Abstract

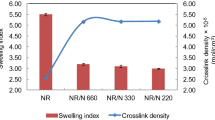

Natural rubber (NR) is the most preferred raw material for both tyre and non-tyre applications, which require good adhesion performance. It has a naturally sticky character to provide green tack. However, it has limitations to improve adhesion further due to its relatively low reactivity. In this study, epoxidised natural rubber (ENR) has been evaluated as an adhesion promoter for NR based model tyre compounds. ENR based adhesive compounds were prepared by blending NR with ENR in various ratios. Rheological, physical, and mechanical properties of NR/ENR compounds were studied. Sufficient cure rate and cure extent were achieved for elevated curing temperatures. The adhesion performance was measured with the T-peel adhesion test. In addition, thermodynamic work of adhesion (TWA) was calculated by using the surface free energy components of the compounds. The correlation between adhesion force and TWA was evaluated together with vulcanisation kinetic parameters in order to understand the adhesion mechanism. ENR incorporation was found to improve adhesion between selected tyre compounds, remarkably.

Similar content being viewed by others

References

Mascia L, Clarke J, Ng KS, Chua KS, Russo P (2015) Cure efficiency of dodecyl succinic anhydride as a cross-linking agent for elastomer blends based on epoxidized natural rubber. J Appl Polym Sci 132(6):41448–41455. https://doi.org/10.1002/app.41448

Imbernon L, Pauchet R, Pire M, Albouy PA, Tencé-Girault S, Norvez S (2016) Strain-induced crystallization in sustainably crosslinked epoxidized natural rubber. Polymer 93:189–197. https://doi.org/10.1016/j.polymer.2016.04.023

Lee K, Whelan A (2012) Developments in rubber technology-4. Springer Science & Business Media, London

Simpson RB (2002) Rubber basics. iSmithers Rapra Publishing, Shawbury

Kohjiya S, Ikeda Y (2014) Chemistry, manufacture and applications of natural rubber, 1st edn. Woodhead Publishing, Cambridge

Poh BT, Firdaus SZ (2010) Effect of hybrid tackifiers on adhesion properties of epoxidized natural rubber-based pressure-sensitive adhesives. J Polym Environ 18(3):335–338. https://doi.org/10.1007/s10924-010-0197-9

Pire M, Norvez S, Iliopoulos I, Le Rossignol B, Leibler L (2010) Epoxidized natural rubber/dicarboxylic acid self-vulcanized blends. Polymer 51(25):5903–5909. https://doi.org/10.1016/j.polymer.2010.10.023

Poh BT, Yong AT (2009) Effect of molecular weight of epoxidized natural rubber on shear strength of adhesives. J Appl Polym Sci 114(6):3976–3979. https://doi.org/10.1002/app.30978

Poh BT, Yong AT (2009) Dependence of peel adhesion on molecular weight of epoxidized natural rubber. J Adhes 85(7):435–446. https://doi.org/10.1080/00218460903040941

Poh BT, Yong AT (2010) Effect of molecular weight of epoxidized-natural rubber on viscosity and tack of pressure-sensitive adhesives. J Appl Polym Sci 115(2):1120–1124. https://doi.org/10.1002/app.31185

Khan I, Poh B (2012) Statistical analysis on the effect of the molecular weight and testing rate on peel strength of epoxidized natural rubber (ENR 25)-based adhesives. J Elastom Plast 44(5):453–475. https://doi.org/10.1177/0095244312439449

Poh BT, Lim AL (2008) Adhesion properties of pressure-sensitive adhesives prepared from SMR 10/ENR 25, SMR 10/ENR 50, and ENR 25/ENR 50 blends. J Appl Polym Sci 109(1):115–119. https://doi.org/10.1002/app.27489

Soo KW, Azahari B, Poh BT (2016) Effect of magnesium oxide loading on adhesion properties of ENR 25/NBR blend adhesives in the presence of petro resin and gum rosin tackifiers. J Polym Environ 24(4):334–342. https://doi.org/10.1007/s10924-016-0778-3

Poh BT, Saari N (2011) Adhesion properties of epoxidized natural rubber (ENR 50)-based adhesive in the presence of magnesium oxide. J Appl Polym Sci 43(4):357–368. https://doi.org/10.1177/0095244311404185

Poh BT, Chee BC (2015) Effect of blend ratio and testing rate on the adhesion properties of epoxidized natural rubber (ENR 25)/styrene–butadiene rubber (SBR) blend adhesive. J Adhes 91(12):950–961. https://doi.org/10.1080/00218464.2014.982863

Choi S-S, Kim J-C, Lee SG, Joo YL (2008) Influence of the cure systems on long time thermal aging behaviors of NR composites. Macromol Res 16(6):561–566. https://doi.org/10.1007/BF03218560

Wang P-Y, Chen Y, Qian H-L (2007) Vulcanization kinetics of low-protein natural rubber with use of a vulcameter. J Appl Polym Sci 105(6):3255–3259. https://doi.org/10.1002/app.26488

Karaağaç İ, Özkoç G, Karaağaç B (2017) Investigation of crosslinking kinetics of silicone rubber/POSS nanocomposites. In: Lion A, Johlitz M (eds) Constitutive models for rubber X. CRC Press, pp 253–257

AD- (2015) ASTM D1876-08-Standard test method for peel resistance of adhesives (T-peel test). Developed by Subcommittee: D14.80

Awaja F, Gilbert M, Kelly G, Fox B, Pigram PJ (2009) Adhesion of polymers. Prog Polym Sci 34(9):948–968. https://doi.org/10.1016/j.progpolymsci.2009.04.007

Yuan Y, Lee TR (2013) Contact angle and wetting properties. In: Bracco G, Holst B (eds) Surface science techniques. Springer, Berlin, pp 3–34. https://doi.org/10.1007/978-3-642-34243-1_1

Uzan G, Uyanik N, Karaagac BJK-KGK (2016) Itaconic acid modified halloy-site/carbon black dual filler system in styrene butadiene rubber nanocomposites. KGK-Kaut Gummi Kunst 69(6):38–44

Chuayjuljit S, Yaowsang C, Na-Ranong N, Potiyaraj P (2006) Oil resistance and physical properties of in situ epoxidized natural rubber from high ammonia concentrated latex. J Appl Polym Sci 100(5):3948–3955. https://doi.org/10.1002/app.22998

Ismail H, Suzaimah S (2000) Styrene butadiene rubber/epoxidized natural rubber blends: dynamic properties, curing characteristics and swelling studies. Polym Test 19(8):879–888. https://doi.org/10.1016/S0142-9418(99)00058-6

Madihally SV (2010) Principles of biomedical engineering. Artech House Publishing, Boston

Acknowledgements

The authors gratefully thank TÜBİTAK (within Project no: 3170880) and Kocaeli University BAP Department (within Project no: 2017/081) for their valuable financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Öter, M., Karaağaç, B. Epoxidised natural rubber as adhesion promoter in natural rubber based compounds. J Rubber Res 23, 333–341 (2020). https://doi.org/10.1007/s42464-020-00061-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42464-020-00061-9