the fact that it can be used to pattern cell tissue, simply by exposing to ultraviolet (UV) light through a mask or writing selectively with a focused beam.

However, this technique has several major challenges, which we first had to overcome: (a) the polymer substrate must be conducive to cell growth and attachment. (b) The energy density and frequency of the radiation must be sufficient to cleave the polymer, yet low enough as not to cause significant damage to the cells. (c) Cleavage of the polymer must occur without release of residues, which are toxic to the cell sheet.

To find the optimum polymer within these constraints, we proposed the following photo-cleavable polymers: poly (4-vinylpyridine) (P4VP); poly (methylmethacrylate) (PMMA); the polymer 1:1 blend, poly (4-vinylpyridine)–poly (methylmethacrylate) (P4VP–PMMA and the tri-block copolymer poly (4-vinylpyridine)–poly(phenylvinylketone)–poly (methylmethacrylate) (P4VP–PVPK–PMMA). We screened these polymers, using various biochemical assays for their influence on cell proliferation and rate of photo cleavage with doses of UVA. The UVA doses should be sufficiently low to have minimal influence on the cell response, and ease of cell detachment and subsequent viability. Even though the UV–visible absorbance spectra of these commonly used polymers are well established, the absorption peaks tend to be in the UVB or UVC regions, which would also cause severe damage to cells. On the other hand, we found that the peaks were sufficiently broad such that it was possible to achieve a small degree of photo cleavage even when they were irradiated with light in the 300-nm region. As cell attachment occurs on the surface, only a small amount of cleavage was sufficient to lift the cells, which also had the advantage of minimizing any chemicals that may be released after the cleavage. Finally, we also demonstrated that the polymers could be irradiated through masks, which allowed for cell efficient patterning of the tissue.

Furthermore, the polymer we selected to demonstrate this principle, P4VP, is shown to be biocompatible and support cell proliferation to the same extend as the industry standard tissue culture Petri dish plastic. P4VP also has similar mechanical properties to polystyrene, and hence, may provide a commercially attractive alternative to tissue culture plastic (TCP).

As the P4VP polymer has the largest sensitive to light, all experiments were then performed only on P4VP.

Experimental procedure

Materials and methods

Materials

P4VP and PMMA were purchased from Aldrich (Milwaukee, WI, USA) and used without further purification. PVPK is an amorphous solid with the melting point of 74–84 °C. Solid and dissolved PVPK is normally used as polymeric photo-sensitizer.

Cell culture and function studies

Neonatal Human Dermal fibroblasts and human Keratinocytes DO33 were purchased from Skin Bank Cascade Biologics (Portland, Oregon). Fibroblasts growth media was comprised of Dulbecco's modified Eagle medium supplemented with 10% fetal bovine serum and 1% penicillin–streptomycin. Keratinocytes were cultured in EPI-Life growth media supplemented with human keratinocyte growth supplements (Cascade Biologics). Cells were maintained using a NAPCO 5430 Incubator (Thermo Scientific, Asheville, NC, USA) at 37 °C with 5.0% CO2 and 100% humidity. Cell numbers were quantified using a Coulter Particle Counter (Beckman Coulter, Miami, FL, USA).

In the classic experiment, cells were grown in the 35 mm2 Petri dish. After that, cells were trypsinized, the enzyme reaction was stopped with media and the aliquot of 100 ml cell solution was placed in each well of the 96-well dish for further experiments. Following the different incubation periods, cells were fixed, permeabilized and then stained with Alexa Flour 488 phaloidin (Invitrogen, Carlsbad, CA, USA) and propidium iodide (HPLC, Sigma Chemical, St Louis, MO, USA) to visualize the actin cytoskeleton and nucleus. The morphology of the cells was visualized with a Leica TCS SP2 laser scanning confocal microscope (Leica Micro-system, Bannockburn, IL, USA). We tested the biocompatibility of the photosensitive polymers using NHDF cells plated at a density of 3000–100 000 cm−2 on polymer-coated Si wafers and placed in 35-mm tissue culture dishes. Cells were allowed to proliferate for 6 days at 37 °C/5% CO2.

UV irradiation at 240–280 nm (λ=270 nm, I=3.98 mW cm−2) was accomplished with a low-pressure mercury lamp (15 W rod bulb) placed at a distance of 6.5 cm above the sample surface .The energy of UV light was measured by a radiometer New Port Optical Power Meter, model 840 (New Port Optical Power, Irvine, CA, USA). The films were then masked with a 500-mesh Cu TEM grid (Ted Pella, Redding, CA, USA) and exposed to UV light for various times.

UV irradiation at 320–400 nm was produce by UVA bulb F20T12BLB (Interlight, Hammond, IN, USA) (I=1.44 mW cm−2) placed at the distance of 20 cm above the sample surface.

Cell viability

Cell viability activity was evaluated with AlamarBlue reagent (Invitrogen). Cells were plate in a 96-well plate at six different densities (100 000 to 3250 cells) in 100 μl of media. After 24 h in the incubator, the samples are exposed to UVA for 15, 30 and 60 min. 10% of AlamarBlue reagent was added directly to each well; the plates were incubated at 37 °C for 1–4 h allowing cells to convert resazurin to resorufin. The absorbance signal is measured on a plate reader of spectrophotometer DAL1025 Microplate reader (Cole Parmer, Vernon Hills, IL, USA) at 560 nm excitation and 590 nm absorbance. Calibration curve was used to calculate the cell numbers on days 1, 3 and 6 after 1.3, 2.6 and 5.2 J cm−2 of UVA light.

Mitochondrial activity assay kit (MTS)

Cell mitochondrial activity was evaluated with Cell Titer 96 Aqueous One Solution Cell Proliferation Assay (Promega, Madison, WI, USA). Cells were plated in a 96-well plate at six different cells densities from (100 000 to 3250 cells) in 100 μl of media. After 24 h incubation the samples were exposed to UVA for 15, 30 and 60 min. In all, 20% of the MTS solution was added to each well; the samples were incubated for 1 h at 37 °C. The absorbance was read at 490 nm by the automated micro plate reader ELX800 (Biotek, Winooski, VT, USA).

Reactive oxygen species determination

Solar irradiation-induced photo-oxidative damage effectively reaches through the upper layers of skin into the human dermis and dermal capillary system. UV-driven reactive oxygen species (ROS) production has been demonstrated in culture human skin cells. ROS were determined using 5-(and-6)-chloromethyl-2′, 7′-dichlorodihydrofluorescein diacetate, acetyl ester (CM-H2DCFDA) (Invitrogen), wherein 50 000 cells were placed in each well of 96-well cell tissue culture dish in 50 ml media. After that, 100 μl of a working solution of CM-H2DCFDA was added to each well and incubated at 37 °C for 20 min. An additional 100 μl of 25 mM NaN3 solution was added to each well and placed to the incubator for 2 h. Fluorescence was determined with a BIO-TEK EL800 Micro plate reader (BioTek) at 490 nm excitation and 580 nm emission.

FITC Annexin V apoptosis detection Kit II

The apoptotic program is characterized by certain morphological features, including loss of plasma membrane asymmetry and attachment, condensation of the cytoplasm and nucleus, and internucleosomal cleavage of DNA. Loss of plasma membrane is one of the earliest features. In apoptotic cells, the membrane phospholipids phosphatidylserine (PS) is translocated from the inner to the outer leaflet of the plasma membrane, thereby exposing PS to the external cellular environment. Annexin V is a 35–36 kDa Ca2+-dependent phospholipids-binding protein that has a high affinity for PS, and binds to cells with exposed PS. Annexin V may be conjugated to fluorochromes including FITC. As externalization of PS occurs in the early states of apoptosis, FITC Annexin V staining can identify apoptosis at an earlier stage than assays based on nuclear changes such as DNA fragmentation.

Photo-cleavable polymers

Background

The photosensitive polymers used in this work are: P4VP, PMMA, the 1:1 blends of these polymers and tri-block copolymer P4VP–PVPK–PMMA. For this work, P4VP with molecular weight of 150 000–200 000 and PMMA with a molecular weight of 75 000 (Polyscience Corporation) were used.

Pyridine is well known to undergo photo cleavage in the pyridine–water solution.12, 13 The origin of the light sensitive system lies with the self-protonated side-chain unit on the backbone of poly P4VP.14 Irradiation of the system P4VP with 250 nm wavelength is leading to the protonation of the polymeric pyridine (Py* in the excited state). This process is irreversible.15 The photo-induced reaction of pyridine under UV light includes three main stages. The first one is pyridine isomerization, the second one is the cleavage of the free pyridine molecule with aldehyde enamine formation and the third one is the photoproduct interaction with the side-chain groups of the polymer. Initially, the P4VP is transforms to Dewar isomer. Then, on photo hydration, a cleave reaction takes place and Dewar-Py turns to the aldehyde enamine. A main active product of the photoreaction is aldehyde enamine, (5-amino-2, 4-pentadienal), and its derivatives and they have an absorption band at 340 m.16

The aldehyde enamine is unstable, and in a time scale of the minutes at room temperature reverts to pyridine. The formation and rearomatization of the aldehyde enamine is observed spectrophotometrically.12, 17 Aldehyde enamine has an intense absorption band at 366 nm. Another possibility is Py2 formation as a product of the bimolecular reaction between Py* and Py.

Irradiated surfaces of PMMA become hydrophilic and unstable peroxides together with carboxylic groups are formed at the polymer surface producing C, H and O gas.18 It has been found that surface carboxylic acid groups are formed on UV exposure (spectrum spanning 240–425 nm range) of PMMA in the atmosphere. It was observed that more carboxylic acid sites were formed with increased modification time.19

Spin-coating and Annealing of the photosensitive polymer

Single crystal (1,0,0, semiconductor processing) Si wafers were cut into 1 × 1 cm2 pieces and cleaned using the Shiraki method20 and rendered hydrophilic. The P4VP was dissolved in dimethylformamide at a concentration of 7 mg ml−1 and spun cast onto the freshly cleaned Si wafers at 2.05 × 103 r.p.m. The samples were then annealed in a vacuum oven (P∼103 Torr, T=170 °C) overnight. This process ensures that the solvent used for spinning is removed, leaving a uniform polymer film. The film surfaces were then examined using scanning force microscopy, which indicated that the films were uniform; root mean square (RMS) relative roughness was <1 nm. The thickness of the film was measured using elipsometer and found to be 388.4±16 nm.

PMMA was dissolved in toluene resulting in homogeneous transparent solution at the concentration of 15 mg ml−1. The thickness of the film was 78.8±18 nm. The blend polymer: P4VP–PMMA was mixed 1:1 solution, resulting in a spun cast film, 140±14 nm thick.

Film patterning

To test the lithographic properties of polymers, the silicon wafers were coated with the spun cast annealed polymer films and exposed to UV irradiation. The samples were immersed in 3 ml of PBS during exposure to UV light.

Compatibility of the photosensitive polymer with neonatal dermal fibroblast cells

To assess the compatibility of the photosensitive polymers, neonatal dermal fibroblasts were plated directly on the silicon wafers coated with spun cast films of the photosensitive polymers and placed in 35 mm2 Petri dishes containing 3 ml of media. Cells were counted on days 1, 3 and 6. Some of the samples were fixed and the actin filaments were stained with Alexaflour, while the nuclei were stained with propidium iodide.

Detachment of confluent culture of neonatal dermal fibroblast cell sheets from P4VP substrate

NHDF cells were plated onto P4VP spin coated and annealed surface (1 × 1 cm2) at a density of 100 000 cells cm–2 and cultured at 37 °C. Cells were incubated for 1 day and the sample was exposed to different UVA irradiation doses causing the etching of the photosensitive polymer.

Results and Discussion

Photolithographic pattern formation

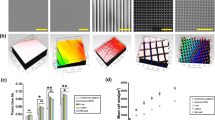

In Figure 1a, we plot the amount of material removed versus exposure time to UVC for the three types of polymer films tested here. In each case, the exposure was performed through a 500-mesh Cu TEM grid and the amount of material removed was determined by measuring the depth of a crater, using atomic force microscopy. From the figure, we can see that the etching rate of P4VP is 40 nm h−1 or nearly seven times faster than that of PMMA, which is 6 nm h−1. The etching rate of the tri-block copolymer is intermediate, 10 nm h−1, and that of a 1:1 blend of PMMA–P4VP is 30 nm h−1, or similar to that of the P4VP homopolymer.

Etching rate of poly (methylmethacrylate) (PMMA), poly (4-vinylpyridine) (P4VP) and P4VP–PMMA polymers exposed to the following radiation: (a) 3.98 mW cm−2 of ultraviolet (UV) C, (b) 1.44 mW cm−2 of UVA and (c) contact angle of P4VP surfaces exposed to different UVA doses. A full color version of this figure is available at Polymer Journal online.

To produce a coating that could be etched during cell culture, it was important to determine whether etching also occurred with light in the UVA frequency band. The results are shown in Figure 1b, where 8 nm of coating was removed in 15 min from the P4VP, whereas nearly no etching occurs in the PMMA film. It is interesting to note though that UVA can etch the polymers as well, albeit at a slower rate. Negligible amounts were removed from the PMMA during the same time, but ∼2 nm was removed from both the polymer blend and the copolymer sample. As cells only attach to the top layer of the polymer film, this etch rate is shown to be sufficient for lifting off layers of cells, which is required for patterning tissue samples. We can also determine whether the surface was modified by the UV light by measuring the water contact angle of the surface post irradiation. In Figure 1c, we plot the water contact angle of P4VP surfaces versus the exposure time for UVA radiation. From the figure, we can see that the water contact angle for the unexposed P4VP surfaces is 64° and decreases to 59° after only 5 min of exposure and 55° after 15 min. Further irradiation for 30 min decreases the angle to 42° indicating that oxidation of the surface may be occurring.

Biocompatibility of neonatal dermal Fibroblasts with the photosensitive polymers

To evaluate biocompatibility of the coated substrates for cell culture, we first compared the doubling times of the neonatal dermal fibroblasts cells on each type of substrate relative to a TCP control. We plated 3000 cells on each substrate, allowed them to adhere for 24 h, and then counted at days 1, 3 and 6. The counts are plotted as a function of incubation time in Figure 2a. We found that the doubling times on the P4VP homopolymer or P4VP blend polymer-coated substrate were indistinguishable from those measured on the TCP, or the doubling times and associated errors were, 36(1), 37(1) and 35(1) h, respectively. However, Figure 2b shows that the doubling times measured on the PMMA-coated substrate was 60(2) h, or significantly longer (P=0.0001).

Neonatal dermal fibroblast were plated with an initial density of 3000 cells cm−2 on poly (4-vinylpyridine) (P4VP), poly (methylmethacrylate) (PMMA), P4VP–PMMA substrates and the control sample was plated on tissue culture Petri dish plastic. (a) The growth curves obtained on the different substrates and (b) the doubling time calculated from the data in (a). A full color version of this figure is available at Polymer Journal online.

To determine the ratio of living/dead cells for P4VP, P4VP–PMMA substrate, 10 μl of tryphan blue was added to 10 μl of cell media. The percentage of cell viability is 98 and 96% on the P4VP and the P4VP–PMMA substrates versus 93% control TCP and 90% on polyisopropylacrylamide (PIPAAm)-grafted TCP surfaces.4

To determine whether the cell morphology was consistent with the cell count data, we also stained the samples for actin with Alexaflour and PI, and imaged the samples with confocal microscopy. The cell counts on each sample are shown in Figure 2a together with the confocal microscopy images taken on day 3. From the Figures 3a–c, we can see that the results are comparable to the TCP control (Figure 3d) for all polymers except for the PMMA film surface, in which a significant decrease in counts is observed.

Confocal microscope images of the neonatal dermal fibroblast obtained on day 3 after platting 3000 cells cm−2. The actin fibers were stained with Alexaflour Phalloidin 488 and the nuclei are stained with propidium iodide. The cells were plated on different substrates (a) poly (methylmethacrylate) (PMMA), (b) poly (4-vinylpyridine) (P4VP), (c) P4VP–PMMA and (d) tissue culture Petri dish. A full color version of this figure is available at Polymer Journal online.

Effects of UV exposure on neonatal dermal fibroblasts

To gauge the effect of UV exposure on the cells in the frequency band and energy density where ablation occurs, we plated neonatal dermal fibroblast cells at a density of 100 000 cells cm−2 on the P4VP-coated substrates. The cells were incubated for 24 h and then exposed to UVA radiation for 15, 30 and 60 min for a total UVA dose of 1.3, 2.6 and 5.2 J cm−2, respectively. The cells were counted immediately after exposure, and then after 1 and 3 days of incubation following irradiation. The results are shown in Figure 4a. From the figure, we can see that immediately after irradiation there is no significant decrease in cell count for the dosages used. After 24 h, we observe no change for the samples exposed for 15 min, and a decrease of 11 and 19% for those exposed for 30 and 60 min, respectively. On day 3, we find that the samples exposed for 15 and 30 min, had completely recovered, and the count rate for those exposed for 1 h was 23% less than the control.

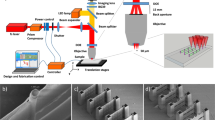

(a) Proliferation of neonatal dermal fibroblasts plated on poly (4-vinylpyridine) at a density of 105cells cm−2 and irradiated with 1.44 mW cm−2 of ultraviolet A (UVA) for 15 min (1.3 J cm−2), 30 min (2.6 J cm−2) and 60 min (5.2 J cm−2). The control sample was not irradiated. Confocal microscopy images of the cells stained with Alexaflour Phalloidin 488 and propidium iodide. Phase-contrast (top view) microscopy image of the sheet of neonatal dermal fibroblasts detached after (b) 5 min of UVA exposure and (c) 30 min of UVA exposure. (d) Confocal microscope picture of the cell sheet removed after 30 min UVA exposure. A full color version of this figure is available at Polymer Journal online.

Cell sheet detachment

Cell sheets detached and floated off from the P4VP substrates were transferred to another P4VP substrate for further testing. Here, we determined that a minimum of 5 min irradiation, which corresponded to 432 mJ cm−2, was required to remove an intact layer of cells. An optical image of the cell sheets removed after irradiation with 432 mJ cm−2 and 2.6 J cm−2 are shown in Figures 4b and c, respectively. The area of the cells plated was 1 cm2 and ∼0.8 cm2 was removed from the center of each sample. The latter sheet was also fixed and stained and the cells imaged with confocal microscopy. From the image shown in Figure 4d, we can see that even at the higher irradiation dose, the cells in the sheet were confluent and well spread.

To further probe the condition of the cells, the cells were re-plated, cultured for various times and tested with different biological assays. The experimental sequence is illustrated in Figure 5.

Schematic of the experimental sequence designed to measure the effects of 30 min exposure to ultraviolet A (UVA) radiation (2.6 J cm−2) on cell proliferation, cells viability, mitochondrial function, ROS production and apoptosis. A full color version of this figure is available at Polymer Journal online.

Investigation of the effects of low-dose UVA irradiation

As shown in Figure 5, we first plated neonatal dermal fibroblasts cells at high density (100 000 cm−2) on a P4VP substrate, incubated for 24 h and irradiated them with 1.44 mW cm−2 for 5, 10, 15, 30 and 60 min. In each case, we observed that the cell sheet could be lifted from the substrate immediately following irradiation without trypsin or other agents, which confirmed our hypothesis that release of the upper layer, even if it was only 8 nm thick, would be sufficient to remove the area on which the cells were adhered. The cell sheet were collected in a flask, diluted in Dulbecco's modified Eagle medium and re-plated on multiple sets of P4VP-coated substrates at a lower density (12 500 cells cm−2), from which a more detailed series of assays were performed as shown in Figure 5.

Cell viability

Cell viability was first determined before plating by staining a group of cells with tryphan blue and comparing the viability with a control group, which was cultured on TCP and lifted by enzymatic digestion with trypsin. The viability of cells collected after UV irradiation was measured to be 94%, which compared very favorable with the value of 93% measured for the control sample collected by enzymatic digestion. Another method for determining viability is testing for apoptosis, where viability is assayed by flow cytometry after Annexin V-FITC/propidium iodide staining. FITC Annexin V staining precedes the loss of membrane integrity, which accompanies the later stages of cells death resulting from either apoptotic or necrotic processes. Staining with FITC Annexin V is typically used in conjunction with a vital dye such as propidium iodide to investigate early apoptotic cells (PI negative, FITC Annexin V positive). The cells that are considered to be viable are FITC Annexin V and PI negative. The results are shown in Figure 6, where the viability of the control sample was found to be 96 versus 95% of the cells exposed to 1.3 J cm−2 and 88% for the cells exposed to 2.6 J cm−2.

Apoptosis detection assay of the cells according to schematic in Figure 5 after incubation of day 1 (a) unexposed sample, (b) sample exposed to 1.3 J cm−2 and (c) sample exposed to 2.6 J cm−2. Cells viability was assayed by flow cytometry after AnnexinV-FITC/propidium iodide staining. Numbers indicated express viable cells (lower left quadrant) as a percentage of total cells.

Cell proliferation

To show the differences in proliferation between cells irradiated for 30 min and un-irradiated cells, the cells were counted with a hemocytometer on days 0, 3 and 6 after plating on P4VP-coated substrates, and the results plotted in Figure 7a. From the data, we were able to obtain a doubling time of 37(2) h for the irradiated samples, in good agreement with 36(1) h obtained from the un-irradiated control sample.

Neonatal dermal fibroblasts plated on a poly (4-vinylpyridine) surface, lifted after exposure and then re-plated at a density of 12 500 cells cm−2, according to the schematic shown in Figure 5. (a) Growth curve of the control (unexposed sample) versus the samples exposed to UV irradiation. Confocal microscopy images of the cells stained with Alexaflour Phalloidin 488 and propidium iodide and imaged on day 0 and day 6 after exposure; (b, c) unexposed control and (d, e) exposed for 30 min. A full color version of this figure is available at Polymer Journal online.

We also imaged the cells with confocal microscopy, on days 0 and 6. From the Figures 7b and c, we can see that immediately after irradiation the appearance of the cells is not changed from that of the non-irradiated control sample Figures 7d and e. From the figures, we see that the cells remain well extended and continue to show highly organized actin fibers and intact nuclear membranes. Hence, no discernable damage in morphology is observed when the exposed cells are lifted and re-plated following irradiation.

AlamarBlue cell viability reagent

Figures 8a–c present cell viability results on days 1, 3 and 6 after UVA exposure. Cell viability and proliferation are indicated through the conversion of resazurin to resorufin. Resazurin, a non-fluorescent indicator dye, is converted to highly red fluorescent resorufin by reduction reactions of metabolically active cells. The amount of fluorescence produced is proportional to the number of living cells, and hence, the florescence could be calibrated as discussed previously. From the Figure 8a, we can see that the difference in florescence intensity between the irradiated samples and the control at day 1 is between 12 and 27% based on the UV irradiation of 1.3, 2.6 and 5.2 J cm−2. On day 3, the difference is between 7 and 12% and on day 6, the difference is between 6 and 9% based on UV dose. This result shows that the cells had a minimal damage after 15 min exposure to UVA. Similarly, the doubling time, as calculated from this technique is 39(1) h for the non-irradiated control and 40(1) h for the irradiated samples, regardless of exposure time.

AlamarBlue viability assays of the neonatal dermal fibroblast cells, removed from the poly (4-vinylpyridine) surface by ultraviolet A (UVA) exposure, re-plated according to Figure 5, measured on days (a) 1 (b) 3 and (c) 6. The corresponding proliferation curve (d) and the doubling time (e) are shown. A full color version of this figure is available at Polymer Journal online.

MTS cell mitochondrial activity

Mitochondrial activity is another measure of cell activity, which can be assessed by using MTS staining. In Figure 9, we plot the mitochondrial activity, normalized to the un-irradiated control samples on days 1 and 6 following UVA irradiation. Figure 9a shows that after 24 h there is a decrease in activity of 1.5, 5, 13, 15, and 20% for the samples irradiated for 5, 10, 15, 30 and 60 min, respectively. On day 6, although the difference decreases to 9% for the samples irradiated for 15, 30 and 60 min, indicating that the cells are recovering.

Mitochondrial activity assays of the cells according to the schematic in Figure 5 after incubation on days (a) 1 and (b) 6. A full color version of this figure is available at Polymer Journal online.

ROS assay

Another way to gauge the damage to the cells is by determination of the ROS production resulting from irradiation, as it is well established that even a small amount of UV exposure results in the production of ROS. We therefore measured the amount of ROS products in the cells following UVA irradiation for different times. The results are plotted in Figure 10, where we can see that on day 1 following irradiation the amount of ROS products produced in the samples after 5 and 10 min of exposure was not significantly different from the control, un-irradiated sample. The amount of ROS products formed seems to increase abruptly after 15 min of irradiation and did not increase further after 30 and 60 min of irradiation. After 3 days, the difference in ROS production for the samples irradiated for 15 min or longer decreased relative to the control, but the differences between the different irradiation times becomes apparent only on day 6. Hence, from these assays we can conclude that the minimum irradiation dose that is capable of ablating the surface polymer layer and removing an intact layer of cells is five minutes or 0.432 J cm−2; the amount of additional ROS produced because of the irradiation is negligible.

Assay of ROS product formation of the cells according to schematic in Figure 5 measured after days (a) 1 (b) 3 and (c) 6. A full color version of this figure is available at Polymer Journal online.

Cell tissue patterning using light sensitive polymers

To demonstrate that we can use the techniques described here to produce a patterned cell layer, the part of the cell layer with a specific geometry was removed from the polymer surface after UVA exposure through a mask and then replaced with cells of a different type. Figure 11a shows a schematic of the patterning experiment. Neonatal dermal fibroblasts were plated at a density of 100 000 cells cm−2 on the polymer surface and incubated for 24 h. The cells were then exposed to the UVA for 30 min through a mask, as shown in the figure, and an oval area, 0.2 mm in diameter, was removed from the center of the layer. In Figure 11b, we show the border between the exposed and unexposed regions, where we can clearly see that all cells were removed from the exposed section, while the cells in the unexposed section are confluent and well spread. Fibronectin was then added to the media and keratinocytes were then plated in the area from which the neonatal dermal fibroblasts were removed after exposure and incubated for 24 h. The border between the two types of cells is imaged with confocal microscopy and shown in Figure 11c, where we can see the keratinocytes adhere to the polymer surface. In Figure 11d, we show high magnification image of the same region, where we can see that the two types of cell layers have begun to inter diffuse.

(a) Schematic of the experimental protocol used to produce tissue with adjacent areas composed of two distinct cell populations. Confocal images of a patterned tissue containing a central area of keratinocytes surrounded by dermal fibroblasts. (b) The dermal fibroblast area imaged immediately after removal of the circular central area, as shown in (a). (c) The central portion of the tissue imaged 24 h after plating keratinocytes. Interfacial region between the two types of tissue is showing attachment of the keratinocytes to the dermal fibroblast layer. (d) High magnification image ( × 63) of (c) presenting the keratinocytes plated on the UVA-exposed area. A full color version of this figure is available at Polymer Journal online.

Conclusion

We have shown that P4VP polymers and their blends with PMMA can be etched by exposure to UVA radiation. Furthermore, we also showed that these polymers could be used as a cell culture substrate, upon which the proliferation rates and cell viability of neonatal cells were comparable to that on tissue culture Petri dish. Based on these findings we also demonstrated that irradiation with UVA could be used to pattern and lift off cell sheets cultured from P4VP substrate. The cell sheets that were removed were then re-plated at a low density and counted at 1, 3 and 6 days after irradiation. We show that only a small amount of degradation occurred and the doubling time was close to the control, indicating that the cells have recovered from the radiation. The minimum exposure radiation dose at the time when the cells were able to be removed was 0.432 J cm−2. At this dose, no discernable effect was observed after 5 min in the production of ROS and metabolism, as measured by MTS assays.

References

Yang, J., Yamato, M., Kohno, C., Nishimoto, A., Sekine, H., Fukai, F. & Okano, T. Cell sheet engineering recreating tissues without biodegradable scaffolds. Biomaterials 26, 6415–6422 (2005).

Yamato, M. & Okano, T. Cell sheet engineering. Mater. Today 7, 42–47 (2004).

Ng, K. W., Tham, W., Lim, T. C. & Hutmacher, D. W. Assimilating cell sheets and hybrid scaffolds for dermal tissue engineering. J. Biomed. Mater. Res. 75A, 425–438 (2005).

Kwon, O. H., Kikuchi, A., Yamato, M., Sakurai, Y. & Okano, T. Rapid cell sheet detachment from poly (N-isoproplyacrylamide)-grafted porous cell culture membranes. J. Biomed. Mater. Res. 50, 82–89 (2000).

Yamato, M., Utsumi, M., Kushida, A., Konno, C., Kikuchi, A. & Okano, T. Thermo-responsive culture dishes allow the intact harvest of multilayered keratinocyte sheets without dispase by reducing temperature. Tissue Eng. 7, 473–480 (2001).

Shimizu, T., Yamato, M., Kikuchi, A. & Okano, T. Cell sheet engineering for myocardial tissue engineering. Biomaterials 24, 2309–2316 (2003).

Yang, J., Yamato, M., Shimizu, T., Sekine, H., Ohashi, K., Kanzaki, M., Ohki, T., Nishida, K. & Okano, T. Reconstruction of functional tissues with cell sheet engineering. Biomaterials 28, 5033–5043 (2007).

Olberding, J. E. & Suh, J. K. F. A dual optimization for the material parameter identification of a biphasic poroviscoelastic hydrogel, potential application to hyper compliant soft tissue. J. Biomech. 13, 2468–2475 (2006).

Stampfl, S., Stampfl, U., Bellemann, N., Sommer, C. M., Thierjung, H, Radeleff, B, Lopez-Benitez, R, Berger, I, Kauffmann, G W & Richter, G M Biocompatibility and recanalization characteristics of hydrogel microsphere with polyzene-F as polymer coating. Cardiovasc. Intervent. Radiol. 31, 799–806 (2008).

Bayramoglu, G., Yilmaz, M., Batislam, E. & Arica, M. Y. Heparin-coated poly (hydroxyethyl methacrylate/albumin) hydrogel network, in vitro hemocompatibility evaluation for vascular biomaterials. J. Appl. Polym. Sci. 109, 749–757 (2009).

Kurihara, T. & Nagamune, T. Cell adhesion ability of artificial extracellular matrix proteins containing a long repetitive Arg-Gly-Asp sequence. J. Biosci. Bioeng. 100, 82–87 (2005).

Wilzback, K. E. & Rausch, D. J. Infrared multiple-photon excited. J. Am. Chem. Soc. 92: 7, 2178–2179 (1970).

Nishiyama, S., Tajima, M. & Yoshida, Y. Photo-irradiation effects on poly (vinyl pyridines). Colloids and Surfaces. A Physicochem. Eng. Aspects 313–314, 479–483 (2008).

Rozenberg, M., Vaganova, E. & Yitzchaik, S. FTIR study of self-protonation and gel formation in pyridinic solution of poly (4-vynilpyridine). New J. Chem. 24, 109–111 (2000).

Vaganova, E., Meshulam, G., Kotler, Z., Rozenberg, M. & Yitzchair, S. Photoinduced structural changes in poly (4-vinyl pyridine) a luminescence study. J. Fluoresc. 2, 10 (2000).

Freitag, H. Photo-induced pyridine reaction. Chem. Ber. 69B, 32–35 (1936).

Vaganova, E., Damm, C., Israel, G. & Yitzchaik, S. Photoinduced pyridine cleavage-closure in viscous polymer solution. J. Fluoresc. 12, 2 (2007).

Welle, A., Gottwald, E. & Weibezahn, K. F. Patterned polymer surfaces for cell culture applications. Biomed. Tech. (Berlin) 47 (Suppl. 1 Part 1), 401–403 (2002).

Wei, S., Vaidya, B., Patel, A., Soper, S. & McCarley, R. Photochemical patterned poly (methyl methacrylate) surfaces used in the fabrication of micro analytical devices. J. Phys. Chem. 109, 16988–16996 (2005).

Ishizaka, A. & Shiraki, Y. Low temperature surface cleaning of silicon and its application to silicon MBE. J. Electrochem. Soc. 4, 666–671 (1986).

Acknowledgements

Support from the NSF-MRSEC program is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Apostol, M., Mironava, T., Yang, NL. et al. Cell sheet patterning using photo-cleavable polymers. Polym J 43, 723–732 (2011). https://doi.org/10.1038/pj.2011.51

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2011.51