Abstract

A general method for assembling patterned interfaces of uniform, flexible mesoporous iron oxide nanopyramid islands (NPIs) is presented. The three-dimensional (3D) mesoporous iron oxide–NPI interfaces possess a unique mesostructure that features a large surface area (~158 m2 g−1), a large pore size (~18 nm) and excellent flexibility (can be folded 100 times). Furthermore, the 3D mesoporous Au–NPI interfaces allow efficient immobilization of cytochrome c (Cyt c; more than 165-fold increase) and a significant enhancement of localized surface plasmon resonance (~26-fold at 625 nm) compared with that of two-dimensional (2D) planar iron oxide films without nanopores. More importantly, the ultrasensitive integrated interfaces demonstrate over 1000-fold enhancement of the photocurrent variation on the 3D mesostructures based on the switchable direct electrochemistry of Cyt c. The strategy of interfacial assembly offers new possibilities for the chemical design of patterned mesoporous semiconductors with high flexibility and tailored photocatalytic characteristics. This investigation provides a novel paradigm for an unconventional 3D porous biointerface that can be used for sub-nanomolar level recognition of biomolecules (~0.2 nM for H2O2) and suggests the new concept of large-surface-area 3D mesostructure–protein interfaces as a step toward using direct electrochemistry for biomedical applications.

Similar content being viewed by others

Introduction

Nanodevice interfaces functionalized with various signal-responsive molecules have been designed to provide these devices with tunable properties that make them suitable for diverse applications.1, 2, 3, 4 External signals of different types (for example, optical, electrical, magnetic, mechanical and chemical/biochemical inputs5, 6, 7, 8, 9) are applied to reversibly activate nanodevice interfaces upon demand.10, 11, 12, 13 From these studies, molecular–semiconductor hetero-interfaces (such as protein–TiO2,14, 15 DNA–quantum dots,16, 17 organic molecule–silicon,18 redox molecule–nanowires19 and photoactive molecule–nanowires20) have been applied to adjust photoelectrochemical (PEC) activities by enhancing the efficiency of PEC conversion.21, 22, 23, 24 In PEC-based bioanalysis (for example, DNA analysis,25, 26, 27 immunoassays28, 29, 30, 31 and enzymatic sensing32), PEC-enzymatic sensing has been the focus of considerable research because of the facile and inexpensive fabrication of appropriate interfaces and, more importantly, their high sensitivities and specificities.33, 34 In addition, third-generation PEC enzyme biosensors based on direct electrochemistry have been shown to be capable of direct electron transfer between their active sites and electrodes.33, 35, 36 A number of enzymes/redox proteins, such as horseradish peroxidase,37 hemoglobin,38 microperoxidase39 and glucose oxidase,40, 41 have been integrated into enzyme-based, third-generation biosensors. Recent studies have revealed the possibilities of switching photocurrent (cathodic or anodic) based on the direct electrochemistry of cytochrome c (Cyt c) for sensitive biosignal monitoring.15, 35 Nonetheless, the sensitive signal capturing and switching toward complex living cells, rather than simple molecule models, has never been reported, for two main reasons. First, solar-driven interface interactions between living cells and semiconductors are still inefficient because of the limited number of active sites on conventional 2D structures.15, 33 Second, direct electron transfer between redox proteins and semiconductors is typically prevented by the thickness of the protein layer and is permitted only at interfaces of a few layers or a single-layer of proteins.30, 38 Passing this bottleneck requires being able to monitor cells by using three-dimensional (3D) micro-structures, as well as ultra-high interaction surfaces/interfaces for direct electron transfer between proteins and semiconductors, and ultrasensitive methods to capture trace signals from cellular activities.42, 43, 44

Herein, we describe a novel 3D, mesoporous, iron oxide-based lab-on-a-chip molecular recognition platform with an integrated PEC–living cell interface for real-time signal-processing, which provides a large surface area for efficient immobilization of Cyt c. As a proof-of-concept, the assembly of redox Cyt c on the unique 3D interfaces enhances the interaction surfaces/interfaces to perform direct electron transfer. The ordered iron oxide pattern arrays possess excellent flexibility, a large surface area (~158 m2 g−1) and large pore sizes (~18 nm). Furthermore, such structures allow the 3D porous interface to exhibit substantial gold plasma enhancement (~26-folds at 625 nm) and efficient loading of oxidized and reduced Cyt c (~45.1 and 49.6 mg g−1, respectively), which is approximately 166- and 183-fold increase, respectively, compared with that on 2D planar Au-iron oxide films without nanopores. More importantly, the 3D electron donor (reduced Cyt c) porous interface demonstrates ~2300-fold enhancement (~0.48 mA) over the 2D iron oxide planar biointerface. The 3D electron acceptor (oxidized Cyt c) porous interface displays ~1350-fold enhancement (~0.33 mA). These unique properties also improve the probing performance at the sub-nanomolar level detection limit (~0.2 nm for H2O2) by simultaneously facilitating electron transfer, enhancing plasmon-induced charge separation and providing more active reaction sites. This investigation paves the way for unconventional porous inorganic biointerfaces to recognize biomolecules and provides a new strategy of using 3D mesostructures to allow direct electron transfer from proteins for biosensing and disease diagnosis.

Experimental procedure

Fabrication of the 3D-patterned mesoporous Au–NPI interface

A 3D-patterned Ti-SiO2 film template with a uniform square space (10 × 10 μm2) for the growth of Prussian blue (PB) was obtained by electron beam physical vapor deposition. Typically, a target anode was bombarded with an electron beam from a charged tungsten filament under a strong vacuum. The electron beam caused SiO2 from the target to transform into the gaseous phase. The SiO2 species in the gaseous phase were then deposited in solid form, thus coating Ti foil in the vacuum chamber with a thin layer (~50 nm) of the anode material. Then, 3D iron oxide nanopyramid islands (NPIs) were prepared by the interfacial growth of single-crystalline PB nanocubes on the flexible patterned space of the Ti foil, followed by the in-situ thermal conversion of PB on the Ti-SiO2 film into a patterned porous 3D NPI array. K3[Fe(CN)6]·3H2O (42.5 mg) was first added to 25 ml of hydrochloric acid (0.005 M) under stirring for 30 min. Then, a 1 × 1.5 cm2 Ti-SiO2 film was slowly immersed into the aforementioned mixture. Subsequently, the container was placed in an oven and heated at 85 °C for 24 h. The obtained PB NPIs were taken from the container, washed with DI water and dried at 55 °C in a vacuum oven for 12 h. To obtain the patterned 3D mesoporous NPIs with various mesostructures, the as-made PB NPIs were first heated to 450 °C with a temperature increase of 1 °C min−1 for 3 h and then etched by NaOH (2.0 M) for 12 h at room temperature. To enhance the efficiency of the mesoporous NPIs for solar energy conversion, a layer of Au nanoparticles was deposited on the 3D NPIs by sputtering.

PEC measurements

The photocurrent was measured in a three-electrode PEC cell with Ag/AgCl as the reference electrode and meshed platinum as the counter electrode. The direct photocurrent measurements were performed with visible light upon application of 0 V on the photoelectrode using an electrochemical analyzer. The measurements were performed at ambient temperature (25±2 °C) in a conventional electrochemical cell consisting of a modified working electrode, a counter electrode made of platinum wire and a connected KCl-saturated Ag/AgCl electrode. Phosphate buffer (0.1 M, pH 7.0) was used as an aqueous background electrolyte. The irradiation of the photoactive electrode was performed from one side of the electrochemical cell through the semi-transparent electrode. Argon bubbling was used to remove oxygen from the solutions in the electrochemical cells. The PEC measurements were performed in the presence of 5 × 10−5 M of Cyt c (oxidized or reduced).

Numerical simulations

The numerical simulations of 3D mesoporous nanopyramid Au-NPs films were performed using CST Microwave Studio Suite. The frequency-domain finite element method (FEM) solver was used to obtain the electric field distribution pattern that describes the light trapping properties of the mesoporous NPIs with Au nanospheres on them. Periodic unit cell boundary conditions were implemented in the lateral dimensions to simulate the characteristics of the 3D mesoporous nanopyramid Au-NP film. The nanopyramids were constructed from materials with a relative permittivity of Fe2O3 (~9.06) with pores with diameters of 18 nm. Furthermore, Au nanospheres with diameters of 8 nm were placed on the nanopyramid surface and in the pores. The permittivity of the Au nanoparticles were obtained using size-dependent corrections35, 36 to the bulk gold permittivity values.37 Linearly polarized plane waves were perpendicularly incident on the nanostructures with periodic in-plane boundary conditions. Tetrahedral meshing with automatic mesh refinement was chosen to be fine enough for the frequency-domain simulations to study the optical response of the structure at the wavelength of interest. The electric field vectors were monitored at 3D mesh points to generate the electric field distribution maps.

Results and Discussion

Fabrication of a 3D patterned mesoporous NPI interface

PB NPIs were constructed by facile patterned interfacial assembly (Figure 1) on the substrate surfaces of Ti foils with SiO2 patterns (Ti-SiO2). The growth of structure-directing, surfactant-free hydrolysis and assembly (Figures 2a–c) is similar to the oriented growth of crystalline molecular sieves (Supplementary Figure 1a). The 3D patterned Ti-SiO2 film template with a uniform square space for the growth of PB was obtained by electron beam physical vapor deposition of a thin layer of SiO2 (~50 nm) on the Ti foils (Supplementary Figure 2). The strongly preferred orientation of PB crystals is attributed to the fast growth rate along the <100> direction, which corresponds to the crystal morphology (Figures 1d and e).45 The 3D PB nanopyramid pattern was typically ~10 × 10 μm2 in width and length, and the equilibrium shape is apparently cubic with one of the corners viewed along the <100> direction (Supplementary Figure 3a).46 Such structures are expected to be clearly visible from the side view of nanocrystals with the preferred orientation (Supplementary Figure 3b). The top-view scanning electron microscopy (SEM) images show that the Ti foil substrates are covered by a layer of patterned nanocrystals with aligned and vertically oriented tips and a nanopyramid bottom size of ~150 nm (Figures 2d–g). The enlarged SEM image (Figures 2h and i) and both the side- and top-view of the structural models of a nanopyramid (Supplementary Figure 4) further illustrate the unique 3D mesostructure. The side-view SEM image reveals that the nanopyramids have a thickness of ~150 nm (Supplementary Figure 5a). High-resolution transmission electron microscopy images show that PB NPIs with patterned arrays are solid and crystalline (Supplementary Figures 5b and c). When subjected to an interface-constrained thermal pyrolysis at 400 °C, the color of the 3D PB NPI films changes from blue to iron red (Supplementary Figure 6a). In addition, the PB nanopyramid thin films exhibit high flexibility and a stable morphology for over 100 times of repeated bending and releasing without any observable deformation (Supplementary Figures 6b–e). The mesoporous iron oxide–NPIs pyrolyzed from PB arrays were obtained by the interface-induced thermal conversion method reported previously in our group (Supplementary Figure 7).46 The enlarged SEM images (Figures 2h and i and Supplementary Figure 8) show that all of the PB nanopyramids transformed to porous nanopyramids by the thermal conversion.

Proposed patterned interfacial assembly of the mesoporous nanopyramid islands (NPIs) based on the van der Drift growth model. (a, b) Hydrolysis and condensation of Prussian blue (PB), K3[Fe(CN)6], which nucleates on the patterned interface. (c) PB nanocrystals meet their lateral neighbors depending on the seed concentration on top of the substrate, which forms a linear Fe2+-CN-Fe3+ linkage layer by layer. (d, e) PB nanocrystals grow on the substrate in a perpendicular or nearly perpendicular growth direction.

Preparation and structural analysis of the patterned mesoporous nanopyramid islands (NPIs). (a–c) Scheme for the formation of NPIs and an enlarged single unit island via pattern-directed interfacial patterned growth. Patterned Prussian blue (PB) NPIs grown on Ti foils (PB-NPI), and mesoporous NPIs on Ti foils after thermolysis (M-NPI). (d) Top-view SEM images of the patterned PB NPIs obtained by interfacial growth on flexible patterned Ti foil. (e) Scanning electron microscopy (SEM) image of the single-unit island of the mesoporous NPIs. (f, g) Enlarged SEM images of the patterned PB NPIs. PB NPIs as viewed perpendicularly to <100>. (h, i) Enlarged SEM images of the patterned mesoporous NPIs.

Fabrication of 3D patterned Plasmon–NPI interfaces

To form the plasmon–NPI interface, a layer of Au nanoparticles was sputtered on 3D NPIs using an Intlvac Nanochrome AC/DC system (Supporting Information). The SEM images show that Au nanoparticles are homogeneously deposited on the surface of the 3D mesoporous NPIs (Supplementary Figure 9). N2 sorption isotherms reveal a large surface area of ~158 m2 g−1 and a large mean pore size of ~18 nm (Supplementary Figure 10). The X-ray photoelectron spectroscopy analysis demonstrates one main peak of O1s (~533 eV), two peaks of Fe 2p1/2 and 2p3/2 in Fe2O3 at ~725 and 710 eV, respectively, and peaks of ~87.5 and 83.8 eV, which correspond to 4f5/2 and 4f7/2 of Au, respectively, and indicate that the NPI films are primarily coated with metal Au0 particles (Supplementary Figure 11).47 The electron dispersive X-ray spectra and mapping reveal that the Au nanoparticles are uniformly deposited on the surface of the iron oxide NPIs (Supplementary Figure 12).

Fabrication of 3D patterned protein–plasmon–NPI interfaces

To further probe the switching effect on the 3D mesoporous NPIs, Cyt c,48, 49 which is one of the most intensively investigated redox proteins, was used as a model to be immobilized on the 3D Au-NPI arrays (Supplementary Figure 13). A Cyt c molecule exists in either an oxidized or reduced state and thus operates as an electron acceptor or donor in PEC systems to switch the photocurrent direction of a photoelectrode.50 The successful engineering of the plasmon–NPI interfaces with Cyt c was confirmed using fluorescein isothiocyanate and C-phycocyanin (from Porphyra tenera) as tracers for oxidized and reduced Cyt c, respectively (Supplementary Figure 14b).51 After being dipped into the fluorescein isothiocyanate- and C-phycocyanin-labeled Cyt c phosphate-buffered solution (25 mM), the fluorescence microscope images of the photoelectrode display that the 3D NPIs have a clear, patterned luminescence. The enlarged images (Supplementary Figures 14b2 and c2) show that luminescence is observed from the single unit NPI (~10 × 10 μm2). The thin film exhibits high flexibility and stable morphology even after being immersed in a buffer solution for 48 h (Supplementary Figure 14d). Spectroscopic characterization also indicates that the oxidized and reduced Cyt c molecules retain their bioactivity without obvious denaturation (Supplementary Figure 15).14 The amounts of immobilized, oxidized and reduced Cyt c on the 3D Au-iron oxide mesoporous NPIs were measured to be ~45.1 and 49.6 mg g−1, respectively, which are ~166- and 183-fold increased compared with those on 2D planar Au-iron oxide films without nanopores, which were obtained by an Intlvac Nanochrome AC/DC sputtering system with the same controlled thickness of ~150 nm.

To further test the switching possibilities, both oxidized and reduced Cyt c molecules were first employed as a redox couple in an integrated Au-NPI electrode (Supplementary Figures 14e and f).14, 42 The direct electron transfer between Cyt c and the Au-NPI nanosystem was first realized by photocurrent measurements in a three-electrode PEC cell with the absence of molecular targets. The electron donor-reduced Cyt c-assembled Au-NPI-biointerface demonstrates a clear anodic photocurrent (~0.48 mA) at 0 V versus Ag/AgCl (in saturated KCl; Supplementary Figure 14g) and a 300-fold enhancement of the anodic photocurrent (~0.21 μA) of the 2D planar Au-iron oxide planar biointerface. Moreover, the electron acceptor-oxidized Cyt c immobilized Au-NPI electrode displays a noticeable cathodic photocurrent (~0.33 mA; Supplementary Figure 14g), which is a ~1350-fold enhancement of the cathodic photocurrent (~0.24 μA) of the 2D iron oxide planar biointerface. As a control experiment, no significant photocurrent was obtained with the Au-NPI nanosystem without redox proteins in the phosphate-buffered solution. Therefore, the redox state of oxidized or reduced Cyt c on the 3D Au-NPIs can act as a switch for the photocurrent direction, which agrees with recent reports that plasmon nanosystems are able to exchange electrons with redox-active couples in a solution under plasmon excitation.14, 42

Fabrication of 3D patterned protein–plasmon–NPI cell interfaces

The schematic to construct the biointerface and in-situ culture of living cells and corresponding switchable photo-response during fabrication is shown in Figure 3. Smart multi-functional biointerfaces based on the mesoporous protein–plasmon–NPI structures for in-situ cell growth and quantitative H2O2 detection are also demonstrated (Figure 3a). The protein–plasmon–NPI interface offers a robust substrate for site-selective cell adhesion and cultivation of living cells, exhibiting high bioaffinity and excellent biostability for living cells (up to 120 h; Supplementary Figure 16). A bare Cyt c–Au–NPI interface was used as a substrate to directly grow the living cardiomyocytes and produce an integrated photoelectrode with flexible features (Figures 3b and c). The mesostructure is combined with the extracellular redox protein to achieve excellent flexibility, good selectivity and enhanced cell adhesion/growth capability. The proposed mechanism for switchable photocurrent generation in the presence of reduced and oxidized Cyt c is simultaneously demonstrated (Figure 3d). The photoelectrode (size of 0.5 × 1.5 cm2) was immersed in phosphate buffered solution (25 mM) and irradiated by visible light from the side, and the amperometric current response was recorded under a N2 atmosphere. The chronoamperometric (I–t) curves for Cyt c–Au–NPI photoelectrodes under simulated visible light (with a 430-nm long-pass filter to the white-light source, ~73.3 mW cm−2) are shown (Figure 3e).46, 52

Characterization and photoelectrical performance of mesoporous nanopyramid island (NPI)–plasmon–cytochrome c (Cyt c)–cell interfaces. (a–c) Schematic illustration of the fabrication of patterned mesoporous NPI–plasmon–Cyt c–cell interfaces. (b) Scanning electron microscopy (SEM) image of NPI–plasmon–Cyt c–cardiomyocyte interface. Scale bar is 20 μm. (c) SEM image of NPI–plasmon–Cyt c–cell interface after cell digestion by trypsin (0.25%) in phosphate-buffered solution solutions (pH of 7.4) as the control. Scale bar is 200 nm. (d) Schematic diagram of the solar-driven nanointerface and proposed mechanism for switchable photocurrent generation in the presence of reduced and oxidized Cyt c simultaneously under simulated solar light radiation. (e) Monitoring the photosignal of integrated NPI–plasmon–Cyt c–cell interfaces under simulated solar light radiation. (f) Real-time probing of the signal responses under successive injection of H2O2 (0.1 μM) followed by catalase injection (500 U ml−1). PMA, phorbol 12-myristate-13-acetate.

It has been reported that phorbol 12-myristate-13-acetate (PMA) can trigger H2O2 generation by living cells.14, 53 For the electrode without AuNPs, the H2O2 oxidation current is insignificant when a low concentration of PMA (5 μg ml−1) is added to the surface of cardiomyocytes (Figure 3f, curve i). In contrast, the electrode with AuNPs shows a large H2O2 reduction current (Figure 3f, curve ii). A clear increase in the cathodic currents (~0.26 μA) at an applied potential of 0.0 V (versus Ag/AgCl) is observed (Figure 3f, curve ii). No response is observed in the control experiments for NPI–Au–Cyt c without cells but with the same PMA injection or for NPI–Au–Cyt c with cultured cells but without PMA dimethyl sulfoxide injection. In addition, after injection of catalase (a selective scavenger of H2O2),53, 35 the cathodic current caused by PMA injection for the NPI–Au–Cyt c electrode with cultured cells almost decreases to the original level before PMA injection (Figure 3f, curve ii). Accordingly, the cathodic current is ascribed to PMA-induced H2O2 released from cultured cells with a detection limit of ~0.2 nm for H2O2, which is electrocatalyzed on the 3D NPI interface.

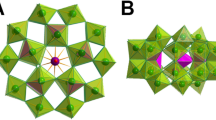

To qualitatively understand the role of plasmonic enhancement in a 3D mesoporous NPI film, the electric field distributions were numerically calculated (Figure 4) using a 3D simulation model, which mimics such mesoporous NPI structures with and without Au nanoparticles. By using periodic unit cell boundary conditions in the lateral dimensions (Figures 4i, ii), a large film of 3D mesoporous NPI–AuNPs was simulated, and near-field patterns at incident light wavelengths of 365, 450, 625 and 685 nm were observed. Featuring spatially confined and strong electromagnetic fields, the plasmonic evanescent waves show maximum field amplitudes around the pores on the 3D nanopyramids at the NPI–AuNPs interface (Figures 4iii, a2–d2), where the field amplitudes decay exponentially into the bulk of iron oxide.54, 55 In addition to the evanescent field around the nanopyramids, photonic-mode light trapping is another important factor for the enhanced photocurrent at the 3D mesoporous NPI–Au interface. This light-trapping effect can be identified by the intense electric field in the valley region between adjacent nanopyramids in the simulated field distribution maps at different incident light wavelengths, for example, at 365, 450, 625 and 685 nm (Figure 4iii and Supplementary Figure 18). The wavelength-dependent electric field confinement, which corresponds to the photonic-mode light trapping in the pores and valley of the porous 3D NPI films (Figures 4iii, a1–d1), was enhanced in the presence of Au nanoparticles, for which additional plasmonic-mode light trapping also has a prominent role (Figures 4iii, a2–d2). This can be observed from the trend of increasing electric-field confinement with incident light wavelength (Supplementary Figure 24). In comparison to the planar structure, 3D mesoporous NPIs have a larger surface area and can therefore host a larger number of Au nanoparticles (Supplementary Figure 17). This results in stronger interparticle coupling and more intense electric field confinement in the 3D mesoporous-NPI film with AuNPs (Supplementary Figure 25) than in the planar mesoporous film with AuNPs, leading to enhanced light trapping.55 Compared with simplified 2D planar smooth surfaces, planar porous substrates or smooth substrates with gold nanoparticles in theoretical simulations, the 3D porous substrate with gold nanoparticles exhibits a more significant evanescent field and photonic light trapping (~26-fold increase at 625 nm), owing to the increased surface roughness and accessible mesopores,55 which agrees with the performance of the 3D porous substrate-enhanced PEC in three-electrode PEC cells (Figure 3f and Supplementary Figure 14g).

Simulation model of a mesoporous-nanopyramid island (NPI) film and numerically calculated near-field distribution maps. (i) Top view and (ii) perspective view of the simulation model depicting a two-dimensionally periodic mesoporous-NPI film with gold nanoparticles (AuNPs). The square boxes in both cases highlight the unit cell of the periodic mesoporous-NPI–AuNPs film. (iii) Normalized near-field distribution maps of the numerically calculated electric field on the surface of a mesoporous-NPI film without (a1, b1, c1 and d1) and with (a2, b2, c2 and d2) gold nanospheres at different incident light wavelengths (365, 450, 625 and 685 nm), which shows electric-field confinement and characteristic evanescent field patterns near the mesoporous-NPI–AuNP interfaces.

Conclusions

3D mesoporous iron oxide NPIs were fabricated by facile patterned directed assembly for the first time. The unique NPIs possess a 3D mesostructure with multiple features, which include a large surface area (~158 m2 g−1), a large pore size (~18 nm) and excellent flexibility (can be folded 100 times). Furthermore, the unique structure allows efficient immobilization of Cyt c (~165-fold increase) and a significant enhancement of localized surface plasmon resonance (~26-fold at 625 nm). Combining 3D porous mesostructures and suitable pore sizes, the porous biointerfaces provide an ultrasensitive photocurrent from direct electrochemistry (over 1000-fold enhancement) on 3D mesostructures, allowing in-situ selective and quantitative monitoring of biomolecules (~0.2 nm for H2O2). The integrated plasmonic Au-NPIs exhibit significantly enhanced PEC conversion performance under simulated solar and visible light radiation. Instead of forming a continuous film coverage over the entire surface, the existence of patterns allows the formation of mesoporous iron oxide NPIs. Thus, the surface strain between adjacent NPIs, which would otherwise exist and have a negative effect on the imitate cell interfacing described above, can be effectively reduced. In addition, compared with a uniform surface, the existence of patterns can further allow multiplexed surface functionalization and measurement. Therefore, combined with the 3D patterned mesostructures, the patterned structure provides a large surface area, a coarse porous surface and a highly biocompatible interface, thereby facilitating the adhesion and direct growth of living cells (more than 120 h). More importantly, this investigation provides a novel paradigm for using an unconventional porous inorganic–biointerface and suggests the new strategy of using 3D mesostructures to perform direct electrochemistry on proteins with the aim of developing biosensing and processing biomedical applications.

References

Jiang, S., Cheng, R., Wang, X., Xue, T., Liu, Y., Nel, A., Huang, Y. & Duan, X. Real-time electrical detection of nitric oxide in biological systems with sub-nanomolar sensitivity. Nat. Commun. 4, 2225 (2013).

Cui, Y., Wei, Q., Park, H. & Lieber, C. M. Nanowire nanosensors for highly sensitive and selective detection of biological and chemical species. Science 293, 1289–1292 (2001).

Wu, H.-J., Henzie, J., Lin, W. C., Rhodes, C., Li, Z., Sartorel, E., Thorner, J., Yang, P. & Groves, J. T. Membrane-protein binding measured with solution-phase plasmonic nanocube sensors. Nat. Methods 9, 1189–1191 (2012).

Liu, X., Chen, L., Liu, H., Yang, G., Zhang, P., Han, D., Wang, S. & Jiang, L. Bio-inspired soft polystyrene nanotube substrate for rapid and highly efficient breast cancer-cell capture. NPG Asia Mater. 5, e63. doi:10.1038/am.2013.43 (2013).

Wang, H., Meng, F., Cai, Y., Zheng, L., Li, Y., Liu, Y., Jiang, Y., Wang, X. & Chen, X. Sericin for resistance switching device with multilevel nonvolatile memory. Adv. Mater. 25, 5498–5503 (2013).

Tang, J., Zhang, Y., Kong, B., Wang, Y., Da, P., Li, J., Elzatahry, A. A., Zhao, D., Gong, X. & Zheng, G. Solar-driven photoelectrochemical probing of nanodot/nanowire/cell interface. Nano Lett. 14, 2702–2708 (2014).

Chen, H., Shao, L., Li, Q. & Wang, J. Gold nanorods and their plasmonic properties. Chem. Soc. Rev. 42, 2679–2724 (2013).

Meng, F., Hervault, Y. M., Shao, Q., Hu, B., Norel, L., Rigaut, S. & Chen, X. Orthogonally modulated molecular transport junctions for resettable electronic logic gates. Nat. Commun. 5, 3023 (2014).

Xia, F., Feng, L., Wang, S., Sun, T., Song, W., Jiang, W. & Jiang, L. Dual-responsive surfaces that switch between superhydrophilicity and superhydrophobicity. Adv. Mater. 18, 432–436 (2006).

Liu, H., Li, Y., Sun, K., Fan, J., Zhang, P., Meng, J., Wang, S. & Jiang, L. Dual-responsive surfaces modified with phenylboronic acid-containing polymer brush to reversibly capture and release cancer cells. J. Am. Chem. Soc. 135, 7603–7609 (2013).

Liu, X., Zhang, F., Wang, Q., Gao, J., Meng, J., Wang, S., Yang, Z. & Jiang, L. Platelet-Inspired multiscaled cytophilic interfaces with high specificity and efficiency toward point-of-care cancer diagnosis. Small 10, 4677–4683 (2014).

Liang, K., Such, G. K., Johnston, A. P., Zhu, Z., Ejima, H., Richardson, J. J., Cui, J. & Caruso, F. Endocytic pH-triggered degradation of nanoengineered multilayer capsules. Adv. Mater. 26, 1901–1905 (2014).

Guillet-Nicolas, R., Popat, A., Bridot, J. L., Monteith, G., Qiao, S. Z. & Kleitz, F. pH-Responsive nutraceutical–mesoporous silica nanoconjugates with enhanced colloidal stability. Angew. Chem. Int. Ed. 52, 2318–2322 (2013).

Zhu, A., Luo, Y. & Tian, Y. Switching the direction of plasmon-induced photocurrents by cytochrome c at Au–TiO2 nanocomposites. Chem. Commun. 42, 6448–6450 (2009).

Zhu, A., Luo, Y. & Tian, Y. Plasmon-induced enhancement in analytical performance based on gold nanoparticles deposited on TiO2 film. Anal. Chem. 81, 7243–7247 (2009).

Freeman, R., Finder, T. & Willner, I. Multiplexed analysis of Hg2+ and Ag+ ions by nucleic acid functionalized CdSe/ZnS quantum dots and their use for logic gate operations. Angew. Chem. Int. Ed. 48, 7818–7821 (2009).

Gill, R., Patolsky, F., Katz, E. & Willner, I. Electrochemical control of the photocurrent direction in intercalated DNA/CdS nanoparticle systems. Angew. Chem. Int. Ed. 44, 4554–4557 (2005).

Halik, M., Klauk, H., Zschieschang, U., Schmid, G., Dehm, C., Schütz, M., Maisch, S., Effenberger, F., Brunnbauer, M. & Stellacci, F. Low-voltage organic transistors with an amorphous molecular gate dielectric. Nature 431, 963–966 (2004).

Duan, X., Huang, Y. & Lieber, C. M. Nonvolatile memory and programmable logic from molecule-gated nanowires. Nano Lett. 2, 487–490 (2002).

Kovtyukhova, N. I. & Mallouk, T. E. Nanowires as building blocks for self-assembling logic and memory circuits. Chem. Eur. J. 8, 4354–4363 (2002).

Javey, A., Kim, H., Brink, M., Wang, Q., Ural, A., Guo, J., McIntyre, P., McEuen, P., Lundstrom, M. & Dai, H. High-κ dielectrics for advanced carbon-nanotube transistors and logic gates. Nat. Mater. 1, 241–246 (2002).

Wei, H., Wang, Z., Tian, X., Käll, M. & Xu, H. Cascaded logic gates in nanophotonic plasmon networks. Nat. Commun. 2, 387 (2011).

Long, R., Mao, K., Gong, M., Zhou, S., Hu, J., Zhi, M., You, Y., Bai, S., Jiang, J., Zhang, Q., Wu, X. & Xiong, Y. Tunable oxygen activation for catalytic organic oxidation: schottky iunction versus plasmonic effects. Angew. Chem. Int. Ed. 53, 3205–3209 (2014).

Wang, X., Liow, C., Qi, D., Zhu, B., Leow, W. R., Wang, H., Xue, C., Chen, X. & Li, S. Programmable photo-electrochemical hydrogen evolution based on multi-segmented CdS-Au nanorod arrays. Adv. Mater. 26, 3506–3512 (2014).

Liang, M. & Guo, L.-H. Photoelectrochemical DNA sensor for the rapid detection of DNA damage induced by styrene oxide and the fenton reaction. Environ. Sci. Technol. 41, 658–664 (2006).

Liu, S., Li, C., Cheng, J. & Zhou, Y. Selective photoelectrochemical detection of DNA with high-affinity metallointercalator and tin oxide nanoparticle electrode. Anal.Chem. 78, 4722–4726 (2006).

Zhang, X., Zhao, Y., Zhou, H. & Qu, B. A new strategy for photoelectrochemical DNA biosensor using chemiluminescence reaction as light source. Biosens. Bioelectron. 26, 2737–2741 (2011).

Kang, Q., Yang, L., Chen, Y., Luo, S., Wen, L., Cai, Q. & Yao, S. Photoelectrochemical detection of pentachlorophenol with a multiple hybrid CdSexTe1−x/TiO2 nanotube structure-based label-free immunosensor. Anal. Chem. 82, 9749–9754 (2010).

Feng, H., Zhou, L., Li, J., Tran, T. T., Wang, N., Yuan, L., Yan, Z. & Cai, Q. A photoelectrochemical immunosensor for tris (2, 3-dibromopropyl) isocyanurate detection with a multiple hybrid CdTe/Au–TiO2 nanotube arrays. Analyst 138, 5726–5733 (2013).

Li, Y. J., Ma, M. J., Yin, G., Kong, Y. & Zhu, J. J. Phthalocyanine-sensitized graphene–CdS nanocomposites: an enhanced photoelectrochemical immunosensing platform. Chem. Eur. J. 19, 4496–4505 (2013).

Fan, G., Han, L., Zhu, H., Zhang, J. & Zhu, J.-J. Ultrasensitive photoelectrochemical immunoassay for matrix metalloproteinase-2 detection based on CdS: Mn/CdTe co-sensitized TiO2 nanotubes and signal amplification of SiO2@Ab2 conjugates. Anal. Chem. 86, 12398–12405 (2014).

Zhao, W.-W., Yu, P.-P., Xu, J.-J. & Chen, H.-Y. Ultrasensitive photoelectrochemical biosensing based on biocatalytic deposition. Electrochem. Commun. 13, 495–497 (2011).

Zhao, W.-W., Xu, J.-J. & Chen, H.-Y. Photoelectrochemical bioanalysis: the state of the art. Chem. Soc. Rev. 44, 729–741 (2015).

Zhao, W.-W., Xu, J.-J. & Chen, H.-Y. Photoelectrochemical DNA biosensors. Chem. Rev. 114, 7421–7441 (2014).

Stoll, C., Kudera, S., Parak, W. J. & Lisdat, F. Quantum dots on gold: electrodes for photoswitchable cytochrome c electrochemistry. Small 2, 741–743 (2006).

Zhu, A., Luo, Y. & Tian, Y. Switching the direction of plasmon-induced photocurrents by cytochrome c at Au-TiO2 nanocomposites. Chem. Commun. 6448–6450 (2009).

Zhu, Y., Cao, H., Tang, L., Yang, X. & Li, C. Immobilization of horseradish peroxidase in three-dimensional macroporous TiO2 matrices for biosensor applications. Electrochim. Acta 54, 2823–2827 (2009).

Zhou, H., Gan, X., Wang, J., Zhu, X. & Li, G. Hemoglobin-based hydrogen peroxide biosensor tuned by the photovoltaic effect of nano titanium dioxide. Anal. Chem. 77, 6102–6104 (2005).

Zhu, X., Yuri, I., Gan, X., Suzuki, I. & Li, G. Electrochemical study of the effect of nano-zinc oxide on microperoxidase and its application to more sensitive hydrogen peroxide biosensor preparation. Biosens. Bioelectron. 22, 1600–1604 (2007).

Ren, X., Chen, D., Meng, X., Tang, F., Hou, X., Han, D. & Zhang, L. Zinc oxide nanoparticles/glucose oxidase photoelectrochemical system for the fabrication of biosensor. J. Colloid Interf. Sci. 334, 183–187 (2009).

Tang, J., Wang, Y., Li, J., Da, P., Geng, J. & Zheng, G. Sensitive enzymatic glucose detection by TiO2 nanowire photoelectrochemical biosensors. J. Mater. Chem. A 2, 6153–6157 (2014).

Kong, B., Tang, J., Zhang, Y., Selomulya, C., Gong, X., Liu, Y., Zhang, W., Yang, J., Wang, W., Sun, X., Wang, Y., Zheng, G. & Zhao, D. Branched artificial nanofinger arrays by mesoporous interfacial atomic rearrangement. J. Am. Chem. Soc. 137, 4260–4266 (2015).

Hu, B., Shi, W., Wu, Y. L., Leow, W. R., Cai, P., Li, S. & Chen, X. Orthogonally engineering matrix topography and rigidity to regulate multicellular morphology. Adv. Mater. 26, 5786–5793 (2014).

Li, Y. Q., Zhu, B., Li, Y., Leow, W. R., Goh, R., Ma, B., Fong, E., Tang, M. & Chen, X. A synergistic capture strategy for enhanced detection and elimination of bacteria. Angew. Chem. Int. Ed. 53, 5837–5841 (2014).

Kong, B., Tang, J., Wu, Z., Wei, J., Wu, H., Wang, Y., Zheng, G. & Zhao, D. Ultralight mesoporous magnetic frameworks by interfacial assembly of Prussian blue nanocubes. Angew. Chem. Int. Ed. 53, 2888–2892 (2014).

Kong, B., Tang, J., Selomulya, C., Li, W., Wei, J., Fang, Y., Wang, Y., Zheng, G. & Zhao, D. Oriented mesoporous nanopyramids as versatile plasmon enhanced interfaces. J. Am. Chem. Soc. 136, 6822–6825 (2014).

Lu, A.-H., Nitz, J. J., Comotti, M., Weidenthaler, C., Schlichte, K., Lehmann, C. W., Terasaki, O. & Schüth, F. Spatially and size selective synthesis of Fe-based nanoparticles on ordered mesoporous supports as highly active and stable catalysts for ammonia decomposition. J. Am. Chem. Soc. 132, 14152–14162 (2010).

Linic, S., Christopher, P. & Ingram, D. B. Plasmonic-metal nanostructures for efficient conversion of solar to chemical energy. Nat. Mater. 10, 911–921 (2011).

Zou, C., Larisika, M., Nagy, G., Srajer, J., Oostenbrink, C., Chen, X., Knoll, W., Liedberg, B. & Nowak, C. Two-dimensional heterospectral correlation analysis of the redox-induced conformational transition in cytochrome c using surface-enhanced raman and infrared absorption spectroscopies on a two-layer gold surface. J. Phys. Chem. B 117, 9606–9614 (2013).

Page, C. C., Moser, C. C., Chen, X. & Dutton, P. L. Natural engineering principles of electron tunnelling in biological oxidation–reduction. Nature 402, 47–52 (1999).

Shimizu, S., Narita, M. & Tsujimoto, Y. Bcl-2 family proteins regulate the release of apoptogenic cytochrome c by the mitochondrial channel VDAC. Nature 399, 483–487 (1999).

Wang, Y., Tang, J., Peng, Z., Wang, Y., Jia, D., Kong, B., Elzatahry, A. A., Zhao, D. & Zheng, G. Fully solar-powered photoelectrochemical conversion for simultaneous energy storage and chemical sensing. Nano Lett. 14, 3668–3673 (2014).

Kong, B., Tang, J., Wu, Z., Selomulya, C., Wang, H., Wei, J., Wang, Y., Zheng, G. & Zhao, D. Y. Bio-inspired porous antenna-like nanocube/nanowire heterostructure as ultra-sensitive cellular interfaces. NPG Asia Mater. 6, e117. doi:10.1038/am.2014.56 (2014).

Gao, H., Liu, C., Jeong, H. E. & Yang, P. Plasmon-enhanced photocatalytic activity of iron oxide on gold nanopillars. ACS Nano 6, 234–240 (2011).

Sikdar, D., Rukhlenko, I. D., Cheng, W. & Premaratne, M. Tunable broadband optical responses of substrate-supported metal/dielectric/metal nanospheres. Plasmonics 9, 659–672 (2014).

Acknowledgements

This work was supported by the State Key Basic Research Program of the PRC (2012CB224805, 2013CB934104), the NSF of China (21210004, 21322311 and 21473038), the Australian Research Council (DP120101194, DP140104062) and the Deanship of Scientific Research of King Saud University (IHCRG#14-102).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Additional information

Supplementary Information accompanies the paper on the NPG Asia Materials website

Supplementary information

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Kong, B., Sikdar, D., Tang, J. et al. Interfacial assembly of mesoporous nanopyramids as ultrasensitive cellular interfaces featuring efficient direct electrochemistry. NPG Asia Mater 7, e204 (2015). https://doi.org/10.1038/am.2015.78

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/am.2015.78

This article is cited by

-

SBA-Pr-IS-MN synthesis and its application as Ag+ optical sensor in aqueous media

Research on Chemical Intermediates (2021)