Highlights

-

MoS2 shows enormous potential for gas sensing due to its high surface to volume ratio, position-dependent gas molecules adsorption and easy control on morphology.

-

The recent experimental and theoretical strategies to develop NO2 chemiresistance sensors based on MoS2 are addressed.

-

A detailed overview of the fabrication of MoS2 chemiresistance sensors in terms of devices, structure, morphology, defects, heterostructures, metal doping, and under light illumination are discussed.

Abstract

Nitrogen dioxide (NO2), a hazardous gas with acidic nature, is continuously being liberated in the atmosphere due to human activity. The NO2 sensors based on traditional materials have limitations of high-temperature requirements, slow recovery, and performance degradation under harsh environmental conditions. These limitations of traditional materials are forcing the scientific community to discover future alternative NO2 sensitive materials. Molybdenum disulfide (MoS2) has emerged as a potential candidate for developing next-generation NO2 gas sensors. MoS2 has a large surface area for NO2 molecules adsorption with controllable morphologies, facile integration with other materials and compatibility with internet of things (IoT) devices. The aim of this review is to provide a detailed overview of the fabrication of MoS2 chemiresistance sensors in terms of devices (resistor and transistor), layer thickness, morphology control, defect tailoring, heterostructure, metal nanoparticle doping, and through light illumination. Moreover, the experimental and theoretical aspects used in designing MoS2-based NO2 sensors are also discussed extensively. Finally, the review concludes the challenges and future perspectives to further enhance the gas-sensing performance of MoS2. Understanding and addressing these issues are expected to yield the development of highly reliable and industry standard chemiresistance NO2 gas sensors for environmental monitoring.

Similar content being viewed by others

1 Introduction

The earth’s environment consists of various chemical elements, gases, and dust particles such as N2, O2, CO, CO2, NO2, NH3. Among these gases, O2, present in the environment is beneficial to living beings, while some gases, such as CO2, NO2, are toxic and dangerous. The presence of these toxic gases is majorly fixed in the environment. Among all toxic and dangerous gases, NO2, a hazardous gas, acidic in nature, highly reactive with a stinky smell is continuously being produced and liberated in the atmosphere due to human activity [1,2,3,4,5,6]. NO2 is produced by fossil fuel burning, forest fires, industry and motor vehicles [7,8,9]. NO2 has recently become a matter of concern in Europe and Australia, owing to its increased concentration. The recent satellite data revealed an unprecedented increase in NO2 concentration due to motor vehicles, power plants and wildfire in Europe and Australia in the year 2019 [10,11,12,13,14]. Moreover, after the worldwide outbreak of the novel COVID-19 virus, the lockdown was implemented in highly affected countries, which resulted in the shutdown of factories, manufacturing firms, and transport. This lockdown benefitted the world inadvertently with a dramatic reduction in NO2 emissions. Importantly, the high reactiveness of NO2 molecules with moisture and its tendency to create an acidic environment makes NO2 production thought of concern [5, 15, 16]. It causes respiratory diseases beyond a certain NO2 concentration limit in the environment, e.g. coronary assault, cancer, asthma, pneumonia, coughing and bronchitis [16,17,18]. The presence of NO2 in the environment makes the air hazy and thick, which reduces the visibility of human eyes. In addition, the World Health Organization (WHO) reported that major cities around the world had failed to qualify the WHO's air quality standards [19]. An estimated 30.7 million people died due to cardiovascular disease, cancer and chronic respiratory disease in 2016 [19, 20]. Thus, considering the toxicity and hazardousness of NO2 gas, there is an urgent need to detect the precise levels of NO2 gas in the environment.

A hazardous gas in the environment can be detected by a gas sensor which is an electronic device having two-essential parts; a receptor unit and a transducer unit. Chemical information generated due to gas molecules exposure is gathered and stored in the form of chemical energy in the receptor device. The energy stored in the transducer component is transmuted to an analytical signal [21]. Hulanicki et al. categorized the gas sensors into six classes depending on the transducer mechanism: (1) electrochemical, (2) mass sensitive, (3) magnetic, (4) optical, (5) thermoelectric, and (6) electrical. The classification of gas sensors is carried out on the basis of their transducer operating principle. In today’s fast moving and unstoppable life, the rapid detection of low concentration of toxic gases is indispensable. Among all gas sensors, electrical transducer-based NO2 gas sensor has grabbed the prime attention due to their easy handling, simple fabrication process, easy to connect with IOTs, real-time gas detection provision, low-cost and power consumptions, small size and long-term stability in harsh working conditions. In electrical or chemical resistance sensors, the resistance of the sensing material is changed due to charge transfer between the gas molecules and the sensing materials whenever the gas molecules are exposed to the sensing device. The chemiresistance gas sensors have extensive applications in H2, NH3, NO, H2S, NO2 gas detection in the environment, industry, cities, space science, transport, vehicles, cultivation, indoors, and various health sectors [22, 23]. Some figures of merits are specified to compare the performance of a gas sensor with different sizes, morphologies and operating conditions, i.e. sensor response, response and recovery time, and selectivity. Generally, sensor response is the ratio of change in resistance with exposure of gas molecules to the resistance of the film before the exposure of gas molecules. It is given by different forms of expression by many groups such as \(S = \frac{{\left( {R_{{{\text{gas}}}} - R_{{{\text{air}}}} } \right)}}{{R_{{{\text{air}}}} }}\); \(\frac{{\left( {R_{{{\text{air}}}} - R_{{{\text{gas}}}} } \right)}}{{R_{{{\text{air}}}} }}\); \(\frac{{\left( {I_{\text{gas}} - I_{\text{air}} } \right)}}{{I_{\text{air}} }};\) \(\frac{{R_{\text{gas}} }}{{R_{\text{air}} }}\), \(\frac{{R_{\text{air}} }}{{R_{\text{gas}} }}\) [17, 24,25,26,27,28,29,30,31,32,33,34,35,36]. Where, \( R_{\text{gas}}\)(\(I_{\text{gas}}\)) is the resistance (current) of the sensing film in the presence of the gas molecules, \(R_{\text{air}}\)(\(I_{\text{air}}\)) is the resistance (current) of the sensing film in the presence of the air and S is the sensor response. The response time is the time taken by any gas sensor to attain 90% of the maximum sensor response when the gas is introduced to the sensor. The recovery time is the time taken by any gas sensor to reach 10% of the maximum sensor response when the gas is turned off. The capacity of a gas sensor to respond to a particular gas in the presence of other gases is called selectivity ability of the gas sensor. Usually, sensing films are sensitive to every gas present in the atmosphere at a same time. Also, some gases have nearly same sensor response for specific sensing film. It is therefore difficult to determine the exact change in the sensor response generated by the target gas. Therefore, sensing film must be very selective for the target gas with highest sensor response.

Graphene as a 2D material has some unique properties such as the large surface area (2360 m2 g−1), zero rest mass of charge carriers near Dirac points and high carrier mobility 200,000 cm2 V−1 s−1 at room temperature (RT) [37,38,39,40,41,42]. Similarly, other 2D layered materials have numerous properties and applications in comparison to their bulk form [43,44,45]. The intriguing properties of 2D TMDCs are their high surface to volume ratio, absence of dangling bonds in the pristine form, strong spin–orbit coupling interaction and the high interaction ability for the gas molecules adsorption [46,47,48,49,50,51,52]. These features of 2D materials offer interest in exploring their new fundamental physics [32, 53]. The layer-dependent mechanical, electronic, and optical properties of 2D materials create curiosity to learn and explore their fundamental properties [54,55,56]. A one atom thick layer of graphene has shown an appealing role in gas sensing by detecting 1 ppb concentration of various gases such as NH3, NO2, H2O, and CO [57]. Gas sensors based on graphene have been widely inspected and employed owing to its high carrier mobility, mechanical strengths greater than to steal, remarkable optical and electronic properties [58,59,60]. Despite having an impressive sensor response and response time, the NO2 sensors have suffered from long recovery time owing to the very high adsorption energy of gas molecules with graphene [61,62,63]. In terms of growth and production, the synthesis of graphene is very costly with the use of toxic chemicals at high temperatures [64,65,66,67]. Another challenge associated with graphene is the production of high quality and large surface area graphene film, which is very difficult to attain and the presence of any non-carbon elements disrupts the hexagonality of graphene [68]. Moreover, graphene has zero bandgap, and less environment stability which reduces the gas-sensing performance and long term stability of graphene-based sensors [47, 69].

These limitations of graphene mold the direction of research to discover new nonzero bandgap 2D materials like MoS2, MoSe2, MoTe2, WS2, WSe2, BP, and many more [70,71,72,73,74,75,76,77,78,79,80,81,82,83]. The interaction between the gas molecules and sensing materials is the indelible part of any gas-sensing process. In 2D materials, especially MoS2, is at the forefront in the race of an ideal gas-sensing material [84, 85]. The other substitutes of the 2D materials family are WS2, WSe2, NbSe2, MoTe2, etc. [86,87,88,89,90]. However, most of the research on NO2 detection is carried out with MoS2. MoS2-based gas sensors have achieved noticeable research interest in recent years. MoS2 has already shown emerging environmental applications in energy storage, light interaction, flexible electronic devices and in biofield due to its semiconducting nature [50, 91,92,93,94,95,96]. MoS2 has two possible crystal phases, trigonal and hexagonal, where hexagonal is semiconducting while trigonal is having metallic nature [97]. The presence of weak Van der Waals force enables the easy isolation of layers from bulk MoS2. The indirect bandgap of 1.2 eV in bulk MoS2 is converted to a direct bandgap of 1.8 eV for monolayer MoS2 [50, 98, 99]. The absence of dangling bonds provides stability to pristine MoS2 flakes in liquid and gaseous media in the presence of oxygen. These facilities make MoS2 compatible for gas-sensing application [100]. The low binding energy of 6.1 and 13.9 eV is needed to create S and Mo vacancies, respectively, which can turn the edges of MoS2 flakes into metallic sites [101, 102]. MoS2 has a tunable bandgap compared to graphene which increases the overall sensing performance of MoS2 film [103]. The MoS2 flakes have strong photoluminescence (PL) absorption due to the presence of direct bandgap, helpful to design the optical gas sensors. The high on/off ratio (108), the high carrier mobility of 400 cm2 V−1 s−1 at RT, low effective electron mass of 0.48 me are advantageous for developing fast gas sensors [54, 104,105,106]. Owing to these electronic properties, any minor change in the electron concentration of MoS2 flakes can be easily detected. MoS2 flakes have four Raman active modes (\(E_{1g} , E_{2g}^{1} , A_{1g} , E_{2g}^{2}\)). The \(E_{2g}^{1}\) mode is an in-plane mode and \( A_{1g}\) is an out of plane mode [107, 108]. Chakraborty et al. studied in situ Raman spectroscopy of single-layer MoS2 flakes [109]. It has been found that \(E_{2g}^{1}\) is not sensitive to electron doping while the \( A_{1g}\) mode is very sensitive to electron doping [109]. With higher electron concentration, the \(A_{1g}\) mode gets soften due to stronger electron–phonon coupling mode than \(E_{2g}^{1}\) mode [109]. These vibrational characteristics are ideal for the chemiresistance gas sensors where charge concentration has remained an important parameter. Furthermore, MoS2 film has impressive mechanical and optical properties with high Young’s modulus up to 300 GPa, deformity up to 11% without any fracture and amazing transparent nature, making it a potential candidate for optical and flexible devices [110,111,112,113,114]. Moreover, MoS2 flakes can be bent up to the radius of 0.75 mm, without deteriorating its electronic properties [115]. Excellent gas molecules detection ability, enormous active sites, large surface to volume ratio and presence of favorable adsorption sites have endorsed MoS2 as the unique sensing material. The development and key accomplishment of MoS2-based NO2 gas sensors in last 8 years are summarized in Fig. 1. With the discovery of the graphene by mechanical exfoliation (ME) technique by the Geim and Novoselov, they further revealed in 2005 that the ME technique can also be employed to thin down the other bulk materials such as MoS2 [43]. Following the uniqueness of the MoS2, Li et al. developed the NOx sensitive gas sensor [34]. In a similar year, He et al. developed the NO2 sensor based on multilayer MoS2 flakes and confirm the role of MoS2 in NO2 detection [42]. The fundamental research to study the electronic properties of MoS2 was boosted after the fabrication of first MoS2 transistor by Kis et al. [116]. In 2013, Late et al. studied the role of negative and positive back gate voltage on NO2 sensing by fabricating the MoS2 field effect transistor (FET) [17]. The year 2014–2015 was devoted to the charge transfer mechanism due to the gas molecules exposure. Yue et al. investigated theoretically and confirmed that gas molecule detection in MoS2 is attributed to the charge transfer process [117]. Liu et al. demonstrated that NO2 gas adsorption strongly affects the Schottky barrier height (SBH) [36]. Cho et al. performed the in-situ PL spectroscopy and investigated the p-type doping in MoS2 flakes due to NO2 exposure [32].

Schematic representation of the 8-year journey of MoS2-based NO2 sensors. Reproduced with permission from Refs. [34, 118]. Copyright @ Wiley-VCH; Refs. [17, 32, 35, 36, 119, 120, 123]. Copyright @ American Chemical Society; Ref. [117]. Copyright @ Springer; Ref. [121]. Copyright @ AIP Publishing; Ref. [122]. Copyright @ Elsevier

Till 2015, MoS2 has been established itself as the potential candidate for the gas sensing with a well-defined gas-sensing mechanism. However, MoS2-based NO2 sensors suffered from the incomplete recovery due to the high adsorption of NO2 on MoS2. Cho et al. studied the role of active sites in gas sensing [35]. NO2 adsorption is very high at the active sites in MoS2. The active sites are highest at the edges due to presence of dangling bonds, defects and vacancies, while the terrace of MoS2 is inert due to absence of dangling bonds. Authors synthesized MoS2 flakes of three different orientations: in-plane MoS2, mixed MoS2 and vertical aligned MoS2 flakes. The number of active sites and NO2 sensing performance were highest in the case of vertical MoS2 flakes. Several studies have been published in parallel years for the fabrication of hybrid MoS2 heterostructures to improve the charge transfer in MoS2. Long et al. fabricated the low temperature MoS2/graphene hybrid structure and develop ultrasensitive NO2 sensors up to 50 ppb [118]. Although researchers have achieved full recovery at high temperatures, but the production of RT-recoverable gas sensors has remained a challenging task.

Since 2017, light-assisted NO2 sensors have attracted the worldwide scientific community. Rahul et al. in 2017, investigated the role of ultraviolet (UV) light in basal plane MoS2 flakes and achieved the full recovery at RT under UV light illumination. Agrawal et al. demonstrated the role of favorable NO2 adsorption sites in MoS2 by synthesizing the unique morphology of MoS2 flakes [119, 120]. Metal NP doping has theoretically proven to be a great combination for enhanced gas sensor response, reactivity and recovery in the past years. Zhou et al. developed the MoS2 sensor decorated with Au NPs [121]. It is important to remember that, until 2018, most of the published report used only UV light to boost the efficiency of the sensing light. In the next years, 2019 and 2020 (running) researchers fabricated the visible spectra and near infrared (NIR) spectra-driven NO2 sensors [122, 123].

Thus we may conclude that gas-sensing characteristics of MoS2 film-based device are highly dependent on size, shape, thickness, morphology, growth direction, polytype composition, defects, metal functionality and the hybrid structure of MoS2 films. These factors can be used to classify MoS2-based NO2 sensors [25, 42, 124].

Apart from the experimental efforts, theoretical studies have also played a noticeable role in designing the experiments and predicting the gas-sensing potential of the proposed materials [125]. Theoretical methods such as density functional theory (DFT) always prove their advantage in terms of time, efforts and cost [125]. DFT provides a broad and detailed view to understand the fundamental mechanism happening between the gas molecules and the sensing material [126, 127]. The key features of DFT are the pre-calculation of the charge transfer and understanding of fundamental interaction between the sensing material and gas molecules. These features are helpful to understand the physical and chemical adsorption of gas molecules, theoretical estimation of defects, their effects on electronic and optical properties and functionalizing the defects with other materials and noble metals. Very few reviews are focused on both the theoretical contribution and the experimental contribution of MoS2 for NO2 sensing.

The goal of this review is to discuss in detail the MoS2-based NO2 gas sensors and to provide in-depth insights into previously established theoretical and experimental approaches. We focused on the various properties of MoS2 which played a vital role in gas sensing. Mainly, the role of 1T and 2H MoS2 phases, large surface area available in MoS2 film for gas molecule adsorption, faster charge transport in MoS2, effect of modulating favourable adsorption sites via morphology, optical properties and defects available in MoS2 will be discussed.

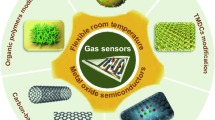

Considering all these points, we have categorized various strategies for enhancing the performances of MoS2 sensors as follows: role of device structure (resistor and transistor), monolayer MoS2, multilayer MoS2, defect tailoring, morphology engineering, heterostructures, functionalizing with noble metals and light-assisted NO2 sensors. We have focused our present review in the direction as mentioned above and a schematic view is shown in Fig. 2.

We also focus a little bit on the traditional NO2 sensing materials such as metal oxides and carbon-based nanomaterials to gain a clear difference between NO2 sensing performance of traditional materials and MoS2.

A tremendous effort has been employed to develop fast, high sensor response, selective and low-cost NO2 electrical sensors. Various nanomaterial-based sensors from zero dimension (0D, quantum dots) [128,129,130,131,132,133,134,135] to two dimensions (2D, metal oxides, TMDCs) [27, 81, 83, 136,137,138] showed their exceptional detection ability to detect parts per billion (ppb) NO2 gas traces [139,140,141,142,143]. Every nanomaterials has its own merits and demerits in the NO2 gas detection. The traditional metal oxides (ZnO, SnO2, TiO2, In2O3, WO3 etc.) based NO2 sensors showed a fast response and high sensor response. However, the highly sensitive nature of metal oxides to humidity reduces the sensor response and stability of gas sensors. Moreover, for accelerating the interaction between the gas molecules and metal oxides, metal oxides gas sensors are need to operate at a higher temperature (250–500 °C). High temperature results in the agglomeration of nanomaterials and increase the grain size of the metal oxide film [28, 143,144,145,146,147,148,149,150,151,152,153,154,155]. On the contrary, the carbon material-based NO2 sensors provide the high sensor response but at RT the desorption rate of gas molecules is too slow. Thus, the CNT-based NO2 sensors are suffered from long recovery time [30, 156,157,158]. In summary, metal oxide and carbon-based NO2 sensors are suffered from thermal safety due to high temperature, structure complexity and complex device fabrication, which restricts the use of metal oxides in smart, wearable and next-generation device for the internet of things (IoT).

The problems associated with metal oxide and carbon-based NO2 sensor have demanded the development of new noble materials with advanced gassensing properties. In Fig. 3, we have summarized the NO2 detection performance of various reported traditional materials-based sensors such as ZnO, SnO2, CNTs, TiO2, In2O3 SnS2, and WO3, in terms of operating temperature, sensor response and recovery time [26, 91, 154, 159,160,161,162,163,164,165,166,167,168,169,170,171,172,173,174,175,176,177,178,179,180,181,182,183,184,185,186,187,188,189,190,191,192,193,194,195,196,197]. Most of the traditional nanomaterial-based NO2 sensors reported good sensor response at high operating temperatures (purple star) and simultaneously, they also suffered from the high recovery time (green circles). However, for an ideal gas sensor, it should be operated near RT for high sensing performances. The ideal sensor should have a high sensor response, lower response, and recovery time near to RT, as shown in star region of Fig. 3. Therefore, there is a great demand to develop a low temperature, highly sensitive and fast NO2 sensors.

Traditional material-based NO2 gas sensors. Most of the traditional NO2 sensors have a high operating temperature requirement. The colored star area shows the ideal states for a gas sensor. Data has been taken from Refs. [26, 91, 154, 160,161,162,163,164,165,166,167,168,169,170,171,172,173,174,175,176,177,178,179,180,181,182,183,184,185,186,187,188,189,190,191,192,193,194,195,196,197,198,199,200,201,202,203,204,205,206,207,208,209]

The roadmap of the review is as follows. In Sect. 1, we introduced MoS2 as the NO2 sensors and addressed its benefits over the traditional metal oxide sensors. In Sect. 2, we will present some peculiar properties of MoS2, which played a critical role in gas molecule adsorption. Section 3 is focused on the interaction mechanism of NO2 with MoS2 and effect of NO2 on electronic, optical and surface properties. In Sect. 4, we will discuss several theoretical findings in which, interaction between NO2 and MoS2 is discussed. Section 5 covers the experimental reports where bare MoS2, morphology-driven MoS2, metal-doped MoS2, vacancy-driven and photon-assisted MoS2-based NO2 sensors will be discussed briefly. In Sect. 6, we are going to present some findings where MoS2-based heterostructures are utilized for NO2 sensing. Finally, in Sect. 7, we will conclude our review and discussed the future of MoS2-based NO2 sensor.

2 MoS2: A Unique Material for Gas Sensing

2.1 Structure of MoS2

The single layer of MoS2 has two polymorphs: trigonal prismatic (2H-MoS2 Phase) and octahedral phase (1T-MoS2 Phase), belonging to D3h and D3d point groups, respectively. Both polytype structures are shown in Fig. 4a, c [210]. Here, H and T depict hexagonal and trigonal symmetry, respectively, while digits equate to layers repeat per unit cells. In general, the 2H phase is obtained by synthesizing MoS2 film using methods such as mechanical exfoliation (ME), chemical vapor deposition (CVD) or ultrasonication [108, 211]. The 1T phase is preferred by the Li intercalation method. The 2H and 1T phases has been widely studied experimentally and theoretically. The 2H-MoS2 phase is semiconducting, while the 1T-MoS2 phase exhibits metallic nature. The varied electronic nature of MoS2 can be understood using crystal field theory (CFT). In CFT, five d orbital \( d_{{x^{2} - y^{2} }}\), \(d_{{z^{2} }}\), \(d_{xy}\), \(d_{yz} \,{\text{and}}\,d_{zx}\) of transition metal (Mo) are non-degenerate. These d-bands are located between the bonding (\(\sigma\)) and antibonding bands (\(\sigma^{*}\)), shown in Fig. 4b, d. In trigonal prismatic (D3h), the orbitals splits into three levels, \(d_{{z^{2} }}\) (\(a_{1}\)), \(d_{{x^{2} - y^{2} }}\) + \(d_{xy}\) (\(e\)) and \(d_{yz} + d_{zx} { }\) (\(e^{\prime}\)). The octahedral group divided into levels \(e_{g}\) having \(d_{{z^{2} }}\) and \(d_{{x^{2} - y^{2} }}\) orbital and in \(t_{2g}\) having \(d_{xy}\), \(d_{yz} \,{\text{and}}\,d_{zx}\) [212]. When the highest orbitals are partially filled the MoS2 possess the metallic like conductivity (1T-MoS2, Fig. 4d) and if the highest orbitals are fully filled, MoS2 behave like semiconductor (2H-MoS2, Fig. 4b). In recent years, a lot of research work has been done on 2H-MoS2 phases in gas-sensing applications and many of them addressed in the next sections [17, 34, 35, 42, 120, 213, 214]. The 1T-MoS2 has higher active sites and electronic conductivity reaches up to sixfold higher than the 2H-MoS2 [99]. Mark et al. prepared a stable metallic phase of MoS2 and they observed an enhanced catalytic performance in 1T phase [215]. In addition, the metallic MoS2 showed enhanced photoluminescence due to higher sulfur vacancies [99]. Furthermore, Kappera et al. studied the device performance of both phases and observed the low contact resistance at zero bias gate voltage. The low contact resistance generates high drive current with high mobility of 50 cm2 V−1 s−1 [216, 217]. These all properties showed that 1T-MoS2 is an important phase for NO2 gas sensing. Thus, consideration of the role of both phases in NO2 sensing is equally important.

a Schematic structure of 2H-MoS2. b d-orbital filling of the semiconducting 2H-MoS2. c Schematic structure of 1T-MoS2. d d-orbital filling of the semiconducting 1T-MoS2. e The reported domain size of individual monolayer MoS2 flakes from the ME and CVD technique. CVD provides a larger flake size compared to the ME technique. The data of MoS2 flakes size has been taken from Refs. [50, 107, 220, 222,223,224,225,226,227,228,229,230,231,232,233,234,235,236,237,238,239]. f Band structure of MoS2. The ‘A’ and ‘B’ PL peaks are corresponding to the direct bandgap (Eg) transition of MoS2. Reproduced with permission from Ref. [50]. Copyright (2010) American Physical Society. g Spectral change in PL due to exposure of O2 alone, H2O alone and with both. O2 and H2O incorporate p-type doping which contribute to a blue shift in the peaks. h Rate of recombination with neutral exciton and charge trion as a function of charge density in n-type MoS2 and p-type MoSe2. Reproduced with permission from Ref. [219]. Copyright (2013) American Chemical Society. i TEM image of the as grown vertical aligned MoS2 flakes. The edges have high catalytic activity than the basal plane and enhance the reactivity of the gas molecules. Reproduced with permission from Ref. [240]. Copyright (2013) American Chemical Society. j STM image of the triangular MoS2 flakes where yellow perimeters were showing the presence of the metallic states at the edges. Reproduced with permission from Ref. [241]. Copyright (2001) American Physical Society. k ADF images of monovacancy S intrinsic defects. Reproduced with permission from Ref. [242]. Copyright (2013) American Chemical Society

2.2 Large Surface Area for Gas Molecule Adsorption

In contrast to metal oxides, the MoS2 has a large specific surface area. The large surface area provides maximum adsorption sites for the adsorption of gas molecules and enhances the surface perturbation in the presence of gas molecules. Moreover, in chemiresistance gas sensors, sensor response is directly proportional to the change in the resistance arises due to the adsorption of gas molecules on the surface [42, 218]. Tongay et al. proposed that if one O2 molecule gets physiosorbed on the unit cell of MoS2, it withdraws 0.04e per unit cell and the sheet charge density reduced up to 5 × 1013 cm−2 [219]. Therefore, MoS2 is very sensitive and amenable to be used in gas-sensing devices. In this context, MoS2 established himself as the promising chemical sensing material due to large highly sensitive surface. CVD, ME, and hydrothermal methods are the most popular methods for synthesizing MoS2 for the gas-sensing devices. Among them, the most effective and occupied method to grow large size wafer-scale MoS2 flakes is the CVD. We have prepared a comparative graph of flakes sizes with the two most prominent methods i.e., ME and CVD. It has been observed that individual flakes size grown by the ME method can go maximum up to 10 µm. However, with CVD, MoS2 flakes of larger size can be grown in comparison with ME. It is worth to mention, we collected data of domain size of only individual MoS2 single-layer flakes generated by ME and CVD methods for the data in Fig. 4e. CVD can grow highly uniform, high density, large area and control on morphology of the film while the ME can synthesize highly pure MoS2 flakes, which is desirable for many electrical and optical applications. Agrawal et al. synthesized uniform vertical MoS2 flakes of 1 × 2 cm2 size on SiO2/Si substrate. Furthermore, Lin et al. synthesized large size MoS2 flakes of 308 µm [220]. Zhan et al. synthesized the centimeter size MoS2 layer by CVD method [221]. The nucleation rate, supply of precursors, S and MoO3 powder, temperature and the carrier gas flow rate, by CVD is mainly responsible for large area MoS2 growth [221, 222]. CVD provides great control on the nucleation rate and mass transport. MoS2 flakes size is increased with time as the more and more nucleation center and sites grow over substrate. Hence, CVD is the better option to grow the large area MoS2 flakes and to fabricate the gas-sensing devices.

2.3 Impact of Gas Adsorption on Optical Properties of MoS2

The photoluminescence (PL) is an essential characterizations to detect changed in the electron concentration of a 2D material-based gas sensor. Gas-sensing ability of 2D materials is governed by either electron depletion or accumulation that depend on the doping behavior of the exposed gas molecules.

The nature of dopants critically affect the PL spectra of MoS2. MoS2 has two well-reported PL peaks ‘A’ and ‘B’. These PL peaks are emerged due to the splitting of the valence band in \(v_{1}\) and \(v_{2}\) [50]. The valence band splitting at the K-point is the collective effect of interlayer spacing and spin–orbit coupling. Figure 4f displays the direct bandgap transition peaks (A and B) and indirect bandgap transition (I) in the MoS2 crystal structure. The spectral weight of exciton and trions can be significantly tuned by the electrical gating, n-type or p-type molecular adsorption (e.g. H2O, TCNQ) doping, and defects present at the cracks [219, 243,244,245].

Nan et al. studied the role of molecular adsorption on the PL through oxygen exposure [246]. Micro PL analysis revealed the enhancement in PL intensity due to molecules adsorption by MoS2 surface at moderate temperatures in high vacuum ambient. The PL spectroscopy was performed over the as prepared monolayer MoS2 films, which were annealed for 1 h in vacuum at 350 and 500 °C. It was observed that the PL intensity was increased sixfold after annealing at 350 °C with the blue shift in energy (from 1.79 to 1.81 eV). Moreover, the PL intensity in sample annealed at 500 °C was erratic at different locations. When the MoS2 film was annealed at 350 °C, the MoS2 film was uniform and environmental O2 and H2O physically got adsorbed by MoS2 flakes. Both O2 and H2O introduced p-type doping in MoS2. When the flakes annealed at 500 °C, cracks were formed in the film with the generation of defects. At these defects’ sites O2 and H2O adsorbed chemically and introduced heavy p doping. DFT calculations were also performed and calculated charge transfer between the O2 and pristine MoS2 was 0.021e, while at the defects site, the charge transfer was 0.997e. Thus, higher charge transfers at the defective sites introduced heavy p-type doping. Tongay et al. also studied the modulation in the PL due to the physisorption of O2 and H2O molecules. Physiosorbed O2 and H2O molecules bonded weakly with MoS2 but introduced significant p doping. The variation in PL intensity due to exposure of O2 alone (green), H2O alone (blue) and with both (red) shown in Fig. 4g [247]. The 0.04e and 0.01e times charges were transferred from MoS2 to O2 and H2O molecules, respectively. The O2 and H2O molecules adsorption modulate the charge concentration in the MoS2. The electrons of the n-type MoS2 flakes are depleted by both molecules. Here, the focus has been given on the low energy exciton peak which is the combination of the neutral exciton (X0) and charge trions (\(X^{ + }\)/\(X^{ - }\)). In actual, the MoS2 layer has high sheet charge density \( \left( {n_{\text{eq}} } \right)\). The high \(n_{\text{eq}}\), destabilizes the neutral exciton X0 due to electrostatic screening between the holes and free electrons while the \(X^{ - }\) stabilizes due to high recombination rate of \(X^{ - }\) trions [248]. Hence, with high \( n_{\text{eq}}\), the overall PL intensity becomes low. With physisorption and chemisorption of molecules such as O2 and H2O, the \(n_{\text{eq}}\) gets reduced. Hence, the number of electrons available in MoS2 for trions formation is decreased. Thus, the intensity of \(X^{ - }\) decreased and \(X^{0}\) enhanced with more stabilization, as can be seen from Fig. 4g, h. Moreover, it has been reported that the electronic gating and molecular doping can dramatically tune the PL [219, 244, 245, 249]. As the gas molecule adsorption introduces n or p doping, the study of PL with adsorption of molecules to MoS2 is an important aspect to understand the nature of the gas molecules.

2.4 High Catalytic Nature and Presence of Metallic States

Another essential feature of MoS2 is the presence of a large number of active sites for promoting the chemical reactions. Jaramillo et al. identified the active sites on the MoS2 through scanning tunneling microscopy (STM) [250]. The MoS2 samples were synthesized on the Au substrate and STM imaging was performed in the ultra-high vacuum. The STM measurements confirmed that flat MoS2 edges have bright rims which appeared as bright lines along the flakes perimeter. To validate the high activity of the edges, the hydrogen evolution reactions (HER) activity was investigated which also confirmed the high reactivity of edges. Kong et al. synthesized MoS2 by the sulfurization of Mo film deposited by e-beam lithography. The tunneling electron microscopy (TEM) image of vertical aligned MoS2 flakes is shown in Fig. 4i and in inset. It is evident from these studies that edges have highly active site. Thermodynamically, the growth of in-plane MoS2 is highly probable than the edge oriented MoS2 flakes. The high activity of the edges boosts the motivation to grow edge-enriched film by forming the various morphology of MoS2 nanoflakes such as vertical aligned MoS2, MoS2 nanowires, MoS2 spheres etc. Kim et al. fabricated 2D SnS2 and develop NO2 sensor by enhancing the active sites [251]. The vertically aligned SnS2 showed high NO2 reactivity due to the presence of a large number of active sites in comparison to the basal plane SnS2. Shim et al. synthesized SiO2 nanorods (NRs) and decorated them with MoS2 flakes [252]. These SiO2 NRs enhanced the catalytic activity of MoS2 flakes by exposing more edges of MoS2 flakes [251]. Hence, the NO2 detection ability of SiO2 NRs encapsulated with MoS2 is increased. The MoS2 surface has maximum number of active sites which enhance the chemical activity of MoS2 film [240, 253, 254]. Another important feature of MoS2 flakes is the presence of metallic states at the edges [241]. The MoS2 edges behaved as the one-dimensional metallic wires and appeared as the bright brim of high conductance, as shown in Fig. 4j. The attention here is given to Mo edges having S dimers. The Mo edges have two metallic wave functions and generate metallic states in MoS2. Therefore, the presence of metallic edges will be helpful in the fast transfer of generated electron and holes. The generated charge can be rapidly transferred along the edges in edge-enriched MoS2 and will be helpful in developing the fast responsive and recoverable gas sensors [255].

2.5 Impact of Gas Molecules Adsorption on Schottky Barrier Height

The gas-sensing performance of 2D materials based on chemiresistance gas sensors is critically influenced by the metal contacts [256,257,258,259]. In 2D materials, the gas molecule adsorption affects the charge concentrations and carrier density. Depending on the nature of the gas molecules, the charge carrier density either increases or reduces and Fermi level of 2D materials is modulated with gas molecule adsorption. The equilibrium Fermi level of metal and semiconductor before and after exposure to the gas molecule will be different due to variation in the charge carrier density in the sensing film. In chemiresistance sensors, the Schottky barrier height between the metal contact and the 2D material surface can alter the surface charge transfer mechanism. Various studies have been reported to understand the role of Schottky barrier height (SBH) and Schottky barrier modulation (SBM) with gas molecule exposure in traditional gas sensors as well as in 2D material-based gas sensors [260, 261]. The band structure of metal and semiconductor can be divided into two regions: (1) alignment of the energy levels of the metal and semiconductor for charge carrier injection and (2) band bending at the space charge region for charge carrier separation [262]. If the metal and semiconductor work functions are \(\emptyset_{M}\) and \(\emptyset_{S}\) respectively, the SBH determined by the Mott–Schottky rule is given by Eq. (1):

Depending on the type of the semiconductor (n-type or p-type), the Schottky or ohmic contact nature of the junction is decided. In 2D materials, ohmic contacts are of great importance due to their low resistance and high charge transfer in terms of high mobility and current on/off ratio [104, 263, 264]. However, the ohmic contacts are not beneficial for gas-sensing point of view. The reason for this is the interaction of gas molecules with sensing film and their effect on the Schottky barrier modulation (SBM) [36, 72]. The importance of the Schottky contact is well established in the metal oxide sensors. Zhou et al. demonstrated the remarkable performance of the ZnO sensors by utilizing the Schottky contact in comparison to the ohmic contact [265]. Similarly, Wei et al. fabricated the ZnO NW-based CO sensor in such a way that one end behaved as the Schottky contact, while the other end behaved as the ohmic contact [266]. Schottky end behaves like a gate terminal and the Schottky barrier height (SBH) was tuned. Nearly 4 times enhanced sensor response with seven times reduce response and recovery time were observed. In all these reports, SBM provides an efficient and enhanced charge transport. Hence, gas-sensing performance is high in the Schottky contacted devices.

2.6 Role of Defects in Gas Molecule Adsorption

In case of MoS2, defects can be generated during the synthesis or transfer of MoS2 due to synthesis imperfections [267,268,269,270]. In addition, these defects are susceptible to ambient environments conditions [271, 272]. Defects can also be created through the irradiations, metal doping and functionalization [273, 274]. Thus, MoS2 structures unavoidably have various defects in terms of vacancies, dopants, adsorbates, adatoms, and impurities. On the contrary, the pristine MoS2 is assumed to have defect free surfaces. However, the synthesis of defect free MoS2 flakes is quite difficult and convoluted. Defects are easily produced during the synthesis process. Defects crucially affect various mechanical, electronic, optical and catalytic properties. Zhou et al. fabricated MoS2 and studied the possible structural defects [242]. The authors studied atomic-resolution annular dark field (ADF) images of CVD-grown MoS2 flakes. The defects were classified into six types (i) mono-sulfur Vacancies (VS), (ii) di-sulfur vacancies (VS2), (iii) Mo atom with three nearby sulfur (VMoS3), (iv) Mo atom with three di sulfur pairs (VMoS6), (v–vi) Antisite defects, Mo atom at S vacancy site (MoS2) and S atom at Mo vacancy site (S2Mo). The formation energy of these vacancies is studied in term of S chemical potential. The formation energy plot revealed that mono S vacancies are most probable and need lowest formation energies. The ADF image of S vacancy site is shown in Fig. 4k. These defects could play a crucial role in the gas molecule adsorption. The benefits of defects in graphene have already received great attention [275, 276]. The findings of the reports revealed that the sensing mechanism in pristine and defective graphene is completely different. The defective graphene has higher interaction with gas molecules due to the presence of the defects. Interestingly in MoS2, defects can greatly influence the gas-sensing properties [86, 277]. Moreover, doping defects with substitutional impurities atoms can greatly improve the MoS2 sensing performances. The effect of dopant and impurities is also well established in graphene. Zhang et al. studied the sensing performance of graphene-doped B, N, Si, Ca, Co and Fe, defective graphene and on pristine graphene [278]. The defective graphene doped with Ca, Co and Fe showed the highest interaction with H2S molecules. In metal-doped graphene, mixing of the graphene orbitals and metals orbitals is enhanced with H2S orbitals which leads to the strong interaction.

3 Charge Transfer Mechanism Between NO2 and MoS2: Effect on Electronic Properties, Optical Properties, and Metal Contacts/MoS2 Interface

In the present section, the nature and effect of NO2 gas molecules on electrical conductivity, PL and MoS2 band alignment will be addressed. NO2 is a secondary product generated from the primary NO source as shown by Eq. (2) [279].

NO2 has the electron acceptor nature and behaves as a strong oxidizing agent due to the unpaired electrons of nitrogen atom. NO2 molecules take the electrons from the sensing materials. Generally, a chemiresistance gas sensor has a sensing layer that detects the presence of interacting gas molecules. The electrical and optical properties changes depending on the nature of interacting gas molecules and the type of semiconducting film. The gas molecules that interact can either behave like a reduction gas (electron donor) or an oxidizing gas (electron acceptor). Similarly, the semiconductor film may also have an n-type or a p-type nature.

In the case of TMDCs materials, gas molecules interaction depends on the nature of TMDC film and gas molecules. The interaction of gas molecules with TMDC film is governed via the physisorption or chemisorption process. The physisorption process occurs with pristine TMDC film while the chemisorption process happens with defective TMDC layers and on the defect sites.

In the case of pristine TMDC films, the gas molecules and TMDC films interact through the physisorption process. The gas molecules have weak adsorption energy and long adsorption distance with pristine TMDC film. Moreover, there is a less charge transfer between the gas molecules and TMDC film with an almost unchanged electronic structure. Hence, gas sensors based on pristine TMDC films have fast recovery but with low sensor response. The physisorption-based gas sensing reported in SnS2 [175]. The SnS2 showed a highly selective nature for NO2 molecules due to the physisorption process. Furthermore, the positive binding energy of O2 molecules with the SnS2 surface indicated high surface resistance for oxygen molecules and supported that NO2 sensing response in SnS2 was through the physisorption process [175].

In the case of the chemisorption process, defects induce during the synthesis of MoS2. The gas molecules interact chemically with MoS2. The chemical interactions of gas molecules enhance gas-sensing performances of sensing material. The adsorption distance between the gas molecules and the adsorption sites is minimal in case of the chemisorption process. Hence, high charge transfer, strong adsorption energy, and significant change in the electronic states have been observed. The charge transfer schematic of NO2 with the MoS2 film (n-type or p-type) is shown in Fig. 5a and Eq. (3).

a Schematic interaction of NO2 gas molecules with the n-type or p-type MoS2 layer. NO2 captures the electrons from MoS2 layer. b Effect of NO2 molecules adsorption on PL spectra. The spectral weight of positively charged trions is increased on the cost of excitons spectral weight in n-type MoS2. Reproduced with permission from Ref. [32]. Copyright (2015) American Chemical Society. Schottky barrier height modulation after NO2 molecules adsorption in c n-type MoS2 d p-type MoS2. e Four possible NO2 adsorption sites on MoS2. Reproduced with permission from Ref. [255]. Copyright (2017) AIP Publishing

Cho et al. experimentally verified the charge transfer mechanism between the MoS2 and NO2 gas molecules using PL spectroscopy [32]. The authors synthesized n-type MoS2 film by the chemical vapor deposition technique. The authors exposed NO2 gas to MoS2 film and investigated the charge transfer mechanism using photoluminescence (PL) spectroscopy. The authors observed that with NO2 exposure, the resistance of the n-type MoS2 film increased (positive sensor response). The increment in the resistance confirmed that NO2 withdraws the electrons from the n-type MoS2 film. NO2 gas molecules exposure modulates the electron concentration in MoS2. The change in the electron concentrations dramatically affects the PL. The MoS2 has two main PL exciton peaks named as 'A' and 'B' [50]. The intensities of these two PL peaks can either decreased or increased with a change in the electron concentrations [243, 244]. The low energy PL peak 'A' can be expanded into a charged trions (\(A^{ + / - }\)) and in neutral exciton (\(A^{0}\)). The MoS2 flakes grown on the SiO2 substrate showed dominated behavior of \(A^{ + }\) peak over \(A^{0} .\) Hence, the authors considered the positively charge trion peak \((A^{ + }\)) and neutral exciton peak (\(A^{0}\)). As NO2 has an electron acceptor nature, it takes the electron from the MoS2 and intensity of the (\(A^{ + }\)) enhanced due to conversion of neutral exciton in (\(A^{ + }\)). Actually, the numerous number of holes generated in MoS2 due to depletion of electrons by NO2. Therefore, intensity of \(A^{ + }\) trions enhanced and neutral exciton suppressed. Similar behavior is observed in the PL spectroscopy, shown in Fig. 5b. The effect of NO2 exposure on the Fermi level of n-type and p-type MoS2 flakes is shown in Fig. 5c, d. MoS2 can have both types of semiconducting nature. In both cases, NO2 exposure depletes the electrons from the MoS2 and manipulate the charge density in the conduction band. Due to electron extraction, the Fermi level in the n-type MoS2 film moves downward toward the valence band and correspondingly the SBH and resistance increased. When MoS2 film has the p-type nature, holes majority increased with NO2 exposure. The Fermi level move toward the conduction band and SBH and resistance decreased. Thus, NO2 adsorption critically affects the electronic as well as the optical properties of MoS2.

Yue et al. theoretically investigated the adsorption of several molecules using DFT on MoS2 such as H2, O2, H2O, NH3, NO, NO2, and CO [117]. Theoretically, gas adsorption behavior is determined by the few terms namely: favorable adsorption sites on MoS2 for particular gas molecule, distance between the gas molecule and the MoS2 layer, the binding energy of gas molecule on the MoS2 layer, charge transfer between the gas molecules and MoS2 layer, and direction of charge transfer. For adsorption of any gas molecule on a sensing surface, there should be a strong favorable interaction between the gas molecules and MoS2 flakes, and it should be adsorbed physically or chemically. This interaction is determined in terms of adsorption energy, calculated by Eq. (4):

where \(E_{{\text{a}}}\) is the adsorption energy, \(E_{{{\text{MoS}}_{2} + {\text{molecule}}}}\) is the total energy of MoS2 and the adsorbed gas molecule.\( E_{{{\text{MoS}}_{2} }}\) and \(E_{{{\text{molecule}}}}\) are the energy of the MoS2 film and single gas molecule, respectively. For a strong interaction, the adsorption energy should be negative and the interaction process should be exothermic. Another term is the charge transfer process. The charge transfer process depends on the relative position of the highest occupied molecular orbitals (HOMO) and lowest unoccupied molecular orbitals (LUMO). If the Fermi level is below the HOMO, then charge transfer from molecule to sensing surface and gas is called the electron donor, and if the Fermi level is above the LUMO, then the charge transfer from sensing surface to molecule and gas called is the electron acceptor [280].

As mentioned above, the adsorption of the gas molecule is determined in terms of favorable adsorption sites. The gas molecules adsorption are highly position dependent in the case of MoS2 due to the difference in the adsorption energy and charge transfer for gas molecules at different adsorption sites on MoS2. The monolayer of MoS2 has a hexagonally packed structure where Mo atoms are sandwiched between the two layers of S atoms. There are four possible adsorption sites, the H sites (Top of the hexagon), TS (top of S atom), TM (top of Mo atom), and B (top of Mo and S bond). The possible sites configurations are shown in Fig. 5e. In the case of NO2, three different NO2 molecules orientations have been considered with these four sites, starting from one N atom with N–O bonds parallel to monolayer, two with NO-bonds pointing up or down to monolayer. After the gas molecule adsorption on MoS2, MoS2 structure with adsorbed gas molecules is reached to the equilibrium state with the highest adsorption energy.

The minimum distance between the adsorbed gas molecule and the relaxed MoS2 surface is called as equilibrium height. The importance of distance between the NO2 and top S layer of MoS2 is also studied and investigated by Yue et al. The highest adsorption energy was found at an equilibrium height of 2.71 Å. It has to be noted that the highest adsorption energy is negative for adsorption of NO2 on MoS2, confirming the favorable adsorption of NO2 on MoS2. Among all, depending on the charge transfer and adsorption energy, the most favorable NO2 orientation was estimated. The H, TS, and B sites (− 276, − 249, and − 249 meV, respectively) found favorable for NO2 adsorption while no adsorption on TM site was observed. The high adsorption energy was attributed to polarization produced in the MoS2 sheet during NO2 adsorption. Hence, the interaction was determined by the electrostatic force and lead to strong adsorption energy. From the adsorption energy calculations, the highest favorable NO2 adsorption site is at the H site. The charge transfer from MoS2 to NO2 was found to vary from 0.1e to 0.119e. The positive charge transfer value implies the transfer of charge from MoS2 to NO2. The difference in the charge density due to NO2 exposure further confirmed the charge accumulation and depletion profile. The effect of NO2 molecule on energy band structure is also studied and it has been found that the adsorbed NO2 molecule introduces an unoccupied flat impurity state at 0.31 eV above the Fermi level in the conduction band of MoS2. The used method, supercell size, lattice parameters and available favorable adsorption sites for NO2 molecules adsorption on MoS2 by Yue et al., are tabulated in Table 1. Another important aspect of the work is the study of the applied electric field on the NO2 adsorption on MoS2. The charge transfer mechanism between the adsorbents and absorber is the key to the gas molecule adsorption.

The amount of charge transfer is very sensitive to the electric field. The applied electric field is considered in two perpendicular directions (i) MoS2 to NO2 molecule (+E) and (ii) NO2 to MoS2 molecule (− E). The charge transfers from MoS2 to NO2 increase with an increase in the positive electric field and it tends to decrease when the direction of the field is reversed. The negative electric field forces the electrons to transfer from NO2 to MoS2. The external electric field and dipole moment direction are well correlated with each other. Hence the direction of the electric field is greatly affected by the charge transfer values.

4 Theoretical Investigations of NO2 Adsorption on MoS2

Here, we discuss the reports where the interaction of NO2 on MoS2, the role of MoS2 polytype and metal doping investigated theoretically.

4.1 Adsorption of NO2 Gas Molecules on Defective MoS2

In the present section, we will discuss some theoretical reports in which adsorption of NO2 is studied on the defective MoS2. The two types of defects are considered mainly in MoS2 the monosulfur vacancies and the Mo-doped S vacancy sites.

Owing to the chemical interaction of NO2 with MoS2, the adsorption mechanism is governed by the chemisorption mechanism. Li et al. used DFT to study the adsorption of NO2 molecule on the single S vacancy site [281]. Initially, the effect of vacancies on the electronic structures was studied. The schematic of a MoS2 unit cell is shown in Fig. 6a. The bandgap with a single S vacancy in MoS2 was decreased up to 1.07 eV [282, 283]. The S vacancies in 2D materials create midgap states which reduce the bandgap of MoS2. These states arise due to the unsaturated Mo atoms near the vacant S sites [284]. When NO2 molecules are adsorbed to the MoS2 surface, the NO2 molecule dissociates at the S vacancy sites into NO and O. The dissociated NO has a bond length equivalent to the free NO molecule. Hence, the dissociated O atom is adsorbed on the single S vacancy site and the other part NO is physiosorbed on the O-doped MoS2. The activation barrier energy and transition states were also calculated. The activation energy of NO2 dissociation was 0.21 eV and the reaction energy was 2.30 eV, as shown in Fig. 6b. This energetically favored the NO2 dissociation process. Furthermore, adsorption energy of physiosorbed NO was 0.44 eV which is minimal and facilitates desorption of NO2 molecules from MoS2.

a Structure of defected MoS2. Black circles represent the S vacancy sites. b Dissociation of NO2 onto the S vacant MoS2. \({\text{Mo}}_{{\text{S}}}\). Reproduced with permission from Ref. [281]. Copyright (2016) The Royal society of chemistry. c Top view of pristine MoS2 d Mo-doped S Antisite defects (MoS) e DOS and PDOS of monolayer MoS2 with Antisite defect-doped MoS2 with gas molecules exposure. Reproduced with permission from Ref. [285]. Copyright (2016) American Chemical Society

Sahoo et al. doped Mo atoms on S vacancy sites, and enhanced adsorption of NO2, as shown in Fig. 6c, d with a red circle [285]. This type of doping is termed as antisite defects (\({\text{Mo}}_{S }\)) in MoS2 (A-MoS2). The insertion of Mo atoms at the S defects sites are highly probable with physical vapor deposition techniques. A-MoS2 may be an innovative method to improve the sensor response, selectivity, and sensing performance of the MoS2 sensor. The insertion of Mo atom at the S vacancy site generates the three midgap states, two states are at -0.02 and -0.11 eV below the Fermi level and the third state above the Fermi level at 0.28 eV. Actually, 4d orbitals of antisite Mo atom is splitted into three states; a (\(d_{z}^{2}\)) state lies above the fermi level, twofold degenerate \( e_{1 } (d_{xy} , d_{{x^{2} - y^{2} }}\)), and \(e_{2 } \left( {d_{yz} ,d_{zx} } \right)\) due to the \(C_{3v}\) symmetry, lies below the Fermi level. It is worth to note that \(e_{1 }\) state splits into \(e_{1}^{^{\prime}}\) and \(e_{1}^{^{\prime\prime}}\) levels due to the John Teller distortion while \(e_{2 }\) lies well below the valence band. The corresponding density of states (DOS) and partial density of states (PDOS) of Mo antisite-doped MoS2 without NO2 and with NO2 exposure are shown in Fig. 6e. Finally, when NO2 gas molecules are exposed to A-MoS2, the NO2 interaction process is highly exothermic and higher charge transfer takes place in A-MoS2 in comparison to the pristine MoS2. The paramagnetic NO2 molecules are adsorbed in the tilted configuration. The strong mixing of antisite defect \({\text{Mo}}_{S }\) and of NO2 orbitals are responsible for high charge transfer and strong adsorption energy. The p orbitals of N and O atom of NO2 molecules are strongly hybridize with the three new mid gap states generated due to the antisites \({\text{Mo}}_{S }\) defects. The DOS and PDOS states of A-MoS2 confirmed this behavior. The strong hybridization occurred between the NO2 molecule and with three new mid gap states which enhanced the charge transfer.

4.2 Adsorption of NO2 Gas Molecules on 2H-MoS2 and 1T-MoS2 Polytype

The two polytype of MoS2, 2H-MoS2, and 1T-MoS2 have their own advantages in NO2 sensing. Both polytypes have distinct electronic nature of semiconductors (2H-MoS2) and metallic (1T-MoS2). Here, in this section, we will enlighten the role of both pristine phases and defective phases MoS2 in NO2 sensing. Linghu et al. has compared the NO2 sensing performance of pristine 2H-MoS2 and pristine 1T-MoS2 [286]. The 1T-MoS2 has shown promising sensing performances in comparison to the 2H-MoS2. The geometric optimization revealed that NO2 has a closer and stronger interaction with the 1T-MoS2 phase than the 2H-MoS2. The calculated adsorption energies for the 2H-MoS2 and 1T-MoS2 phases are -0.21 eV and − 0.25 eV, respectively, reasonable to assume the higher NO2 interaction with the 1T phase. The higher adsorption energy comparative to 2H -MoS2 confirmed the higher and closer interaction in 1T MoS2.

Taking a step further, Linghu et al. studied the role of defects in both 2H and 1T polytype and found again that defective 1T-MoS2 is superior in NO2 adsorption [287]. The single S vacancy defects are considered in both phases due to their low formation energy requirement.

Figure 7a, b demonstrates the geometric perspective structure with S vacancy of 2H and 1T MoS2. The S vacancies in both 2H and 1T phase affect the electronic structure of the MoS2. S vacancies introduced mid gaps states and further reduced the MoS2 bandgap. Moreover, the metallic behavior of 1T-MoS2 is increased due to these mid gap states. The band structure of 2H and 1T MoS2 of pristine and defective MoS2 are shown in Fig. 7c–f. When NO2 is exposed to these polytypes, it dissociates in NO and O, as shown in Fig. 7g, h. The O atom tri-coordinated with the neighboring three Mo atom and occupied the S vacancy site and NO gets physisorbed on MoS2. The variation of adsorption energy with different molecules is shown in Fig. 7i. The red encircled values depict the NO2 adsorption energies.

a S vacancy in 2H-MoS2. b S vacancy in 1T-MoS2. Band structure of c pristine 2H-MoS2, d pristine 1T-MoS2, e S vacant 2H-MoS2, f S vacant 1T-MoS2. Adsorption of NO2 on g defective 2H-MoS2, h defective 1T-MoS2. i Variation of adsorption energy for different molecules. Reproduced from Ref. [286]. Copyright (2019) American Chemical Society

4.3 Theoretical Adsorption of NO 2 Gas Molecules on Metal-Functionalized MoS 2

The absence of dangling bonds makes the pristine monolayer MoS2 surface defects free. However, the defects are highly probable and S vacancies are the most favorable defect due to the less energy required for their formation [102, 288,289,290]. There are various experimental reports in which S defects have been controlled by using the argon and electron irradiation. Filling these mono vacancy sites with substitutional atoms can be a promising way to enhance the chemical, electrical and optical properties of MoS2 layers [289, 291]. These vacancy sites have been filled with various metal atoms such as Cr, Nb, V, and N, experimentally and the electronic and chemical activities of MoS2 layers changed dramatically [291,292,293]. Yuan et al. doped graphene with Al, Si, Cr, and Mn and studied the oxygen adsorption on the metal-doped graphene using DFT. The metal doping tuned the adsorption interaction of oxygen with carbon atoms of graphene. The bonding of the metal atom with the carbon atom is a responsible factor for enhance oxygen adsorption on the doped graphene [294]. Lu et al. embedded the graphene with Au and investigated the CO oxidation using DFT [295]. Au embedding reduces the reaction barrier and increases the oxidation rate of the CO on Au embedded graphene. Similarly, the inert 2D materials surface can be changed to a highly active surface for gas interaction due to the bonding of 2D materials with metal atoms.

Therefore, metal doping has a great impact on the electronic and gas-sensing properties such as adsorption energy, charge transfer, the direction of charge transfer and interaction of gas molecules with the MoS2 surface. The choice of appropriate metal for a particular gas will strongly modulate the chemical activity, selectivity and sensor response of the MoS2 surface.

Fan et al. investigated the effect of transition metals (Fe, Co, Ni, Cu, Ag, Au, Rh, Pd, Pt, and Ir) doping on MoS2 flakes for various gas molecules adsorption (CO, NO, O2, NO2, and NH3). The effect of transition metal doping in the absence of the gas molecules has been systematically studied. All the mentioned metals have been doped on the mono-sulfur vacancy site due to the low formation energy of S vacancies in comparison to other vacancies such as Mo vacancy, dia Mo vacancy and antisite vacancies [102, 288,289,290]. The equilibrium height (M-Mo) is taken from the metal atom and S atom plane. The stability of the metal embedded MoS2 in terms of binding energy and charge transfer was tested to have a better grasp. The binding energy (\(E_{{\text{b}}}\)) between the metal atom and unexposed MoS2 is calculated by Eq. (5):

The highest binding energy (energy required to bind the metal atom on the S vacant MoS2) was found 5.21 eV for Pt metal atoms and the lowest for 1.98 eV for the Ag atoms. The maximum charge 0.36e was transferred from Fe metal to MoS2 and the lowest − 0.34e to Pt metal atom from MoS2. The negative charge value means transition metals obtain the electrons from the MoS2 and vice versa for positive charge value. The binding energy and charge transfer values mentioned above are without NO2 exposure. The charge depletion and accumulation between the metals and MoS2 are due to the Pauling electronegativity. For the case of NO2 adsorption on the metal-doped MoS2 sheet, two different modes were obtained after the relaxation of the exposed MoS2 system. One mode is with Fe, Co, Cu, Ag, and Au embedded MoS2 system via bonding of two O atoms with transition metals forming TM–O–N–O (four membered ring). The other mode is the bonding of NO2 with Ni-, Rh-, Pd-, Pt-, and Ir-doped MoS2 in which N-atom bonded with the transition metal. The adsorption energies and charge transfer in case of NO2 adsorbed on the metal-doped MoS2 are tabulated in Table 2. Fan et al. calculated the adsorption energy of gas molecules by Eq. (6):

The Fe metal-embedded MoS2 has shown promising NO2 adsorption properties with charge transfer value − 0.66e and adsorption energies of 210 meV. The negative values indicate that charge transferred from metal embedded MoS2 to NO2 than pristine MoS2. These extra electrons are obtained from the embedded transition metals, which reflect the importance of the transition metals. The electronic structure with NO2 and metal embedded MoS2 was studied deeply. The higher interaction of NO2 is due to the mixing of Fe 3d states and 6a1, 1a2, and 4b1 orbitals of NO2 over a wide range of energy, as shown in the Fig. 8a, b. These mixing or hybridization resulted in enhanced NO2 interaction with charge transfer of − 0.66e. A similar behavior is observed with other metal-doped MoS2.

a, b Total density of states and density of states for Fe-embedded NO2 molecule. Reproduced with permission from Ref. [296]. Copyright (2017) Elsevier; Calculated projected density of states c with NO2 adsorbed on monolayer MoS2, d Si-doped MoS2. Reproduced with permission from Ref. [297]. Copyright (2016) Elsevier

Luo et al. doped Al, Si, and P metal atoms at the S vacancy site [297]. These metals were chosen because of their exactness and closeness of covalent radii to the radius of the S atom. The NO2 and NH3 adsorption were studied at five adsorption sites on MoS2. The five adsorption sites are \(T_{x}\) (gas molecule on top of doped metal), \(H_{x}\) (gas molecule on top of hexagon near to doped metal), \(T_{{\text{S}}}\) (gas molecule on top of S atom near to doped metal), \(T_{{{\text{Mo}}}}\) (gas molecule on top Mo atom near to doped metal). Among all five sites, the most stable site for NO2 adsorption was \( H_{x}\) after a complete structure relaxation. The doping of Al, Si, and P generates impurities in the Mo 4d state which create strong hybridization coupling between the Al-3p, Si-3p, and P-3p. Therefore a strong charge is transferred between the atoms and monolayer MoS2. Si-doped MoS2 was found most suitable for NO2 adsorption due to the highest charge transfer between them. PDOS calculation was performed to investigate the NO2 adsorption on undoped MoS2 and doped MoS2, and shown in Fig. 8c, d. In the case of undoped MoS2, the NO2 peaks were situated at − 7.7 and − 3.09 eV while the PDOS peak of bare MoS2 was situated at 2.33, − 12.04 and between − 1.5 and − 5 eV. Hence the weak interaction occurs between NO2 and MoS2. However, when Al was doped in MoS2, there is more orbital coupling at − 1.35 and − 3.31 eV not only with Al orbitals but also with S and Mo orbitals. Hence, the interaction and charge transfer increased with Al doping. NO2 molecules partially obtained electrons from the doped Al. With Si atom, the hybridization of orbitals is further increased and a higher number of electrons, i.e., 0.52e transfer to MoS2. Similar behavior was observed with the P atom.

Zhu et al. studied the doping of V, Tb, and Ta on the S vacancy site [298]. It is important to note that the size of these metal atoms is large in comparison to the S atom. These atoms are thus situated outside the S plane. Among all, the high binding energy suggested that Ta atoms bound firmly with MoS2. The NO2 gas molecules prefer to make bond on metal atoms. The two oxygen atoms form bond with the metal atom and N atom, and form a four-membered ring like structure M–O–N–O, shown in Fig. 9a–c. The calculated adsorption energies were 2.59, 3.88, and 3.64 eV for V, Nb, and Ta atoms, respectively. The Bader charge analysis revealed that charge transferred from MoS2 to NO2 and with V, Nb, and Ta atoms metals doping. NO2 has shown strong oxidizing behavior. The charge density differences are shown in Fig. 9d–f. The NO2 adsorption with monolayer MoS2 were further calculated with NO2 exposure.

a, d, g NO2 molecule adsorbed on V metal: optimized geometry after NO2 adsorption (a), charge density difference (d), spin-polarized density of state with V 3d and NO2 (g). b, e, h NO2 molecule adsorbed on Nb metal: optimized geometry after NO2 adsorption (b), charge density difference (e), spin-polarized density of state with Nb 4d and NO2 (h). c, f, i NO2 molecule adsorbed on Ta metal: optimized geometry after NO2 adsorption (c), charge density difference (f), spin-polarized density of state with Ta 5d and NO2 (i). Reproduced with permission from Ref. [298]. Copyright (2017) Elsevier

However, the charge transfer and adsorption energies are comparatively smaller than metal-doped V, Nb, and Ta. Moreover, NO2 as a paramagnetic molecule is critically affected by the bond length [300]. The bond length was 1.21 Å in the case of pristine MoS2 while NO2 bond length was elongated from 0.07 to − 0.11 Å with metal-doped MoS2. Thus, the NO2 activation on metal-doped MoS2 is enhanced. Further electronic properties of MoS2 after NO2 doping was analyzed in terms of DOS, shown in Fig. 9g–i. The metal orbitals and NO2 orbitals have a strong hybridization between their orbitals. The d orbitals of metals especially for Nb atoms get mixed with NO2 orbitals over a wide range of energy. Hence, doping of MoS2 with V, Nb, and Ta improves the electronic and chemical performance of the NO2 molecule. The supercell size, lattice parameter, occupied method, adsorption energy, and charge transfer are summarized in Table 2.

5 Experimental Investigations of NO2 Adsorption on MoS2

In this section, we discuss various experimental approaches employed to develop the NO2 sensors. This section has been divided into five sub-section in which we summarize the various experimental approaches adopted in terms of bare MoS2, morphology-driven MoS2, metal-doped MoS2, vacancy-driven MoS2, and finally light-assisted MoS2-based NO2 sensors.

5.1 Bare MoS2 NO2 Sensor

Here, we addressed several efforts and experimental reports where NO2 sensors were fabricated with single and multilayered MoS2 flakes. The reports include the impact of NO2 adsorption on the single and multilayer MoS2 and as well as the on the SBH. Li et al. developed the first NOx gas sensor using an n-type MoS2 flakes-based FET device [34]. The schematic of fabricated device is shown in Fig. 10a. The monolayer (1L) to quadrilayer (4L) MoS2 flakes were synthesized by the mechanical exfoliation technique and had the detection limit of 0.8 ppm. The thickness of the MoS2 layers was confirmed by the atomic force microscopy (AFM) technique. The current versus voltage characteristics measurements of the device with varied layers were performed. The single layer device showed unstable behavior while bi- to quadrilayer film-based devices demonstrated better sensing performance. The NO gas exposure to bilayer MoS2 film showed a decrease in the current, which confirm the p-type doping due to the electron acceptor nature of the NO gas [57, 301]. Figure 10b displays the gas-sensing performance of the MoS2 device with different NO concentrations. The adsorption and desorption rate of NO was a two-step process: fast rate and slower rate. The fast reduction in current confirmed the presence of a large number of NO adsorption sites and slow reduction confirmed saturation of MoS2 film in NO exposure. Another significant aspect of the different thickness of MoS2 film was the quick response to NO exposure. The single layer MoS2 film showed a 50% response within 5 s while multilayer MoS2 showed a 50% response in 30 s. However, the disadvantage with single-layer MoS2 film was its instability.

a Optical image of bilayer MoS2-based FET NO sensor. b MoS2 FET response to different concentrations NO. The inset showed the typical response and recovery of the MoS2 FET device. Reproduced with permission from Ref. [34]. Copyright (2012) Wiley-VCH. c MoS2 TFT NO2 sensor with different thickness MoS2 flakes. Reproduced with permission from Ref. [42]. Copyright (2012) Wiley-VCH; d optical image of MoS2 device mounted on a chip. e NO2 response for the bi and five-layer MoS2 devices at different gate voltages. f Theoretically calculated resistance variation with different gate voltages. Reproduced with permission from Ref. [17]. Copyright (2013) American Chemical Society. g Device schematic of atomic layer MoS2-based sensing device. h Response of NO2 at RT and at moderate temperature of 100 °C. i Change in the low energy PL peak due to NO2 adsorption. Reproduced with permission from Ref. [32]. Copyright (2015) Springer Nature

He et al. developed a flexible MoS2 thin film transistor (TFT) arrays for the NO2 sensing [42]. The single layer MoS2 film suspension was drop cast over patterned rGO electrodes covered with Ag pads. The Ag pads had only been used to improve the robustness of the rGO electrodes. The MoS2 area and thickness for NO2 sensing were 1.5 mm2 and 2, 4, 8, and 18 nm, respectively. It is worth to note that the deposited MoS2 film showed p-type behavior attributing to the structural changes caused by the lithium intercalation process. The structural changes in the MoS2 lead to a change in the band structures. During distortion from the octahedral system to zigzag chain, the system was filled up to \(d^{2 + n}\) states. Hence, residual negative charges semi filled the bands and contributed to p-type conductivity [302]. The NO2 gas exposed to the various thickness of MoS2 film and the highest change in the sensor response was occurred for the thinnest MoS2 film. The NO2 exposure increased the conductance of the film due to its electron acceptor nature. The high NO2 detection ability of thin MoS2 film was attributed to the increased surface area available in 2 nm film. The sensor response of different thickness of MoS2 film is shown in Fig. 10c. Late et al. studied the NO2 sensing behavior of single and multiple layer MoS2 film synthesized by the mechanical exfoliation method [17]. A detailed gas-sensing performance with and without applying the bias voltage was presented. A detailed AFM, Raman, and TEM characterization were performed to understand the thickness, expansion, crystallographic orientation, and structure of MoS2. The device schematic with Ti/Au contact is shown in Fig. 10d. The I–V characteristic of single layer MoS2 device was unstable while multilayer MoS2 showed stable I–V characteristics. Few layers (single and five layers) MoS2 device demonstrated good behavior. The three and four-layer MoS2 flakes device showed identical behavior to two layer and five-layer devices. The NO2 sensing for five-layer MoS2 device is shown in Fig. 10e. However, this higher performance was due to the redox potential that greatly influences the sensing behavior of MoS2 flakes. Once again, the NO2 interaction with MoS2 revealed that the NO2 has an electron acceptor nature. The influence of the external electric field in terms of bias voltage on the NO2 sensing was further studied. When a positive back gate biasing voltage + 15 V was applied to two and five layers of MoS2 flakes, the sensor response was improved in comparison to zero bias voltage. A larger number of electrons were collected at the MoS2 and SiO2 interface under positive back gate voltage. Therefore, NO2 has a higher number of electrons to detach from the MoS2. With positive gate biasing voltage, the NO2 sensor response was thus increased. In addition, Ti/Au electrode played a vital role under positive gate voltage. Under positive gate voltage, electrons get accumulated in MoS2 film and the barrier between the electrode and MoS2 film is reduced. Thus, the charge transfer in MoS2 film facilitated further. The device resistance in the presence of NO2 gas is shown in Fig. 10f at different biasing voltages.

Cho et al. synthesized the atomic layered MoS2 flakes by the CVD technique and performed the NO2 gas sensing [32]. The resistance of the n-type MoS2 film increased due to the electron-accepting nature of NO2. The interdigitated electrodes of Ag metal were fabricated on the MoS2 film. The NO2 sensing performance was studied at RT and at a moderate temperature of 100 °C.

The device schematic and NO2 sensor response versus time profile at each temperature are shown in Fig. 10g, h. It can be seen clearly that the RT sensor response was quite high in comparison to 100 °C, while the sensor showed rapid recovery at 100 °C and no recovery was obtained at RT. The NO2 gas strongly adsorbed on MoS2 and hence at RT the desorption rate is quite low. However, thermal energy greatly impacts the adsorption of NO2 at a higher temperature. The thermal energy accelerates the NO2 desorption rate than the adsorption rate. As a result, the NO2 gas interaction decreases at a higher temperature at the sensor response cost. The NO2 sensing mechanism based on the charge transfer process, confirmed by the change in the peaks of PL spectra is shown by Fig. 10i, as we discussed in Fig. 5b of Sect. 3.

These all layer-dependent studies show that the single layer MoS2-based gas sensors suffered from unstable current, but they have a quick response with NO2 exposure. The few layer MoS2 flakes-based gas sensors show a good response with the stable current. Moreover, the MoS2 FET gas sensors are very sensitive to the applied bias voltage. However, the MoS2 gas sensors have an incomplete recovery at RT. So, operating sensors at a higher temperature may be a good option to achieve full recovery but it will reduce the sensor response. The summary of the results for bare MoS2-based NO2 gas sensors by various groups are tabulated in Table 3.

Liu et al. studied the NO2 sensing efficiency of monolayer MoS2 flakes grown by CVD [36, 303]. The effect of gas molecules adsorption on the Schottky barrier height (SBH) between the MoS2 and metal electrodes was studied. The sensing device area was 1 µm2 and film showed the 3 cm2 V−1 s−1 mobility with Ti/Au electrodes, shown in Fig. 11a. The Ti was used for improving the electrode adhesion with MoS2 film. The device showed highly rectifying behavior with a positive and negative drain to source voltage (VDS) with 400 ppb NO2 exposure, as shown in Fig. 11b. The device showed an excellent sensor response of 174% with back gate voltage 30 V. The response time was 300 to 540 s with the full recovery in 12 h. To confirm the NO2 gas-sensing mechanism via the charge transfer process, the back gate voltage was fixed at 5 V and gas concentration was varied from 20 to 400 ppb. The threshold voltage for the NO2 sensing received a monotonic shift in the positive VDS direction. The resistance modulation in the device due to gas exposure is the sum of channel resistance \((R_{{{\text{channel}}}} )\) and \(R_{{{\text{contact}}}}\) determined by Eq. (7):