Abstract

A bicycle is considered to be an environment-friendly and fuel-conserving mode of transport with the increasing user group and rapid innovation in production systems, but how much this assumption represents the reality needs to be ascertained. In the transportation sector, the abundance of private motorized vehicle is responsible for poor environmental condition. Bicycle can be a solution to traffic jam along with carbon dioxide (CO2) emission in a densely populated country like Bangladesh, and nowadays, it become more popular than other private transports in the country. The study aims to identify environmental impacts and hot spot of bicycle production in Bangladesh and prediction of estimate the carbon dioxide (CO2) reduction through bicycle use instead of motorized private vehicles in the country. This study was conducted under the ISO 14044 guideline. The study considered the entire life cycle of bicycle production in Bangladesh, and material preparation, manufacturing and assembly, packaging, transportation and waste generation were modeled using the life cycle assessment software SimaPro 8.5, and environmental impacts were assessed using ReCiPe version 1.3 method. Results indicate that the process of aluminum parts production is the most important factor of impacts. On the other hand, human toxicity (28.92 kg 1,4-DB eq) is the highest among all the impact categories. During the evaluation of the entire life cycle study, it was found that material preparation causes maximum environmental burden. Scenario analysis of the study reveals that 53% of carbon dioxide (CO2) emission can be reduced if only 40% of people use bicycles instead of using private transport for short distance. Comparative analysis also reveals that bicycle production in Bangladesh is better than Europe in terms of climate change, human toxicity, particulate matter formation, metal depletion and fossil depletion impact categories. Bicycle use can reduce automobile dependency and be a step toward a sustainable transportation system in Bangladesh. Development in the identified hot spot of the study and adoption of green technology can ensure a much cleaner production of bicycle.

Similar content being viewed by others

1 Introduction

Bicycles are an effective means of transport for short-distance travel. In recent years, conventional bicycles and electric bicycles have become more popular and affordable and this makes bicycle an attractive transportation mode [1]. The market for bicycles is currently growing at annual rates of more than 100% [2]. It is not easy to manage the space required for parking and movement of a large number of vehicles. Moreover, the large number of traffic burns huge amount of fuel, which incurs a major cost [3]. Thus, a large number of traffic leads to huge energy consumption and pollution as well as a significant economic loss [4]. Moreover, non-motorized traffic flow is also preferred to reduce environmental impact in terms of residential street construction, and here, bicycle can be a good non-motorized traffic option for city dwellers [5].

At present, there is a huge interest in cycling and also a tendency among the manufacturers to introduce more attractive models of bicycles with the use of new and more suitable materials [6]. Annually 132 million bicycles are produced in the USA, and the total value of the US bicycle market is 6.1 billion USD [7]. Moreover, expected value of world bicycle market will reach at 34.9 billion USD by 2022 [8]. The highest selling bicycle model is mountain bicycle 24%, and the second highest is hybrid bicycle 21% followed by road bicycle 20% [9]. Bangladesh is a well-known bicycle producer around the world. The country is the second largest bicycle exporter to European Union (EU) as a non-EU country and 8th largest among all the countries [8]. Bicycle production is a growing industry in Bangladesh, and the country has also started growing its export market. This export secures 12% of the country’s total engineering exports which is 0.24% of total exports [10].

Life cycle assessment (LCA) is a technique to assess environmental impacts associated with all the stages of a product’s life from raw material extraction through materials processing, manufacture, distribution, use, repair and maintenance, and disposal or recycling [11]. The life cycle also consists of the transport routes used during raw materials extraction, production and distribution, and it is sometimes called a ‘cradle-to-grave’ assessment [12, 13].

A life cycle assessment-based approach of cycling mobility study indicates that aluminum bicycle has the highest environmental impact and a bicycle of carbon fiber has the least impact for the most of the environmental categories [14]. Cherry et al. [15] showed the materials used for the construction of different transport modes, focusing on the energy consumption, waste generation and emission associated with the production system of different transport modes with two wheels. Less amount of materials is required for bicycle production, and thus, bicycle has less impact on the environment. The study identified the environmental impacts of electric bikes in China on its production and use [15]. Environmental and social life cycle assessment study of bamboo bicycle frames made in Ghana indicates that the environmental impact of bamboo frame bicycle is about 50% less than the aluminum and about 30% less than the steel frame bicycle [16].

There are some research on the life cycle assessment (LCA) applied to different transport modes and materials substitution in motor vehicles [17, 18], but the studies regarding bicycles are very limited. Though Bangladesh is a producer of bicycles, there is no research found on the LCA of the bicycle. So, there is a big gap of knowledge of the environmental impact of bicycle production and its use in Bangladesh. Hence, this study has been carried out to build a bridge over the knowledge gap in the environmental impact of mountain bike production and its use in Bangladesh. This has been done by using SimaPro 8.5 LCA software, where we measure the impact from ‘cradle’ to ‘grave’ with the help of ecoinvent 3.4 [19, 20]. Here, ecoinvent is a widely used large database in terms of diversified country- and region-specific datasets among all exiting databases. This research focuses on the production of a regular mountain bike in Bangladesh.

The objective of the study was to identify the flow chain of bicycle production and to assess the environmental impact of bicycle production along with addressing benefit of using bicycle instead of motorized vehicle for reducing CO2 emission in Bangladesh.

2 Materials and methods

2.1 Life cycle assessment (LCA) framework

Through the life cycle assessment (LCA), the impact at the global and regional scales, such as climate change, acidification, eutrophication, toxicological effects and abiotic resources use is accounted [21]. It also includes identifying and quantifying energy and materials used and waste released to the environment, assessing their environmental impact and evaluating opportunities for improvement. The methodological framework for LCA, ISO 14044 defines requirements for the reporting of the assessment and guideline for the possible implementation of the critical review [22]. According to ISO 14044 [23], the methodological framework for LCA consists of four phases adopted by this present study.

2.2 Goal and scope definition

Bicycles are the single largest export commodity in the engineering sector of Bangladesh. It accounts for 7.5% of the total engineering exports [24]. The study aims at identifying the environmental impacts of bicycle production in Bangladesh also with three scenarios of using bicycle. To perform life cycle assessment, production of bicycle in Bangladesh is modeled. Some parts are imported from different countries, and environmental impact of materials used in these parts is also included in the model, whereas 2017 was the temporal boundary of the study due to data availability in Bangladesh.

2.3 Functional unit

Functional unit is the amount, weight and quantity of the specific product material investigated. It is an important basis that enables alternative goods, or services, to be compared and analyzed [25]. The functional unit of this study is a regular bicycle with 18.4 kg of weight which is produced for daily use in city and rural area. Previous life cycle assessment studies related to bicycle also use regular or standard city bicycle because regular bicycle is cheap and affordable [16, 17, 26]. Coelho and Almeida [14] considered mountain bike in their study, and in Bangladesh, actual mountain bicycle with both front and rear suspensions is very rare. So, environmental impact assessment of regular bicycle will reflect an actual scenario of current situation of Bangladesh.

2.4 System boundary

The system boundary defines the process or operations, and the inputs and outputs that are considered in the LCA. The system boundary of this study starts with the raw material acquisition, manufacturing, packaging, use, recycling and waste management of bicycle production. Natural resources, water and energy are considered as inputs, and atmospheric emission, waste and other releases as outputs of bicycle production. System boundary of bicycle production in Bangladesh is depicted in Fig. 1.

This study represents the current production practices of bicycle production. Although major parts of bicycle are produced and assembled in Bangladesh, some parts are imported from Japan, Taiwan and China.

2.5 Data source, quality and assumptions

Bicycle-related data used in this study were collected from a bicycle industry in Bangladesh, which agree to provide information and interviews. In addition, this industry consists of 12 interrelated facilities and 3 manufacturing units for producing large number of bicycles and this industry is the largest manufacturer and exporter of bicycle in Bangladesh with holding lion’s share of this sector [27]. Reference bicycle was considered, because data regarding the parts and production were available by the authority. Inventory data related to bicycle production were collected through questionnaire and interviews. Mass of all parts or components of reference bicycle was measured precisely. Transportation distance was calculated from secondary sources. Moreover, secondary data were collected from different literature sources, newspapers, reports, online sources, previous research article and ecoinvent 3.5 [20]. Ecoinvent 3.5 bicycle production dataset for Europe (RER) was used to compare bicycle production in Bangladesh with Europe.

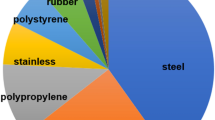

2.5.1 Material preparation phase

Different materials and parts are required for bicycle production, and more than 20 parts are used to assemble a complete cycle. Parts which are produced in Bangladesh (i.e., frame, handlebar, stem, seat post, bearings, wheels, tires, pedals, saddle, cables, etc.) and other imported parts from China, Japan and Taiwan (i.e., brake levers, brakes, cassette and sprockets, chain, crankset, front derailleurs, rear derailleurs, fork, shifters, etc.) were considered in the study. Aluminum alloy, stainless steel, plastic, rubber, pu flexible foam and wire are used to manufacture these parts. The list of parts used in production is shown in Table 1.

2.5.2 Manufacturing and assembly phase

Impacts that are generated from assembly of bicycle parts and manufacturing are calculated in the manufacturing and assembly phase. Assembling of different parts is required for final manufacturing of bicycle. Assembly phase needs electricity for welding along with natural gas and tap water. Painting of bicycle is also included in this phase. On the other hand, the machinery or equipment used for bicycle production has a very low environmental impact for one bicycle production along with long lifespan. So, the study assessment did not include machinery and industrial buildings.

2.5.3 Packaging phase

In order to transport manufactured bicycle, good quality packaging is crucial. Corrugated board and plastic are used as packaging material for storing and safe transportation.

2.5.4 Transportation

Transportation is required for importing bicycle parts and distribution of manufactured bicycle to the retailers. Average distance between industry and bicycle retailer shop of the domestic market was assumed as 100 km by heavy truck (16 ton). Moreover, impact of bicycle parts transportation from Japan, Taiwan and China was also accounted for. In this case, parts were transported from the correspondent country by sea (ocean freighter) to Bangladesh, and then, all these parts were carried in a heavy 16-ton truck up to industry, which was considered about 250-km travel distance.

2.5.5 Use and maintenance phase

Bicycle use phase has a very minimal environmental burden than motorized vehicle, because no fuel is required to run bicycle [17]. So, we can ignore this use phase in case of comparing with other modes of transportation and production system. However, maintenance and parts replacement are required in use phase, for instance tire, chain, brake pads, etc. It is assumed that average lifespan of a bicycle is 15,000 km and tires need to be replaced in every 4000 km [17, 26]. Again, 1 chain, 6 brake pads (two wheels) and 1 cassette need to be replaced during the lifetime of a bicycle.

2.5.6 Recycling and waste management phase

Waste generated from bicycle production was considered in the waste management phase, for example plastic waste, rubber waste, wastewater, etc. On the other hand, after end use metals and plastic of bicycle are recycled and almost 100% of these are recyclable and others are dumped as solid waste.

2.6 Impact assessment method

Inventory for bicycle production was prepared with careful attention. Microsoft Excel 2016 was used for data compiling regarding functional unit and graphical representation of results. Unit process input and output background data were taken from the Ecoinvent database [20]. Production system modeling and calculation were done by the SimaPro 8.5 software which is the world’s leading life cycle assessment (LCA) modeling software [19]. The ReCiPe version 1.3 hierarchist impact assessment method was used for the calculation of production impact related to environmental emission throughout the production system [28]. The production process of the bicycle in Bangladesh was evaluated under eight impact categories at midpoint level: climate change, freshwater eutrophication, human toxicity, particulate matter formation, freshwater ecotoxicity, marine ecotoxicity, metal depletion and fossil depletion. These eight impact categories contributed more than 80% among eighteen impact categories. Environmental burden generated from the whole process was also evaluated at endpoint level. Total analysis was performed under ISO guideline for Life Cycle Assessment [29].

2.7 Calculations

To visualize the benefit of using bicycle as a regular transportation mode, this study compared the CO2 emissions for 1-km movement of different modes of transportation used by city dwellers commonly at a busy road in Dhaka city which is the capital of Bangladesh. This road connects a considerable number of offices, schools, colleges, shopping malls and a huge number of vehicles continuously moving on the road. To perform this analysis, vehicle- and passenger-related data were adopted from a previous study based on the same location [30]. We considered leguna, bus, minibus and double-decker bus as public transportation and car, microbus and motor cycle as private mode for presenting the result easily. According to Barua and Hoque [30], in a range of 1 h at the above-mentioned place, 72% of people use public transport followed by 26% of people use private transport as their mode of transportation where only 2% use bicycle. But a large portion (72%) of people uses only 10% of vehicles where 86% of vehicles are used by 26% (Table 2). However, we did not consider rickshaw in this calculation. Huge number of private vehicles in Dhaka city creates a significant amount of CO2 emission. Bicycle use can reduce this CO2 emission.

For better comparison, three scenarios were created in this study on the basis of passenger number. These three scenarios were examined for comparing how more bicycle use can reduce CO2 emissions. Percentage of bicycle use for the scenario development was selected based on bicycle per capita of top countries of Asia and Europe and age structure of Bangladesh. Table 3 represents percentage of cyclist in top countries of Asia and Europe [31]. It is revealed that in average 63% people of the above countries are using bicycle as their transport, and in Bangladesh, 59.21% of total population are fallen into 15–54 age group; they are physically fit for cycling [32]. So, for the best-case scenario 40% of passengers were selected for bicycle transport in Bangladesh and others are selected based on current situation.

The scenarios were a percentage of people used different transportation modes:

-

(Scenario 1) Public transportation 65%, private transportation 15% and bicycle 20%

-

(Scenario 2) Public transportation 60%, private transportation 10% and bicycle 30%

-

(Scenario 3) Public transportation 55%, private transportation 5% and bicycle 40%

In order to calculate CO2 emission per kilometer from public and private transportation, total number of vehicles passed in 1 h was multiplied by the CO2 emission factors (Table 4), and then, per person emission was calculated from these values for different transportation modes (Eq. 1). Finally, total CO2 emission from private or public mode was revealed by Eq. 2. Here, this study assumed that bicycle has no emission in its use phase.

2.8 Inventory analysis

The life cycle inventory (LCI) aims to identify and quantify the environmental interventions related to the systems and results in a list of environmental inputs and outputs. Collection of data, their validation and collection methods are involved in the LCI. Raw materials from environment are required for bicycle production, including inputs from technosphere, and background data for raw material preparation (i.e., metal, rubber, plastic, etc.) were taken from ecoinvent 3.4 database [20]. Table 5 and 6 show material specification for bicycle production in Bangladesh and components required for its whole life cycle, respectively.

3 Results and discussion

3.1 Life cycle impact assessment results

Table 7 summarizes the characterized result of bicycle produced in Bangladesh for selected eight impact categories. The result was calculated with ReCiPe impact assessment method. A normalization step was done with World ReCiPe (H) for the better understanding and to rank the impact categories of the production system. Figure 2 shows the normalized result for the system. Normalization step has done to understand the relative dominance of impacts among selected categories, and it is clear that human toxicity is in the peak among all impact categories with 21.6% of shares followed by marine ecotoxicity (17.0%), metal depletion (16.1%) and freshwater eutrophication (13.0%). However, bicycle production has relatively less impact on climate change (7%).

Figure 3 represents comparative environmental impact among different life cycle phases of bicycle production in Bangladesh. It is seen that the material preparation phase for bicycle generates majority of impact in all eight impact categories. Energy consumption and use of different metals such as aluminum, steel and steel alloy are relatively high in this phase, and these create a huge environmental burden. On the other hand, use and maintenance phase has huge environmental impact on all the categories. It is usual that no fuel is required for bicycle use, but maintenance is required which includes replacement of tire, chain, brake pad and cassette. Here, environmental burden of this phase is high because this study considered all exchange of components of bicycle over its entire life span. Again, the figure also depicted that assembly and recycle and waste management phase has also significant environmental impact.

3.2 Hot spot analysis

3.2.1 Climate change

Main contributor to climate change is material preparation phase (74.4%) followed by use and maintenance face (15.5%) and assembly phase (4.96%). Aluminum for frame production (67.3%) is mainly responsible in material production and use and maintenance phase. On the other hand, steel for different parts and rubber for tire production has also significant amount of impact in this impact category. Avoiding aluminum frame and replacing aluminum with other material like carbon fiber could be another choice to reduce climate change impacts. Figure 4 represents major contributors in this impact category.

3.2.2 Freshwater eutrophication

Figure 5 depicts major contributors for freshwater eutrophication impact category. Here, material preparation phase has the highest impact (44%) due to use of aluminum in frame followed by recycling and waste management phase (42.8%) and use and maintenance phase (11.3%). In waste management phase, wastewater is generated as effluent and this is one of the major contributors in this impact category. Efficient use and reuse of water can be reduced environmental footprint of bicycle production in Bangladesh.

3.2.3 Human toxicity

Figure 6 represents major contributions for human toxicity impact category, and here, material preparation phase (80.2) has the highest environmental impact. It is clear that aluminum for frame production (67.8) is mainly responsible for burden generation in this impact category.

3.2.4 Particulate matter formation

Like human toxicity impact category, material preparation phase has major contribution of burden generation regarding particulate matter formation impact category (78.4%). Aluminum frame production represents a contribution of 67.7% of total impacts, and steel (16.24%) and rubber (8.29%) also have significant impact on particulate matter formation. High amount of rubber is required for producing tire, which is used in the maintenance of bicycle. Strong, durable and lightweight material can reduce such burden on environment (Fig. 7).

3.2.5 Freshwater ecotoxicity

For freshwater ecotoxicity impact category, material preparation phase (37.3%), recycle and waste management phase (27%), assembly phase (18%) and use and maintenance phase (14.2%) are main contributors among all six phases. Like most of the impact categories, aluminum (27.6%) produces more burden than other processes. This is happened because frame is the largest single part used to manufacture a bicycle, and therefore, bicycle manufactures have great opportunities to bring innovation in this part of bicycle. Besides aluminum, electricity (15.7%) and natural gas (24%) use for production also generates considerable amount of burden on environment. Figure 8 represents a clear view of this section.

3.2.6 Marine ecotoxicity

Figure 9 shows network for major contributors of marine ecotoxicity impact categories. Material preparation phase is the more representative with 59.6% of shares, and among different processes, aluminum (31.9%) for frame production holds major portion of environmental burden in this impact category. Again, steel used in different parts, rubber for tire and wastewater from production process has significant impact on environment.

3.2.7 Metal depletion

Major contributors in metal depletion category are shown in Fig. 10. Like most of the impact categories, material preparation phase (75.2%) generated the highest environmental burden in this category, but unlike other categories steel (47.8% for stainless steel and 42.1% for steel alloy) is the main contributor in this category instead of aluminum. So, here is a sector which required more attention by developers.

3.2.8 Fossil depletion

For fossil depletion, material preparation represents a contribution of 64.2% of total impacts followed by use and maintenance (25.3%) phase. Aluminum accounts for 51.3% share of environmental burden, and Fig. 11 also reveals that synthetic rubber and polyethylene granulate has a great impact on fossil depletion.

3.3 Damage assessment at endpoint level

Table 8 shows actual environmental impact of bicycle production in Bangladesh in terms of endpoint indicators. According to the outcome, impact on human health in terms of disability adjusted life years (DALY) is 0.00042, which is explained by the production, and maintenance of a bicycle in Bangladesh can lose 3.7 days of healthy and perfect life. Besides this, impact of ecosystems expresses species extinction rate due to activities and it is assumed that one extinction is estimated per million species.years. In this study, it is revealed that 1.7E−06 species may go extinct in 1 million year by bicycle production and maintenance activity. Finally, a bicycle production and maintenance in Bangladesh generates environmental burden, which is equivalent to the use of global resource worth USD 10.9. Contribution of three endpoint indicators after normalization is depicted in Fig. 12, which indicates that resources (58%) are highly affected followed by human health (40%) and ecosystems (2%) during the production system.

3.4 Scenario analysis

Figure 13 compares CO2 emission among public transport, private transport and bicycle. In the present context, only 2% people use bicycle, and as a result, CO2 emission is significantly high due to frequent use of fuel burning transport. In scenario 1, assuming that 20% city dwellers use bicycle, CO2 emission can be reduced considerably (27%). Again, according to scenario 2, 40% CO2 emission can be reduced by increasing bicycle use to 30%. Finally, as shown in scenario-3, where 40% people use bicycle, it significantly reduces 53% CO2 emission from the present situation.

3.5 Comparing results with existing studies

In this study, the raw material preparation phase has the highest impact on environment; besides this, aluminum produces more environmental burden than other processes considered. Although aluminum frame bicycle has significant environmental impact, its popularity forces producers to produce this particular type of bicycle. On the other hand, producers should think about more environment-friendly material to make bicycle frame instead of aluminum frame bicycle. According to Agyekum et al. [16], raw material extraction and refining phase has the highest environmental impact and bamboo frame bicycle is less environmentally harmful then aluminum and steel frame bicycle. Bangladesh needs to produce bamboo frame bicycle to reduce environmental burden and create public choice on the less impact frame at policy level. A study on cycling mobility [14] revealed that production phase has the highest negative impact among all phases of bicycle production, which strengthens the findings of the present study. Another study by Chang et al. [34] showed that the production of the parts of bicycles leads to main environmental impacts through the life cycle of both aluminum and bamboo bicycles. The present study indicates similar results like this study where both studies use ReCiPe indicators. Again, Leuenberger and Frischknecht [26] compiled inventories of two-wheeled vehicles and bicycle is one of them and this inventory is close to the current study which justify the acceptance of the inventory. A comparative study on conventional and electric bicycle was carried out, and they showed that conventional bicycle is more environment-friendly with no emission in use phase due to no fuel consumption. The current study reveals the similar result where bicycle use and maintenance has comparatively low impact on environment and this burden mainly generated due to replacement of parts for maintenance in its lifespan [17].

3.5.1 Comparison with Europe

To understand the status of bicycle production in Bangladesh, this study considered a comparison with European bicycle production practice, and here, only impacts of bicycle production were accounted. Figure 14 represents a clear overview on bicycle production of both regions. For climate change, human toxicity, particulate matter formation, metal depletion and fossil depletion, impact from European practice is higher than the practice in Bangladesh, except freshwater eutrophication and freshwater ecotoxicity, where Bangladesh produces more environmental burden than Europe for bicycle production. This happened due to more electricity (10.2 kWh) use and wastewater (7.1 m3) emission by Bangladeshi production systems, whereas for rest impact categories, Europe uses more aluminum and steel than Bangladesh. However, the impact generated in marine ecotoxicity category is almost same for Bangladesh and Europe.

3.6 Policy discussion

Bangladesh is an overpopulated country, and a large number of people move at the same time for their livelihood. For this reason, traffic jam and transport shortage are a regular problem in city. Moreover, the practice of using private transport is increasing day by day, which can move only a few people. Policy makers should think about increasing bicycle use in city areas which performs well in terms of CO2 emission. Bicycle is an environment-friendly transport and needs very little space to move which might be a good solution to traffic jam. However, the government should support bicycle industry and industry owners should think about adopting green technologies, also with efficient product design for reducing resources use. From an LCA perspective, Bangladesh creates comparatively low environmental burden in climate change, human toxicity, particulate matter formation, metal depletion and fossil depletion impact categories than Europe.

4 Conclusion

This study has explored the environmental impact of bicycle production in Bangladesh. CO2 emission scenario is also performed comparing among bicycle, public transport sector (i.e., leguna, bus, minibus and double-decker bus) and private transport sector (i.e., car, microbus and motor cycle).

The life cycle impact assessment results reveal that the material preparation phase creates comparatively high impacts on environment. On the other hand, human toxicity is the highest among all impact categories. Simultaneously, marine ecotoxicity, metal depletion, freshwater eutrophication, fossil depletion, particulate matter formation and climate change also occurred by the production process of bicycle in Bangladesh. At present, 26% people use 86% of vehicles moved in city area which are private vehicles and generate huge amount of CO2 gas. Scenario analysis of the study reveals that if 26% people of private transport user reduced to 5% and increase bicycle user to 40% then 53% of CO2 emissions can be reduced. However, bicycle production in Bangladesh is better than that in Europe considering climate change, human toxicity, particulate matter formation, metal depletion and fossil depletion impact categories. Assessment of the study shows a great potential of bicycle production in Bangladesh in terms of reducing environmental risks. This study will help to identify and prolong best manufacturing and management practices of bicycle production. Collaboration among industries should be ensured for sustainable use of natural resources and clean production practices.

References

Monitor (2018) Duranta set to rule bicycle market worldwide. The Bangladesh Monitor, p 1

Velosuisse (2008) Statistiken uber den Velomarkt Schweiz http://www.velosuisse.ch/de/statistikaktuell.html. Accessed 1 Jan 2019

Dresselhaus M, Thomas I (2001) Alternative energy technologies. Nature 414(6861):332. https://doi.org/10.1038/35104599

Van Mierlo J, Maggetto G, Van de Burgwal E, Gense R (2004) Driving style and traffic measures-influence on vehicle emissions and fuel consumption. Proc Inst Mech Eng Part D J Automob Eng 218(1):43–50. https://doi.org/10.1243/095440704322829155

Gámez-García DC, Saldaña-Márquez H, Gómez-Soberón JM, Corral-Higuera R, Arredondo-Rea SP (2019) Life cycle assessment of residential streets from the perspective of favoring the human scale and reducing motorized traffic flow. From cradle to handover approach. Sustain Cities Soc 44:332–342. https://doi.org/10.1016/j.scs.2018.10.018

Ahmed S (2018) Bicycle industry shows promise as export earnings grow. The Independent, Independent Publications Limited, p 1

SB (2017) Bicycle industry statistics. Statistic Brain Research Institute. http://www.statisticbrain.com/bicycle-industry-statistics/. Accessed 30 Dec 2018

Rizwan N, Kathuria S, Singla N (2017) Bicycles can boost Bangladesh’s exports. World Bank. http://blogs.worldbank.org/endpovertyinsouthasia/bicycles-can-boost-bangladeshs-exports. Accessed 28 Nov 2018

NBDA (2015) A look at the bicycle industry’s vital statistics. The National Bicycle Dealers Association, Laguna Hills, CA

Begum FA (2018) Expanding bicycle export market. The Financial Express, International Publications Limited, p 1

Finkbeiner M, Schau EM, Lehmann A, Traverso M (2010) Towards life cycle sustainability assessment. Sustainability 2(10):3309–3322. https://doi.org/10.3390/su2103309

DEAT (2004) Life cycle assessment, integrated environmental management, information series 9. (DEAT) DoEAaT, Pretoria, South Africa18

Kloepffer W (2008) Life cycle sustainability assessment of products. Int J LCA 13(2):89. https://doi.org/10.1065/lca2008.02.376

Coelho MC, Almeida D (2015) Cycling mobility–a life cycle assessment based approach. Transp Res Procedia 10:443–451. https://doi.org/10.1016/j.trpro.2015.09.094

Cherry CR, Weinert JX, Xinmiao Y (2009) Comparative environmental impacts of electric bikes in China. Transp Res Part D Transp Environ 14(5):281–290. https://doi.org/10.1016/j.trd.2008.11.003

Agyekum EO, Fortuin KPJ, van der Harst E (2017) Environmental and social life cycle assessment of bamboo bicycle frames made in Ghana. J Clean Prod 143:1069–1080. https://doi.org/10.1016/j.jclepro.2016.12.012

Del Duce A (2011) Life cycle assessment of conventional and electric bicycles. In: Paper presented at the Eurobike, Friedrichshafen, Germany, p 31

Hakamada M, Furuta T, Chino Y, Chen Y, Kusuda H, Mabuchi M (2007) Life cycle inventory study on magnesium alloy substitution in vehicles. Energy 32(8):1352–1360. https://doi.org/10.1016/j.energy.2006.10.020

Consultant P (2017) PRé consultant-enabling fact-based sustainability. https://simapro.com/. Accessed 30 Oct 2018

Ecoinvent (2018) Ecoinvent—the world’s most consistent & transparent life cycle inventory database. https://www.ecoinvent.org/. Accessed 15 Nov 2018

Koellner T, De Baan L, Beck T, Brandão M, Civit B, Margni M, i Canals M, Saad R, De Souza DM, Müller-Wenk R (2013) UNEP-SETAC guideline on global land use impact assessment on biodiversity and ecosystem services in LCA. Int J LCA 18(6):1188–1202. https://doi.org/10.1007/s11367-013-0579-z

Lehtinen H, Saarentaus A, Rouhiainen J, Pitts M, Azapagic A (2011) A review of LCA methods and tools and their suitability for SMEs. Eur Innov Eco Innov Bio Chem 17:2014

ISO (2006) ISO 14040:2006-Environmental management-life cycle assessment-principles and framework, 2nd edn. ISO, Geneva, p 20

Rajon S (2015) Exporting of bicycles: a new window for Bangladesh’s economy. Dahaka Tribune, p 1

Rebitzer G, Ekvall T, Frischknecht R, Hunkeler D, Norris G, Rydberg T, Schmidt W-P, Suh S, Weidema BP, Pennington DW (2004) Life cycle assessment: part 1: framework, goal and scope definition, inventory analysis, and applications. Environ Int 30(5):701–720. https://doi.org/10.1016/j.envint.2003.11.005

Leuenberger M, Frischknecht R (2010) Life cycle assessment of two wheel vehicles, vol 2. Villigen, ESU-Service Ltd, p 30

Group M (2018) Bicycle division. Meghna group. http://www.meghnagroup.com.bd/bicycle-division/about-us/. Accessed 2 May 2019

Goedkoop M, Heijungs R, Huijbregts M, De Schryver A, Struijs J, Van Zelm R (2009) ReCiPE 2008: A life cycle impact assessment method which comprises harmonised category indicators at the midpoint and the endpoint level, vol 1, pp 1–126

ISO (2006) ISO 14044 2006-Environmental management—life cycle assessment-requirements guidelines. International Organization for Standardization, Geneva, p 46

Barua L, Hoque MS (2016) Potentiality of bicycle to mitigate traffic congestion and improve environmental condition of Dhaka City. In: Paper presented at the international conference on recent innovation in civil engineering for sustainable development, Gazipur, Bangladesh, pp 692–697

Kawser (2018) Top 10 countries with most bicycles per capita ApexBikes. https://www.apexbikes.com/top-10-countries-with-bicyclists/. Accessed 2 Jan 2019

CIA (2018) The World Factbook: Bangladesh: People and society. Central Intelligence Agency. https://www.cia.gov/library/publications/the-world-factbook/geos/bg.html#People. Accessed 2 Jan 2019

Wadud Z, Khan T (2011) CNG conversion of motor vehicles in Dhaka: valuation of the cobenefits. In: Transportation research board (TRB) 90th annual meeting was held in Washington, DC, 2011

Chang Y-J, Schau EM, Finkbeiner M (2012) Application of life cycle sustainability assessment to the bamboo and aluminum bicycle in surveying social risks of developing countries. In: 2nd world sustainability forum, 2012, pp 1–30

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Roy, P., Miah, M.D. & Zafar, M.T. Environmental impacts of bicycle production in Bangladesh: a cradle-to-grave life cycle assessment approach. SN Appl. Sci. 1, 700 (2019). https://doi.org/10.1007/s42452-019-0721-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-019-0721-z