Abstract

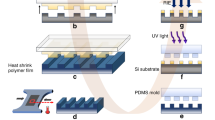

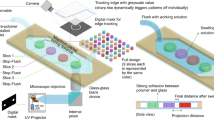

The patterning of polydimethylsiloxane (PDMS) into complex two-dimensional (2D) or 3D shapes is a crucial step for diverse applications based on soft lithography. Nevertheless, mould replication that incorporates time-consuming and costly photolithography processes still remains the dominant technology in the field. Here we developed monolithic quasi-3D digital patterning of PDMS using laser pyrolysis. In contrast with conventional burning or laser ablation of transparent PDMS, which yields poor surface properties, our successive laser pyrolysis technique converts PDMS into easily removable silicon carbide via consecutive photothermal pyrolysis guided by a continuous-wave laser. We obtained high-quality 2D or 3D PDMS structures with complex patterning starting from a PDMS monolith in a remarkably low prototyping time (less than one hour). Moreover, we developed distinct microfluidic devices with elaborated channel architectures and a customizable organ-on-a-chip device using this approach, which showcases the potential of the successive laser pyrolysis technique for the fabrication of devices for several technological applications.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The authors declare that all data supporting the findings of this study are available within the main text and Supplementary Information. Source data for the figures are available at https://doi.org/10.6084/m9.figshare.12601793.

References

Xia, Y. & Whitesides, G. M. Soft lithography. Angew. Chem. Int. Ed. Engl. 37, 550–575 (1998).

McDonald, J. C. & Whitesides, G. M. Poly(dimethylsiloxane) as a material for fabricating microfluidic devices. Acc. Chem. Res. 35, 491–499 (2002).

Sia, S. K. & Whitesides, G. M. Microfluidic devices fabricated in poly(dimethylsiloxane) for biological studies. Electrophoresis 24, 3563–3576 (2003).

Thorsen, T., Maerkl, S. J. & Quake, S. R. Microfluidic large-scale integration. Science 298, 580–584 (2002).

Huh, D. et al. Reconstituting organ-level lung functions on a chip. Science 328, 1662–1668 (2010).

Huh, D. et al. Microfabrication of human organs-on-chips. Nat. Protocols 8, 2135–2157 (2013).

Ko, S. H. et al. Direct nanoimprinting of metal nanoparticles for nanoscale electronics fabrication. Nano Lett. 7, 1869–1877 (2007).

Bhattacharjee, N., Urrios, A., Kang, S. & Folch, A. The upcoming 3D-printing revolution in microfluidics. Lab Chip 16, 1720–1742 (2016).

Choi, K. M. & Rogers, J. A. A photocurable poly(dimethylsiloxane) chemistry designed for soft lithographic molding and printing in the nanometer regime. J. Am. Chem. Soc. 125, 4060–4061 (2003).

Coenjarts, C. A. & Ober, C. K. Two-photon three-dimensional microfabrication of poly(dimethylsiloxane) elastomers. Chem. Mater. 16, 5556–5558 (2004).

Bhattacharjee, N., Parra-Cabrera, C., Kim, Y. T., Kuo, A. P. & Folch, A. Desktop-stereolithography 3D-printing of a poly(dimethylsiloxane)-based material with Sylgard-184 properties. Adv. Mater. 30, e1800001 (2018).

Wolfe, D. B. et al. Customisation of poly(dimethylsiloxane) stamps by micromachining using a femtosecond-pulsed laser. Adv. Mater. 15, 62–65 (2003).

Liu, H. B. & Gong, H. Q. Templateless prototyping of polydimethylsiloxane microfluidic structures using a pulsed CO2 laser. J. Micromech. Microeng. 19, 037002 (2009).

Marcinkevi Ius, A. et al. Femtosecond laser-assisted three-dimensional microfabrication in silica. Opt. Lett. 26, 277–279 (2001).

Cheng, Y., Sugioka, K. & Midorikawa, K. Microfluidic laser embedded in glass by three-dimensional femtosecond laser microprocessing. Opt. Lett. 29, 2007–2009 (2004).

Liao, Y. et al. Three-dimensional microfluidic channel with arbitrary length and configuration fabricated inside glass by femtosecond laser direct writing. Opt. Lett. 35, 3225–3227 (2010).

Cho, S. H., Chang, W. S., Kim, K. R. & Hong, J. W. Femtosecond laser embedded grating micromachining of flexible PDMS plates. Opt. Commun. 282, 1317–1321 (2009).

Liu, H. B. & Gong, H. Q. Templateless prototyping of polydimethylsiloxane microfluidic structures using a pulsed CO2 laser. J. Micromech. Microeng. 19, 037002 (2009).

Li, M. et al. A simple and cost-effective method for fabrication of integrated electronic-microfluidic devices using a laser-patterned PDMS layer. Microfluid. Nanofluid. 12, 751–760 (2012).

Yang, H., Deschatelets, P., Brittain, S. T. & Whitesides, G. M. Fabrication of high performance ceramic microstructures from a polymeric precursor using soft lithography. Adv. Mater. 13, 54–58 (2001).

Hidai, H., Yoshioka, M., Hiromatsu, K. & Tokura, H. Glass modification by continuous-wave laser backside irradiation (CW-LBI). Appl. Phys. A 96, 869–872 (2009).

Nakajima, Y., Hayashi, S., Katayama, A., Nedyalkov, N. & Terakawa, M. Femtosecond laser-based modification of PDMS to electrically conductive silicon carbide. Nanomaterials 8, 558 (2018).

Huan, H. & Zhixiong, G. Ultra-short pulsed laser PDMS thin-layer separation and micro-fabrication. J. Micromech. Microeng. 19, 055007 (2009).

Wang, Z. K., Zheng, H. Y., Lim, R. Y. H., Wang, Z. F. & Lam, Y. C. Improving surface smoothness of laser-fabricated microchannels for microfluidic application. J. Micromech. Microeng. 21, 095008 (2011).

Minerick, A. R., Ostafin, A. E. & Chang, H.-C. Electrokinetic transport of red blood cells in microcapillaries. Electrophoresis 23, 2165–2173 (2002).

Bahrami, M., Yovanovich, M. M. & Culham, J. R. Pressure drop of fully developed, laminar flow in rough microtubes. J. Fluids Eng. 128, 632–637 (2005).

Yang, S. C. Effects of surface roughness and interface wettability on nanoscale flow in a nanochannel. Microfluid. Nanofluid. 2, 501–511 (2006).

Heng, Q., Tao, C. & Tie-chuan, Z. Surface roughness analysis and improvement of micro-fluidic channel with excimer laser. Microfluid. Nanofluid. 2, 357–360 (2006).

Unger, M. A., Chou, H. P., Thorsen, T., Scherer, A. & Quake, S. R. Monolithic microfabricated valves and pumps by multilayer soft lithography. Science 288, 113–116 (2000).

Gerlach, A. et al. Microfabrication of single-use plastic microfluidic devices for high-throughput screening and DNA analysis. Microsyst. Technol. 7, 265–268 (2002).

Rötting, O., Röpke, W., Becker, H. & Gärtner, C. Polymer microfabrication technologies. Microsyst. Technol. 8, 32–36 (2002).

Campo, A. D. & Greiner, C. SU-8: a photoresist for high-aspect-ratio and 3D submicron lithography. J. Micromech. Microeng. 17, R81–R95 (2007).

Chen, C., Hirdes, D. & Folch, A. Gray-scale photolithography using microfluidic photomasks. Proc. Natl Acad. Sci. USA 100, 1499–1504 (2003).

Jeon, N. L. et al. Generation of solution and surface gradients using microfluidic systems. Langmuir 16, 8311–8316 (2000).

Cacucciolo, V. et al. Stretchable pumps for soft machines. Nature 572, 516–519 (2019).

Mishra, A. K. et al. Autonomic perspiration in 3D-printed hydrogel actuators. Sci. Robot. 5, eaaz3918 (2020).

Toepke, M. W. & Beebe, D. J. PDMS absorption of small molecules and consequences in microfluidic applications. Lab Chip 6, 1484–1486 (2006).

Regehr, K. J. et al. Biological implications of polydimethylsiloxane-based microfluidic cell culture. Lab Chip 9, 2132–2139 (2009).

Su, X. et al. Microfluidic cell culture and its application in high-throughput drug screening: cardiotoxicity assay for hERG channels. J. Biomol. Screen. 16, 101–111 (2011).

Hinson, J. T. et al. Titin mutations in iPS cells define sarcomere insufficiency as a cause of dilated cardiomyopathy. Science 349, 982–986 (2015).

Acknowledgements

This work is supported by the National Research Foundation of Korea (NRF) Grant funded through the Basic Science Research Program (2017R1A2B3005706, 2018R1A2A1A05019550).

Author information

Authors and Affiliations

Contributions

J.S. and S.J. prepared the samples with the assistance of P.W., Y.L. and J.Kim. S.H. assisted in analysing the data and improving the discussion. J.Ko designed the biochip and conducted cell culture experiments. J.S. and S.H.K. developed the SLP concept and wrote the manuscript. N.L.J. and S.H.K. supervised the overall project. All the authors contributed to the discussion and preparation of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Notes 1–11, Methods 1–3, Figs. 1–33, Tables 1–5 and refs 1–90.

Supplementary Video 1

Initiation and progression.

Supplementary Video 2

Onset of pyrolysis.

Supplementary Video 3

SiC cleaning.

Supplementary Video 4

Demonstration: concentration gradient generator.

Supplementary Video 5

Demonstration: skin-on-a-chip.

Supplementary Video 6

Demonstration: perfusable cell-bed.

Supplementary Video 7

Demonstration: MN array mould.

Supplementary Video 8

Medium through-put manufacturing (vasculature-on-a-chip).

Rights and permissions

About this article

Cite this article

Shin, J., Ko, J., Jeong, S. et al. Monolithic digital patterning of polydimethylsiloxane with successive laser pyrolysis. Nat. Mater. 20, 100–107 (2021). https://doi.org/10.1038/s41563-020-0769-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41563-020-0769-6

This article is cited by

-

Utilizing bioprinting to engineer spatially organized tissues from the bottom-up

Stem Cell Research & Therapy (2024)

-

Microfluidic high-throughput 3D cell culture

Nature Reviews Bioengineering (2024)

-

Pyrolytic Jetting of Highly Porous Laser-Induced Graphene Fiber for Cost-Effective Supercapacitor

International Journal of Precision Engineering and Manufacturing-Green Technology (2024)

-

Machining water through laser cutting of nanoparticle-encased water pancakes

Nature Communications (2023)

-

Stretchable graphene–hydrogel interfaces for wearable and implantable bioelectronics

Nature Electronics (2023)