Abstract

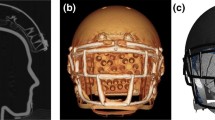

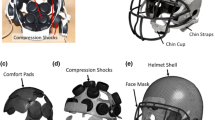

Epidemiological data and measurement of biomechanical data collected through physical experiments have contributed to the understanding of potential head injury risk in contact sports such as football. Further improvement of protective helmets requires repeatable conditions and detailed parametric studies that may be addressed in part using the Finite Element (FE) method. However, such an approach requires thorough experimentation and validation of the helmet materials and subcomponents, which previous studies do not fully address, prior to implementing these subcomponents in a full helmet model. Development of a modern football helmet FE model requires a bottom-up approach, focusing on material testing, constitutive models and subcomponent-level validation, which has not been fully addressed in the literature to date. Material samples were extracted from a modern football helmet including the helmet shell, energy-absorbing structures, comfort foam, and strap system. The subcomponents were tested across a range of quasi-static and high deformation rates relevant to football impact scenarios. FE models of the subcomponents were developed and validated, focusing on verification of material behaviour, representative loading conditions, and mesh convergence to achieve realistic responses and increase computational efficiency. Evaluation of the FE models comparing experimental with simulated responses, yielded good to excellent CORrelation and Analysis (CORA) ratings of 0.954–0.985, 0.931, 0.937–0.974, and 0.847–0.958 for the helmet shell, facemask, energy-absorbing structures, and comfort pads, respectively. The resulting validated subcomponent-level models provide an important foundation for integration into a full helmet model to ultimately optimize performance and reduce head injury.

Similar content being viewed by others

Change history

05 March 2019

M.A. Corrales’s name appeared incorrectly on the original publication of this article. It is corrected here.

References

Langlois JA, Rutland-Brown W, Wald MM (2006) The epidemiology and impact of traumatic brain injury: a brief overview. J Head Trauma Rehabil 21:375–378

Harmon KG, Drezner JA, Gammons M et al (2013) American medical society for sports medicine position statement: concussion in sport. Br J Sports Med 47:15–26. https://doi.org/10.1136/bjsports-2012-091941

Gessel LM, Fields SK, Collins CL et al (2007) Concussions among United States high school and collegiate athletes. J Athl Train 42:495–503

Marar M, McIlvain NM, Fields SK, Comstock RD (2012) Epidemiology of concussions among united states high school athletes in 20 sports. Am J Sports Med 40:747–755. https://doi.org/10.1177/0363546511435626

Rowson S, Duma SM, Beckwith JG et al (2012) Rotational head kinematics in football impacts: an injury risk function for concussion. Ann Biomed Eng 40:1–13. https://doi.org/10.1007/s10439-011-0392-4

Slobounov SM, Sebastianelli WJ (2014) Concussions in athletics. Springer, New York

Moss WC, King MJ (2011) Impact response of US Army and National Football League helmet pad systems. Livermore

Johnston JM, Ning H, Kim JE et al (2015) Simulation, fabrication and impact testing of a novel football helmet padding system that decreases rotational acceleration. Sport Eng 18:11–20. https://doi.org/10.1007/s12283-014-0160-4

Tan LB, Tse KM, Lee HP et al (2012) Performance of an advanced combat helmet with different interior cushioning systems in ballistic impact: Experiments and finite element simulations. Int J Impact Eng 50:99–112. https://doi.org/10.1016/j.ijimpeng.2012.06.003

Darling T, Muthuswamy J, Rajan SD (2016) Finite element modeling of human brain response to football helmet impacts. Comput Methods Biomech Biomed Engin 19:1432–1442. https://doi.org/10.1080/10255842.2016.1149574

Pellman EJ, Viano DC, Withnall C et al (2006) Concussion in professional football: helmet testing to assess impact performance—part 11. Neurosurgery 58:78–95. https://doi.org/10.1227/01.NEU.0000196265.35238.7C

Viano DC, Withnall C, Halstead D (2012) Impact performance of modern football helmets. Ann Biomed Eng 40:160–174. https://doi.org/10.1007/s10439-011-0384-4

Jankowski M (2010) Dynamic compression tests of a polyurethane flexible foam as a step in modelling impact of the head to the vehicle seat head restraint. FME Trans 38:121–127

Whyte T, Gibson T, Eager D, Milthorpe B (2016) Response of a full-face motorcycle helmet FE model to the UNECE 22.05 chin bar impact test. Int J Crashworthiness 21:555–565. https://doi.org/10.1080/13588265.2016.1199007

Krzeminski DE, Fernando BMD, Curtzwiler G et al (2016) Repetitive impact exposure and characterization of stress-whitening of an American football helmet outer shell material. Polym Test 55:190–203. https://doi.org/10.1016/j.polymertesting.2016.08.019

Yin ZN, Wang TJ (2012) Investigation of tensile deformation behavior of PC, ABS, and PC/ABS blends from low to high strain rates. Appl Math Mech (English Ed 33:455–464. https://doi.org/10.1007/s10483-012-1563-x

Lamb L, Post A, Hoshizaki TB et al (2009) Development of a new methodology capable of characterizing the contribution of a controlled venting system to impact attenuation in chamber structures for head protection. J ASTM Int 6:101884. https://doi.org/10.1520/JAI101884

Qi HJ, Boyce MC (2005) Stress-strain behavior of thermoplastic polyurethane. Mech Mater 37:817–839. https://doi.org/10.1016/j.mechmat.2004.08.001

Sarva SS, Deschanel S, Boyce MC, Chen W (2007) Stress-strain behavior of a polyurea and a polyurethane from low to high strain rates. Polymer 48:2208–2213. https://doi.org/10.1016/j.polymer.2007.02.058

Yi J, Boyce MC, Lee GF, Balizer E (2005) Strain rate dependence of the stress-strain behavior of polyurethane. 889–898

Hibbeler R (2016) Mechanics of Materials, 10th edn. Pearson, Boston

Trimiño LF, Cronin DS (2016) Evaluation of numerical methods to model structural adhesive response and failure in tension and shear loading. J Dyn Behav Mater 2:122–137. https://doi.org/10.1007/s40870-016-0045-7

Salisbury C, Cronin D, Lien F-S (2015) Deformation Mechanics of a non-linear hyper-viscoelastic porous material, part i: testing and constitutive modeling of non-porous polychloroprene. J Dyn Behav Mater 1:237–248. https://doi.org/10.1007/s40870-015-0026-2

Bustamante M, Cronin DS, Singh D (2018) Experimental Testing and Computational Analysis of Viscoelastic Wave Propagation in Polymeric Split Hopkinson Pressure Bar. In: Dyn. Behav. Mater. Vol. 1 Proc. 2017 Annu. Conf. Exp. Appl. Mech. Dynamic Behavior of Materials, Volume 1: Proceedings of the 2017 Annual Conference on Experimental and Applied Mechanics, pp 67–72

Salisbury C, Cronin D, Lien F-S (2015) Deformation Mechanics of a Non-Linear Hyper-Viscoelastic Porous Material, Part II: Porous Material Micro-Scale Model. J Dyn Behav Mater 1:249–258. https://doi.org/10.1007/s40870-015-0027-1

Giudice JS, Kong K, Caudillo A et al (2018) User Manual: Finite Element Models of Helmet Assessment Tools (Hybrid III Head-Neck, NOCSAE Headform, Linear Impact, Pendulum Impact, Drop Impact) Version 1.0 for LS-DYNA. Charlottesville

Roache PJ (1994) Perspective: A Method for Uniform Reporting of Grid Refinement Studies. J Fluids Eng 116:405–413. https://doi.org/10.1115/1.2910291

Gehre C, Gades H, Wernicke P (2009) Objective rating of signals using test and simulation responses. Enhanc. Saf. Veh

Vavalle NA, Davis ML, Stitzel JD, Gayzik FS (2015) Quantitative Validation of a Human Body Finite Element Model Using Rigid Body Impacts. Ann Biomed Eng 43:2163–2174. https://doi.org/10.1007/s10439-015-1286-7

Miller LE, Urban JE, Stitzel JD (2016) Development and validation of an atlas-based finite element brain model. Biomech Model Mechanobiol 15:1201–1214. https://doi.org/10.1007/s10237-015-0754-1

Barker JB, Cronin DS, Nightingale RW (2017) Lower Cervical Spine Motion segment computational model validation: kinematic and kinetic response for quasi-static and dynamic loading. J Biomech Eng 139:061009. https://doi.org/10.1115/1.4036464

Thunert C (2012) CORA Release 3.6 User’s Manual. Ingolstadt, Germany

Lu J, Ravi-Chandar K (1999) Inelastic deformation and localization in polycarbonate under tension. Int J Solids Struct 36:391–425. https://doi.org/10.1016/S0020-7683(98)00004-3

Shah QH, Abakr YA (2008) Effect of distance from the support on the penetration mechanism of clamped circular polycarbonate armor plates. Int J Impact Eng 35:1244–1250. https://doi.org/10.1016/j.ijimpeng.2007.07.012

Du Bois P (2003) A simplified approach to the simulation of rubber-like materials under dynamic loading. 4th Eur LS-DYNA Users Conf 31–46

Serifi E, Hirth A, Matthaei S, Mullerschon H (2003) Modelling of foams using MAT83—preparation and evaluation of eperimental data. 4th Eur LSDYNA Users Conf 59–72

Chang F, Song Y, Lu DX (1998) Unified constitutive equations of foam materials. J Eng Mater Technol 120:212–217. https://doi.org/10.1115/1.2812345

Cronin DS, Ouellet S (2016) Low density polyethylene, expanded polystyrene and expanded polypropylene: strain rate and size effects on mechanical properties. Polym Test 53:40–50. https://doi.org/10.1016/j.polymertesting.2016.04.018

Davallo M, Pasdar H (2012) The Influence of a variety of plasticisers on properties of poly (vinyl chloride). Adv Appl Sci Res 3:1900–1904

Uhlemann J, Stranghöner N, Saxe K (2015) Comparison of stiffness properties of common coated fabrics. Steel Constr 8:222–229. https://doi.org/10.1002/stco.201510030

Tsukinovsky D, Zaretsky E, Rutkevich I (1997) Material Behavior in plane polyurethane-polyurethane impact with velocities from 10 to 400 m/sec. Le J Phys IV 07:C3-335-C3-339. https://doi.org/10.1051/jp4:1997359

Cronin D, Barker J, Gierczycka D et al (2018) User Manual: Finite Element Model of 2016 Xenith X2E (Safety Equipment Institute model X2E) Version 1.0 for LS-DYNA. Charlottesville

Lamb L, Hoshizaki TB (2009) Deformation mechanisms and impact attenuation characteristics of thin-walled collapsible air chambers used in head protection. Proc Inst Mech Eng Part H J Eng Med 223:1021–1031. https://doi.org/10.1243/09544119JEIM573

Acknowledgements

The research presented in this paper was made possible by a Grant from Football Research, Inc. (FRI.) The views expressed are solely those of the authors and do not represent those of FRI or any of its affiliates or funding sources.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bustamante, M.C., Bruneau, D., Barker, J.B. et al. Component-Level Finite Element Model and Validation for a Modern American Football Helmet. J. dynamic behavior mater. 5, 117–131 (2019). https://doi.org/10.1007/s40870-019-00189-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40870-019-00189-9