Abstract

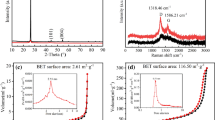

Direct mass exfoliation of graphene from bulk graphite with high yield and productivity for commercial applications is challenging. This work proposes self-grinding exfoliation using the mutual shear friction of graphite particles to fabricate graphene from microcrystalline graphite. The concept is implemented using microbeads as the grinding medium to drive the shear friction between graphite nanocrystals in a high-concentration paste. The proposed approach substantially improves graphene yield from 6.3% to 100% and simultaneously generates a record productivity of 7.5 g h−1 L−1, achieving total graphite-to-graphene conversion on the kilogram scale. The as-prepared graphene nanosheets have an average lateral size of 298 nm and the same C/O atomic ratio as the pristine graphite. In addition, the well-exfoliated, small nanosheets display good electrical conductivity and exhibit significant potential as conductive additives that improve the specific capacity and cyclic stability of Li-ion batteries better than commercial carbon-based conductive particles.

摘要

在过去十五年, 将块状石墨直接高产率、高效率地剥离为石墨 烯一直是一个重大挑战. 针对这一问题, 本文提出了一种自研磨剥离新 概念, 即利用石墨颗粒之间相互剪切摩擦, 从微晶石墨矿中剥离石墨烯. 实验中通过微珠作为研磨介质驱动高浓度石墨晶体颗粒相互研磨的过 程成功执行了这一概念. 经证实, 自研磨大幅提高了石墨烯的剥离产率 (从6.3%提高至100%), 并获得了破纪录的剥离效率(7.5 g h−1 L−1), 在实 验室实现了从微晶石墨到石墨烯的公斤级转化. 所制备的石墨烯纳米 片横向尺寸小(298 nm), C/O原子比与起始微晶石墨相同, 导电性良好. 该小尺寸石墨烯适合作为锂离子电池的导电添加剂, 在改善电池的比 容量和循环稳定性方面优于商用碳基导电颗粒.

Similar content being viewed by others

References

Wang B, Li Z, Wang C, et al. Folding large graphene-on-polymer films yields laminated composites with enhanced mechanical performance. Adv Mater, 2018, 30: 1707449

Papageorgiou DG, Kinloch IA, Young RJ. Mechanical properties of graphene and graphene-based nanocomposites. Prog Mater Sci, 2017, 90: 75–127

Shin SE, Choi HJ, Shin JH, et al. Strengthening behavior of few-layered graphene/aluminum composites. Carbon, 2015, 82: 143–151

Yang H, Li Q, Wang Z, et al. Effect of graphene on microstructure and mechanical properties of Si3N4/SiC ceramics. ES Mater Manuf, 2021, 12: 29–34

Pierleoni D, Xia ZY, Christian M, et al. Graphene-based coatings on polymer films for gas barrier applications. Carbon, 2016, 96: 503–512

Chang KC, Ji WF, Lai MC, et al. Synergistic effects of hydrophobicity and gas barrier properties on the anticorrosion property of PMMA nanocomposite coatings embedded with graphene nanosheets. Polym Chem, 2014, 5: 1049–1056

Du J, Pei S, Ma L, et al. 25th anniversary article: Carbon nanotube- and graphene-based transparent conductive films for optoelectronic devices. Adv Mater, 2014, 26: 1958–1991

Kobayashi T, Bando M, Kimura N, et al. Production of a 100-m-long high-quality graphene transparent conductive film by roll-to-roll chemical vapor deposition and transfer process. Appl Phys Lett, 2013, 102: 023112

Fu Y, Hansson J, Liu Y, et al. Graphene related materials for thermal management. 2D Mater, 2019, 7: 012001

Dai W, Lv L, Lu J, et al. A paper-like inorganic thermal interface material composed of hierarchically structured graphene/silicon carbide nanorods. ACS Nano, 2019, 13: acsnano.8b07337

Pomerantseva E, Bonaccorso F, Feng X, et al. Energy storage: The future enabled by nanomaterials. Science, 2019, 366: eaan8285

Kumar R, Sahoo S, Joanni E, et al. Recent progress in the synthesis of graphene and derived materials for next generation electrodes of high performance lithium ion batteries. Prog Energy Combust Sci, 2019, 75: 100786

Wu J. Multichannel absorption enhancement in graphene based on metal-photonic crystal hetero-structure. ES Energy Environ, 2021, 13: 25–30

Xia ZY, Pezzini S, Treossi E, et al. The exfoliation of graphene in liquids by electrochemical, chemical, and sonication-assisted techniques: A nanoscale study. Adv Funct Mater, 2013, 23: 4684–4693

Dreyer DR, Park S, Bielawski CW, et al. The chemistry of graphene oxide. Chem Soc Rev, 2010, 39: 228–240

McAllister MJ, Li JL, Adamson DH, et al. Single sheet functionalized graphene by oxidation and thermal expansion of graphite. Chem Mater, 2007, 19: 4396–4404

Voiry D, Yang J, Kupferberg J, et al. High-quality graphene via microwave reduction of solution-exfoliated graphene oxide. Science, 2016, 353: 1413–1416

Bagri A, Mattevi C, Acik M, et al. Structural evolution during the reduction of chemically derived graphene oxide. Nat Chem, 2010, 2: 581–587

Stankovich S, Dikin DA, Piner RD, et al. Synthesis of graphene-based nanosheets via chemical reduction of exfoliated graphite oxide. Carbon, 2007, 45: 1558–1565

Paton KR, Varrla E, Backes C, et al. Scalable production of large quantities of defect-free few-layer graphene by shear exfoliation in liquids. Nat Mater, 2014, 13: 624–630

Phiri J, Gane P, Maloney TC. High-concentration shear-exfoliated colloidal dispersion of surfactant-polymer-stabilized few-layer graphene sheets. J Mater Sci, 2017, 52: 8321–8337

Khan U, O’Neill A, Lotya M, et al. High-concentration solvent exfoliation of graphene. Small, 2010, 6: 864–871

De S, King PJ, Lotya M, et al. Flexible, transparent, conducting films of randomly stacked graphene from surfactant-stabilized, oxide-free graphene dispersions. Small, 2010, 6: 458–464

Hernandez Y, Nicolosi V, Lotya M, et al. High-yield production of graphene by liquid-phase exfoliation of graphite. Nat Nanotech, 2008, 3: 563–568

Teng C, Xie D, Wang J, et al. Ultrahigh conductive graphene paper based on ball-milling exfoliated graphene. Adv Funct Mater, 2017, 27: 1700240

Shi D, Yang M, Chang B, et al. Ultrasonic-ball milling: A novel strategy to prepare large-size ultrathin 2D materials. Small, 2020, 16: 1906734

Coleman JN. Liquid exfoliation of defect-free graphene. Acc Chem Res, 2013, 46: 14–22

Bourlinos AB, Georgakilas V, Zboril R, et al. Liquid-phase exfoliation of graphite towards solubilized graphenes. Small, 2009, 5: 1841–1845

Blake P, Brimicombe PD, Nair RR, et al. Graphene-based liquid crystal device. Nano Lett, 2008, 8: 1704–1708

Lee D, Lee B, Park KH, et al. Scalable exfoliation process for highly soluble boron nitride nanoplatelets by hydroxide-assisted ball milling. Nano Lett, 2015, 15: 1238–1244

Stolle A, Szuppa T, Leonhardt SES, et al. Ball milling in organic synthesis: Solutions and challenges. Chem Soc Rev, 2011, 40: 2317–2329

Tyurnina AV, Tzanakis I, Morton J, et al. Ultrasonic exfoliation of graphene in water: A key parameter study. Carbon, 2020, 168: 737–747

Trappe V, Prasad V, Cipelletti L, et al. Jamming phase diagram for attractive particles. Nature, 2001, 411: 772–775

Vallés C, Young RJ, Lomax DJ, et al. The rheological behaviour of concentrated dispersions of graphene oxide. J Mater Sci, 2014, 49: 6311–6320

Chan D, Powell RL. Rheology of suspensions of spherical particles in a newtonian and a non-newtonian fluid. J Non-Newtonian Fluid Mech, 1984, 15: 165–179

Wang Y, Teng C, Hu T, et al. Total conversion from graphite to few-layer graphene nanocomposite. Carbon Trends, 2021, 2: 100017

Li H, Zhao J, Wang J. Total-conversion, high-concentration exfoliation of two-dimensional boron nitride by paste-based sand milling strategy for massively producing high-performance nanocomposites. Compos Sci Tech, 2021, 201: 108545

Karagiannidis PG, Hodge SA, Lombardi L, et al. Microfluidization of graphite and formulation of graphene-based conductive inks. ACS Nano, 2017, 11: 2742–2755

Li D, Müller MB, Gilje S, et al. Processable aqueous dispersions of graphene nanosheets. Nat Nanotech, 2008, 3: 101–105

Meng K, Wang Z, Guo H, et al. Enhanced cycling stability of LiNi0.8Co0.1Mn0.1O2 by reducing surface oxygen defects. Electrochim Acta, 2017, 234: 99–107

Gao L, Jin Y, Liu X, et al. A rationally assembled graphene nanoribbon/graphene framework for high volumetric energy and power density Li-ion batteries. Nanoscale, 2018, 10: 7676–7684

Hsu TH, Liu WR. Effects of graphene nanosheets with different lateral sizes as conductive additives on the electrochemical performance of LiNi0.5Co0.2Mn0.3O2 cathode materials for Li ion batteries. Polymers, 2020, 12: 1162

Acknowledgements

This work was supported by the National Natural Science Foundation of China (51973054), the High-level Innovative Talent Project in Hunan Province (2018RS3055), the Young Talents Program in Hunan Province (2020RC3024), the Natural Science Funds of Hunan Province for Distinguished Young Scholars (2021JJ10018) and the Science Research Project of Hunan Provincial Education Department (21B0027).

Author information

Authors and Affiliations

Contributions

Huang L and Wang J conceived and designed the project, and wrote the manuscript Li H participated in the investigation and drew the schematic diagram Wang X and Ding Y participated in the investigation Wang J and Jiang L supervised the experiments and provided theoretical guidance. All authors contributed to the general discussion

Corresponding author

Additional information

Conflict of interest

The authors declare that they have no conflict of interest

Supplementary information

Supporting data are available in the online version of the paper.

Limei Huang is currently a PhD candidate at the College of Materials Science and Engineering, Hunan University. Her research interest focuses on 2D nanomaterial exfoliation from layered bulk materials.

Jianfeng Wang received his PhD degree from Beihang University in 2013. Afterward, he worked as an assistant professor at the School of Chemistry, Beihang University. He worked as a visiting scholar at Nanotech Institute, University of Texas at Dallas in 2015. He joined Hunan University in 2017 and is now a professor at the College of Materials Science and Engineering. His research interest focuses on exfoliation of 2D nanomaterials and their bioinspired assembly.

Supplementary Material

40843_2021_2015_MOESM1_ESM.pdf

High-efficiency, self-grinding exfoliation of small graphene nanosheets from microcrystalline graphite driven by microbead milling as conductive additives

Rights and permissions

About this article

Cite this article

Huang, L., Li, H., Wang, X. et al. High-efficiency, self-grinding exfoliation of small graphene nanosheets from microcrystalline graphite driven by microbead milling as conductive additives. Sci. China Mater. 65, 2463–2471 (2022). https://doi.org/10.1007/s40843-021-2015-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40843-021-2015-8