Abstract

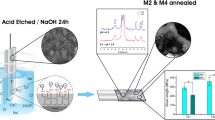

This work investigates the deposition of hydroxyapatite (HA) onto superelastic nickel-titanium (NiTi) using an ambient temperature coating process known as CoBlast. The process utilises a stream of abrasive alumina (Al2O3) and a coating medium (HA) sprayed simultaneously at the surface of the substrate. The use of traditional coatings methods, such as plasma spray, is unsuitable due to the high temperatures of the process. This can result in changes to both the crystallinity of the HA and properties of the thermally sensitive NiTi. HA is a biocompatible, biodegradable and osteoconductive ceramic, which when used as a coating can promote bone growth and prevent the release of nickel from NiTi in vivo. Samples were coated using different blast pressures and abrasive particle sizes and were examined using a variety of techniques. The coated samples had a thin adherent coating, which increased in surface roughness and coating thickness with increasing abrasive particle size. X-ray diffraction analysis revealed that the process gave rise to a stress-induced martensite phase in the NiTi which may enhance mechanical properties. The study indicates that the CoBlast process can be used to deposit thin adherent coatings of HA onto the surface of superelastic NiTi.

Similar content being viewed by others

References

Clarke B et al (2006) Influence of nitinol wire surface treatment on oxide thickness and composition and its subsequent effect on corrosion resistance and nickel ion release. J Biomed Mater Res Part A 79(1):61–70

Pelton AR, Dicello J, Miyazaki S (2000) Optimisation of processing and properties of medical grade Nitinol wire. Minim Invasive Ther Allied Technol 9(2):107–118

Haverty D et al (2005) Structure and stability of hydroxyapatite: density functional calculation and Rietveld analysis. Phys Rev B 71(9):094103

Geetha M et al (2009) Ti based biomaterials, the ultimate choice for orthopaedic implants–a review. Prog Mater Sci 54(3):397–425

Aliağaoğlu C et al (2012) Relation of nickel allergy with in-stent restenosis in patients treated with cobalt chromium stents. Ann Dermatol 24(4):426–429

Choi J et al (2003) Calcium phosphate coating of nickel–titanium shape-memory alloys. Coating procedure and adherence of leukocytes and platelets. Biomaterials 24(21):3689–3696

Tofail MS et al (2005) Structural order and dielectric behaviour of hydroxyapatite. Ferroelectrics 319(1):117–123

Cheang P et al (1996) Pulsed laser treatment of plasma-sprayed hydroxyapatite coatings. Biomaterials 17(19):1901–1904

Dunne CF et al (2015) On the fate of particles liberated from hydroxyapatite coatings in vivo. Irish J Med Sci (1971-) 184(1):125–133

Yang Y, Kim K-H, Ong JL (2005) A review on calcium phosphate coatings produced using a sputtering process—an alternative to plasma spraying. Biomaterials 26(3):327–337

Tsui Y, Doyle C, Clyne T (1998) Plasma sprayed hydroxyapatite coatings on titanium substrates Part 1: mechanical properties and residual stress levels. Biomaterials 19(22):2015–2029

Prevéy PS (2000) X-ray diffraction characterization of crystallinity and phase composition in plasma-sprayed hydroxyapatite coatings. J Therm Spray Technol 9(3):369–376

Sobieszczyk S, Zieliński A (2008) Coatings in arthroplasty. Adv Mater Sci 8(4):35–54

Cook SD, Thomas KA, Kay JF (1991) Experimental coating defects in hydroxylapatite-coated implants. Clin Orthop Relat Res 265:280–290

Collier JP et al (1993) Loss of hydroxyapatite coating on retrieved, total hip components. J Arthroplas 8(4):389–393

Nicholson JW (2002) Ceramics. In The chemistry of medical and dental materials. Royal Society of Chemistry, Cambridge. p. 63–105

Li H, Khor K, Cheang P (2002) Titanium dioxide reinforced hydroxyapatite coatings deposited by high velocity oxy-fuel (HVOF) spray. Biomaterials 23(1):85–91

Picas J, Forn A, Matthäus G (2006) HVOF coatings as an alternative to hard chrome for pistons and valves. Wear 261(5–6):477–484

Khor K, Li H, Cheang P (2003) Processing–microstructure–property relations in HVOF sprayed calcium phosphate based bioceramic coatings. Biomaterials 24(13):2233–2243

Zhitomirsky I, Gal-Or L (1997) Electrophoretic deposition of hydroxyapatite. J Mater Sci 8(4):213–219

Han Y et al (2001) Characterization and stability of hydroxyapatite coatings prepared by an electrodeposition and alkaline-treatment process. J Biomed Mater Res Part A 54(1):96–101

Lacefield WR (2013) Hydroxylapatite coatings In An introduction to bioceramics. Imperial College Press, New Jersey. p. 331–347

Hench LL, West JK (1990) The sol-gel process. Chem Rev 90(1):33–72

Nguyen H et al (2004) The effect of sol–gel-formed calcium phosphate coatings on bone ingrowth and osteoconductivity of porous-surfaced Ti alloy implants. Biomaterials 25(5):865–876

Haddow D, James P, Van Noort R (1998) Sol-gel derived calcium phosphate coatings for biomedical applications. J Sol-Gel Sci Technol 13(1–3):261–265

Tkalcec E et al (2001) Sol-gel-derived hydroxyapatite powders and coatings. J Mater Sci 36(21):5253–5263

Liu D-M, Troczynski T, Tseng WJ (2001) Water-based sol–gel synthesis of hydroxyapatite: process development. Biomaterials 22(13):1721–1730

Dunne CF et al (2015) Biological response to hydroxyapatite and fluorapatite coated dental screws. J Mater Sci 26:1–14

Dunne CF et al (2014) Co-blasting of titanium surfaces with an abrasive and hydroxyapatite to produce bioactive coatings: substrate and coating characterisation. J Biomater Appl 28(5):767–778

Dunne CF, Twomey B, Stanton KT (2015) Effect of a blast coating process on the macro-and microstructure of Grade 5 titanium foam. Mater Lett 147:75–78

Dunne CF et al (2015) Blast coating of superelastic NiTi wire with PTFE to enhance wear properties. Shape Mem Superelast 1(1):41–49

Byrne GD et al (2013) Comparison between shot peening and abrasive blasting processes as deposition methods for hydroxyapatite coatings onto a titanium alloy. Surf Coat Technol 216:224–231

O’Sullivan C et al (2011) A modified surface on titanium deposited by a blasting process. Coatings 1(1):53–71

O’Neill L et al (2009) Deposition of substituted apatites onto titanium surfaces using a novel blasting process. Surf Coat Technol 204(4):484–488

Liao Y et al (2012) Deformation induced martensite in NiTi and its shape memory effects generated by low temperature laser shock peening. J Appl Phys 112(3):033515

Liu Y, Tan G, Miyazaki S (2006) Deformation-induced martensite stabilisation in [100] single-crystalline Ni–Ti. Mater Sci Eng A 438:612–616

Montross CS et al (2002) Laser shock processing and its effects on microstructure and properties of metal alloys: a review. Int J Fatigue 24(10):1021–1036

ASTM (2011) ASTM F1147-05—Standard Test Method for Tension Testing of Calcium Phosphate and Metallic Coatings. ASTM International: West Conshohocken, PA

Le Guéhennec L et al (2007) Surface treatments of titanium dental implants for rapid osseointegration. Dent Mater 23(7):844–854

ISO (2008) ISO 13779-2:2008—Implants for surgery—Hydroxyapatite—Part 2: Coatings of hydroxyapatite. International Standards Organisation: Geneva, Switzerland

Dunne CF et al (2016) Corrosion behaviour of biodegradable magnesium alloys with hydroxyapatite coatings. Surf Coat Technol 289:37–44

Acknowledgements

This research is funded under the Programme for Research in Third-Level Institutions (PRTLI) and co-funded under the European Regional Development Fund (ERDF).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dunne, C.F., Roche, K., Ruddy, M. et al. Deposition of Hydroxyapatite Onto Superelastic Nitinol Using an Ambient Temperature Blast Coating Process. Shap. Mem. Superelasticity 4, 337–343 (2018). https://doi.org/10.1007/s40830-018-0179-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40830-018-0179-7