Abstract

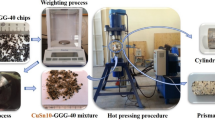

In this study, the low-velocity impact behavior of porous metal matrix composites (MMCs) has been investigated. The MMCs consisting of spheroidal cast iron chips (GGG-40) and bronze chips (CuSn10) were produced by hot isostatic pressing. The MMCs were produced with different CuSn10 contents as 90–80–70–60%. The hot isostatic pressing was performed under three different pressures and temperatures. The produced MMCs were exposed to low-velocity impact loading under 2 m/s by using a drop weight test stand. The test results were compared with the bulk CuSn10 and bulk GGG-40, separately. The test results revealed that hot-isostatic-pressed MMCs can successfully represent bulk material properties when subjected to low-velocity impact loading even these MMCs have porosity 2–8%.

Similar content being viewed by others

References

Abrate S (2005) Impact on composite structures. Cambridge University Press, Cambridge

Anderson TL (2000) Fracture mechanics fundamentals and applications. CRC Press Inc., Baca Raton

Aslan A (2014) Production of metal matrix composites by recycling of waste metal chips and their mechanical properties, Ms Thesis, Selçuk University, Department of Mechanical Engineering

Aslan A, Sahin OS, Salur E et al (2015) A new method for recycling of metal chips. J Selçuk Univ Nat Appl Sci 4(1):1

Aydelotte BB, Thadhani NN (2013) Mechanistic aspects of impact initiated reactions inexplosively consolidated metal aluminum powder mixtures. Mater Sci Eng A 570:164–171

Barbosa AP, Bobrovnitchii GS, Skury ALD et al (2010) Structure, microstructure and mechanical properties of pm fe–cu–co alloys. Mater Des 31:522–526

Bourcier RJ, Koss DA, Smelser RE, Richmond O (1986) The influence of porosity on the deformation and fracture of alloys. Acta Metal 34:2443–2453

Brochu M, Zimmerly T, Ajdelsztajn L, Lavernia EJ, Kim G (2007) Dynamic consolidation of nanostructured Al–7.5%Mg alloy powders. Mater Sci Eng, A 466:84–89

Carrollt MM, Holt AC (1972) Static and Dynamic pore-collapse relations for ductile porous materials. J Appl Phys 43:1626

Chawla N, Deng X (2005) Microstructure and mechanical behavior of porous sintered steels. Mater Sci Eng, A 390A:98–112

Dieter GE, Bacon DJ (2001) Mechanical metallurgy. McGraw-Hill, New York City

Fiedler T, Taherishargh M, Krstulović-Opara L, Vesenjak M (2015) Dynamic compressive loading of expanded perlite/aluminum syntactic foam. Mater Sci Eng, A 626:296–304

Fogagnolo JB, Ruiz-Navas EM, Simón MA et al (2003) Recycling of aluminium alloy and aluminium matrix composite chips by pressing and hot extrusion. J Mater Process Technol 143–144:792–795

German RM (2001) Powder metallurgy & particulate materials processing. Prentice-Hall, Upper Saddle River

Gourdin WH (1986) Dynamic consolidation of metal powders. Prog Mater Sci 30:39–80

Gronostajski J, Matuszak A (1999) The recycling of metals by plastic deformation: an example of recycling of aluminum and its alloy’s chips. J Mater Process Technol 92–93:34–41

Gronostajski JZ, Kaczmar JW, Marciniak H et al (1997) Direct recycling of aluminum chips into extruded product. J Mater Process Technol 64:149–156

Gronostajski J, Marciniak H, Matuszak A (2000) New methods of aluminum and aluminum alloy chips recycling. J Mater Process Technol 106:34–39

Guluzade R, Avcı A, Demirci MT, Erkendirci ÖF (2013) Fracture toughness of recycled AISI 1040 steel chip reinforced ALMG1SICU aluminium chip composites. Mater Des 52:345–352

Kanel GI, Ivanov MF, Parshikov AN (1995) Computer simulation of the heterogeneous materials response to the impact loading. Int J Impact Eng 17:455–464

Karadağ HB (2012) Production and mechanical properties of steel/bronze chips composite, PhD Thesis, Selçuk University, Department of Mechanical Engineering

Li Y, Li JB, Zhang R (2004) Energy-absorption performance of porous materials in sandwich composites under hypervelocity impact loading. Compos Struct 64:71–78

Molinari A, Mercier S (2001) Micromechanical modelling of porous materials under dynamic loading. J Mech Phys Solids 49:1497–1516

Nair AR, Mason BA, Groven LJ, Son SF, Strachan A, Cuitiño AM (2013) Micro-RVE modeling of mechanistic response in porous intermetallics subject to weak and moderate impact loading. Int J Plast 51:1–32

Page NW, Killen PD, John DH (1990) Sintering enhancement in dynamically compacted commercial iron powders. Mater Sci Eng A 130:231–240

Partom Y (2014) Modelling dynamic compaction of porous materials with the overstress approach. J Phys: Conf Ser 500:182030

Sano T, Kato K, Takeishi H (1995) Analysis of dynamic deformation mechanisms in powder metals. J Mater Process Technol 48:391–397

Sano T, Obinata A, Negishi H, Suginami K, Takeishi H (1997) Effects of temperature rise on dynamic powder compaction. J Mater Process Technol 67(19):23

Shuyan W, Zesheng J, Tielei Z (2009) Microstructure and mechanical properties of AZ31B magnesium alloy recycled by solid-state process from different size chips. J Mater Process Technol 209:5319–5324

Spitzig WA, Semlser RE, Richmond O (1998) The evolution of damage and fracture in iron compacts with various initial porosities. Acta Metal 36:1201–1211

Tao Y, Ming-yi Z, Xiao-shi H et al (2010) Recycling of az91 mg alloy through consolidation of machined chips by extrusion and ECAP. Trans Nonferrous Met Soc China 20:604–607

Tong W, Ravichandran G (1993) Dynamic pore collapse in viscoplastic materials, 1993. J Appl Phys 74(4):2425

Wei CT, Vitali E, Jiang F, Dub SW, Benson DJ, Vecchio KS, Thadhani NN, Meyers MA (2012) Quasi-static and dynamic response of explosively consolidated metal–aluminum powder mixtures. Acta Mater 60:1418–1432

Acknowledgements

This study has been financially funded by the Scientific and Technological Research Council of Turkey (TUBITAK) under Grant Number: MAG-113M141.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Şahin, Ö.S., Güneş, A., Aslan, A. et al. Low-Velocity Impact Behavior of Porous Metal Matrix Composites Produced by Recycling of Bronze and Iron Chips. Iran J Sci Technol Trans Mech Eng 43 (Suppl 1), 53–60 (2019). https://doi.org/10.1007/s40997-017-0139-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40997-017-0139-4