Abstract

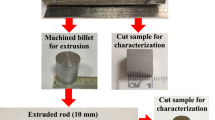

Synergistic effects of partial replacement of Al with Ca, homogenization heat treatment, and hot extrusion on the microstructure and mechanical properties of Mg–(7-x)Al–xCa magnesium alloys were studied. The Mg17Al12 compound in Mg–7Al alloy, Mg17Al12 and Al2Ca compounds in AX52 alloy, Al2Ca and Mg–Al–Ca compounds in AX43 alloy, and Mg–Al–Ca compound in AX25 were characterized. The as-cast alloys were quite brittle with low strength values due to the deleterious effects of the continuous intergranular brittle constituents that completely masked the alloying effect. Homogenization resulted in the spheroidization of the eutectic constituents and gave the alloys some tensile ductility, which was remarkable for the AX43 alloy due to its fine grain size. Hot extrusion resulted in the fragmentation and dispersion of particles as well as formation of equiaxed, fine microstructures by the recrystallization processes, which led to the profound enhancements of the tensile properties in terms of both strength and elongation to failure. The product of strength and ductility of ~ 5500 MPa.% for the extruded AX43 alloy was far better than the value of ~ 314 MPa.% for the as-cast counterpart.

Similar content being viewed by others

Data availability

The authors stated that the processed data required to reproduce these findings were available in this manuscript.

References

Kurzynowski T, Pawlak A, Smolina I. The potential of SLM technology for processing magnesium alloys in aerospace industry. Arch Civ Mech Eng. 2020;20:23.

Nasiri Z, Sarkari Khorrami M, Mirzadeh H, Emamy M. Enhanced mechanical properties of as-cast Mg–Al–Ca magnesium alloys by friction stir processing. Mater Lett. 2021;296:129880.

Kumar A, Meenashisundaram GK, Manakari V, Parande G, Gupta M. Lanthanum effect on improving CTE, damping, hardness and tensile response of Mg–3Al alloy. J Alloy Compd. 2017;695:3612–20.

Lv S, Meng F, Lu X, Yang Q, Qiu X, Duan Q, Meng J. Influence of Nd addition on microstructures and mechanical properties of a hot-extruded Mg–6.0Zn–0.5Zr (wt.%) alloy. J Alloys Compd. 2019;806:1166–79.

Saleh B, Jiang J, Fathi R, Xu Q, Wang L, Ma A. Study of the microstructure and mechanical characteristics of AZ91–SiC p composites fabricated by stir casting. Arch Civ Mech Eng. 2020;20:71.

Fatemi-Varzaneh SM, Zarei-Hanzaki A, Cabrera JM. Shear banding phenomenon during severe plastic deformation of an AZ31 magnesium alloy. J Alloy Compd. 2011;509:3806–10.

Razzaghi M, Mirzadeh H, Emamy M. Mechanical properties of Mg–Al–Mn magnesium alloys with low Al content in the as-cast and extruded conditions. Mater Res Express. 2019;6:106521.

Zhuang Y, Zhou P, Wang H, Nie K, Liu Y, Liang W, Wang L, Zheng L. The formation mechanism of the lamellar phase precipitated during solid solution treatment in the Mg–Gd–Al alloy. J Market Res. 2020;9:11392–401.

Elamami HA, Incesu A, Korgiopoulos K, Pekguleryuz M, Gungor A. Phase selection and mechanical properties of permanent-mold cast Mg–Al–Ca–Mn alloys and the role of Ca/Al ratio. J Alloy Compd. 2018;764:216–25.

Li ZT, Zhang XD, Zheng MY, Qiao XG, Wu K, Xu C, Kamado S. Effect of Ca/Al ratio on microstructure and mechanical properties of Mg–Al–Ca–Mn alloys. Mater Sci Eng, A. 2017;682:423–32.

Li ZT, Qiao XG, Xu C, Kamado S, Zheng MY, Luo AA. Ultrahigh strength Mg–Al–Ca–Mn extrusion alloys with various aluminum contents. J Alloy Compd. 2019;792:130–41.

Ninomiya R, Ojiro T, Kubota K. Improved heat resistance of Mg–Al alloys by the Ca addition. Acta Metall Mater. 1995;43:669–74.

Xiao D, Chen Z, Wang X, Zhang M, Chen D. Microstructure, mechanical and creep properties of high Ca/Al ratio Mg–Al–Ca alloy. Mater Sci Eng, A. 2016;660:166–71.

Han L, Hu H, Northwood DO. Effect of Ca additions on microstructure and microhardness of an as-cast Mg–50 wt.% Al alloy. Mater Lett. 2008;62:381–4.

Zhang L, Deng K, Nie K, Xu F, Su K, Liang W. Microstructures and mechanical properties of Mg–Al–Ca alloys affected by Ca/Al ratio. Mater Sci Eng, A. 2015;636:279–88.

Rokhlin LL, Dobatkina TV, Nikitina NI, Tarytina IE. Calcium-alloyed magnesium alloys. Met Sci Heat Treat. 2009;51:164.

Koltygin AV, Bazhenov VE, Belova EA, Nikitina AA. Development of a magnesium alloy with good casting characteristics on the basis of Mg–Al–Ca–Mn system, having Mg–Al2Ca structure. J Magn Alloys. 2013;1:224–9.

Suzuki A, Saddock ND, Jones JW, Pollock TM. Structure and transition of eutectic (Mg, Al) 2Ca Laves phase in a die-cast Mg–Al–Ca base alloy. Scripta Mater. 2004;51:1005–10.

Han G, Chen D, Chen G, Huang J. Development of non-flammable high strength extruded Mg–Al–Ca–Mn alloys with high Ca/Al ratio. J Mater Sci Technol. 2018;34:2063–8.

Liang SM, Chen RS, Blandin JJ, Suery M, Han EH. Thermal analysis and solidification pathways of Mg–Al–Ca system alloys. Mater Sci Eng, A. 2008;480:365–72.

Afsharnaderi A, Lotfpour M, Mirzadeh H, Emamy M, Malekan M. Enhanced mechanical properties of as-cast AZ91 magnesium alloy by combined RE-Sr addition and hot extrusion. Mater Sci Eng A. 2020;792:139817.

Kim WJ, Lee GE, Lee JB. Achieving low temperature superplasticity from Ca-containing magnesium alloy sheets. Adv Eng Mater. 2009;11:525–9.

Ghorbani F, Emamy M, Mirzadeh H. Enhanced tensile properties of as-cast Mg–10Al magnesium alloy via strontium addition and hot working. Arch Civ Mech Eng. 2021;21:86.

Xu SW, Matsumoto N, Yamamoto K, Kamado S, Honma T, Kojima Y. High temperature tensile properties of as-cast Mg–Al–Ca alloys. Mater Sci Eng, A. 2009;509:105–10.

Imandoust A, Barrett CD, Al-Samman T, Tschopp MA, Essadiqi E, Hort N, El Kadiri H. Unraveling recrystallization mechanisms governing texture development from rare-earth element additions to magnesium. Metall Mater Trans A. 2018;49:1809–29.

Lotfpour M, Bahmani A, Mirzadeh H, Emamy M, Malekan M, Kim WJ, Taghizadeh M, Afsharnaderi A. Effect of microalloying by Ca on the microstructure and mechanical properties of as-cast and wrought Mg–Mg2Si composites. Mater Sci Eng A. 2021;820:141574.

Khorasani F, Emamy M, Malekan M, Mirzadeh H, Pourbahari B, Krajnák T, Minárik P. Enhancement of the microstructure and elevated temperature mechanical properties of as-cast Mg–Al2Ca–Mg2Ca in-situ composite by hot extrusion. Mater Charact. 2019;147:155–64.

Pourbahari B, Mirzadeh H, Emamy M. Elucidating the effect of intermetallic compounds on the behavior of Mg–Gd–Al–Zn magnesium alloys at elevated temperatures. J Mater Res. 2017;32:4186–95.

Mirzadeh H. A comparative study on the hot flow stress of Mg–Al–Zn magnesium alloys using a simple physically-based approach. J Mag Alloys. 2014;2:225–9.

Homma T, Hirawatari S, Sunohara H, Kamado S. Room and elevated temperature mechanical properties in the as-extruded Mg–Al–Ca–Mn alloys. Mater Sci Eng, A. 2012;539:163–9.

Xu SW, Oh-Ishi K, Kamado S, Uchida F, Homma T, Hono K. High-strength extruded Mg–Al–Ca–Mn alloy. Scripta Mater. 2011;65:269–72.

Funding

This work received no funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Ethical statement

The manuscript has been prepared by the contribution of all authors, it is the original authors work, it has not been published before, it has been solely submitted to this journal, and if accepted, it will not be submitted to any other journal in any language.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nasiri, Z., Mirzadeh, H., Khorrami, M.S. et al. Synergistic effects of alloying, homogenization, and hot extrusion on the mechanical properties of as-cast Mg–Al–Ca magnesium alloys. Archiv.Civ.Mech.Eng 21, 126 (2021). https://doi.org/10.1007/s43452-021-00283-7

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-021-00283-7