Abstract

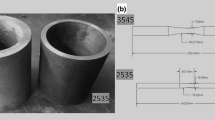

The fatigue limits and fracture characteristics for a Pd–Cu–Ga alloy and a Pd–Ga alloy were studied. The alloys were cast into tensile test bars with gauge diameter of 3 mm and gauge length of 15 mm, and the surfaces of the castings were neither air-abraded nor polished after removal from the investment. Specimens were prepared from all-new metal (not previously melted), a combination of 50% new metal and 50% old metal (previously melted one time) and 100% old metal. The cast bars were subjected to heat treatment simulating the complete firing cycles for dental porcelain, and fatigued in air at room temperature under uniaxial tension-compression stress at 10 Hz and a ratio of tensile stress amplitude to compressive stress amplitude (R-ratio) of −1. The alloy microstructures and fracture surfaces were examined with a scanning electron microscope (SEM). Results showed that the fatigue limits at 2 x 106cycles of the Pd–Cu–Ga and Pd–Ga alloys were approximately 0.20 and 0.15 of their 0.1% yield strength (YS) in tension, respectively. The fatigue resistance for specimens from both alloys containing 50% old metal and 50% new metal was comparable to that of specimens containing all-new metal, although this decreased dramatically for Pd–Cu–Ga alloy specimens containing all-old metal. The fatigue resistance of the Pd–Cu–Ga alloy subjected to heat treatment simulating the porcelain firing cycles was not adversely affected by remnants of the original as-cast dendritic microstructure that remained in the relatively large test specimens. A longer heat treatment than recommended by the manufacturer for the porcelain firing cycles is needed to completely eliminate the as-cast dendritic structure in these specimens. The Pd–Cu–Ga alloy exhibited superior fatigue resistance to the Pd–Ga alloy, which has an equiaxed-grain microstructure and lower yield strength.

Similar content being viewed by others

References

A. B. Carr and W. A. Brantley, Int. J. Prosthodont. 4 (1991) 265.

R. B. Stewart, K. Gretz and W. A. Brantley, J. Dent. Res. 71 (1992) 158, Abstract No. 423.

E. Papazoglou, Q. Wu, W. A. Brantley, J. C. Mitchell and G. Meyrick, Cells Mater. 9 (1999) 43.

E. Papazoglou, Q. Wu, W. A. Brantley, J. C. Mitchell and G. Meyrick, J. Mater. Sci.: Mater. Med. 11 (2000) 601.

E. Papazoglou, W. A. Brantley, A. B. Carr and W. M. Johnston, J. Prosthet. Dent. 70 (1993) 386.

E. Papazoglou and W. A. Brantley, Dent. Mater. 14 (1998) 112.

E. Papazoglou, W. A. Brantley, W. M. Johnston and A. B. Carr, J. Prosthet. Dent. 79 (1998) 514.

M. M. Stavridakis, E. Papazoglou, R. R. Seghi, W. M. Johnston and W. A. Brantley, J. Prosthod. 9 (2000) 71.

M. C. Nutt, in “Metallurgy and Plastics for Engineers” (Pergamon Press, Oxford, UK, 1976), p. 360.

H. W. Anselm Wiskott, J. I. Nicholls and U. C. Belser, Int. J. Prosthodont. 8 (1995) 105.

G. E. Dieter, in “Mechanical Metallurgy”, 3rd edn (McGraw-Hill, New York, 1986), Chap 9.

N. E. Dowling, in “Mechanical Behavior of Materials: Engineering Methods for Deformation, Fracture and Fatigue” (Prentice Hall, Englewood Cliffs, NJ, USA, 1993), Chaps 9–11.

B. S. Kelly, W. A. Brantley, J. A. Holloway, A. S. Litsky, J. C. Mitchell and D. Li, J. Dent. Res. 79 (2000) 188, Abstract No. 355.

W. A. Brantley, Z. Cai, D. W. Foreman, J. C. Mitchell, E. Papazoglou and A. B. Carr. Dent. Mater. 11 (1995) 154.

W. A. Brantley, Z. Cai, A. B. Carr and J. C. Mitchell, Cells Mater. 3 (1993) 103.

ANSI/ADA Specification No. 5 for dental casting alloys (Council on Dental Materials, Instruments and Equipment, Chicago, IL, USA, 1988).

ANSI/ADA Specification No. 38 for metal-ceramic systems (Council on Dental Materials, Instruments and Equipment, Chicago, IL, USA, 1991).

D. A. Bridgeport, W. A. Brantley and P. F. Herman, J. Prosthod. 2 (1993) 144.

R. G. Craig (ed), “Restorative Dental Materials”, 10th edn (Mosby, St. Louis, 1997), pp. 456 and 496.

W. A. Brantley, Q. Wu, Z. Cai, S. G. Vermilyea, J. C. Mitchell and M. C. Comerford, Cells Mater. 9 (1999) 83.

K. J. Anusavice, in “Phillips' Science of Dental Materials”, 10th edn (Saunders, Philadelphia, 1996), pp. 517-522.

H. Jiang, P. Bowen and J. F. Knoot, J. Mater. Sci. 34 (1999) 719.

A. A. Dabayeh, R. X. Xu, B. P. Du and T. H. Topper, Int. J. Fatig. 18 (1996) 95.

P. Heuler, C. Berger and J. Motz, Fatig. Fract. Eng. Mater. Struct. 16 (1993) 115.

W. Guo, W. A. Brantley, W. A. T. Clark, D. Li and P. Monaghan, J. Mater. Sci.: Mater. Med. 13(4) 369-374.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, D., Brantley, W.A., Mitchell, J.C. et al. Fatigue studies of high-palladium dental casting alloys: Part I. Fatigue limits and fracture characteristics*. Journal of Materials Science: Materials in Medicine 13, 361–367 (2002). https://doi.org/10.1023/A:1014332416832

Issue Date:

DOI: https://doi.org/10.1023/A:1014332416832