Abstract

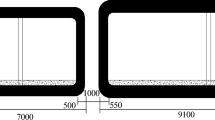

In this study, the rectangular pipe-jacking tunnel project of the Liuye Avenue West Extension under the Changzhang Highway is used to study highway pavement settlement and deformation during pipe-jacking construction through on-site monitoring. A three-dimensional numerical simulation method is employed to analyse the factors contributing to the significant settlement and rebound of the pavement. This study identifies the fundamental law governing the development of pavement settlement over time. The findings indicate that settlement increases rapidly when the jacking distance reaches approximately 10 m and then stabilizes at a consistent growth level. Furthermore, completion of the jacking of the left pipe leads to a transition in the surface settlement groove from a "V"-type distribution to a "W"-type distribution. Comparative analysis reveals that horizontal and vertical displacements exhibit similar characteristics, with maximum displacements occurring in the lagging jacking area. On both sides of the axis, the settlement groove curve remains stable within a range of 30–40 m, while the horizontal displacement curve stabilizes within a range of 20–30 m.

Similar content being viewed by others

Data availability

Some or all data, models, or code that support the findings of this study are available from the corresponding author upon reasonable request.

References

Mamaqani B, Najafi M (2015) Arching effects in box jacking projects. Pipelines 2015:145–153

Sun J, Yu X, Sun M, Li X (2006) Analysis and prediction on soft ground deformation of a super-large shallow burried’pipe-roofing and box-culvert’ jacking project under construction. Yantu Lixue (Rock Soil Mech) 27(7):1021–1027

Xia C, Gong J, Chen Y, Jiang K (2008) Analysis of ground settlements of over-length pile and box culvert advancing under airport taxiway. Chin J Rock Mech Eng 27(4):696–703

Qin W, Chu B, Long L (2009) Analysis of construction monitoring of large-section box culvert jacking process underpass expressway. Chin J Rock Mech Eng 28(09):1790–1797

Wang X, Zhou F, Zhang Z, Guo J (2016) Dynamic deformation of the oversized cross-section rectangular pipe-jacking tunnel. Earth Sci 41(11):1959–1965

Zhou X, Shi P, Liu W, Guo J, Yang Y (2021) Analysis on ground surface settlement during rectangular box jacking in saturated soft ground. J Beijing Jiaotong Univ 45(03):69–76

Zhu J (2020) Study on loss control measures of large-section rectangular pipe jacking stratum in complex environment. Mod Tunn Technol 57(S1):1015–1021

Shou K, Yen J (2007) Analysis of pipe–soil interaction of pipejacking. Tunn Constr S2:30–35

Loganathan N, Poulos H (1998) Analytical prediction for tunneling-induced ground movements in clays. J Geotech Geoenviron Eng 124(9):846–856

Yin R, Yang W, Zhang P, Deng E (2018) Stratum deformation characteristics and evolution laws induced by porous large section rectangular pipe jacking construction. J Railw Sci Eng 15(10):2597–2605

Zhen L, Pan Y, Li X (2021) Visualization test of synchronous grouting for large-break rectangular pipe jacking. Mod Tunn Technol 58(S1):387–393

Wei G, Hao W, Wei X, Wang X (2022) Indoor model tests on the construction of vertical pipe jacking in shield tunnel. Chin J Geotech Eng 44(1):62–71

Cheng M, Lu Y (2015) Developing a risk assessment method for complex pipe jacking construction projects. Autom Constr 58:48–59

Huang J, Bao F, Wang Y, Li H (2021) Influence of ground-surface deformation in pipe jacking construction with parallel differential section. Bull Geol Sci Technol 40(6):185–192

Ding W, Wang Z, Guo X, Chen R (2021) Calculation method of limit support pressure for large diameter rectangular pipe jacking tunnel face. Sci Technol Eng 21(22):9563–9569

Peck R (1969) Deep excavations and tunneling in soft ground. In: Proceedings of 7th ICSMFE, Mexico, vol 7, pp 215–285

Lu D, Lin Q, Tian Y, Du X, Gong Q (2020) Formula for predicting ground settlement induced by tunnelling based on Gaussian function. Tunn Undergr Space Technol 103:103443

Xu Y, Wang Y, Feng C, Liu Z, Zhu J (2018) Research on ground deformation caused by rectangular pipe jacking construction. Chin J Underg Space Eng 14(1):192–199

Xu Y, Shi M, Li Y, Zhang Z (2020) Study on vertical deformation of ground surface caused by construction of large section soil pressure balanced rectangular pipe jacking. Eng J Wuhan Univ 53:597604

Wang R (2014) Calculating methods of soil deformation induced by rectangular pipe jacking construction. J Jiamusi Univ (Natural Science Edition) 32(5):711–714

Wei G, Li Z (2016) Research on distribution of initial excess pore water pressure due to rectangular pipe jacking. Eng J Wuhan Univ 49(06):886–892

Ong D, Choo C (2018) Assessment of non-linear rock strength parameters for the estimation of pipe-jacking forces. Part 1. Direct shear testing and backanalysis. Eng Geol 244:159–172

Hao Z, Zhang H, Zhang G, Xiong W, Wang L (2022) The prediction of ground settlement of a box culvert jacked under the action of an ultra-shallow buried pipe curtain. Arab J Sci Eng 47(10):12423–12438

Zhang Z et al (2022) Analysis of upheaval and settlement deformation of ground surface caused by excavation of rectangular pipe jacking in soft soil stratum. Rock Soil Mech 43(S1):419–430

Ma W, Wang B, Wang X, Zhou S, Wang B (2021) Soil layer disturbance caused by pipe jacking: measurement and simulation of a case study. KSCE J Civ Eng 25(4):1467–1478

Wang Y, Zhang D, Fang Q, Liu X, Wang J (2022) Analytical solution on ground deformation caused by parallel construction of rectangular pipe jacking. Appl Sci 12(7):3298

Xu Y, Wen Z, Yan L, Bai X, Liu X (2016) Experimental study on soil improvement during construction of EPB rectangular pipe jacking with multi-cutter. Chin J Geotech Eng 38(2):288–296

Zhang X et al (2021) Optimization thixotropic slurry ratio and drag reduction performance test for rectangular pipe jacking in anhydrous sand layer. J Eng Geol 29(5):1611–1620

Li T, Zhao W, Liu R, Han J, Cheng C (2021) Experimental study on the pipe-soil interface under the influence of pipe jacking stagnation time. KSCE J Civ Eng 26:1–11

Zhou S, Wang Y, Huang X (2009) Experimental study on the effect of injecting slurry inside a jacking pipe tunnel in silt stratum. Tunn Undergr Space Technol 24(4):466–471

Wei X, Zhang S, Wang X, Lu L, Ding Z (2022) Study of the indoor model test and CEL simulation of jacking force in the vertical tunnelling method. Adv Civ Eng 2022:1–11

Yuan Y, Yuan D-J, Xu Y-S, Arulrajah A (2020) Ground response due to construction of shallow pipe-jacked tunnels in sandy soil. J Test Eval 48(5):3602–3622

Wu D, Zhao H, Shen H (2022) Bending performance of the steel longitudinal joint for quasi-rectangular pipe-jacking tunnels. J Pipeline Syst Eng Pract 13(3):04022026

Mamaqani B, Najafi M, Kaushal V (2020) Developing a risk assessment model for trenchless technology: box jacking technique. J Pipeline Syst Eng Pract 11(4):04020035

Kilic K, Toriya H, Kosugi Y, Adachi T, Kawamura Y (2022) One-dimensional convolutional neural network for pipe jacking EPB TBM cutter wear prediction. Appl Sci 12(5):2410

Wang S, Jierula A, Wang P, Zhao Y (2021) Mechanical behaviors of “easy cracking zones” of precast rectangular utility tunnels. Case Stud Constr Mater 15:e00648

Wu Y, Xu R, Duan J, Xu X, Zhu Y (2017) Environmental effects caused by construction of rectangular jacking pipes with large section, small space and shallow overburden. Mod Tunn Technol 54(05):78–85

Karakouzian M, Karami M, Nazari-Sharabian M, Ahmad S (2019) Flow-induced stresses and displacements in jointed concrete pipes installed by pipe jacking method. Fluids 4(1):34

Qi Z, Liu J, Gong K (2021) The impact of pipe jacking method entrance and exit construction on the surrounding environment. In: IOP conference series: earth and environmental science, 2021, vol 634(1). IOP Publishing, pp 012103

Liu W, Wu Y, Zhao H, Xu X, Miao L (2021) Deformations of subway tunnels induced by the overcrossing jacked box tunnels. Symmetry 13(10):1800

Deng Z, Liang N, Liu X, de la Fuente A, Lin P, Peng H (2021) Analysis and application of friction calculation model for long-distance rock pipe jacking engineering. Tunn Undergr Space Technol 115:104063

Wen K, Shimada H, Zeng W, Sasaoka T, Qian D (2018) Frictional analysis of pipe-slurry-soil interaction and jacking force prediction of rectangular pipe jacking. Eur J Environ Civ Eng 24(6):814–832

Wang L et al (2023) Construction scheme of metro station based on rectangular pipe jacking method with SuperLarge CrossSection. China Railw Sci 44(02):42–55

Cui G, Ma J, Ning M, Tang Z, Liu S, Tian Y (2022) Comparative analysis of construction reinforcement scheme of super large rectangular pipe jacking shield tunnel close to and under high-speed railway. Rock Soil Mech 43(S2):414–424

Sun Y, Su J, Xia X, Xu Z (2015) Numerical analysis of soil deformation behind the reaction wall of an open caisson induced by horizontal parallel pipe-jacking construction. Can Geotech J 52(12):2008–2016

Ma W, Wang B, Wang X, Zhou S, Wang B (2021) Soil layer disturbance caused by pipe jacking: measurement and simulation of a case study. KSCE J Civ Eng 25:1467–1478

Wang Z, Xie Y, Liu H, Feng Z (2019) Analysis on deformation and structural safety of a novel concrete-filled steel tube support system in loess tunnel. Eur J Environ Civ Eng 25(1):39–59

Wang H, Qin W, Jiao Y (2013) Stability assessment for highway with large-span box culvert jacking underneath: a case study. Can Geotech J 50(6):585–594

Acknowledgements

The authors would like to acknowledge the financial support provided by the National Natural Science Foundation of China (Grant no. 51678226), the Natural Science Foundation of Hunan Province (Grant nos. 2023JJ30110; Grant nos. 2021JJ50147; Grant nos. 2021JJ30078), the Science and Technology Innovation Project of Yiyang City (Grant nos. 2019YR02; Grant nos. 2020YR02), and the Open Research Foundation of Hunan Provincial Key Laboratory of Key Technology on Hydropower Development (Grant no. PKLHD202005).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author order of this paper has been unanimously agreed by all authors, and there is no conflict of interest between them.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hu, D., Zhou, R., Xiao, L. et al. A Supershallow Buried Large-Span Rectangular Pipe Jacking Tunnel Undercrossing an Expressway: Construction Method, Monitoring Results, and Numerical Simulation. Int J Civ Eng 22, 757–771 (2024). https://doi.org/10.1007/s40999-023-00908-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40999-023-00908-3