Abstract

We herein demonstrate the unusual effectiveness of two strategies in combination to enhance photoelectrochemical water splitting. First, the work function adjustment via molybdenum (Mo) doping significantly reduces the interfacial energy loss and increases the open-circuit photovoltage of bismuth vanadate (BiVO4) photoelectrochemical cells. Second, the creation and optimization of the heterojunction of boron (B) doping carbon nitride (C3N4) and Mo doping BiVO4 to enforce directional charge transfer, accomplished by work function adjustment via B doping for C3N4, substantially boost the charge separation of photo-generated electron-hole pairs at the B-C3N4 and Mo-BiVO4 interface. The synergy between the above efforts have significantly reduced the onset potential, and enhanced charge separation and optical properties of the BiVO4-based photoanode, culminating in achieving a record applied bias photon-to-current efficiency of 2.67% at 0.54 V vs. the reversible hydrogen electrode. This work sheds light on designing and fabricating the semiconductor structures for the next-generation photoelectrodes.

Similar content being viewed by others

Introduction

Photoelectrochemical cell (PEC) for water splitting is a key technology of the future for hydrogen production1,2,3. Despite the widespread attention that has been received, this technology still has many hurdles to overcome and uncharted territories to explore. Ultimately, the photon to hydrogen conversion efficiency has yet to be increased to such a level that commercial applications could become viable4.

In the PEC water splitting process, photons are first absorbed by the photoelectrode producing electrons and holes, which are then separated and participated in the hydrogen evolution reaction (HER) on cathode and the oxygen evolution reaction (OER) on anode, possibly with the assistance of a bias voltage1. Therefore, one way to enhance the PEC efficiency is to increase the quantum efficiency of photons in a PEC system by improving the efficiencies of light harvesting, charge separation and surface charge transfer3,4,5,6,7,8,9,10. Another strategy to enhance the PEC efficiency is to minimize the overpotential by reducing the voltage loss related to charge recombination, sluggish surface kinetics, etc.

BiVO4 has received great attention in recent years because it is a promising sustainability-inspired photoanode material for PEC with a suitable band gap for visible light absorption11 and favorable conduction band edge position (0.1–0.2 V vs. NHE) for H2 evolution7. However, the PEC efficiency at low bias voltages of BiVO4 photoanode still has much room for improvement11,12,13. In particular, due to the presence of numerous trap states and surface defects as well as the associated surface Fermi-level pinning effect, the BiVO4 films variously prepared so far are still plagued by the quite low open-circuit photo-voltage when used as photoanodes11,14,15. To address this issue, doped photoanodes, such as W-BiVO4, Mo-BiVO4, have been fabricated aiming to enhance charge transport and to reduce the charge recombination11,12,16,17. Meanwhile, W-BiVO4/BiVO4, Co2O3/BiVO4, and BiOI/BiVO4 photoanodes have been developed in the form of so-called homojunctions and heterojunctions to enhance the charge separation in PEC systems6,13,18. Other problems of the BiVO4-based photoanode include the still low coverage of the solar spectrum which it is able to harvest as well as the low charge separation efficiency. To address these problems, carbon quantum dots/BiVO4 and nitrogen doped BiVO4 photoanodes have been reported showing broadened light absorption range, enhanced light harvesting efficiency, and boosted interfacial charge transfer for PEC water splitting9,18. As for improving the utilization efficiency of surface charge for oxygen evolution, the combined catalyst/photoelectrode systems, such as FeOOH/BiVO4, NiFeOx/BiVO4, Co-Pi/BiVO4, and NiOOH/FeOOH/BiVO4, have been commonly used7,19,20,21.

Recent efforts have improved the photocurrent density of BiVO4 based photoanodes for water splitting to nearly 90% of its theoretical value at 1.23 V vs. RHE22,23. However, the photon to hydrogen conversion efficiency is still far from its theoretical value mainly due to the stagnant carrier transport. Especially when a PEC cell works at low bias, the carrier transport is more susceptible to blockage by any potential barriers in the energy landscape along the carrier passage. Specifically, poor performance at low bias of BiVO4 based photoanodes led to poor applied bias photon-to-current efficiencies (ABPEs) as reported in some PEC water splitting systems, such as Bi-NiFeOx/BiVO4 (2.25%)20, NiOOH/FeOOH/BiVO4 (1.75%)7, NiO/CoOx/BiVO4 (1.5%)11, NiOOH/FeOOH/N-BiVO4 (2.2%)9. Previously, nanostructures and cocatalysts have been used to promote photocurrents and to minimize onset potentials, respectively7,19,20,21.

Meanwhile, because C3N4 has a favorable conduction band edge position relative to that of BiVO4, a heterojunction between the two could increase the charge separation. Prompted by this expectation, the conjugation of C3N4 with BiVO4 has received great attention in recent years24,25,26,27,28. However, before the C3N4/BiVO4 junction could efficiently drive the PEC water splitting, new strategies must be developed to elaborate the band structure at the junction to optimize charge separation by minimizing interfacial kinetic barriers and energy losses.

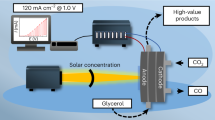

In this work, we endeavored to explore such ways to further improve the PEC performance of the BiVO4 photoanode. First, we systematically studied the effect of Mo doping on the electron band structure of BiVO4, and discovered that a moderate Mo doping of BiVO4, a low end doping regime that has not been explored before, can increase the photo-voltage of BiVO4 photoanodes from 0.24 V to ~1 V in 10 s irradiation. Second, to further improve the charge separation efficiency at low bias, we elaborated a cliff like junction between B-C3N4 and Mo-BiVO4, for which the band structure of C3N4 was judiciously tuned as well by B doping. With such an elaborated junction, interfacial charge transfer was remarkably enhanced. As the main thread running through this work, we make special efforts to advance our ability to modulate the work functions with a view to toning up the NiFeOx/B-C3N4/Mo-BiVO4 photoanodes for PEC water splitting. We have significantly increased the light harvesting efficiency (LHE) of the B-C3N4/Mo-BiVO4 photoanode, achieving photocurrent densities of 4.7 mA cm−2 at 0.6 V vs. RHE (ΦSep = 79%) and 6 mA cm−2 at 1.23 V vs. RHE (ΦSep = 98%) in potassium phosphate buffer (PPB) solution with 0.5 M Na2SO3 hole scavenger (pH 7). When the NiFeOx was anchored on the B-C3N4/Mo-BiVO4 photoanode as an OER catalyst layer forming the NiFeOx/B-C3N4/Mo-BiVO4 photoanode, we obtained photocurrent densities of 3.85 mA cm−2 at 0.54 V vs. RHE (71% IPCE) and 5.93 mA cm−2 at 1.23 V vs. RHE (92% IPCE) in PPB solution without any hole scavengers such as Na2SO3 (pH 7). Significantly, the NiFeOx/B-C3N4/Mo-BiVO4 photoanode has achieved an ABPE up to 2.67% at 0.54 V vs. RHE, which is the highest reported to date and yet, with the lowest biased-voltage, for BiVO4-based PEC devices.

Results

Characterization of the NiFeOx/B-C3N4/Mo-BiVO4 photoanode

The XRD patterns collected from BiVO4, Mo-BiVO4, B-C3N4/Mo-BiVO4, NiFeOx/B-C3N4/Mo-BiVO4 prepared on the F-doped SnO2 conducting glass (FTO), C3N4 and B-C3N4 are shown in Supplementary Fig. 1. All of the diffraction peaks in the XRD patterns obtained can be well indexed to monoclinic BiVO4 (JCPDS PDF #75–1866), SnO2 (JCPDS PDF #41–1445) and graphite-C3N4 (JCPDS PDF #50–1250)18,29,30. As shown in Fig. 1a, the champion photoanode consisted of nanoporous B-C3N4/Mo-BiVO4 heterojunctions in tandem with a NiFeOx oxygen evolution catalyst (OEC) layer, which were successfully grown on the FTO substrate. (Supplementary Fig. 2) As shown in Fig. 1b–g, signals of Bi, C, O, and Fe elements are clearly observed in a row, suggesting that the newly-coated B-C3N4 has covered the nanoporous Mo-BiVO4, and NiFeOx layer has covered the B-C3N4/Mo-BiVO4 as the OEC. Figures 1h, i is a typical TEM image and a high-resolution TEM (HRTEM) image of the NiFeOx/B-C3N4/Mo-BiVO4 sample, respectively, revealing that the B-C3N4 and Mo-BiVO4 are crystallized (Fig. 1j, k) while NiFeOx is non-crystallized (Fig. 1l). The lattice fringes of 0.325 nm and 0.254 nm are ascribed to the (002) plane31 of C3N4 and the (020) plane32 of BiVO4, respectively.

Electron microscopic characterization of the NiFeOx/B-C3N4/Mo-BiVO4 photoanodes. a Top-view (inset is the magnified image) SEM images of the NiFeOx/B-C3N4/Mo-BiVO4 photoanode. b HADDF-STEM image of the NiFeOx/B-C3N4/Mo-BiVO4 photoanode and c–f the corresponding STEM-EDS elemental mapping images for Bi, C, O, and Fe, respectively. g Overlay of the elemental mapping images of Fe, C, and Bi. h TEM, i HRTEM image of the NiFeOx/B-C3N4/Mo-BiVO4 photoanode and j–l corresponding diffraction patterns via fast Fourier transform of NiFeOx, B-C3N4, and Mo-BiVO4, respectively

Work function tuning

The first strategy we used to optimize the PEC performance of BiVO4-based photoanodes, more precisely, to lower the onset potential, was to systematically adjust the work function by Mo doping below 1%, which is a previously uncharted doping regime (the atomic ratio is shown in Supplementary Table 1). Figure 2a compares the linear sweep voltammograms (LSV) curves of BiVO4 (black line), 0.05% Mo doped BiVO4 (blue line) and 0.1% Mo doped BiVO4 (red line) 0.5% Mo doped BiVO4 (purple line) at a scan rate of 25 mV s−1 in 0.5 M Na2SO3 aqueous solution as a hole scavenger with PPB (pH 7) under AM 1.5 G one-sun illumination. The pure BiVO4 photoanode achieved photocurrent density of 3.2 (±0.3) mA cm−2 at 0.6 V vs. RHE and 4.7 (±0.3) mA cm−2 at 1.23 V vs. RHE, in agreement with the previous report7. With a slight doping, the photocurrent density of 0.1% Mo-BiVO4 increased to 3.4 (±0.2) mA cm−2 at 0.6 V vs. RHE and 4.98 (±0.2) mA cm−2 at 1.23 V vs. RHE. From our extensive measurements, the photocurrent densities assuming 100% absorbed photon-to-current efficiency (Jabs) of the BiVO4-based and the Mo-BiVO4-based photoanodes were consistently ~4.7 mA cm−2 and ~5.01 mA cm−2, respectively (Supplementary Fig. 3). The increase in Jabs could be ascribed to the enhanced LHE, carrier concentration (Supplementary Fig. 27) and mobility (Supplementary Fig. 28) resulting from the Mo doping33,34,35,36,37. More interestingly, the onset potential of Mo doped BiVO4 (0.05, 0.1, and 0.5%) photoanodes became significantly more negative than that of pure BiVO4 photoanode, and the rapid photocurrent increase region against bias for the 0.05% and 0.1% Mo doped BiVO4 is also more negative than that of the BiVO4 photoanode. However, the rapid photocurrent increase region against bias for the 0.5% Mo doped BiVO4 is more positive than that of BiVO4. This phenomenon is caused by the changed open-circuit photo-voltage (OCP) of BiVO4 due to the work function adjustment by the Mo doping.

Photoelectrochemical and photo-voltage characterization of the BiVO4-based photoanodes. a LSV curves of pure-BiVO4, 0.05% Mo-BiVO4, 0.1% Mo-BiVO4, and 0.5% Mo-BiVO4 recorded at a scan rate of 25 mV s−1 under AM 1.5 G one-sun irradiation in PPB solution with 0.5 M Na2SO3 as a hole scavenger (pH 7). b Band structures and band bending schematics of pure-BiVO4, 0.05% Mo-BiVO4, 0.1% Mo-BiVO4, and 0.5% Mo-BiVO4, constructed from the XPS, UPS and photoelectrochemical measurement data

Supplementary Fig. 5 shows OCP changes of the Mo doped BiVO4 (0.05, 0.1, and 0.5%) relative to the pure BiVO4 photoanode due to the truncation of Fermi-level pinning and surface trap states of BiVO4. OCP is essentially the difference between open-circuit voltage in dark (OCVdark) and light (OCVlight). The work function is tuned in such a way that the Fermi level (Ef) is far from CBM when light is off resulting in a small OCVdark, but when light is on (AM 1.5 G), the quasi-Fermi-level (Efn) becomes as close as possible to CBM giving rise to a large OCVlight. Consequently, a large OCP (Vph) can be obtained. Shown in Supplementary Fig. 5 are the OCP timing profiles of the Mo doped BiVO4 (0.05, 0.1, and 0.5%) and the pure BiVO4 photoanodes in PPB solution with the Na2SO3 hole scavenger (pH 7) over a testing interval of 30 s (Supplementary Fig. 5a) and 2000 s (Supplementary Fig. 5b). The most important observation is that the 0.1% Mo-BiVO4 photoanode achieved the highest OCP (~1 V in the first irradiation on/off cycle, and ~0.55 V in the cycles after testing for 1600 s). These OCP values are much higher than those of pure-BiVO4 (~0.35 V and ~0.15 V), 0.05% Mo-BiVO4 (~0.8 V and ~0.4 V), and 0.5% Mo-BiVO4 photoanode (~0.23 V and ~0.16 V) when tested under otherwise the same conditions. A higher OCP value means a more favorable driving force for water oxidation since it determines the difference between the hole quasi-Fermi-level of the semiconductor heterojunction and the redox potential of the electrolyte.

The above presented OCP result can be captured by the picture illustrated in Fig. 2b. For the pure BiVO4, the Fermi-level position of ideal BiVO4 is close the valence band edge of BiVO49, but the lattice defects formed during synthesis and surface state trapped electrons (V4+) of pure BiVO4 move the Ef of pure BiVO4 negatively (Supplementary Fig. 23)38,39,40. When the pure BiVO4 photoanode was immersed in the solution, the Ef of pure BiVO4 became more negative than the redox potential due to Fermi-level pinning by surface trapped electrons, making the OCVdark of BiVO4 relatively high11. Meanwhile, under AM 1.5 G illumination, the Fermi-level pinning effect prevented the Efn moving very close to the conduction band minimum (CBM) of BiVO411,38, leading to a moderate OCVlight and thus a low OCP (Vph) of pure BiVO4 very low. Importantly, the Mo doping in BiVO4 could reduce the surface trap states and at the same time introduced new states, thus moderating the Fermi-level pinning effect (Supplementary Fig. 4)41. Due to the reduced Fermi-level pinning effect by Mo doping, for the 0.05% and 0.1% Mo-BiVO4 photoanodes, the Ef and Efn became more positive and negative than Ef of the pure BiVO4 photoanode, respectively, thereby enhancing the OCPs. However, for the 0.5% Mo-BiVO4, new states were introduced due to the excess Mo doping, and the Ef became much closer to CBM, leading to high OCVdark (Supplementary Fig. 6) and thus a low OCP. As such, the OCP of 0.1% Mo-BiVO4 is the best of all the samples we studied, in agreement with the corresponding PEC performance as will be presented below. As can be seen from Fig. 2a, the photocurrent density of 0.1% Mo-BiVO4 reached 5.0 (±0.2) mA cm−2 at 1.23 V vs. RHE in solution with hole scavenger, which represents ~73% the theoretical water oxidation photocurrent density (Jmax) of BiVO4 (6.8 mA cm−2). Thus the moderate Mo doping of BiVO4 in the low end doping regime can increase the photo-voltage carrier concentration and mobility of the BiVO4 photoanodes, and improve their onset potential and photocurrent density.

Heterojunction engineering

We now turn to our second strategy to optimize the PEC performance of BiVO4-based photoanodes by further increasing the utilization of Jmax. To accomplish it, we started with the basic C3N4/BiVO4 junction, and then work up for optimization by B-doping C3N4 and the Mo-doping BiVO4. Both LHE and charge separation have been enhanced, leading to the increase of Jabs and ΦSep of the photoanode. Supplementary Fig. 7 shows the UV–vis absorption spectra from the diffuse reflectance measurements and photographs of B-C3N4 and C3N4. From visual inspection, the yellow color of B-C3N4 is clearly deeper than C3N4, and correspondingly, the absorption of B-C3N4 is also stronger than C3N4. From the plots in Supplementary Fig. 8a of (αhν)2 vs. the photon energy (hν), the band-gap energy of C3N4 and B-C3N4 are 2.53 eV and 2.41 eV, respectively. Supplementary Fig. 8b is the LHE of B-C3N4/Mo-BiVO4, which exhibits stronger absorption in the range between 300 nm and 500 nm than Mo-BiVO4. Supplementary Fig. 8c shows the spectra of the solar irradiance of AM 1.5 G (ASTM G173-03) and those weighted by the LHE spectra of B-C3N4/Mo-BiVO4, which shows the Jabs of B-C3N4/Mo-BiVO4 achieved ~6.0 mA cm−2. Figure 3a compares the LSV curves of 0.1% Mo-BiVO4 (black line), C3N4/Mo-BiVO4 (cyan line) and B-C3N4/Mo-BiVO4 (purple line) at a scan rate of 25 mV s−1 using 0.5 M Na2SO3 as a hole scavenger in a PPB buffered aqueous solution (pH7) under AM 1.5 G irradiation. The photocurrent density of B-C3N4/Mo-BiVO4 reached ~6 mA (±0.2) cm−2 at 1.23 V vs. RHE, and this is higher than that of 0.1% Mo-BiVO4 (5 mA cm−2), at least partly due to the increase in LHE and Jabs after the conjugation with B-C3N4. At 0.6 V vs. RHE, the photocurrent density of B-C3N4/Mo-BiVO4 was 4.7 mA cm−2, which is much higher than that of 0.1% Mo-BiVO4 (3.4 mA cm−2). However, the photocurrent of C3N4/Mo-BiVO4 only achieved 2.9 and 4.2 mA cm−2 at 0.6 and 1.23 V vs. RHE, which are lower than that of Mo-BiVO4 (3.4 and 5 mA cm−2), although increased LHE and Jabs by compositing C3N4 and B-C3N4. The results of ΦSep of Mo-BiVO4 (black line), C3N4/Mo-BiVO4 (cyan line) and B-C3N4/Mo-BiVO4(purple line) clearly shows that B-C3N4 decoration can great increase the ΦSep of Mo-BiVO4, while pure C3N4 decoration will reduce the ΦSep of Mo-BiVO4 (Fig. 3b). The ΦSep of B-C3N4/Mo-BiVO4 achieved 79 and 98% at 0.6 V and 1.23 V vs. RHE, respectively. The ΦSep of B-C3N4/Mo-BiVO4 at 0.6 V vs. RHE is higher than that of Mo-BiVO4 (69%), and at 1.23 V vs. RHE, the ΦSep of Mo-BiVO4 andB-C3N4/Mo-BiVO4 are achieved near 100% cause the charge separation of Mo-BiVO4 and B-C3N4/Mo-BiVO4 have reached their limits at higher bias voltage. However, the ΦSep of C3N4/Mo-BiVO4 only achieved 60 and 80% at 0.6 V and 1.23 V vs. RHE, which are even lower than that of Mo-BiVO4. This result shows that when C3N4 is compositing the Mo-BiVO4, it has no effect on the separation of the photo-generated charges. These results mean that although the thermodynamic potential of pure C3N4 and Mo-BiVO4 are match, the heterojunction of pure C3N4 and Mo-BiVO4 became a compound center of photo-generated charge.

Photoelectrochemical performances and charge transfer processes. a LSV curves of C3N4/Mo-BiVO4, 0.1% Mo-BiVO4 and B-C3N4/Mo-BiVO4 measured at a scan rate of 25 mV s−1 under AM 1.5 G irradiation in PPB solution with Na2SO3 as a hole scavenger (pH 7). b Separation efficiency (ΦSep) of C3N4/Mo-BiVO4, 0.1% Mo-BiVO4 and B-C3N4/Mo-BiVO4. XPS core-level shifts of c V 2p, O 1 s and d N 1 s. Schematic diagrams of the band structures of e C3N4/Mo-BiVO4, f B-C3N4/Mo-BiVO4

As shown in Fig. 3c, d, when the Mo-BiVO4 and pure C3N4 are in contact, the O1s and V2p positive shift 0.34 eV and N1s negative shifts 0.96 eV. Supplementary Fig. 9 shows the CBM, VBM and Fermi level of BiVO4, Mo-BiVO4, C3N4 and B-C3N4 by UPS and XPS VB spectra data (Supplementary Figs. 10, 11, 12, and 13). The Fermi level of BiVO4 and Mo-BiVO4 are in the middle of their band gap (BiVO4: 1.21 eV and Mo-BiVO4: 1.16 eV) and the Fermi level of B-C3N4 is close to its VBM, and the Fermi level of pure C3N4 is close to its CBM. The DFT data confirms that the Fermi energy level of Mo-BiVO4 and B-C3N4 changed after Mo and B element doping (Supplementary Fig. 14). In detail, when Mo-BiVO4 and C3N4 come into contact to form a heterojunction, the bands on the two sides bend oppositely into the spike-like structure (Fig. 3e), and thus the electrons from the C3N4 side can hardly transfer to the Mo-BiVO4 side. The holes inside Mo-BiVO4 will hardly transfer to C3N4, as the existence of energy barrier at the interface. Therefore, the contact interface of pure C3N4 and Mo-BiVO4 will reduce the separation of photo-generated charges. On the other hand, due to the B element doping, the Fermi level of B-C3N4 is getting closer to the VBM (Supplementary Fig. 9b). As shown in Fig. 3d, when the Mo-BiVO4 and B-C3N4 are in contact, a cliff like junction is formed with the correct charge transfer direction, which will increase the separation of photo-generated charges. Supplementary Fig. 15 displays the Raman spectra of Mo-BiVO4, C3N4, B-C3N4, C3N4/Mo-BiVO4 and B-C3N4/Mo-BiVO4. The Raman peaks at 702 cm−1 and 746 cm−1 are attributed to the C-N vibration of B-C3N4 (Blue line). The peak at 816 cm−1 are attributed to the V–O vibration, while the peaks at 362 cm−1 and 323 cm−1 can be attributed to the VO43- vibration of the Mo-BiVO4. The Raman peaks of B-C3N4 (702 cm−1, 746 cm−1) and Mo-BiVO4 (362 cm−1, 323 cm−1) shifted to 545 cm−1, 620 cm−1, and 340 cm−1, 314 cm−1 in B-C3N4/Mo-BiVO4 sample, indicating the formation of chemical bonds between B-C3N4 and Mo-BiVO4. In other words, the B-C3N4 is chemically linked to Mo-BiVO4.

PEC water splitting performance

In order to use the B-C3N4/Mo-BiVO4 photoanode for PEC water splitting in solution without hole scavenger, the NiFeOx layer was used as an OEC material, which was deposited on the photo-active area of B-C3N4/Mo-BiVO4 photoanode surface by photoelectrodeposition method. Supplementary Figs. 16 and 17 show the XPS data of Ni, N, B, C, Bi, Mo, O, and Fe. For B-doped C3N4, as can be seen from Supplementary Figs. 16c, the peak of B is located at around 191.9 eV, fairly close to the binding energy of B in the –C–N–B– and –N–B–(N)2– groups (192.1 eV) of the B-C3N4 materials reported in the literature42. The oxidation state of B is consistent with the results of B-doped C3N4 in the reported literature27. As shown in Fig. 4a and Supplementary Fig. 21, the PEC water splitting capability of NiFeOx/B-C3N4/Mo-BiVO4 photoanode (orange solid line) achieves 4.18 mA cm−2 and 5.93 (±0.3) mA cm−2 at 0.6 V vs. RHE and 1.23 V vs. RHE in PPB solution (pH 7), which are much higher than that of Mo-BiVO4 photoanode and B-C3N4/Mo-BiVO4, Meanwhile, the photocurrent density of NiFeOx/B-C3N4/Mo-BiVO4 photoanode at 0.6 V vs. RHE and 1.23 V vs. RHE are much close to that of NiFeOx/B-C3N/Mo-BiVO4 photoanode (orange dotted line) in PPB solution with Na2SO3 hole scavenger (pH 7, 4.37 (±0.3) mA cm−2 and 5.96 (±0.3) mA cm−2). Supplementary Fig. 18 shows that the B-C3N4 can not only increase the photocurrent density in the low biased-voltage range (0.1~0.8 V vs. RHE) by increasing the separation efficiency of photoanode, but also increase the photocurrent density in the high biased-voltage range (0.8~1.3 V vs. RHE). The IPCEs of NiFeOx/B-C3N4/Mo-BiVO4, NiFeOx/Mo-BiVO4, NiFeOx/ BiVO4, B-C3N4/Mo-BiVO4, Mo-BiVO4, and BiVO4 at 0.54 V vs. RHE in PPB solution (pH 7), which shows that the B-C3N4 can increase the charge separation efficiency and light absorption of photoanode. On the other hand, the NiFeOx cannot increase light absorption of photoanode, and it only plays the role of a co-catalyst (OEC) here (Supplementary Fig. 19). In Fig. 4b, due to the high oxygen evolution reaction capacity of NiFeOx OEC, the dark LSV of NiFeOx/B-C3N/Mo-BiVO4 photoanode shows a remarkable cathodic shift (~340 mV) of onset potential compared to B-C3N4/Mo-BiVO4 photoanode and Mo-BiVO4 photoanode. However, the LSV curves of the B-C3N4/Mo-BiVO4 and NiFeOx/B-C3N4/Mo-BiVO4 recorded at a scan rate of 25 mV s−1 in PPB solution with Na2SO3 as a hole scavenger (pH 7), which shows that the photocurrent density of samples measured in solution with Na2SO3 will decline after the NiFeOx layer deposition (Supplementary Fig. 20). Figure 4c shows the half-cell applied bias photo-to-current efficiency (ABPE) of the NiFeOx/B-C3N4/Mo-BiVO4 photoanode. The ABPE is calculated to be 2.67% at 0.54 V vs. RHE, which is the highest recorded for BiVO4-based photoanodes (Fig. 6c). Evidently, the highest efficiency has been achieved for the NiFeOx/B-C3N4/Mo-BiVO4 photoanode at the lowest potential (0.54 V vs. RHE) among the previously reported values, which shows the highest performance of PEC water splitting for BiVO4-based photoanodes. Shown in Supplementary Figs. 25 and 26 are the LSV curves and ABPE measurement results in the two electrodes configuration (NiFeOx/B-C3N4/Mo-BiVO4 photoanode and Pt cathode) in PPB solution (pH 7). It can be seen that the ABPE of whole PEC system (without reference electrode) achieved 2.1% at 0.62 V vs. Pt. Figure 4d shows the incident-photon-to-current conversion efficiency (IPCE) and the absorbed photon-to-current efficiency (APCE) spectra of NiFeOx/B-C3N4/Mo-BiVO4 photoanode at 0.54 V vs. RHE and 1.23 V vs. RHE in PPB solution (pH 7). The maximum IPCE value of NiFeOx/B-C3N4/Mo-BiVO4 photoanode reaches ~71 and 92% at 0.54 V vs. RHE and 1.23 V vs. RHE. The APCE of NiFeOx/B-C3N4/Mo-BiVO4 photoanode reaches ~100% at 1.23 V vs. RHE, establishing the NiFeOx/B-C3N4/Mo-BiVO4 photoanode used all the light it could absorb for PEC water splitting at 1.23 V vs. RHE. Therefore, these results clearly show that the NiFeOx OEC can greatly improve the PEC capacity of B-C3N4/Mo-BiVO4 photoanode in the absence of any hole scavenger.

Photoelectrochemical performances. LSV curves of the Mo-BiVO4, B-C3N4/Mo-BiVO4 and NiFeOx/B-C3N4/Mo-BiVO4 recorded at a scan rate of 25 mV s−1 in PPB solution without Na2SO3 as a hole scavenger (pH 7) a under AM 1.5 G irradiation and b in dark. c ABPE of NiFeOx/B-C3N4/Mo-BiVO4. d IPCE and APCE of NiFeOx/B-C3N4/Mo-BiVO4 at 0.54 V vs. RHE (left) and 1.23 V vs. RHE (right) in PPB solution (pH 7)

As shown in Fig. 5 and Supplementary Video 1, the NiFeOx/B-C3N/Mo-BiVO4 photoanode exhibits excellent operational stability for half-cell PEC water splitting in PPB solution (pH 7) at 0.54 V vs. RHE under AM 1.5 G irradiation. Figure 5a shows the photograph of the NiFeOx/B-C3N/Mo-BiVO4 photoanode half-cell PEC water splitting system, and Fig. 5b–d show the photographs of the photoanode, the Pt cathode and the Ag/AgCl reference electrode separately. The chronoamperometry curve of the NiFeOx/B-C3N4/Mo-BiVO4 photoanode was collected at 0.54 V vs. RHE in 10 h. The photocurrent density of the NiFeOx/B-C3N4/Mo-BiVO4 photoanode was initially 3.85 mA cm−2 and decreased by only 10% after 10 h of operation, demonstrating the good stability of the NiFeOx/B-C3N4/Mo-BiVO4 photoanode during the long time irradiation in PPB solution (Fig. 5e). And the photocurrent densities of the NiFeOx/Mo-BiVO4 and NiFeOx/B-C3N4/Mo-BiVO4 photoanodes decayed by 5 and 8% (Supplementary Fig. 24), respectively, very close to the stability testing result of the NiFeOx/B-C3N4/Mo-BiVO4 photoanode at 0.54 V vs. RHE. These results confirm that the NiFeOx is a stable co-catalyst for the BiVO4-based photoanodes, essentially consistent with the recent reports. The generation rates of H2 and O2 by our half-cell system are measured to be 77.5 μM/h and 336 μm 33.6 μM/h, respectively, with Faradic efficiency of 98% (Fig. 5f).

Photoelectrochemical water splitting performances. Photographs of the NiFeOx/B-C3N4/Mo-BiVO4 photoanode in the PEC water splitting system (a), the NiFeOx/B-C3N4/Mo-BiVO4 photoanode in a blown-up view (b), the Pt cathode (c), and the Ag/AgCl reference electrode (d). e Chronoamperometry (i–t) curve of NiFeOx/B-C3N4/Mo-BiVO4 photoanode collected at 0.54 V vs. RHE under AM 1.5 G illumination in PPB solution (pH 7). f H2 and O2 evolution of the NiFeOx/B-C3N4/Mo-BiVO4 photoanode at 0.54 V vs. RHE; dashed curves indicate the H2 and O2 evolution with 98% Faraday efficiency

Discussion

In conclusion, the NiFeOx/B-C3N4/Mo-BiVO4 photoanode has provided an archetype to exploit the potential of boosting the photoelectrochemical performance by the synergistic combination of work function tuning and heterojunction construction. The bespoke photoanode achieved a remarkable photocurrent density of 3.85 mA cm−2, ABPE of 2.67% and IPCE of 71% at 0.54 V vs. RHE, which are the highest yet reported with the lowest biased-voltage for BiVO4-based PEC materials. The NiFeOx/B-C3N/Mo-BiVO4 photoanode exhibited significantly enhanced PEC activity for water splitting by systematically work function adjustment (Fig. 6a). We have demonstrated the work function adjustment via Mo doping could reduce the interfacial energy loss and increase the open-circuit photo-voltage of BiVO4 PEC cells. In addition, the creation and optimization of the heterojunction (p-n) of B-C3N4 and Mo-BiVO4 with correct charge transfer direction were accomplished by work function adjustment via B doping for C3N4, thereby increasing the separation of photo-generated electron-hole pairs at the B-C3N4 and Mo-BiVO4 interface (Fig. 6a, b). The data of DFT calculation, XPS and UPS confirm the Fermi level and band shift of B-C3N4 and Mo-BiVO4. This synergistic effect between B doping of C3N4 and Mo doping of BiVO4 with the NiFeOx OEC has allowed the NiFeOx/B-C3N4/Mo-BiVO4 photoanode to achieve the record – the highest PEC water splitting performance (2.67% ABPE) with a fairly low bias-voltage (0.54 V vs. RHE), which shows the efficiency of ABPE are the highest recorded for BiVO4-based photoanodes4,7,9,11,13,18,20,43,44,45. The demonstration of the NiFeOx/B-C3N4/Mo-BiVO4 photoanode with excellent PEC water splitting capability achieved by the synergistic combination of work function tuning and heterojunction deliberation will inform the design and development of the next-generation PEC materials and devices.

Photoelectrochemical water splitting characterization. a Schematic diagram illustrating the separation of photo-generated electrons and holes of the NiFeOx/B-C3N4/Mo-BiVO4 photoanode, b LSV curves of pure-BiVO4, B-C3N4/Mo-BiVO4 recorded at a scan rate of 25 mV s−1 under AM 1.5 G one-sun irradiation in PPB solution using 0.5 M Na2SO3 as a hole scavenger (pH 7), c specific photocurrent density at 1.23 V vs. RHE and applied bias photo-to-current efficiency (ABPE) of BiVO4 based photoanode4,7,9,11,13,18,20,41,42,43.

Methods

Preparation of BiVO4 and Mo-BiVO4 electrode

BiVO4 photoanodes were fabricated by a two-step process via a modified method which was originally developed by Kim and Choi7. At first, a template-free electrochemical deposition was applied to prepare the BiOI nanosheets using a conventional three-electrode glass cell, where a piece of F-doped SnO2 coated glass (FTO, Nippon Sheet Glass, 1 × 2 cm) served as the working electrode, a Pt electrode served as the counter electrode and an Ag/AgCl electrode served as the reference electrode. Generally, 50 mL of solution containing 0.4 M KI (99.0%, Tianjin Zhiyuan Reagent Co. Ltd.) and 0.04 M Bi(NO3)3 (99.0%, Shanghai Macklin Biochemical Co. Ltd) was adjusted pH to 1.7 by adding HNO3 (65–68%, AR, Guangzhou Chemical Reagent). Then, 20 mL of absolute ethanol (100%) containing 0.23 M p-benzoquinone (97%, Aladdin) was mixed into the above solution and vigorously stirred for several minutes. Cathodic deposition of BiOI (1 × 1 cm area) was performed potentiostatically in the final solution at −0.1 V vs. Ag/AgCl at room temperature (RT) for 200 s. The second step was the conversion of BiOI to BiVO4. Dimethyl sulfoxide (DMSO, AR, Tianjin Damao Reagent) solution containing 0.2 M vanadyl acetylacetonate (VO(acac)2, 95%, Aladdin) was impregnated on BiOI electrodes (50 μL cm−1) and then annealed in air at 450 °C for 2 h with ramping rate of 2 °C min−1. Lastly, the BiVO4 electrodes were soaked in 1 M NaOH (AR, Guangzhou Chemical Reagent) solution for 1 h with gentle stirring to remove the excess V2O5. The obtained pure BiVO4 electrodes were rinsed by deionizer water and dried at RT.

Molybdenum doped BiVO4 (Mo-BiVO4) photoanodes were prepared in the same way by adding Na2MoO4 as the Mo source. In detail, 1, 2, and 10 μL 0.1 M Na2MoO4 (AR, Tianjin Damao Reagent) aqueous solution was added into 1 mL the above VO(acac)2 DMSO solution before it was impregnated on BiOI electrodes. The corresponding concentration ratio of Mo/Bi was 0.05%, 0.1%, and 0.5%, respectively.

Preparation of C3N4 and B-C3N4

The bulk graphite-C3N4 (C3N4) was fabricated by directly heating low-cost melamine (99%, Aladdin). In detail, 5 g melamine powder was placed in an alumina crucible with a cover, then heated to 500 °C for 2 h in a muffle furnace with a heating rate of 2 °C min−1. The obtained bulk C3N4 was grind into small powder, and 100 mg C3N4 powder was dispersed in 100 mL isopropyl alcohol (AR, Tianjin Damao Reagent) and exfoliated by ultrasonication for 24 h to obtain C3N4 nanosheets (C3N4-NS). The resultant dispersion was centrifuged at 3000 rpm for 10 min, and the supernatant containing exfoliated C3N4-NS was collected by pipette. Boron doped C3N4 nanosheets (B-C3N4-NS) supernatants were prepared in the same way but heating the mixture of 0.5 g boric acid (GR, Aladdin) and 5 g melamine.

Preparation of C3N4/BiVO4 and B-C3N4/Mo-BiVO4 electrode

The BiVO4 or Mo-BiVO4 photoanodes were immersed into 20 mL C3N4-NS or B-C3N4-NS supernatants for 1 h. After rinsed with deionizer water, the obtained (B-)C3N4/(Mo-)BiVO4photoanodes were annealed at 350 °C in air for 1 h for better combination.

Photoelectrodeposition of NiFeOx OEC layer

NiFeOx OEC layer were synthesized using a simple photoelectrodeposition method reported. NiFeOx layer was photoelectrodeposited on the B-C3N4/Mo-BiVO4 in 0.4 M FeSO4 and 0.04 M NiSO4 solution at 0.6 V vs. Ag/AgCl (total charge 100 mC/cm2) at RT. The NiFeOx/B-C3N4/Mo-BiVO4 electrode was then washed with deionizer water and dried in air at 60 °C.

Analysis

The as-synthesized products were characterized by a scanning electron microscope (SEM, Zeiss G-500), transmission electron microscopy (TEM, JEOL 2100 F, FEI Tecnai G2F30), X-Ray Diffractometer (XRD, D8 ADVANCE), X-ray Photoelectron Spectroscopy (XPS) and Ultroviolet Photoelectron Spectroscopy (UPS, Thermo Fisher Scientific ESCALab250) and Raman spectroscopy (Renishaw inVia). The optical properties of the products were measured with an UV–vis–NIR Spectrophotometer (UV–vis–NIR, Shimadzu UV-2450).

Photoelectrochemical and electrochemical measurements

All the PEC and electrochemical measurements were carried out in a three-electrode cell with a flat quartz window to facilitate illumination of the photoelectrode surface. The working electrode is the product fabricated in this work, while Pt electrode was used as a counter electrode and Ag/AgCl electrode was used as a reference electrode, respectively. The illumination source was AM 1.5 G solar simulator (Newport, LCS 100 94011 A (class A, Supplementary Fig. 29) directed at the quartz PEC cell (100 mW cm−2). Incident-photon-to-current conversion efficiency (IPCE) were collected by a Solartron 1280B electrochemical station with a solar simulator (Newport 69920, 1000 W xenon lamp), coupled with an infrared water filter (Oriel 6127) and aligned monochromator (Oriel Cornerstone 130 1/8 m). All the electrochemical measurements were performed on an SP-150 electrochemical workstation (SP-150, Bio-Logic SAS, France) at RT. More PEC and electrochemical calculations are shown in the Supporting information.

Data availability

The authors declare that the main data supporting the findings of this study are available within the article and its Supplementary Information files. Extra data are available from the corresponding author upon request. All relevant data are available from the authors upon reasonable request.

References

Grätzel, M. Photoelectrochemical cells. Nature 414, 338–344 (1983).

Sivula, K. & Van De Krol, R. Semiconducting materials for photoelectrochemical energy conversion. Nat. Rev. Mater. 1, 15010 (2016).

Moniz, S. J. A. et al. Visible-light driven heterojunction photocatalysts for water splitting—a critical review. Energy Environ. Sci. 8, 731–759 (2015).

Ye, K.-H. et al. Carbon quantum dots as a visible light sensitizer to significantly increase the solar water splitting performance of bismuth vanadate photoanodes. Energy Environ. Sci. 10, 772–779 (2017).

Shi, X. et al. Efficient photoelectrochemical hydrogen production from bismuth vanadate-decorated tungsten trioxide helix nanostructures. Nat. Commun. 5, 4775 (2014).

Abdi, F. F. et al. Efficient solar water splitting by enhanced charge separation in a bismuth vanadate-silicon tandem photoelectrode. Nat. Commun. 4, 2195 (2013).

Kim, T. W. & Choi, K.-S. Nanoporous BiVO4 photoanodes with dual-layer oxygen evolution catalysts for solar water splitting. Science 343, 990–994 (2014).

Park, Y., McDonald, K. J. & Choi, K. Progress in bismuth vanadate photoanodes for use in solar water oxidation. Chem. Soc. Rev. 42, 2321–2337 (2013).

Kim, T. W. et al. Simultaneous enhancements in photon absorption and charge transport of bismuth vanadate photoanodes for solar water splitting. Nat. Commun. 6, 8769 (2015).

Ye, K.-H. et al. A novel CoOOH/(Ti, C)-Fe2O3 nanorod photoanode for photoelectrochemical water splitting. Sci. China Mater. 61, 887–894 (2018).

Zhong, M. et al. Surface modification of CoOx loaded BiVO4 photoanodes with ultrathin p-type NiO layers for improved solar water oxidation. J. Am. Chem. Soc. 137, 5053–5060 (2015).

Zhong, D. K., Choi, S. & Gamelin, D. R. Near-complete suppression of surface recombination in solar photoelectrolysis by “Co-Pi” catalyst-modified W: BiVO4. J. Am. Chem. Soc. 133, 18370–18377 (2011).

Chang, X. et al. Enhanced surface reaction kinetics and charge separation of p–n heterojunction Co3O4/BiVO4 photoanodes. J. Am. Chem. Soc. 137, 8356–8359 (2015).

Abdi, F. F. et al. The origin of slow carrier transport in BiVO4 thin film photoanodes: a time-resolved microwave conductivity study. J. Phys. Chem. Lett. 4, 2752–2757 (2013).

Ding, K. et al. Why the photocatalytic activity of Mo-doped BiVO4 is enhanced: a comprehensive density functional study. Phys. Chem. Chem. Phys. 16, 13465–13476 (2014).

Xi, Y. et al. First-principle study on the photocatalystic properties of tungsten doped monoclinic BiVO4 crystallites. Adv. Mater. Res. 873, 845–849 (2014).

Nasir, S. N. F. M. et al. New insights into Se/BiVO4 heterostructure for photoelectrochemical water splitting: a combined experimental and DFT study. J. Phys. Chem. C 121, 6218–6228 (2017).

Ye, K.-H. et al. BiOI–BiVO4 photoanodes with significantly improved solar water splitting capability: p–n junction to expand solar adsorption range and facilitate charge carrier dynamics. Nano Energy 18, 222–231 (2015).

Zhang, H., Yu, Y., Zhang, L. & Dong, S. Fuel-free bio-photoelectrochemical cells based on a water/oxygen circulation system with a Ni: FeOOH/BiVO4 photoanode. Angew. Chem. 130, 1563–1567 (2018).

Kuang, Y. et al. A front-illuminated nanostructured transparent BiVO4 photoanode for > 2% efficient water splitting. Adv. Energy Mater. 6, 1501645 (2016).

Pilli, S. K. et al. Cobalt-phosphate (Co-Pi) catalyst modified Mo-doped BiVO4 photoelectrodes for solar water oxidation. Energy Environ. Sci. 4, 5028–5034 (2011).

Pihosh, Y. et al. Photocatalytic generation of hydrogen by core-shell WO3/BiVO4 nanorods with ultimate water splitting efficiency. Sci. Rep. 5, 11141 (2015).

Kosar, S. et al. Highly efficient photocatalytic conversion of solar energy to hydrogen by WO3/BiVO4 core–shell heterojunction nanorods. Appl. Nanosci. 17, 1–8 (2018).

Jiang, C. et al. Facile synthesis of g-C3N4/BiVO4 heterojunctions with enhanced visible light photocatalytic performance. Ceram. Int. 43, 301–307 (2017).

Safaei, J. et al. Enhanced photoelectrochemical performance of Z-scheme g-C3N4/BiVO4 photocatalyst. Appl. Catal. B Environ. 234, 296–310 (2018).

Raziq, F. et al. Enhanced cocatalyst-free visible-light activities for photocatalytic fuel production of g-C3N4 by trapping holes and transferring electrons. J. Phys. Chem. C 120, 98–107 (2015).

Yan, S. C. et al. Photodegradation of rhodamine B and methyl orange over boron-doped g-C3N4 under visible light irradiation. Langmuir 26, 3894–3901 (2010).

Lu, C. et al. Boron doped g-C3N4 with enhanced photocatalytic UO22+ reduction performance. Appl. Surf. Sci. 360, 1016–1022 (2016).

Li, H. et al. A g-C3N4/WO3 photoanode with exceptional ability for photoelectrochemical water splitting. Mater. Chem. Front. 1, 338–342 (2017).

Li, C. et al. Monoclinic porous BiVO4 networks decorated by discrete g-C3N4 nano-islands with tunable coverage for highly efficient photocatalysis. Small 10, 2783–2790 (2014).

Sun, Q. et al. Effect of contact interface between TiO2 and g-C3N4 on the photoreactivity of g-C3N4/TiO2 photocatalyst:(001) vs (101) facets of TiO2. Appl. Catal. B Environ. 164, 420–427 (2015).

Madhusudan, P. et al. Novel urea assisted hydrothermal synthesis of hierarchical BiVO4/Bi2O2CO3 nanocomposites with enhanced visible-light photocatalytic activity. Appl. Catal. B Environ. 110, 286–295 (2011).

Rettie, A. J. E. et al. Combined charge carrier transport and photoelectrochemical characterization of BiVO4 single crystals: intrinsic behavior of a complex metal oxide. J. Am. Chem. Soc. 135, 11389–11396 (2013).

Zhang, L. et al. Plasmonic enhancement in BiVO4 photonic crystals for efficient water splitting. Small 10, 3970–3978 (2014).

Nair, V. et al. Textured nanoporous Mo: BiVO4 photoanodes with high charge transport and charge transfer quantum efficiencies for oxygen evolution. Energy Environ. Sci. 9, 1412–1429 (2016).

Xie, S. et al. NiO decorated Mo: BiVO4 photoanode with enhanced visible-light photoelectrochemical activity. Int. J. Hydrog. Energy 39, 4820–4827 (2014).

Antony, R. P. et al. Electrospun Mo-BiVO4 for efficient photoelectrochemical water oxidation: direct evidence of improved hole diffusion length and charge separation. Electrochim. Acta 221, 173–182 (2016).

Vaidyanathan, S. et al. Catalysis with TiO2/gold nanocomposites. Effect of metal particle size on the Fermi level equilibration. J. Am. Chem. Soc. 126, 4943–4950 (2004).

Wood, A. et al. Fermi level equilibration in quantum dot−metal nanojunctions. J. Phys. Chem. B 105, 8810–8815 (2001).

Tan, H. L. et al. BiVO4 {010} and {110} relative exposure extent: governing factor of surface charge population and photocatalytic activity. J. Phys. Chem. Lett. 7, 1400–1405 (2016).

Yin, W. J. et al. Doping properties of monoclinic BiVO4 studied by first-principles density-functional theory. Phys. Rev. B 83, 970–978 (2011).

Kawaguchi, M. et al. Syntheses and structures of new graphite-like materials of composition BCN(H) and BC3N(H). Chem. Mater. 8, 1197–1201 (1996).

Fujimoto, I. et al. WO3/BiVO4 composite photoelectrode prepared by improved auto-combustion method for highly efficient water splitting. Int. J. Hydrog. Energ. 39, 2454–2461 (2014).

Qiu, Y. et al. Efficient solar-driven water splitting by nanocone BiVO4-perovskite tandem cells. Sci. Adv. 2, e1501764 (2016).

Yu, F. et al. Fabrication and kinetic study of ferrihydrite modified BiVO4 photoanode. ACS Catal. 7, 1868–1874 (2017).

Acknowledgements

The authors acknowledge the financial support from the National Science Fund for Distinguished Young Scholars (21425627), Natural Science Foundation of China-SINOPEC Joint fund (U1663220), Local Innovative and Research Teams Project of Guangdong Pearl River Talents Program (2017BT01C102), Shenzhen Peacock Plan (KQTD2016053015544057) and Nanshan Pilot Plan (LHTD20170001), NSFC/Hong Kong RGC Research Scheme (N_HKUST610/14), Fund for Innovative Chemical Experiment and Research of School of Chemistry and Chemical Engineering, Sun Yat-sen University. We thank He Lin for helpful discussion.

Author information

Authors and Affiliations

Contributions

H.J. and S.Y. supervised this project; K.Y., H.L. and D.H. designed and conducted the experiments; S.X., W.Q. and W.M. calculated the DFT results; W.Q. and M.L. performed the PEC oxidations; K.Y. and H.L. wrote the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information: Nature Communications would like to thank Yuriy Pihosh, X. Y.Wang, and other, anonymous, reviewers for their contributions to the peer review of this work.

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ye, KH., Li, H., Huang, D. et al. Enhancing photoelectrochemical water splitting by combining work function tuning and heterojunction engineering. Nat Commun 10, 3687 (2019). https://doi.org/10.1038/s41467-019-11586-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-019-11586-y

This article is cited by

-

All-perovskite-based unassisted photoelectrochemical water splitting system for efficient, stable and scalable solar hydrogen production

Nature Energy (2024)

-

rGO@Cu2ZnSnS4 chalcopyrites modified polypyrrole paper-based photoanode for solar water splitting

Carbon Letters (2024)

-

The new method of ZnIn2S4 synthesis on the titania nanotubes substrate with enhanced stability and photoelectrochemical performance

Scientific Reports (2023)

-

Architecture modification and In3+-doping of WO3 photoanodes to boost the photoelectrochemical water oxidation performance

Science China Chemistry (2023)

-

Photoelectrochemical Water Splitting Over Decahedron Shaped BiVO4 Photoanode by Tuning the Experimental Parameters

Journal of Cluster Science (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.