Abstract

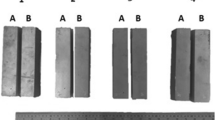

Cast irons are widely used in the automotive industry for engine parts due to their excellent casting properties, low cost, high thermal conductivity and mechanical properties. However, the increasingly demanding expectations on an engine necessitate improved mechanical properties and corrosion resistance of cast-iron engine parts. Therefore, the nitriding of cast irons can be considered as a promising surface modification technique. In this paper, the effect of matrix microstructure and graphite morphology on the nitriding mechanism for cast irons was investigated. In the first part; in order to determine the effect of nitriding time, EN-GJV-450 compacted graphite iron samples were gas nitrided at 525 °C, with a nitriding potential value (KN) of 2 atm−1/2 at different periods of nitriding duration of 1, 3 and 6 h. The resultant microstructure characterizations show that with increasing nitriding time, the thickness of the compound layer and nitriding depth increase monotonically. In the second part, the effect of microstructure and graphite morphology on nitriding was examined on three types of cast iron (EN-GJS-500 Nodular, EN-GJV-450 Compacted and EN-GJL-250 Gray) by nitriding at the same temperature and nitriding potential as the first part, but at a nitriding duration of 6 h. The resultant microstructural characterization for the second part revealed that iron nitrides were formed at grain boundaries and around graphite particles, in addition to the surface layer. Nitrogen diffusion paths in cast irons are as follows: grain itself, grain boundaries and graphite boundaries. However, it was observed that nitrogen atoms primarily follow grain boundaries and graphite boundaries. Furthermore, the compacted graphite and gray cast-iron samples have higher nitriding depth than that of nodular cast-iron sample due to 3-D network structure of graphite. Thus, it was concluded that the graphite boundary diffusion was the differentiating factor for the nitriding mechanism in cast irons.

Similar content being viewed by others

References

S. Dawson, China Foundry 6(3), 241–246 (2009)

X. Wu, G. Quan, R. Macneil, Z. Zhang, X. Liu, C. Sloss, Metall. Mater. Trans. A 46(6), 2530–2543 (2015)

V.L. Diaconu, T. Sjögren, P. Skoglund, A. Dioszegi, Int. J. Cast Metal. Res. 25(5), 277–286 (2012)

X. Su, M. Zubeck, J. Lasecki, H. Sehitoglu, C.C. Engler-Pinto Jr., C-Y. Tang, J.E. Allison, in Thermomechanical Fatigue Behavior of Materials, vol. 4, ed. by M.A. McGraw, S. Kalluri, J. Bressers, S.D. Peteves (ASTM International, Pennsylvania, 2003), p. 240

F. Szmytka, P. Michaud, L. Remy, A. Köster, Int. J. Fatigue 55, 136 (2013)

D. Pye, Practical Nitriding and Ferritic Nitrocarburizing, 1st edn. (ASM International, Novelty, 2003)

E.J. Mittemeijer, in ASM Handbook, vol. 4A, ed. by J.L. Dossett, G.E. Totten (ASM International, Novelty, 2013), p. 619

E.J. Mittemeijer, M.A.J. Somers, Surface Eng. 13, 483 (1997)

N.E.V. Diaz, R.E. Schacherl, L.F. Zagonel, E.J. Mittemeijer, Acta Mater. 56, 1196 (2008)

K.S. Rao, R.G. Chandra, K. Dinesh, IJEIT 2, 54 (2013)

O.D. Sokolov, O.V. Mannapova, A.I. Kostrzhyts’kyi, A.P. Olik, Mater. Sci. 42, 849 (2006)

Y. Liu, Y. Sun, W. Zhang, X. Du, Int. J. Metalcast. (2019). https://doi.org/10.1007/s40962-019-00384-3

E.J. Mittemeijer, M.A.J. Somers, Thermochemical Surface Engineering of Steels, 1st edn. (Woodhead Publishing, Cambridge, 2015)

R. Konecna, G. Nicoletto, V. Majerova, in 15th International Metallurgical and Material Conference, Metal 2006, Hradec nad Moravici, 1 (2006)

R. Konecna, V. Konstantova, G. Nicoletto, P. Jancovic, in 17th International Metallurgical and Materials Conference Proceedings, Metal 2008, Hradec nad Moravici, 1 (2008)

R. Konecna, G. Nicoletto, V. Majerova, P. Baicchi, Strength Mater. 40, 75 (2008)

M.M. Tosic, R. Gligorijevic, Mat. Sci. Eng. AStruct. 140, 469 (1991)

R. Gligorijevic, J. Jevtic, D. Borak, Mach. Des. 1, 435 (2009)

R.N. Penha, J.C. Morilla, J. Vatavuck, L.C.F. Canale, Int. Heat Treat. Surf. Eng 6, 33 (2012)

G. Nicoletto, R. Konecna, V. Majerova, in CP 2006, Parma (2013), p. 1

R. Gligorijevic, J. Jevtic, G. Vidanovic, N. Radojevic, SAE Transactions, vol. 110 (2001), p. 1187

A.V. Bil’chenko, S.A. Dunaeva, Met. Sci. Heat Treat. 17, 1021 (1975)

M. Nikolussi, A. Leineweber, E.J. Mittemeijer, Philos. Mag. 90(9), 1105–1122 (2010)

T. Czerwiec, H. He, G. Marcos, T. Thiriet, S. Weber, H. Michel, Plasma Process. Polym. 6, 401 (2009)

Z. Cheng, C.X. Li, H. Dong, T. Bell, Surf. Coat. Technol. 191, 195 (2005)

Acknowledgements

The authors would like to express their gratitude to Dr. Derya Dışpınar and Dr. Mustafa Ürgen for their contributions. This work was supported by Research Fund of the Istanbul Technical University. Project Number MOA-2019-42309.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kondakci, E., Solak, N. The Effect of Microstructure on Nitriding Mechanism of Cast Iron. Inter Metalcast 14, 1033–1040 (2020). https://doi.org/10.1007/s40962-019-00404-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-019-00404-2