Abstract

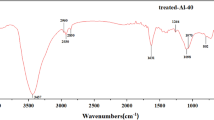

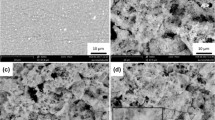

Bionic alumina samples were fabricated on convex dome type aluminum alloy substrate using hard anodizing technique. The convex domes on the bionic sample were fabricated by compression molding under a compressive stress of 92.5 MPa. The water contact angles of the as-anodized bionic samples were measured using a contact angle meter (JC2000A) with the 3 μL water drop at room temperature. The measurement of the wetting property showed that the water contact angle of the unmodified as-anodized bionic alumina samples increases from 90° to 137° with the anodizing time. The increase in water contract angle with anodizing time arises from the gradual formation of hierarchical structure or composite structure. The structure is composed of the micro-scaled alumina columns and pores. The height of columns and the depth of pores depend on the anodizing time. The water contact angle increases significantly from 96° to 152° when the samples were modified with self-assembled monolayer of octadecanethiol (ODT), showing a change in the wettability from hydrophobicity to super-hydrophobicity. This improvement in the wetting property is attributed to the decrease in the surface energy caused by the chemical modification.

Similar content being viewed by others

References

Hong Y C, Uhm H S. Superhydrophobicity of a material made from multiwalled carbon nanotubes. Applied Physics Letters, 2006, 88, 244101–244101–3.

Yang C, Tartaglino U, Persson B N J. Influence of surface roughness on superhydrophobicity. Physical Review Letters, 2006, 97, 116103–116103–4.

Tang K J, Wang X F, Yan W F, Yu J H, Xu R R. Fabrication of superhydrophilic Cu2O and CuO membranes. Journal of Membrane Science, 2006, 286, 279–284.

Liu X L, Jiang Z H, Li J, Zhang Z H, Ren L Q. Super-hydrophobic property of nano-sized cupric oxide films. Surface & Coatings Technology, 2010, 204, 3200–3204.

Erbil H Y, Demirel A L, Avci Y, Mert O. Transformation of a simple plastic into a superhydrophobic surface. Science, 2003, 299, 1377–1380.

Zhou Y, Song X M, Yu M N, Wang B, Yan H. Superhydrophobic surfaces prepared by plasma fluorination of lotus-leaf-like amorphous carbon films. Surface Review and Letters, 2006, 13, 117–122.

Cheng Y T, Rodak D E. Is the lotus leaf superhydrophobic? Applied physical letters, 2005, 86, 144101–144101–3.

Gao X F, Jiang L. Water-repellent legs of water striders. Nature, 2004, 432, 36.

Sun T L, Feng L, Gao X F, Jiang L. Bio-inspired surfaces with special wettability. Accounts of Chemical Research, 2005, 38, 644–652.

Guo Z G, Zhou F, Hao J C, Liu W M. Effects of system parameters on making aluminum alloy lotus. Journal of Colloid and Interface Science, 2006, 303, 298–305.

Guo Z G, Liu W M. Progress in bio-mimicing of super-hydrophobic surface. Progress in Chemistry, 2006, 18, 721–726.

Guo Z G, Zhou F, Hao J C, Liang Y M, Liu W M, Huck W T S. Stick and slide ferrofluidic droplets on superhydrophobic surfaces. Applied Physical Letters, 2006, 89, 081911–081911–3.

Jung Y C, Bhushan B. Contact angle, adhesion and friction properties of micro- and nanopatterned polymers for superhydrophobicity. Nanotechnology, 2006, 17, 4970–4980.

Roach P, Shirtcliffe N J, Newton M I. Progess in superhydrophobic surface development. Soft Matter, 2008, 4, 224–240.

Wang Y H, Wang W, Zhong L, Wang J, Jiang Q L, Guo X Y. Super-hydrophobic surface on pure magnesium substrate by wet chemical method. Applied Surface Science, 2010, 256, 3837–3840.

Xu J H, Li M, Zhao Y, Lu Q H. Control over the hydrophobic behavior of polystyrene surface by annealing temperature based on capillary template wetting method. Colloids and surface A: Physicochemical and Engineering Aspects, 2007, 302, 136–140.

Shirtcliffe N J, McHale G, Newton M I, Perry C C. Wetting and wetting transitions on copper-based super-hydrophobic surfaces. Langmuir, 2005, 21, 937–943.

Patermarakls G, Moussoutzanis K. Electrochemical kinetic study on the growth of porous anodic oxide films on aluminium. Electrochemical Acta, 1995, 40, 699–708.

Vorobyova A I, Outkina E A. Study of pillar microstructure formation with anodic oxides. Thin Solid Films, 1998, 324, 1–10.

Yakovleva N M, Anicai L, Yakovlev A N, Dima L, Khanina Y E, Buda M, Chupakhina E A. Structure study of anodic films formed on aluminum alloyin nitric acid electrolyte. Thin Solid Films, 2002, 416, 16–23.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, J., Du, F., Liu, X. et al. Superhydrophobicity of bionic alumina surfaces fabricated by hard anodizing. J Bionic Eng 8, 369–374 (2011). https://doi.org/10.1016/S1672-6529(11)60042-5

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1672-6529(11)60042-5