Abstract

Scaling transistors’ dimensions has been the thrust for the semiconductor industry in the last four decades. However, scaling channel lengths beyond 10 nm has become exceptionally challenging due to the direct tunneling between source and drain which degrades gate control, switching functionality, and worsens power dissipation. Fortunately, the emergence of novel classes of materials with exotic properties in recent times has opened up new avenues in device design. Here, we show that by using channel materials with an anisotropic effective mass, the channel can be scaled down to 1 nm and still provide an excellent switching performance in phosphorene nanoribbon MOSFETs. To solve power consumption challenge besides dimension scaling in conventional transistors, a novel tunnel transistor is proposed which takes advantage of anisotropic mass in both ON- and OFF-state of the operation. Full-band atomistic quantum transport simulations of phosphorene nanoribbon MOSFETs and TFETs based on the new design have been performed as a proof.

Similar content being viewed by others

Introduction

Shrinking the size of metal oxide semiconductor field effect transistors (MOSFETs) has improved the functionality, speed, and cost of microprocessors over the last four decades. However, the advantages of scaling are quickly fading away1. For example, the operational frequency of CPUs has stopped improving since 2003 due to power consumption of CPUs reaching their cooling limit (≈100 W/cm2)2. Moreover, scaling down Lch towards the few nanometer regime is becoming more challenging due to source-to-drain (SD) leakage current3,4; the gate controlled potential barrier becomes more transparent as channel becomes shorter and direct SD tunneling increases. Another challenge in miniaturizing MOSFETs is scaling down the supply voltage VDD2. A smaller VDD can be achieved in a switch with sharper ON to OFF transition. However, the steepness of conventional MOSFETs have a fundamental limit due to thermionic injection of carriers over the channel barrier (60 mV/decade at room temperature). Accordingly, VDD in MOSFETs does not scale very well. On the other hand, tunnel FETs (TFETs) can, in principle, provide steeper switching5,6. Nevertheless, scaling TFETs is even trickier than MOSFETs, since scaling affects both ON- and OFF-states of the TFETs7,8,9. Hence, the tremendous improvement in processing power of transistors every few years linked to the dimension scaling and empirically described by Moore’s law has reached a dead end. Fortunately, it is shown here that 2D materials with anisotropic effective mass (m*) can be used to solve these problems and save Moore’s law.

First, we discuss the source-to-drain tunneling challenge of the ultra scaled MOSFETs. Reducing the channel size makes the potential barrier more transparent. To visualize this, the transmission is shown in colormap on a logarithm scale and with an overlayed band diagram of MOSFETs in Fig. 1. The band diagram and transmission profile of a 12 nm and 5 nm long channel GaAs MOSFET are compared respectively in Fig. 1a,b. 5 nm long channel GaAs MOSFET suffers significantly from SD leakage which reduces the gate control. Equation (1) shows the dependence of tunneling current through barrier on m* of the channel material4,10,11,12,13. According to Equ. (1), an apparent solution to the high transparency of channel barriers in short channel regime is a channel material with higher effective mass.

The band diagram of (a) 12 nm long GaAs, (b) 5 nm long GaAs, and (c) 5 nm long phosphorene MOSFETs. The colormap shows the transparency of the channel. The potential barrier in the 5 nm long GaAs MOSFET is transparent and hence, the gate efficiency is low. This problem can be solved by using phosphorene with high m*.

Although high m* channel materials block SD tunneling effectively, they have a set of drawbacks too. Quantum capacitance (CQ) of channel material increases as a result of larger density of states (DOS) and m*. Accordingly, the gate capacitance (CG) which is the net series capacitance of CQ and oxide capacitance (Cox) increases. Hence, a larger m* translates into a larger switching delay (τ = CGVDD/ION).

Anisotropic effective mass can provide a solution to this problem with reducing CQ by a factor of  . This reduction of CQ is the result of the decreased density of states (DOS) in anisotropic materials:

. This reduction of CQ is the result of the decreased density of states (DOS) in anisotropic materials:

where  and

and  are low and high effective masses of the channel material along its two main axes. If high m* axis of channel is aligned with transport direction and low m* axis is aligned with the confinement direction, both low transparency and small switching delay can be achieved. Note that high m* along the channel increases the carriers decay rate through barrier exponentially, whereas low confinement m* reduces DOS and CQ. Hence, a 2D material such as phosphorene14 with anisotropic m*15 can provide an excellent switching performance in MOSFETs ensuring the continuation of Moore’s Law to atomic dimensions.

are low and high effective masses of the channel material along its two main axes. If high m* axis of channel is aligned with transport direction and low m* axis is aligned with the confinement direction, both low transparency and small switching delay can be achieved. Note that high m* along the channel increases the carriers decay rate through barrier exponentially, whereas low confinement m* reduces DOS and CQ. Hence, a 2D material such as phosphorene14 with anisotropic m*15 can provide an excellent switching performance in MOSFETs ensuring the continuation of Moore’s Law to atomic dimensions.

Here, we discuss the scaling challenge of TFETs. Although TFETs were intended to reduce the power consumption of transistors5,6, scaling TFETs below 10 nm is even more challenging than MOSFETs7,8,9. The ON-state and OFF-state tunneling currents (ION and IOFF) depend on the same device parameters12. Thus decreasing IOFF would reduce ION. Roughly, the ON/OFF ratio of TFETs depends on8,12,13,36:

where Λ and Lch are the tunneling distances in the ON- and OFF-state respectively.  and Eg1 (

and Eg1 ( and Eg2) are the reduced effective mass and the bandgap of the channel material (source-to-channel junction), respectively.

and Eg2) are the reduced effective mass and the bandgap of the channel material (source-to-channel junction), respectively.

Shrinking the channel length to few nanometers brings Lch close to Λ and reduces ION/IOFF significantly. One apparent solution can be a heterostructure channel where the term  is much smaller than

is much smaller than  due to different materials used in the source and channel regions16,17. However, heterostructure TFETs suffer from interface states which deteriorate their OFF-state performance18,19,20. Although homojunction TFETs do not have the interface states, it is challenging to provide high ON/OFF ratio especially below 6 nm8,21. Anisotropic effective mass can also provide a solution for this challenge by setting source-channel junction along low m* axis of channel material and the channel barrier along high m* axis. In this work, a novel TFET is proposed which works based on homojunction channel and anisotropic m* and hence it is free of interface states between different channel materials in heterojunctions.

due to different materials used in the source and channel regions16,17. However, heterostructure TFETs suffer from interface states which deteriorate their OFF-state performance18,19,20. Although homojunction TFETs do not have the interface states, it is challenging to provide high ON/OFF ratio especially below 6 nm8,21. Anisotropic effective mass can also provide a solution for this challenge by setting source-channel junction along low m* axis of channel material and the channel barrier along high m* axis. In this work, a novel TFET is proposed which works based on homojunction channel and anisotropic m* and hence it is free of interface states between different channel materials in heterojunctions.

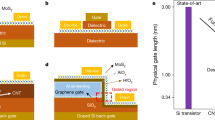

Although, many novel materials and designs have been proposed to enhance the performance of TFETs such as 2D material TFETs22,23,24, Nitride heterostructures16, dielectric engineering25, there are not many proposals for solving the scaling challenge of TFETs8. In this work, a new TFET design is proposed to overcome the scaling challenge and enable downsizing to 2 nm channel lengths. Figure 2a shows a novel TFET device structure to take advantage of anisotropic effective mass. Notice that the gate is L-shaped. Figure 2b depicts that the tunneling in the ON-state occurs along the low m* axis of the channel enhancing the ION. However, the tunneling in the OFF-state occurs along the high m* axis and results in a very low IOFF. Hence, this new TFET design can revive Moore’s law for sub-10 nm TFETs.

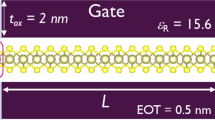

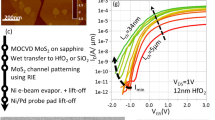

In this work, phosphorene nanoribbon has been chosen as the channel material since it has a large effective mass anisotropy in zigzag and armchair directions. The electron and hole effective mass values of phosphorene along zigzag and armchair directions calculated from our tight-binding method are compared with the DFT calculations from literature26,27 in Table 1. Moreover, multi-layer phosphorene provides a range of bandgap (Eg ≈ 1.45 to 0.4 eV28,29) suitable for transistor applications. Eg of monolayer (1L-) and bilayer (2L-) phosphorene is about 1.45 eV and 0.8 eV, respectively. Since MOSFETs require larger Eg for a smaller source-to-drain leakage, a monolayer phosphorene has been used here. The situation is more tricky in TFETs which need optimized Eg. It was shown previously that 2L-phosphorene has an optimum Eg21, and hence 2L has been chosen for TFETs. HfO2 is used as the gate dielectric with an equivalent oxide thickness (EOT) of 0.5 nm in both MOSFETs and TFETs and IOFF is set to 10−4 μA/μm.

Figure 3a compares IDS-VGS of a conventional 2L-phosphorene nanoribbon along zigzag and armchair transport directions with L-shaped gate (L-gate) TFET calculated from full-band atomistic quantum transport simulations using NEMO530,31. Not only does the L-gate TFET have ION close to that of the armchair ribbon (low m*), but it also has IOFF similar to that of the zigzag ribbon (high m*). Hence, the L-gate design has the advantages of both low and high m* devices simultaneously: high ION and low IOFF.

(a) The comparison between IDS-VGS of conventional 2L-phosphorene nanoribbons along zigzag and armchair directions with that of the L-gate TFET. (b) ON-current and SS of L-gate TFET as a function of dL. (c) Impact of channel length scaling on IDS-VGS of L-gate TFETs. (d) ION/IOFF ratio of the L-gate TFET as a function of Lch. (e) The top view of edge-less L-gate design.

The performance of the L-gate TFET depends on the length dL (see Fig. 3b) which determines the width for ON-current. In conventional TFETs, dL equals 0. Figure 3b shows ION of L-gate TFET as a function of dL for a fixed IOFF of 10−4 μA/μm. Increasing dL enhances ION significantly. The larger ION/IOFF ratio translates into a lower SS as shown in Fig. 3b. However, increasing dL reduces the source extension by dL/2. Accordingly, there is a limit on dL according to the footage requirements in the design. Nevertheless, a dL of about 2.5 nm can improve the performance of TFET approximately by 2 orders of magnitude.

Figure 3c shows ultra-scaled L-gate TFETs with channel lengths from 9 nm down to 2.3 nm with a VDD of 0.2 V. In ultra-scaled TFETs, VDD cannot scale below VDD = 0.2 V since the maximum tunneling energy window is limited by VDD. The L-gate TFETs with Lch above 2 nm provide ION/IOFF > 104 and satisfy the minimal ITRS requirement for ION/IOFF ratio. Although the L-gate design has improved the performance of TFETs significantly, the ON/OFF ratio of TFET decreases for devices with Lch and VDD below 2 nm and 0.2 V, respectively.

Figure 3d shows ION/IOFF ratio of L-gate TFETs as a function of Lch. Ultra-scaled channel lengths put a limit on dL. Hence, dL shrinks down from 3.5 nm to 1 nm when the channel length scales down from 9 nm to 2.3 nm. L-gate TFETs with channel lengths down to 2 nm provide ION/IOFF ratio larger than 104 (required by ITRS as minimum amount of ION/IOFF ratio). This result proves that L-gate TFETs with a channel material of anisotropic m* enable successful scaling of TFETs down to the ultimate limit; a channel with a few atoms.

The unpaired bonds at the edges of phosphorene nanoribbon can introduce metallic edge states32,33. To avoid these edge states, all the unpaired phosphorene bonds have to be properly passivated (e.g. by hydrogen). In this work, a hydrogen passivation model for tight-binding basis is used to passivate the dangling bonds34. It is also possible to create an edge-less L-gate structure as shown in Fig. 3e. This structure pattern is created by repeating and mirroring the original L-gate pattern providing the same current density per unit width compared with the original design.

As mentioned before, ultra-scaled MOSFETs require large m* and Eg to block source-to-drain tunneling. Hence, 1L-phosphorene nanoribbon has been chosen here which has the highest m* and Eg compared to multilayer phosphorene. The schematic of the 1L-phosphorene MOSFET has been shown in Fig. 4a. The supply voltage is fixed to 0.5 V, much higher than VDD of TFETs, since the Boltzmann limit of subthreshold swing in MOSFETs (i.e. 60 mV/decade in room temperature) does not allow the scaling of VDD.

(a) Device structure of zigzag monolayer phosphorene MOSFET. (b) The comparison between IDS-VGS of phosphorene nanoribbon MOSFETs with transport direction along high m* (zigzag: blue) and low m* (armchair: red) axes. (c) Impact of Lch scaling on IDS-VGS of phosphorene MOSFETs. (d) ION/IOFF ratio of MOSFETs as a function of Lch along zigzag and armchair transport directions.

The transfer characteristics of a short channel 1L-phosphorene (Lch = 3 nm) with transport direction along low m* (armchair) and high m* (zigzag) are compared in Fig. 4b. As expected, the gate efficiency of a phosphorene MOSFET is much better when the high m* (zigzag) axis is along the transport direction. This better gate efficiency improves the subthreshold slope of MOSFET significantly.

Figure 4c shows IDS-VGS of zigzag scaled phosphorene MOSFETs with channel lengths from 12 nm to 1.6 nm. Notice that for phosphorene MOSFETs with Lch > 1.6 nm an ION larger than 1.1 mA/μm and an ION/IOFF ratio larger than 106 have been achieved. 1L-phosphorene MOSFETs show a significant advantage over other 2D materials whose performances are diminished below 5 nm channel lengths35.

MOSFETs with long channels do not suffer from source-to-drain tunneling. Accordingly, a high transport m* is not required for blocking this leakage current. Actually, in long channel regime, a low transport m* can be beneficial and enhance the ON-state performance of the transistor since it leads to a higher carrier injection velocity. Figure 4d shows ION/IOFF ratio of phosphorene nanoribbon MOSFETs as a function of Lch along zigzag and armchair transport directions. Although zigzag nanoribbon MOSFETs significantly outperform the armchair ones in short channels due to lower source-to-drain tunneling, armchair nanoribbon MOSFETs show a better performance in longer channels due to higher injection velocity. There is a critical channel length (i.e. 6 nm in 1L-phosphorene) in MOSFETs below which having a high m* becomes critical and above which a low m* is beneficial.

In summary, the channel materials with anisotropic effective mass can be used to design transistors scalable to 1–2 nm channel lengths. In MOSFETs, the high effective mass along transport direction blocks the direct source to drain tunneling and low effective mass reduces the quantum capacitance and switching delay. On the other hand in TFETs, a novel L-shaped gate design is proposed which can provide advantage of high tunneling rate in the ON-state and low tunneling rate in OFF-state by engineering the tunneling paths along low and high effective mass directions. In summary, anisotropic effective mass can be used in an L-gate design to obtain large ON/OFF ratio in an ultra-scaled homojunction TFET.

Methods

The atomistic quantum transport simulation results have been obtained from the self consistent solution of 3D-Poisson equation and Non-equilibrium Green’s Functions (NEGF) method using the Nanoelectronics modeling tool NEMO530,31. The Poisson equation provides the potential for NEGF method and takes the free charge in return. The tight-binding Hamiltonian of phosphorene used in NEGF calculations employs a 10 bands sp3d5s* model. Phosphorene is a material with anisotropic dielectric properties. The details of the Poisson equation with anisotropic dielectric tensor and NEGF equations can be found in our previous works21,22,36,37.

Additional Information

How to cite this article: Ilatikhameneh, H. et al. Saving Moore’s Law Down To 1 nm Channels With Anisotropic Effective Mass. Sci. Rep. 6, 31501; doi: 10.1038/srep31501 (2016).

References

A. M. Ionescu & H. Riel . “Tunnel field-effect transistors as energy-efficient electronic switches”. Nature 479, 329–337 (2011).

K. Bernstein, R. K. Cavin, W. Porod, A. C. Seabaugh & J. Welser . “Device and architectures outlook for beyond CMOS switches”. Proc. IEEE 98, 2169–2184 (2010).

J. Wang & M. Lundstrom . “ Does source-to-drain tunneling limit the ultimate scaling of MOSFETs?” IEEE, International Electron Devices Meeting, IEDM (2002).

M. Salmani-Jelodar, S. Mehrotra, H. Ilatikhameneh & G. Klimeck . “Design Guidelines for Sub-12 nm Nanowire MOSFETs”. IEEE Trans. on Nanotechnology 14(2), 210–213 (2015).

J. Appenzeller, Y.-M. Lin, J. Knoch & Ph. Avouris . “Band-to-band tunneling in carbon nanotube field-effect transistors”. Phys. Rev. Lett. 93(19), 196805 (2004).

J. Appenzeller, Y.-M. Lin, J. Knoch, Z. Chen & Ph. Avouris . “ Comparing carbon nanotube transistors-the ideal choice: a novel tunneling device design ”. IEEE Trans. on Electron Dev. 52, 2568–2576 (2005).

U. E. Avci & I. Young . “Heterojunction TFET scaling and resonant-TFET for steep subthreshold slope at sub-9 nm gate-length”. In IEEE International Electron Devices Meeting (IEDM) 4–3 (2013).

H. Ilatikhameneh, G. Klimeck & R. Rahman . “ Can Homojunction Tunnel FETs Scale Below 10 nm?” IEEE EDL 37(1), 115–118 (2016).

H. Lu & A. Seabaugh . “ Tunnel Field-Effect transistors: state-of-the-art ”. IEEE Electron Devices Society 2(4), 44–49 (2014).

M. Salmani-Jelodar, H. Ilatikhameneh, S. Kim, K. Ng & G. Klimeck . “Optimum High-k Oxide for the Best Performance of Ultra-scaled Double-Gate MOSFETs”. IEEE Transactions on Nanotechnology, 10.1109/TNANO.2016.2583411 (2016).

Schwierz, F., J. Pezoldt & R. Granzner . “Two-dimensional materials and their prospects in transistor electronics”. Nanoscale 7(18), 8261–8283 (2015).

H. Ilatikhameneh, R. B. Salazar, G. Klimeck, R. Rahman & J. Appenzeller . From Fowler-Nordheim to Non-Equilibrium Green’s Function Modeling of Tunneling. IEEE Transactions on Electron Devices 63(7), 2871–2878 (2016).

E. O. Kane . “Zener tunneling in semiconductors”. Journal of Physics and Chemistry of Solids 12(2), 181–188 (1960).

H. Liu, A. T. Neal, Z. Zhu, Z. Luo, X. Xu, D. Tomanek & P. D. Ye . “ Phosphorene: an unexplored 2d semiconductor with a high hole mobility ”. ACS nano 8(4), 4033–4041 (2014).

J. Qiao, X. Kong, Z. X. Hu, F. Yang & W. Ji . “High-mobility transport anisotropy and linear dichroism in few-layer black phosphorus”. Nature communications 5 (2014).

W. Li, S. Sharmin, H. Ilatikhameneh, R. Rahman, Y. Lu, J. Wang, X. Yan, A. Seabaugh, G. Klimeck, D. Jena & P. Fay . “Polarization-Engineered III-Nitride Heterojunction Tunnel Field-Effect Transistors”. IEEE Exploratory Solid-State Computational Devices and Circuits 1(1), 28–34, 10.1109/JXCDC.2015.2426433 (2015).

T. Krishnamohan, D. Kim, S. Raghunathan & K. Saraswat . “ Double-Gate Strained-Ge Heterostructure Tunneling FET (TFET) With record high drive currents and subthreshold slope ¡¡ 60 mV/dec ”. In IEEE International Electron Devices Meeting IEDM 1–3 (2008).

J. Knoch & J. Appenzeller . “Modeling of high-performance p-type IIIV heterojunction tunnel FETs”. IEEE Electron Device Letters 31(4), 305–307 (2010).

M. Kim, Y. K. Wakabayashi, M. Yokoyama, R. Nakane, M. Takenaka & S. Takagi . “ Ge/Si Heterojunction Tunnel Field-Effect Transistors and Their Post Metallization Annealing Effect ”. IEEE Transactions on Electron Devices 62(1), 9–15 (2015).

S. Agarwal & E. Yablonovitch . “Band-Edge Steepness Obtained From Esaki/Backward Diode CurrentVoltage Characteristics”. IEEE Transaction on Electron Devices 61(5), 1488–1493 (2014).

T. A. Ameen, H. Ilatikhameneh, G. Klimeck & R. Rahman . “ Few-layer Phosphorene: An Ideal 2D Material For Tunnel Transistors ”. Scientific reports 6, 28515, 10.1038/srep28515 (2016).

H. Ilatikhameneh, Y. Tan, B. Novakovic, G. Klimeck, R. Rahman & J. Appenzeller . “Tunnel Field-Effect Transistors in 2D Transition Metal Dichalcogenide Materials”. IEEE Exploratory Solid-State Computational Devices and Circuits 1(1), 12–18 (2015).

G. Fiori, F. Bonaccorso, G. Iannaccone, T. Palacios, D. Neumaier, A. Seabaugh, S. K. Banerjee & L. Colombo . “Electronics based on two-dimensional materials”. Nature nanotechnology 9(10), 768–779 (2014).

F. W. Chen, H. Ilatikhameneh, G. Klimeck, Z. Chen & R. Rahman . “Configurable Electrostatically Doped High Performance Bilayer Graphene Tunnel FET”. IEEE Journal of the Electron Devices Society 4(3), 124–128 (2016).

H. Ilatikhameneh, T. Ameen, G. Klimeck, J. Appenzeller & R. Rahman . “Dielectric Engineered Tunnel Field-Effect Transistor”. IEEE Electron Device Letters 36(10), 1097–1100, 10.1109/LED.2015.2474147 (2015).

J. Qiao et al. “High-mobility transport anisotropy and linear dichroism in few-layer black phosphorus”. Nature communications 5 (2014).

Y. Cai, G. Zhang & Y. W. Zhang . “Layer-dependent band alignment and work function of few-layer phosphorene”. arXiv preprint arXiv:1409.8418 (2014).

Y. Cai, G. Zhang & Y. W. Zhang . “Layer-dependent band alignment and work function of few-layer phosphorene”. Scientific reports 4 (2014).

S. Das, W. Zhang, M. Demarteau, A. Hoffmann, M. Dubey & A. Roelofs . “Tunable transport gap in phosphorene”. Nano letters 14(10), 5733–5739 (2014).

J. E. Fonseca, T. Kubis, M. Povolotskyi, B. Novakovic, A. Ajoy, G. Hegde, H. Ilatikhameneh, Z. Jiang, P. Sengupta, Y. Tan & G. Klimeck . “Efficient and realistic device modeling from atomic detail to the nanoscale”. Journal of Computational Electronics 12(4), 592–600 (2013).

S. Steiger, M. Povolotskyi, H. H. Park, T. Kubis & G. Klimeck . “ NEMO5: a parallel multiscale nanoelectronics modeling tool ”. IEEE Transaction on Nanotechnology 10(6), 1464–1474 (2011).

X. Peng, A. Copple & Q. Wei . “Edge effects on the electronic properties of phosphorene nanoribbons”. Journal of Applied Physics 116(14), 144301, Oct 14 (2014).

Q. Wu, L. Shen, M. Yang, Y. Cai, Z. Huang & Y. P. Feng . “Electronic and transport properties of phosphorene nanoribbons”. Physical Review B 92(3), 035436 (2015).

S. Lee, F. Oyafuso, P. von Allmen & G. Klimeck . “Boundary conditions for the electronic structure of finite-extent embedded semiconductor nanostructures”. Physical Review B 69(4), 045316 (2004).

A. K. A. Lu et al. “ Origin of the performances degradation of two-dimensional-based metal-oxide-semiconductor field effect transistors in the sub-10 nm regime: A first-principles study ”. Applied Physics Letters 108.4, 043504 (2016).

R. B. Salazar, H. Ilatikhameneh, R. Rahman, G. Klimeck & J. Appenzeller . “A predictive analytic model for high-performance tunneling field-effect transistors approaching non-equilibrium Green’s function simulations”. Journal of Applied Physics 118, 164305, http://dx.doi.org/10.1063/1.4934682 (2015).

M. Luisier & G. Klimeck . “ Simulation of nanowire tunneling transistors: From the WentzelKramersBrillouin approximation to full-band phonon-assisted tunneling ”. Journal of Applied Physics 107(8), 084507 (2010).

Acknowledgements

This work was supported in part by the Center for Low Energy Systems Technology (LEAST), one of six centers of STARnet, a Semiconductor Research Corporation program sponsored by MARCO and DARPA.

Author information

Authors and Affiliations

Contributions

H.I. came up with the idea of the L-gate TFET. H.I., T.A. and B.N. worked on the atomistic simulations and analyzed the data. Y.T. provided the tight-binding model for phosphorene. G.K. and R.R. supervised the work. All authors contributed to writing the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Ilatikhameneh, H., Ameen, T., Novakovic, B. et al. Saving Moore’s Law Down To 1 nm Channels With Anisotropic Effective Mass. Sci Rep 6, 31501 (2016). https://doi.org/10.1038/srep31501

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep31501

This article is cited by

-

Low-frequency noise performance of a molybdenum ditelluride double-gate MOSFET

Journal of Computational Electronics (2023)

-

Semi-analytical SPICE-compatible ballistic I–V model for 5 nm channel MoS2 FETs

Journal of Computational Electronics (2022)

-

An ultra-miniature broadband operational transconductance amplifier utilizing 10 nm wrap-gate CNTFET technology

Analog Integrated Circuits and Signal Processing (2021)

-

Investigation of 6-armchair graphene nanoribbon tunnel FETs

Journal of Computational Electronics (2021)

-

Charge Plasma-Based Phosphorene Tunnel FET Using a Hybrid Computational Method

Journal of Electronic Materials (2021)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.