Abstract

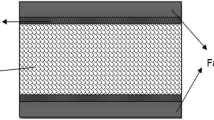

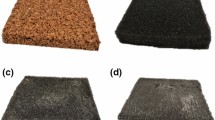

Nowadays, lightweight and eco-friendly composites with improved mechanical properties are highly interesting. Sandwich-structured composites are a type of high-performance structural composite that is lightweight with a high strength-to-weight ratio and excellent specific energy absorption capabilities. In this study, cork-based sandwich structures resistant to impact and vibrations were designed and produced for the possibility of being used in the protective structures of low-speed aerial vehicles. To identify and match the best combination of different face sheets with a cork core, first, aramid fabric-reinforced polymer (AFRP), carbon fiber-reinforced polymer (CFRP), and glass fiber-reinforced polymer (GFRP) face-sheet composites were produced using the compression molding method (prepreg layup). Then, sandwich structures consisting of AFRP, CFRP, GFRP, and aluminum face sheets with a fixed core layer of cork were designed and assembled. Since the design goal of these structures is to use them in low-speed aerial vehicles, impact deceleration and vibration tests were applied to face sheets and sandwich structures individually, which are the most important factors involved in these structures during flight, particularly in rotary-wing drone applications. A low-energy drop-tower system was used for the calculation of deceleration results. Besides, the vibration properties of the structures were investigated using the modal analysis method and based on the natural frequency responses of the tested face sheets and sandwich structures, damping ratios and structural stiffness were measured. According to the results, compared to other face sheets, CFRP showed better resistance along with the cork core, when the structure was exposed to impact and vibration threats. This study provides useful information on cork core sandwich structures for academic and industrial researchers in choosing the right face sheet.

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

Code availability

Not applicable.

References

Mangalgiri P. Composite materials for aerospace applications. Bull Mater Sci. 1999;22(3):657–64.

Castanié B, Bouvet C, Ginot M. Review of composite sandwich structure in aeronautic applications. Compos Part C Open Access. 2020;1: 100004.

Vinson JR. Sandwich structures: past, present, and future. In: Sandwich structures 7: advancing with sandwich structures and materials. Springer; 2005. p. 3–12.

Davies JM. Lightweight sandwich construction. Wiley; 2008.

Feng Y, et al. Creative design for sandwich structures: a review. Int J Adv Rob Syst. 2020;17(3):1729881420921327.

Ma W, Elkin R. Sandwich structural core materials and properties. In: Sandwich structural composites. CRC Press; 2021. p. 1–72.

Fernandes F, Pascoal R, De Sousa RA. Modelling impact response of agglomerated cork. Mater Des. 2014;58:499–507.

Fernandes F, et al. Comparing the mechanical performance of synthetic and natural cellular materials. Mater Des. 2015;82:335–41.

Gil L. Cork composites: a review. Materials. 2009;2(3):776–89.

Ptak M, et al. Assessing impact velocity and temperature effects on crashworthiness properties of cork material. Int J Impact Eng. 2017;106:238–48.

Castro O, et al. Cork agglomerates as an ideal core material in lightweight structures. Mater Des. 2010;31(1):425–32.

Santos Silva J, Dias Rodrigues J, Moreira R. Application of cork compounds in sandwich structures for vibration damping. J Sandwich Struct Mater. 2010;12(4):495–515.

Gil L. Cork: sustainability and new applications. Front Mater. 2015;1:38.

Yoon S, et al. Detection of core-skin disbonds in honeycomb composite sandwich structures using highly nonlinear solitary waves. Compos Struct. 2021;256: 113071.

Gundberg TA. Face sheet materials for sandwich composites. In: Sandwich structural composites. CRC Press; 2021. p. 85–123.

Palomba G, Crupi V, Epasto G. Collapse modes of aluminium honeycomb sandwich structures under fatigue bending loading. Thin-Walled Struct. 2019;145: 106363.

Zenkert D. An introduction to sandwich construction. Engineering materials advisory services. 1995.

Xiong J, et al. Sandwich-walled cylindrical shells with lightweight metallic lattice truss cores and carbon fiber-reinforced composite face sheets. Compos A Appl Sci Manuf. 2014;56:226–38.

Sergi C, et al. Experimental and numerical analysis of the ballistic response of agglomerated cork and its bio-based sandwich structures. Eng Fail Anal. 2022;131: 105904.

Sutherland L, Soares CG. Impact resistance of cork-skinned marine PVC/GRP sandwich laminates. Thin-Walled Struct. 2022;180: 109830.

Fernandes F, et al. Manufacturing and testing composites based on natural materials. Procedia Manuf. 2017;13:227–34.

Di Bella G, Palomba G. Cork/aluminium double-layer sandwich panels under impact loading for lightweight ship structures. Int J Crashworthiness. 2022. https://doi.org/10.1080/13588265.2022.2130619.

Nashif AD, Jones DI, Henderson JP. Vibration damping. Wiley; 1991.

Chung D. Materials for vibration damping. J Mater Sci. 2001;36(24):5733–7.

Gürgen S, Sofuoğlu MA. Smart polymer integrated cork composites for enhanced vibration damping properties. Compos Struct. 2021;258: 113200.

Karpenko M, Nugaras J. Vibration damping characteristics of the cork-based composite material in line to frequency analysis. Theor Appl Mech. 2022;60:593–602.

Stewart R. Going green: eco-friendly materials and recycling on growth paths. Plast Eng. 2008;64(1):16–24.

Rosa W. Goal 12. Ensure sustainable consumption and production patterns. A new era in global health: nursing and the United Nations 2030 agenda for sustainable development. Springer; 2017. p. 345.

Kaczynski P, et al. High-energy impact testing of agglomerated cork at extremely low and high temperatures. Int J Impact Eng. 2019;126:109–16.

Kaczyński P, et al. Development and testing of advanced cork composite sandwiches for energy-absorbing structures. Materials. 2019;12(5):697.

Sheikhi MR, Gürgen S. Anti-impact design of multi-layer composites enhanced by shear thickening fluid. Compos Struct. 2022;279: 114797.

Gürgen S, et al. Development of eco-friendly shock-absorbing cork composites enhanced by a non-Newtonian fluid. Appl Compos Mater. 2021;28(1):165–79.

Fu Z-F, He J. Modal analysis. Elsevier; 2001.

Schwarz BJ, Richardson MH. Experimental modal analysis. CSI Reliability Week. 1999;35(1):1–12.

Correia JMD, Serra GF, de Alves Sousa RJ, Pereira AB, Fernandes FAO. Expanded (black) cork for the development of an eco-friendly surfboard: environmental impact and mechanical properties. Sustainability. 2022;14:668.

Acknowledgements

This work was supported by the European Union (#2020‐1‐TR01‐KA203‐092763).

Author information

Authors and Affiliations

Contributions

Conceptualization: SG, OA. Methodology: SG, OA. Writing—reviewing and editing: SG, OA. Investigation: MRS, MAS. Data curation: MRS, MAS.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sheikhi, M.R., Gürgen, S., Altuntas, O. et al. Anti-impact and vibration-damping design of cork-based sandwich structures for low-speed aerial vehicles. Archiv.Civ.Mech.Eng 23, 71 (2023). https://doi.org/10.1007/s43452-023-00613-x

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-023-00613-x