Abstract

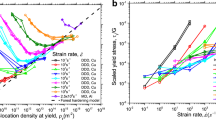

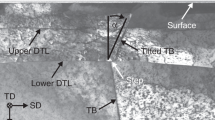

The motion of dislocations in response to stress dictates the mechanical behaviour of materials. However, it is not yet possible to directly observe dislocation motion experimentally at the atomic level. Here, we present the first observations of the long-hypothesized kink-pair mechanism in action using atomistic simulations of dislocation motion in iron. In a striking deviation from the classical picture, dislocation motion at high strain rates becomes rough, resulting in spontaneous self-pinning and production of large quantities of debris. Then, at still higher strain rates, the dislocation stops abruptly and emits a twin plate that immediately takes over as the dominant mode of plastic deformation. These observations challenge the applicability of the Peierls threshold concept to the three-dimensional motion of screw dislocations at high strain rates, and suggest a new interpretation of plastic strength and microstructure of shocked metals.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Hirth, J.P. & Lothe, J. Theory of dislocations (Wiley, New York, 1982).

Kuhlmann-Wilsdorf, D. & Wilsdorf, H.G.F. Dislocation movements in metals. Science 144, 17–25 (1964).

Bullough, R. & Tewary, V.K. in Dislocations in Solids Vol. 2 (ed. Nabarro, F.R.N.) Ch. 5 (North-Holland, Amsterdam, 1979).

Duesbery, M.S. in Dislocations in Solids Vol. 8 (ed. Nabarro, F.R.N.) Ch. 39 (North Holland, Amsterdam, 1989).

Bulatov, V.V., Abraham, F.F., Kubin, L., Devincre, B. & Yip, S. Connecting atomistic and mesoscale simulations of crystal plasticity. Nature 391, 669–672 (1998).

Zhou, S.J., Preston, D.L., Lomdahl, P.S. & Beazley, D.M. Large-scale molecular dynamics simulations of dislocation intersection in copper. Science 279, 1525–1527 (1998).

Gumbsch, P. & Gao, H. Dislocations faster than the speed of sound. Science 283, 965–968 (1999).

Diaz de la Rubia, T. et al. Multiscale modelling of plastic flow localization in irradiated metals. Nature 406, 871–874 (2000).

Miguel, M.-C., Vespignani, A., Zapperi, S., Weiss, J. & Grasso, J.-R. Intermittent dislocation flow in viscoplastic deformation. Nature 410, 667–671 (2001).

Li, J., Van Vliet, K.J., Zhu, T. & Yip, S. Atomistic mechanisms governing elastic limit and incipient plasticity in crystals. Nature 418, 307–310 (2002).

Maunuksela, J. et al. Kinetic roughening in slow combustion of paper. Phys. Rev. Lett. 79, 1515–1518 (1997).

Barabasi, A.-L. & Stanley, H.E. Fractal Concepts in Surface Growth (Cambridge Univ. Press, Cambridge, UK, 1995).

Tonomura, A. et al. Motion of vortices in superconductors. Nature 397, 308–309 (1999).

Surdeanu, R. et al. Kinetic roughening of penetrating flux fronts in high-Tc thin film superconductors. Phys. Rev. Lett. 83, 2054–2057 (1999).

Kardar, M., Parisi, G. & Zhang, Y.-C. Dynamic scaling of growing interfaces. Phys. Rev. Lett. 56, 889–892 (1986).

Devincre, B. & Kubin, L.P. Mesoscopic simulations of dislocations and plasticity. Mater. Sci. Eng. A 234, 8–14 (1997).

Duesbery, M.S. Dislocation motion, constriction and cross-slip in fcc metals. Model. Simul. Mater. Sci. 6, 35–49 (1998).

Vegge, T., Rasmussen, T., Leffers, T., Pedersen, O.B. & Jacobsen, K.W. Atomistic simulations of cross-slip of jogged screw dislocations in copper. Phil. Mag. Lett. 81, 137–144 (2001).

Peierls, R.E. The size of a dislocation. Proc. Phys. Soc. 52, 34–37 (1940).

Marian, J. Improved Understanding of Radiation Damage in Ferritic Alloys: A Multiscale Modeling Study Thesis, Universidad Politécnica de Madrid (2002).

Ngan, A.H.W. & Wen, M. Dislocation kink-pair energetics and pencil glide in body-centered-cubic crystals. Phys. Rev. Lett. 87, 075505 (2001).

Louchet, F. & Viguier, B. Ordinary dislocations in γ-TiAl: cusp unzipping, jog dragging and stress anomaly. Phil. Mag. A 80, 765–779 (2000).

Vitek, V. Theory of core structures of dislocations in body-centered cubic metals. Cryst. Latt. Def. Amorp. 5, 1–34 (1974).

Ackland, G.J., Bacon, D.J., Calder, A.F. & Harry, T. Computer simulation of point defect properties in dilute Fe-Cu alloy using a many-body interatomic potential. Phil. Mag. A 75, 713–732 (1997).

Chang, J., Cai, W., Bulatov, V.V. & Yip, S. Molecular dynamics simulations of motion of edge and screw dislocations in a metal. Comp. Mater. Sci. 23, 111–115 (2002).

Woodward, C. & Rao, S.I. Flexible ab initio boundary conditions: simulating isolated dislocations in bcc Mo and Ta. Phys. Rev. Lett. 88, 216402 (2002).

Kaufmann, H.-J., Luft, A. & Schulze, D. Deformation mechanism and dislocation structure of high-purity molybdenum single-crystals at low temperatures. Cryst. Res. Technol. 19, 357–372 (1984).

Pal-Val, P.P. & Kauffman, H.-J. Variation of low-temperature internal-friction at microplastic deformation of high-purity molybdenum single-crystals. Cryst. Res. Technol. 19, 1049–1055 (1984).

Dai, Y. & Victoria, M. Defect structures in deformed FCC metals. Acta Mater. 45, 3495–3501 (1997).

Kiritani, M. et al. Anomalous production of vacancy clusters and the possibility of plastic deformation of crystalline metals without dislocations. Phil. Mag. Lett. 79, 797–804 (1999).

Vegge, T., Leffers, T., Pedersen, O.B. & Jacobsen, K.W. Atomistic simulations of jog migration on extended screw dislocations. Mater. Sci. Eng. A 319, 119–123 (2001).

Hirsch, P.B. & Humphrey, F.J. Deformation of single crystals of copper and copper-zinc alloys containing alumina particles. 1. Macroscopic properties and work hardening theory. Proc. R. Soc Lon. A 318, 45–72 (1970).

Bacon, D.J., Kocks, U.F. & Scattergood, R.O. Effect of dislocation self-interaction on Orowan stress. Philos. Mag. 28, 1241–1263 (1973).

Hsiung, L.M. & Lassila, D.H. Initial dislocation structure and dynamic dislocation multiplication in Mo single crystals. CMES-Comp. Model. Eng. 3, 185–191 (2002).

Odette, G.R., Wirth, B.D., Bacon, D.J. & Ghoniem, N.M. Multiscale-multiphysics modeling of radiation-damaged materials: embrittlement of pressure-vessel steels. Mater. Res. Soc. Bull. 26, 176–182 (2001).

Alshits, V.I. & Indenbom, V.L. in Dislocations in Solids Vol. 7 (ed. Nabarro, F.R.N.) Ch. 34 (North-Holland, Amsterdam, 1986).

Sleeswyk, A.F. 1/2[111] screw dislocations and nucleation of [112][111] twins in the bcc lattice. Philos. Mag. 8, 1467–1486 (1963).

Lagerlof, K.P.D. On deformation twinning in bcc metals. Acta Metall. Mater. 41, 2143–2151 (1993).

Allen, M.P. & Tildesley, D.J. Computer Simulation of Liquids (Clarendon, Oxford, UK, 1989).

Hoover, W.G. Canonical dynamics: equilibrium phase-space distributions. Phys. Rev. A 31, 1695–1697 (1985).

Kelchner, C.L., Plimpton, S.J. & Hamilton, J.C. Dislocation nucleation and defect structure during surface indentation. Phys. Rev. B 58, 11085 (1998).

Acknowledgements

This work was performed under the auspices of the US Department of Energy by Lawrence Livermore National Laboratory under Contract W-7405-Eng-48.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

About this article

Cite this article

Marian, J., Cai, W. & Bulatov, V. Dynamic transitions from smooth to rough to twinning in dislocation motion. Nature Mater 3, 158–163 (2004). https://doi.org/10.1038/nmat1072

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nmat1072

This article is cited by

-

Atomic-scale observation of nucleation- and growth-controlled deformation twinning in body-centered cubic nanocrystals

Nature Communications (2024)

-

Investigation of the deformation behavior and mechanical characteristics of polycrystalline chromium–nickel alloys using molecular dynamics

Journal of Molecular Modeling (2022)

-

Phase-field dislocation modeling of cross-slip

Journal of Materials Science (2022)

-

Cyclic Plastic Deformation Response of Nanocrystalline BCC Iron

Metals and Materials International (2021)

-

Walker-like domain wall breakdown in layered antiferromagnets driven by staggered spin–orbit fields

Communications Physics (2020)