Abstract

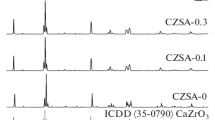

An investigation has been carried out into the possibility of in situ formation of MoS2 within porous anodic films on aluminium, to improve subsequent tribological behaviour, by re-anodizing in thiomolybdate electrolyte. Acidification of thiomolybdate was employed to simulate the conditions for formation of the sulphide at the anodic film/electrolyte interface, followed by appropriate vacuum heat treatments to study possible temperature effects on the sulphide due to either friction or Joule heating during anodizing. The products of both acidification and heat treatment, characterized by X-ray powder diffraction and scanning electron microscopy, were compared with those formed by direct thermal decomposition of ammonium tetrathiomolybdate crystals. The precipitate formed by acidification was mainly amorphous molybdenum trisulphide (MoS3), which on heat treatment at 450 and 850°C yielded 3R-MoS2. 3R-MoS2 also formed by the thermal decomposition of thiomolybdate crystals. Thermogravimetric and differential thermal analyses showed that the decomposition of MoS3 to MoS2 occurred in the range 220–370°C and revealed the sequence of reaction steps. The findings suggest that mainly amorphous MoS3 is formed as a consequence of changes in the pH of the film/electrolyte interface during re-anodizing but the product is relatively easily transformed to crystalline MoS2 on moderate heating which may occur during wear processes.

Similar content being viewed by others

References

M. S. Whittingham, Sci. 192 (1976) 1126.

D. S. Takur and B. Delmon, J. Catal. 91 (1985) 308.

J. A. Ogilvy, Wear 160 (1993) 171.

R. L. Fusaro, American Society of Lubrication Engineers Trans. 25 (1982) 141.

W. O. Winer, Wear 10 (1967) 422.

R. Murray and B. L. Evans, J. Appl. Cryst. 12 (1979) 312.

R. N. Viswanath and S. Ramasamy, J. Mater. Sci. Lett. 25 (1990) 5029.

S. H. El-Mahalawy and B. L. Evans, J. Appl. Cryst. 9 (1976) 403.

A. A. Al-Hilli and B. L. Evans, J. Cryst. Growth5 (1972) 93.

J. Mering and A. Levialdi, C.R. Acad. Sci. Paris 213 (1941) 798.

C. N. R. Rao and K. P. Pisharody, Prog. Solid State Chem. 10 (1975) 207.

J. C. Wildervanck and F. Jellinek, Z. Anorg. Allgem. Chem. 328 (1964) 309.

A. Vazquez, J. M. Dominguez, C. Pina, A. Jaidar and S. Fuentes, J. Mater. Sci. Lett. 9 (1990) 712.

B. C. Stupp, Thin Solid Films 84 (1981) 257.

S. Chandra and S. N. Sahu, J. Phys. D. 17 (1984) 2115.

P. Pramanik and S. Bhattacharya, J. Mater. Sci. Lett. 8 (1989) 781.

G. Guang, Y. Wu, J. Li and H. Liu, Acta Metall. Sinica B 6 (1993) 102.

K. Isawa, M. Maejima and K. Sarawatari, New Mater. New Process. 2 (1983) 420.

A. W. Brace and M. G. Faul, Trans. Inst. Met. Finish. 66 (1988) 133.

R. G. Dickinson and L. Pauling, J. Amer. Chem. Soc. 45 (1923) 1466.

Y. Takeuchi and W. Nowacki, Schweiz. Mineral. Petrogr. Mitt. 44 (1964) 105.

F. E. Wickman and D. K. Smith, Amer. Mineral. 55 (1970) 1843.

J. W. Frondel and F. E. Wickman, ibid. 55 (1970) 1857.

R. J. J. Newberry, ibid. 64 (1979) 758.

Idem, ibid. 64 (1979) 768.

E. P. KHLYBOV, G. M. KUZüMICHEVA and V. V. EVDOKIMOVA, Russ. J. Inorg. Chem. 31 (1986) 627.

R. CHEVREL, M. SERGENT and J. PRIGENT, Mater. Res. Bull. 9 (1974) 1487.

J. M. Tarascon and G. W. Hull, ibid. 21 (1986) 859.

F. Mawrow and M. Nokolow, Z. Anorg. Allgem. Chem. 95 (1916) 188.

ASTM Diffraction Data File, Card No. 17-744

P. Ratnasamy, L. Rodrique and A. J. Leonard, J. Phys. Chem. 77 (1973) 2242.

E. Y. Rode and B. A. Lebedev, Russ. J. Inorg. Chem. 6 (1961) 608.

W. W. Wendlandt, “Thermal Methods of Analysis”, 2nd Edn (John Wiley & Sons, New York, 1974) pp. 928.

F. R. Applewhite, J. S. L. Leach and P. Neufeld, Corros. Sci. 9 (1969) 305.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

WANG, H., SKELDON, P., THOMPSON, G. et al. Synthesis and characterization of molybdenum disulphide formed from ammonium tetrathiomolybdate. Journal of Materials Science 32, 497–502 (1997). https://doi.org/10.1023/A:1018538424373

Issue Date:

DOI: https://doi.org/10.1023/A:1018538424373