Abstract

Transformation induced plasticity (TRIP) steel exhibited high or rather high carbon equivalent (CE) because of its chemical composition, which was a particularly detrimental factor affecting weldability of steels. Thus the weldability of a TRIP steel (grade 600) containing (in mass percent, %) 0.11C-1. 19Si-1.67Mn was extensively studied. The mechanical properties and impact toughness of butt joint, the welding crack susceptibility of weld and heat affected zone (HAZ) for tee joint, control thermal severity (CTS) of the welded joint, and Y shape 60° butt joint were measured after the gas metal arc welding (GMAW) test. The tensile strength of the weld was higher than 700 MPa. Both in the fusion zone (FZ) and HAZ for butt joint, the impact toughness was much higher than 27 J, either at room temperature or at −20 °C, indicating good low temperature impact ductility of the weld of TRIP 600 steel. In addition, welding crack susceptibility tests revealed that weldments were free of surface crack and other imperfection. All experimental results of this steel showed fairly good weldability. For application, the crossmember in automobile made of this steel exhibited excellent weldability, and fatigue and durability tests were also accomplished for crossmember assembly.

Similar content being viewed by others

References

De Cooman B C. Structure-Properties Relationship in TRIP Steels Containing Carbide-Free Bainite [J]. Current Opinion in Solid State and Materials Science, 2004, 8(3–4): 285.

ZHANG Mei, FU Ren-yu, CAO Dong-dong, et al. Development of the Micro-Alloyed TRIP Steels and Properties of Their Laser Welded Blanks [J]. Iron and Steel, 2005, 40(suppl): 754.

ZHANG Mei, LI Lin, FU Ren-yu, et al. Application Properties of Low Carbon Transformation Induced Plasticity Steels [J]. Iron and Steel, 2007, 42(3): 65 (in Chinese).

GB 2649–89, Method of Sampling for Mechanical Properties Tests of Welded Joint [S] (in Chinese).

GB 2651–89, Method of Tensile Test for Welded Joint [S] (in Chinese).

GB 2650–89, Method of Impact Test for Welded Joint [S] (in Chinese).

GB 2654–89, Method of Hardness Tests for Welded Joint and Surfacing Metal [S] (in Chinese).

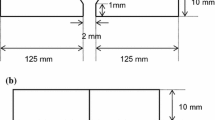

GB 4675. 1–89, Weldability Testing-Method of Y-Groove Cracking Test [S] (in Chinese).

GB 4675. 2–89, Weldability Testing-Method of Controlled Thermal Severity Cracking Test [S] (in Chinese).

GB 4675. 3–89, Weldability Testing-Method of Cracking Test of Welded Tee Joint [S] (in Chinese).

SI Chong-yao, ZHOU Zhen-feng, QIAN Bai-nian. Welding Handbook [M]. Beijing: Mechanical Industry Press, 1992 (in Chinese).

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National Natural Science Foundation of China (50671061); the China-Belgium Bilateral Project (2001-242); Shanghai Leading Academic Discipline Project (T0101)

Rights and permissions

About this article

Cite this article

Zhang, M., Li, L., Fu, Ry. et al. Weldability of low carbon transformation induced plasticity steel. J. Iron Steel Res. Int. 15, 61–65 (2008). https://doi.org/10.1016/S1006-706X(08)60250-2

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(08)60250-2