Abstract

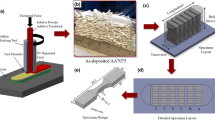

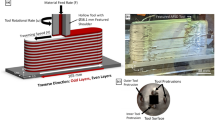

In this work, a strain rate dependent plasticity-damage material model is presented for precipitation hardened aluminum alloys made using Additive Friction Stir Deposition (AFS-D). The AFS-D process is a solid-state layer-by-layer additive deposition technique that extrudes a solid consumable feedrod through a hollow rotating tool. The friction generated between the rotating tool and build plate produces enough heat to soften the exiting feedrod and promote severe plastic deformation resulting in subsequent metallurgical bonding of the deposited layer. In this study, a fully-dense AA7050 build was manufactured via AFS-D at an average deposition rate of 0.8 kg/h. The microstructural characterization of the as-deposited AA7050 revealed a refined microstructure present throughout the AFS-D build. Quasi-static and high rate tensile experiments were conducted in the through thickness and the transverse orientations for the initial and final deposition layers of the AFS-D build in order to quantify the mechanical response of the as-deposited AA7050. A gradient in the mechanical properties was experimentally observed, where the final layers deposited with the AFS-D process exhibited a higher mechanical strength compared to the initial deposition layers of the component due to coarsening of secondary phases. Finally, an internal-state variable (ISV) plasticity-damage model was modified to capture observed material anisotropy as a function of precipitate free zones (PFZ) and size of secondary phases within the grain.

Similar content being viewed by others

References

Mason CJT et al (2019) Plasticity-damage modeling of strain rate and temperature dependence of aluminum alloy 7075–T651. J Dyn Behav Mater 5(1):868–874. https://doi.org/10.1007/s40870-019-00188-w

Follansbee PS, Kocks UF (1988) A constitutive description of the deformation of copper based on the use of the mechanical treshold stress as an internal state variable. Acta Met 36(1):81–93. https://doi.org/10.1016/0001-6160(88)90030-2

Freed AD (1988) Thermoviscoplastic model with application to copper. NASA Technical Paper 2845

Bammann DJ (1984) An internal variable model of viscoplasticity. Int J Eng Sci 22(8–10):1041–1053. https://doi.org/10.1016/0020-7225(84)90105-8

Horstemeyer MF, Gokhale AM (1999) A void-crack nucleation model for ductile metals. Int J Solids Struct 36:5029–5055

Horstemeyer MF, Lathrop J, Gokhale AM, Dighe M (2000) Modeling stress state dependent damage evolution in a cast Al–Si–Mg aluminum alloy. Theor Appl Fract Mech 33(1):31–47. https://doi.org/10.1016/S0167-8442(99)00049-X

McClintock FA (1968) A criterion for ductile fracture by the growth of holes. J Appl Mech 35(2):363. https://doi.org/10.1115/1.3601204

Allison PG, Horstemeyer MF, Brown HR (2012) Modulus dependence on large scale porosity of powder metallurgy steel. J Mater Eng Perf 21(7):1422–1425. https://doi.org/10.1007/s11665-011-0001-6

Jordon JB, Horstemeyer MF, Solanki K, Bernard JD, Berry JT, Williams TN (2009) Damage characterization and modeling of a 7075–T651 aluminum plate. Mater Sci Eng A 527(1–2):169–178. https://doi.org/10.1016/j.msea.2009.07.049

Mason CJT et al (2021) Process-structure-property relations for as-deposited solid-state additively manufactured high-strength aluminum alloy. Addit Manuf 40:101879. https://doi.org/10.1016/j.addma.2021.101879

Rutherford BA et al (2020) Effect of thermomechanical processing on fatigue behavior in solid-state additive manufacturing of Al-Mg-Si alloy. Metals (Basel) 10(7):1–17. https://doi.org/10.3390/met10070947

Anderson-Wedge K et al (2021) Characterization of the fatigue behavior of additive friction stir-deposition AA2219. Int J Fatigue 142:105951. https://doi.org/10.1016/j.ijfatigue.2020.105951

Beck SC et al (2019) Mechanical Behavior Effects and Optimization of Heat Treatment of Aluminum Alloy 6061 Post Additive Friction Stir Deposition. Unpublished

Avery DZ et al (2020) Influence of grain refinement and microstructure on fatigue behavior for solid-state additively manufactured Al-Zn-Mg-Cu alloy. Metall Mater Trans A. https://doi.org/10.1007/s11661-020-05746-9

Phillips BJ et al (2019) Microstructure-deformation relationship of additive friction stir-deposition Al–Mg–Si. Materialia 7:100387. https://doi.org/10.1016/j.mtla.2019.100387

Rivera OG et al (2018) Influence of texture and grain refinement on the mechanical behavior of AA2219 fabricated by high shear solid state material deposition. Mater Sci Eng A. https://doi.org/10.1016/j.msea.2018.03.088

Park JK, Ardell AJ (1983) Microstructures of the commercial 7075 Al alloy in the T651 and T7 tempers. Metall Trans A. https://doi.org/10.1007/BF02662363

Adler PN, DeIasi R (1977) Calorimetric studies of 7000 series aluminum alloys: II. Comparison of 7075, 7050 and RX720 alloys. Metall Trans A. https://doi.org/10.1007/BF02667404

Adler PN, Deiasi R, Geschwind G (1972) Influence of microstructure properties and stress corrosion of 7075 aluminum alloy on the mechanical susceptibility. Metall Trans 3:1

De Ardo AJ, Townsend RD (1970) The effect of microstructure on the stress-corrosion susceptibility of a higs purity AI-Zn-Mg alloy in a NaCI solution. Metall Trans 1(September):2573–2581

Rodriguez RI, Jordon JB, Allison PG, Rushing T, Garcia L (2015) Microstructure and mechanical properties of dissimilar friction stir welding of 6061-to-7050 aluminum alloys. Mater Des 83:60–65. https://doi.org/10.1016/j.matdes.2015.05.074

Zhang J, Deng Y, Yang W, Hu S, Zhang X (2014) Design of the multi-stage quenching process for 7050 aluminum alloy. Mater Des 56:334–344. https://doi.org/10.1016/j.matdes.2013.09.029

Wang YL, Pan QL, Wei LL, Li B, Wang Y (2014) Effect of retrogression and reaging treatment on the microstructure and fatigue crack growth behavior of 7050 aluminum alloy thick plate. Mater Des 55:857–863. https://doi.org/10.1016/j.matdes.2013.09.063

Abolhasani A, Zarei-Hanzaki A, Abedi HR, Rokni MR (2012) The room temperature mechanical properties of hot rolled 7075 aluminum alloy. Mater Des 34:631–636. https://doi.org/10.1016/J.MATDES.2011.05.019

Rokni MR, Zarei-Hanzaki A, Roostaei AA, Abolhasani A (2011) Constitutive base analysis of a 7075 aluminum alloy during hot compression testing. Mater Des 32:4955–4960. https://doi.org/10.1016/j.matdes.2011.05.040

Albrecht J, Thompson AW, Bernstein IM (1979) The role of microstructure in hydrogen-assisted fracture of 7075 aluminum. Metall Trans A 10(11):1759–1766. https://doi.org/10.1007/BF02811712

El-Magd E, Brodmann M (2001) Influence of precipitates on ductile fracture of aluminium alloy AA7075 at high strain rates. Mater Sci Eng A 307(1–2):143–150. https://doi.org/10.1016/S0921-5093(00)01961-4

ASTM, “E384 -17 Standard Test Method for Microindentation Hardness of Materials,” ASTM Int., pp. 1–40, 2017, doi: https://doi.org/10.1520/E0384-17.

ASTM (2014) Standard Practice for Determining Average Grain Size Using Electron Backscatter Diffraction (EBSD) in Fully Recrystallized Polycrystalline Materials. ASTM International, pp. 1–5. https://doi.org/10.1520/E2627.

Chen W, Song B (2011) Split Hopkinson (Kolsky) Bar Design Testing and Applications. Spinger, Berlin\

Francis D, Whittington WR, LawrimoreII WB, Allison PG, Turnage SA, Bhattacharyya JJ (2017) Split Hopkinson Pressure Bar Graphical Analysis Tool, pp. 179–183

Horstemeyer MF (2012) Integrated Computational Materials Engineering (ICME) for metals. Wiley, Hoboken

Allison PG, Horstemeyer MF, Hammi Y, Brown HR, Tucker MT, Hwang Y-K (2011) Microstructure–property relations of a steel powder metal under varying temperatures, strain rates, and stress states. Mater Sci Eng A 529:335–344. https://doi.org/10.1016/j.msea.2011.09.037

Bammann DJ, Chiesa ML, Horstemeyer MF, Weingarten LI (1993) Failure in ductile materials using finite element methods

Acknowledgements

The authors gratefully acknowledge the thoughtful discussions with Dr. Rogie Rodriguez from the Boeing Co., the financial support of the Alabama Transportation Institute (ATI), and the resources of The Manufacturing at the Point-of-Need Center (MPNC) and the Alabama Analytical Research Center (AARC) at The University of Alabama.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix A

Appendix A

Rights and permissions

About this article

Cite this article

Mason, C.J.T., Avery, D.Z., Phillips, B.J. et al. Strain Rate Dependent Plasticity Model for Precipitate Hardened Aerospace Aluminum Alloy Produced with Solid-State Additive Manufacturing. J. dynamic behavior mater. 8, 214–230 (2022). https://doi.org/10.1007/s40870-021-00325-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40870-021-00325-4