Abstract

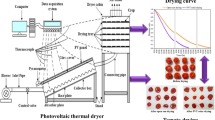

This paper presents the energy and exergy-based environmental sustainability analyses of a developed solar dryer equipped with electric heater as supplementary heat. The experimental study was applied for drying a local variety of red pepper (Shombo) near a coastal region of eastern Nigeria. The objectives of the study were to assess the suitability and overall performances of the hybrid solar dryer in this area. Results obtained indicate that the solar collector contributed about 39.4 to 48.5% of the total drying air temperature required for drying operation. The energy efficiency of the hybrid solar dryer ranged between 13.2 to 35.6%, whereas the specific energy requirements varied between 7.24 kJkg− 1 to 63.5 kJkg− 1. The percent solar energy contribution to the total energy requirement ranged between 28.8–52.68% at varying air temperatures (50, 60, and 70oC) and air velocities (1.14, 2.29, and 3.43 ms− 1). The drying time varied between 75 ± 5 to 180 ± 24 min. The energy and exergy efficiencies varied between 13.2–35.6% and 35.8 to 92.3%, respectively. The exergy-based sustainability indicators which take into account the ratio of waste exergy, sustainability index, and improvement capacity of the hybrid heat source dryer were found to be 0.11–0.167, 1.14–6.12, and 0.099–0.289 kJs− 1, respectively. Comparison between a CI-engine powered dryer reveals that the use of a hybrid solar-electric dryer can prevent emission of 398.86 to 3872.7 tons of CO2 into the environment per annum. Recommendation for future studies was suggested.

Similar content being viewed by others

References

Afolabi TJ, Akintunde TY, Oyelade OJ (2014) Influence of drying conditions on the effective moisture diffusivity and energy requirements of ginger slices. J Food Res 3:103–112

Aghbashlo M, Kianmehr MH, Arabhosseini A (2008) Energy and exergy analyses of thin-layer drying of potato slices in a semi-industrial continuous band dryer. Dry Technol 26:1501–1508

Aghbashlo M, Mobli H, Rafiee S, Madadlou A (2013) A review on exergy analysis of drying processes and systems. Renew Energy Rev 22:1–22. https://doi.org/10.1016/j.rser.2013.01.015

Akpinar EK (2004) Energy and exergy analyses of drying of red pepper slices in a convective type dryer. Int Comm Heat Mass Transfer 31:1165–1176. Available at: https://www.sciencedirect.com. Accessed 4 Feb 2020

Akpinar EK (2011) Drying of parsley leaves in a solar dryer and under open sun: modeling, energy and exergy aspects. J Food Process Eng 34:27–48

Alejandro R, Andrea M, Fracisco C, Pedro H (2013) Mushroom dehydration in a hybrid solar dryer. Energy Convers Manag 70:31–39

Amer BMA, Hossain MA, Gottschalk K (2010) Design and performance evaluation of a new hybrid solar dryer for banana. Energ Conv Manag 51:813–820. https://doi.org/10.1016/j.enconman.2009.11.016

Amer BMA, Gottschalk K, Hossain MA (2018) Integrated hybrid solar drying system and its drying kinetics of chamomile. Renew Energy 121:539–547

Aviara NA, Onuoha LN, Falola OE, Igbeka JC (2014) Energy and exergy analyses of native cassava starch drying in a tray Dryer. Energy 73:809–817. https://doi.org/10.1016/j.energy.2014.06.087

Azadbakht M, Torshizi VM, Ziaratban A, Aghili H (2017) Energy and exergy analysis during eggplant drying in a fluidized bed dryer. Agric Eng Int 19:177–182

Beigi M (2016) Energy efficiency and moisture diffusivity of apple slices during convective drying. Food Sci Technol 36:145–150. https://doi.org/10.1590/1678-457X0068

Bennamoun L (2012) An overview on application of exergy and energy for determination of solar drying efficiency. Int J Energy Eng 2:184–194. https://doi.org/10.5923/j.ijee.20120205.01

Borah A, Sethi LN, Sarkar S, Hazarika K (2017) Drying kinetics of sliced turmeric (curcuma longa l.) in a solar- biomass integrated drying system. J Food Process Preserv 41(3):e12904

Boughali S, Benmoussa H, Bouchekima B, Mennouche D, Bouguettaia H, Bechki D (2009) Crop drying by indirect active hybrid solar– electrical dryer in the eastern Algerian Septentrional Sahara. Solar Energy 83:2223–2232

Castro M, Roman C, Echegaray M, Mazza G, Rodriguez R (2018) Exergy analyses of onion drying by convection: influence of dryer parameters on performance. Entropy 20:2–9

Cheng F, Zhoubn X, Liu Y (2018) Methods for improvement of the thermal efficiency during spray drying: E3S Web of Conferences. 53, 1–3. https://doi.org/10.1051/e3sconf/20185301031

Chowdhury MM, Bala BK, Haque MA (2011) Energy and exergy analysis of the solar drying of jackfruit leather. Biosyst Eng 110:222–229

Darvishi H, Asi RA, Asghari A, Najafi G, Gazorix HA (2013) Mathematical modeling, moisture diffusion, energy consumption and efficiency of thin-layer drying of potato slices. J Food Pro Technol 4:215–219

Doymaz I (2004) Convective air drying characteristics for thin-layer carrots. J Food Eng 61(3):359–364

Dincer I, Rosen MA (2013) Exergy, energy, environment and sustainable development. Elsevier Ltd, Oxford

El-Ferouali H, Zoukit A, Salhi I, El Kilali T, Doubabi S, Abdenouri N (2019) Optimization study and design of a hybrid solar-electric dryer suitable to the developing countries context. Solar Afr Renew Energ J 1(19):35–39

Erbay Z, Icier F (2011) Energy and exergy analysis on drying of olive leaves (oleaeuropaca L.) in tray drier. J Food Process Eng 34:2105–2123

Eltawil MA, Azam MM, Alghannam AO (2018) Energy analysis of hybrid solar tunnel dryer with PV system and solar collector for drying mint (MenthaViridis). J Clean Prod 181:352–364

Fu M, Roman C, Echegaray M, Mazza G, Rodriguez R (2018) Exergy analyses of onion drying by convection: influence of dryer parameters on performance. Entropy 20:2–9. https://doi.org/10.3390/e20050310

Fudholi A, Yendra R, Basri DF, Ruslan MH, Sopian K (2016) Energy and exergy analysis of hybrid solar drying system. Cont Eng Sci 9:215–223. https://doi.org/10.12988/ces.2016.512323

Hatami S, Payehaneh G, Mehrpanahi A (2019) Energy and exergy analysis of an indirect solar dryer based on a dynamic model. J Clean Prod. https://doi.org/10.1016/j.jclepro.2019.118809

Hossain MZ, Alam MM, Hossain MF, Sarker MS (2018) Performance evaluation of a cabinet solar dryer for drying red pepper in Bangladesh. J Agric Eng 774:100–109

Jamil B, Bellos E (2019) Development of empirical models for estimation of global solar radiation exergy in India. J Clean Prod 207:1–16

Joshi AS, Dincer I, Reddy B (2011) Analysis of energy and exergy efficiencies for PV/T systems. Int J Low Carbon Technol 6:64–69. https://doi.org/10.1093/ijlct/ctq045

Maia CB, Kumar D, Prasad S, Murthy GS (2017) Optimization of microwave-assisted hot air drying conditions of okra using response surface methodology. J Food Sci Technol 4:1–13

Lamidi RO, Jiang L, Pathare PB, Wang Y, Roskilly AP (2019) Recent advances in sustainable drying of agricultural produce: A review. Appl Energy 233:367–385

Lamrani B, Khouya A, Draoui A (2019) Energy and environmental analysis of an indirect solar dryer of wood using TRNSYS software. Sol Energy 183:132–145

Lopez-Vidana EC, Mendez-Lagunas LL, Rodriguez-Ramirez J (2013) Efficiency of a hybrid solar-gas dryer. Sol Energy 93:23–31. https://doi.org/10.1016/j.solener.2013.01.027

Midilli A, Kucuk H (2014) Exergy-based sustainability indicators for a single layer solar drying process. Progress Exerg Energ Env 3:705–712. https://doi.org/10.1007/978-3-319-04681-5_67

Minaei S, Chenarbon HA, Motevali A, Arabhosseini A (2014) Energy consumption, thermal utilization efficiency and hypericin content in drying leaves of St John’s Wort (Hypericum Perforatum). J Energ S Afr 25:27–35

Motevali A, Abbaszadeh A, Minaei S, Khoshtaghaza MH, Ghobadian B (2012) Effective moisture diffusivity, activation energy and energy consumption in thin-layer drying of jujube (Zizyphus jujube Mill). J Agric Sci Technol 14:523–532

Nazghelichi T, Kianmehr MH, Aghbashlo M (2010) Thermodynamic analysis of fluidized bed drying of carrot cubes. Energy 35:4679–4684

Ndukwu MC, Bennamoun L, Abam FI, Eke AB, Ukoha D (2017) Energy and exergy analysis of a solar dryer integrated with sodium sulfate decahydrate and sodium chloride as thermal storage medium. Renew Energy 113:1182–1192. https://doi.org/10.1016/j.renene.2017.06.097

Ndukwu MC, Bennamoun L, Anozie O (2018a) Evolution of thermo-physical properties of Akuama (picralima nitida) seed and antioxidants retention capacity during hot air drying. Sol Energy 54:3533–3546

Ndukwu MC, Bennamoun L, Abam FI (2018) Experience of solar drying in Africa: presentation of designs, operations, and models. Food Eng Rev 10:211e244. https://doi.org/10.1007/s12393-018-9181-2

Ndukwu MC, Simo-Tagne M, Abam FI, Onwuka OS, Prince S, Bennamoun L (2020a) Exergetic sustainability and economic analysis of hybrid solar-biomass dryer integrated with copper tubing as heat exchanger. Heliyon 6(2020):e03401. https://doi.org/10.1016/j.heliyon.2020.e03401

Ndukwu MC, Onyenwigwe D, Abam FI, Eke AB, Dirioha C (2020b) Development of a low-cost wind-powered active solar dryer integrated with glycerol as thermal storage, Renewable Energy (2020) https://doi.org/10.1016/j.renene.2020.03.016

Ndukwu MC, Simo-Tagne M, Bennamoun L (2020c) Solar drying research of medicinal and aromatic plants: An African experience with assessment of the economic and environmental impact. African Journal of Science, Technology, Innovation and Development. https://doi.org/10.1080/20421338.2020.1776061

Nwajinka CO, Onuegbu CU (2014) Development of a solar cabinet dryer for root crops chips in Nigeria. J Agric Eng Tech 22:47–58

Nwakuba NR, Asoegwu SN, Nwaigwe KN (2016) Energy consumption of agricultural dryers: an overview. Agric Eng Int CIGR 18:119–132

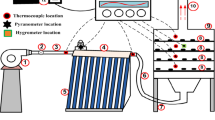

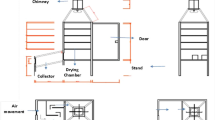

Nwakuba NR, Asoegwu SN, Nwaigwe KN, Chukwuezie OC (2017) Design and development of a hybrid solar-electric dryer for sliced vegetable crops. J Agric Eng Tech 2:48–64

Nwakuba NR, Chukwuezie OC, Asonye GU, Asoegwu SN (2018) Energy analysis and optimization of thin layer drying conditions of okra. Arid Zone J Eng Tech Env 14:135–154

Nwakuba NR, Okafor VC, Okorafor OO (2020) Techno-economic analysis of a hybrid solar-electric dryer. Energy Sour A Recover Utilization Environ Eff. https://doi.org/10.1080/15567036.2020.1782537

Nwofe PA (2014) Utilization of solar and biomass energy- a panacea to energy sustainability in a developing economy. Int J Electron Eng Res 2(3):10e19

Okoroigwe EC, Eke MN, Ugwu HU (2013) Design and evaluation of combined solar and biomass dryer for small and medium enterprises for developing countries. Int J Phy Sci 8:1341–1349

Ould-Amrouche S, Rekioua D, Hamidat A (2010) Modelling photovoltaic water pumping systems and evaluation of their CO2 emissions mitigation potential. Appl Energy 87:3451–3459

Reyes A, Mahn A, Huenulaf P, Gonzalez T (2014) Tomato dehydration in a hybrid solar dryer. Chem Eng Pro Tech 5:1–8

Rosen MA, Dincer I, Kanoglu M (2008) Role of exergy in increasing efficiency and sustainability and reducing environmental impact. Energy Policy 36:128–137. https://doi.org/10.1016/j.enpol.2007.09.006

Shamekhi-Amiri S, Gorji TB, Gorji-Bandpy M, Jahanshahi M (2018) Drying behaviour of lemon balm leaves in an indirect double-pass packed bed forced convection solar dryer system. Case Stud Therm Eng 12:677–686

Silva GM, Ferreira AG, Coutinho RM, Maia CB (2020) Experimental analysis of corn drying in a sustainable solar dryer. J Adv Res in Fluid Mech Therm Sci 67(2):1–12

Sansaniwal SK, Sharma V, Mathur J (2018) Energy and exergy analyses of various typical solar energy applications: a comprehensive review, Renew. Sustain. Energy Rev. 82 (2018):1576e1601

Tiwari GN (2012) Solar Energy Fundamentals, Design, Modeling and Application. Narosa Publishing House PVT Ltd., New Delhi, pp 203–250

Uzoma S, Nwakuba NR, Anyaoha K (2020) Response surface optimization of convective air drying process in a hybrid PV/T solar dryer. Turk J Agric Eng Res 1(1):111–130

Acknowledgements

Authors are thankful to the staff of Centre for Industrial Studies (CIS) Unit of the Federal University of Technology, Owerri, Nigeria.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

Authors have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nwakuba, N.R., Ndukwu, M.C., Asonye, G.U. et al. Environmental Sustainability Analysis of a Hybrid Heat Source Dryer. Polytechnica 3, 99–114 (2020). https://doi.org/10.1007/s41050-020-00026-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41050-020-00026-2